Tire tread zipper saw-tooth type groove and wide base tire using same

A tire tread, zigzag technology, applied in tire tread/tread pattern, tire parts, transportation and packaging, etc., can solve problems such as poor stone-embedding effect, reduce cracking, and significantly discharge stone. effect, safety accident prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

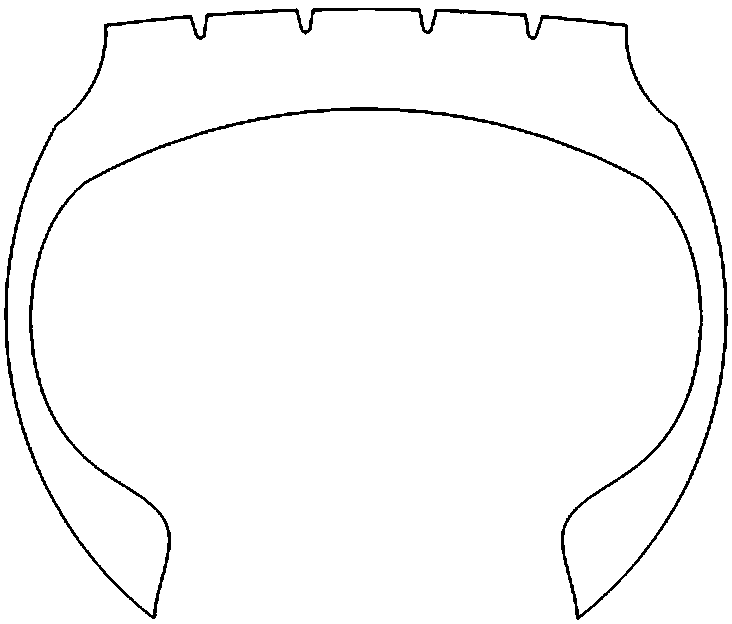

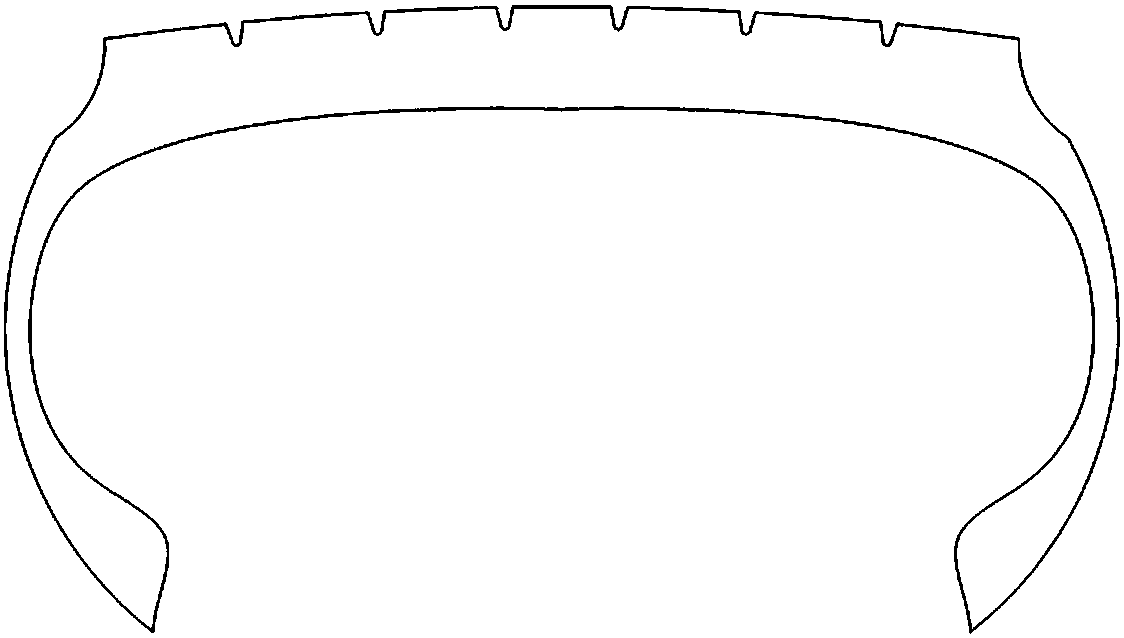

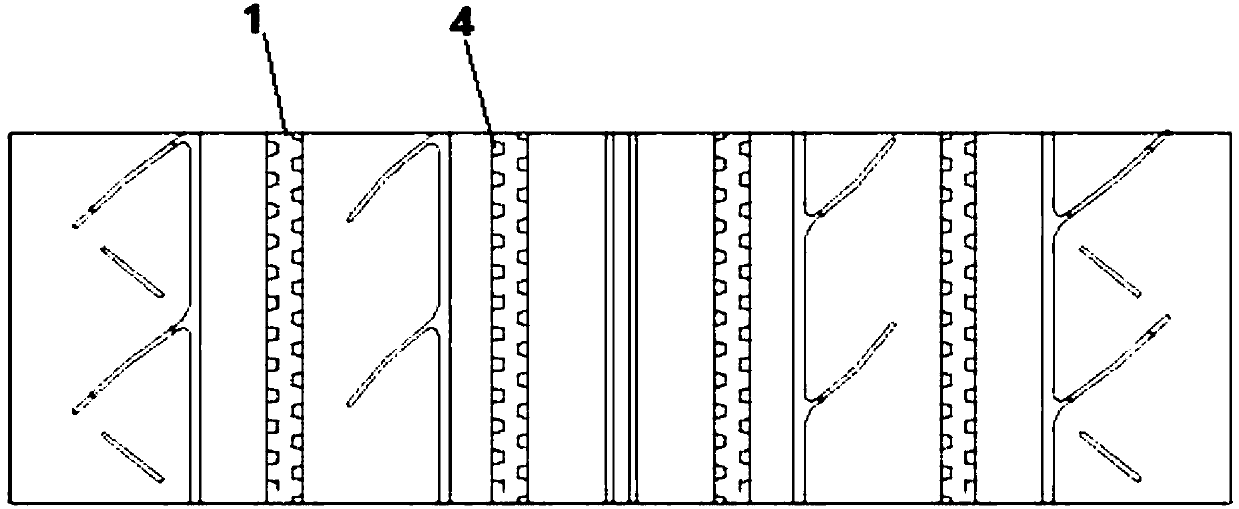

[0016] like image 3 , Figure 4 Shown is a tire tread zipper zigzag groove, the bottom of the groove is an arc-shaped annular bottom surface 1, and the upper two annular sides of the arc-shaped bottom surface are the first annular slope 2 and the first annular slope 2 respectively. It is inclined outward from the bottom, and the two first annular slopes 2 are respectively provided with annular sawtooth strips 3 protruding from the first annular slope 2, and the annular sawtooth strips 3 are arranged at intervals by bosses 4 and grooves 5 to form a ring structure, The bosses 4 and the grooves 5 on the two ring-shaped zigzag strips 3 are arranged in a zipper-like misalignment; the side of the boss 4 and the annular bottom surface 1 obliquely is a second slope 6, and the second slope 6 is composed of The bottom is inclined to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com