Tire tread pattern provided with stone guard structure

A tire tread and tread pattern technology, which is applied in the field of tire tread, can solve the problems that the anti-rock effect of the tire cannot be guaranteed, cracks at the bottom of the groove, and affect the life of the tire, etc., and achieve good stone removal performance and good noise reduction performance. , the effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

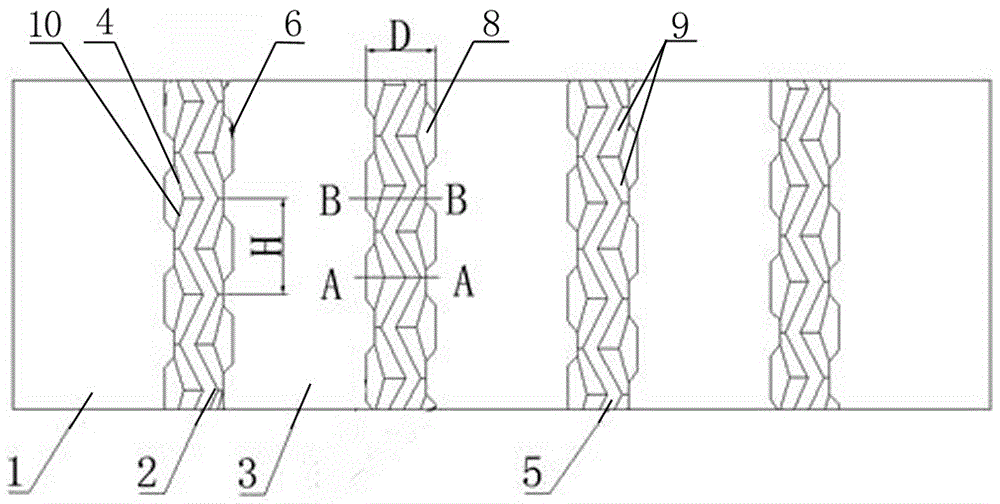

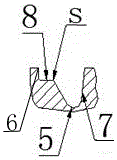

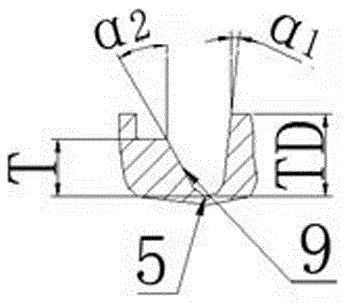

[0019] as attached Figure 1-3 As shown, a tire tread pattern provided with an anti-stone structure includes a tread pattern 1, the tread pattern 1 is composed of circumferentially continuous annular grooves 2 and pattern blocks 3, and the annular groove 2 is composed of discontinuous The first side edge 6 is bounded, and the portion concave relative to the first side edge 6 in the annular groove 2 is provided with a first polygonal surface 8 parallel to the tread, the second side edge 4 of the first polygonal surface 8 and The third side ribs 10 are respectively extended along the groove bottom direction to form two second polygonal surfaces 9, and the two second polygonal surfaces 9 and the first polygonal surface 8 share a vertex S; the annular groove 2 The groove bottom lines 5 are zigzag along the circumference.

[0020] The first side edge 6 is an edge flush with the tread at the junction of the tread and the first polygonal surface 8 .

[0021] The vertical distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com