Prestressed concrete three-web trough girder

A concrete and prestressed technology, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of large lateral force of double-line trough beams, small bridge spans, and poor lateral stiffness, and achieve beautiful appearance and low building height. , The effect of comprehensive low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

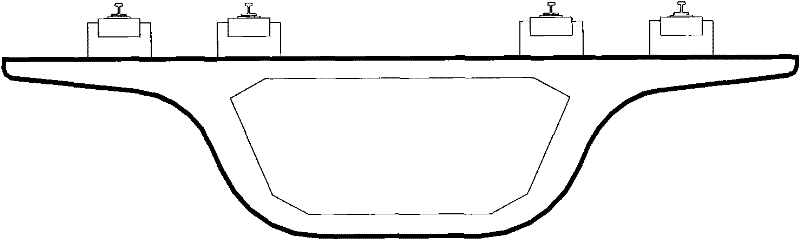

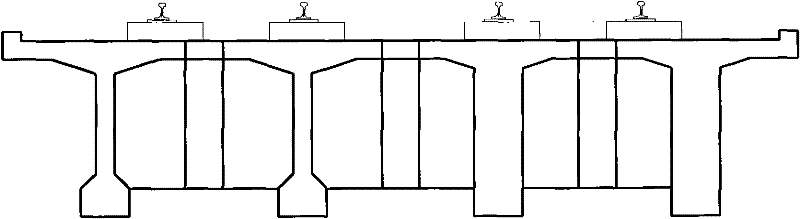

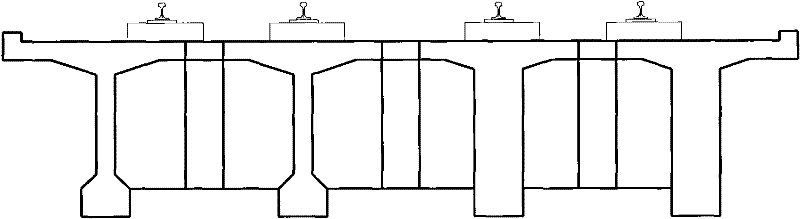

[0019] Such as Figure 5 , 6 As shown, the prestressed concrete three-web channel beam of the present invention is mainly composed of a bottom plate 1, a side web 2 and a middle web 3.

[0020] Among them, the bottom plate 1 is also provided with an end beam 4 at the support at both ends of the beam, the side web 2 is provided with a side web upper flange 5 at the top, and the middle web 3 is provided with a middle web upper flange 6 at the top.

[0021] The bottom plate 1 is integrally cast with the side web 2 and the middle web 3 , the bottom plate 1 is arranged at the bottom of the side web 2 and the middle web 3 , and the end beams 4 at both ends of the beam are cast together with the bottom plate 1 .

[0022] In this embodiment, the included angle between the center line of the side web 2 and the normal direction of the bottom plate 1 is 18°, and the middle web 3 is perpendicular to the bottom plate 1 . The top surface of the side web 2 and the middle web 3 is 1.89m hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com