Prestressed concrete superimposed sheet with steel trusses and manufacturing method

A concrete and prestressed technology, applied in the processing of floors, building materials, construction, etc., can solve the problems of floor structure fire resistance that does not meet the standard design requirements, peeling steel bars, hidden dangers, etc., to increase the evacuation and rescue time, Reduce the effect of back arching and delayed peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

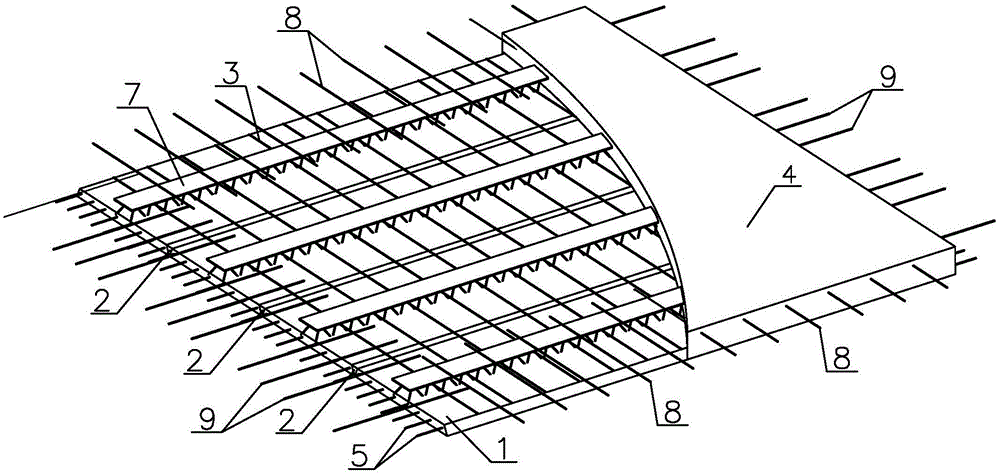

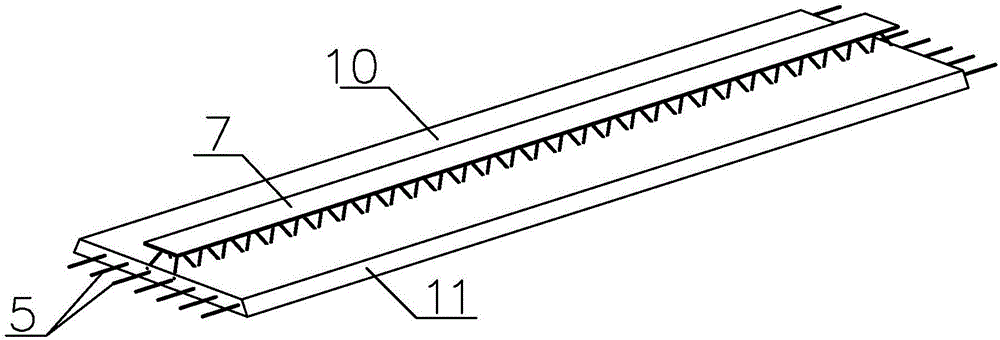

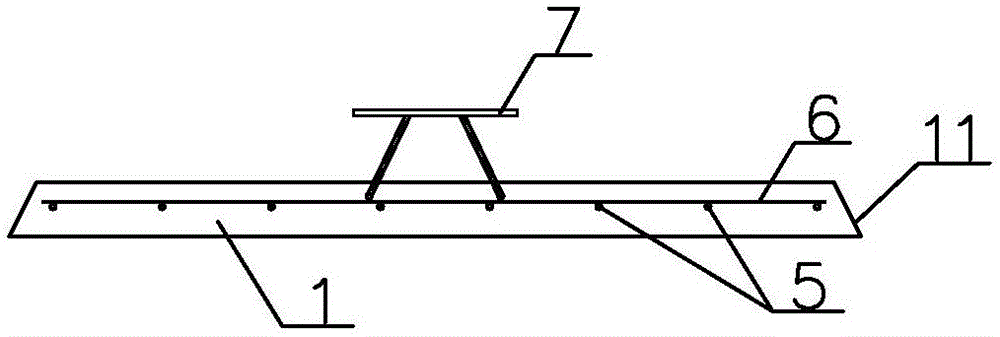

[0047] Refer to the attached figure 1 To attach Figure 9 A prestressed concrete laminated slab with steel truss and its manufacturing method of the present invention will be described in detail below.

[0048] A prestressed concrete laminated slab with steel truss of the present invention, its structure includes a prefabricated bottom slab 1, a transverse steel bar 3 and a laminated layer 4, the prefabricated bottom slab 1 includes a plurality of pieces, each prefabricated bottom slab 1 along the length direction The two sides of the two sides are slopes 11, and wedge-shaped joints 2 are formed between adjacent prefabricated bottom plates 1. The wedge-shaped joints 2 are filled with high-strength grouting material to the upper surface 10 of the prefabricated bottom plate. The interior of the prefabricated bottom plate 1 is arranged longitudinally along the length Prestressed steel bars 5, horizontally distributed steel bars 6 are arranged along the width direction, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com