Pneumatic tire

一种充气轮胎、轮胎的技术,应用在充气轮胎、轮胎零部件、车辆部件等方向,能够解决带状吸音件断裂、耐久性恶化等问题,达到抑制倒塌、改善耐久性、容易断裂的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

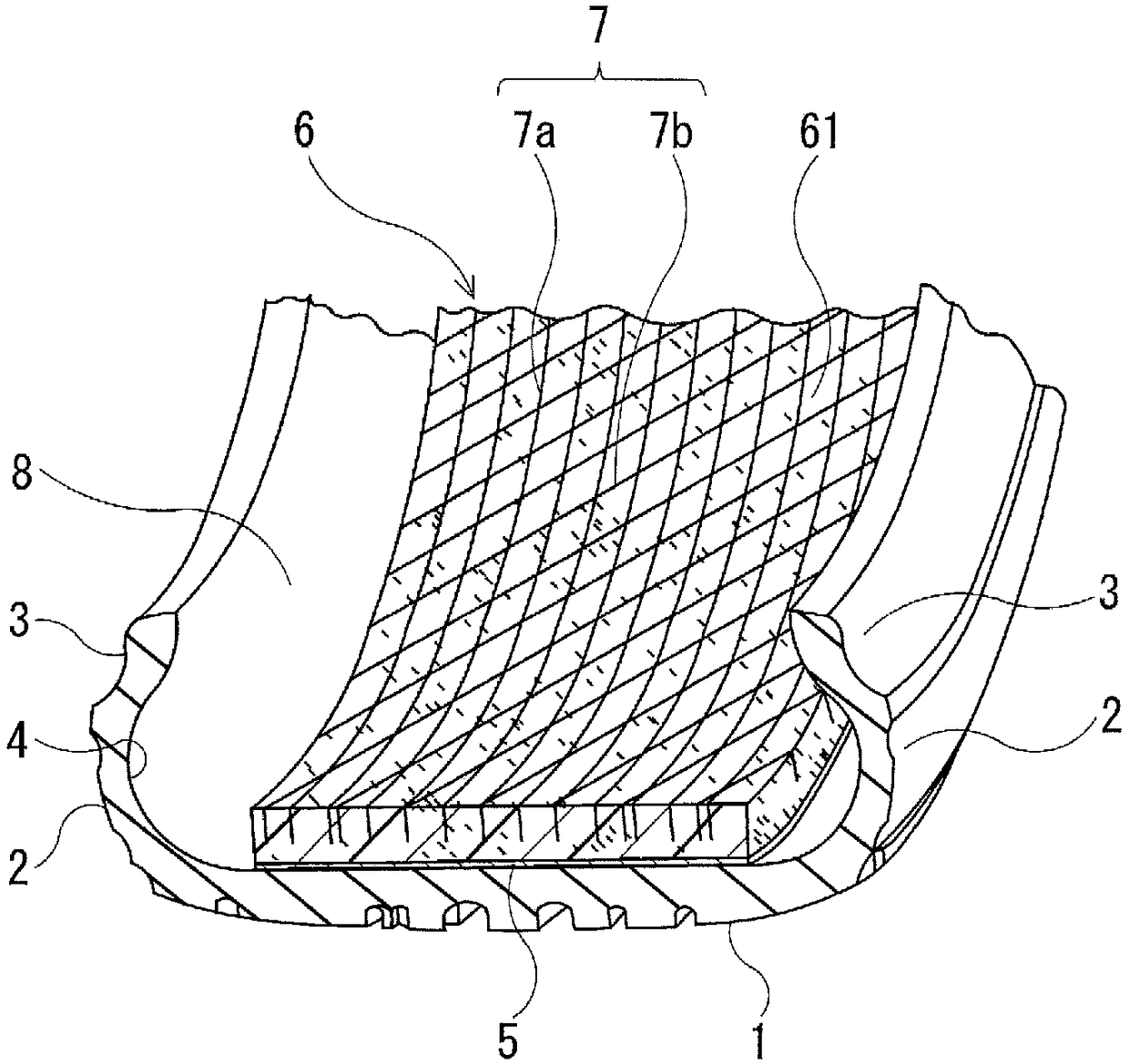

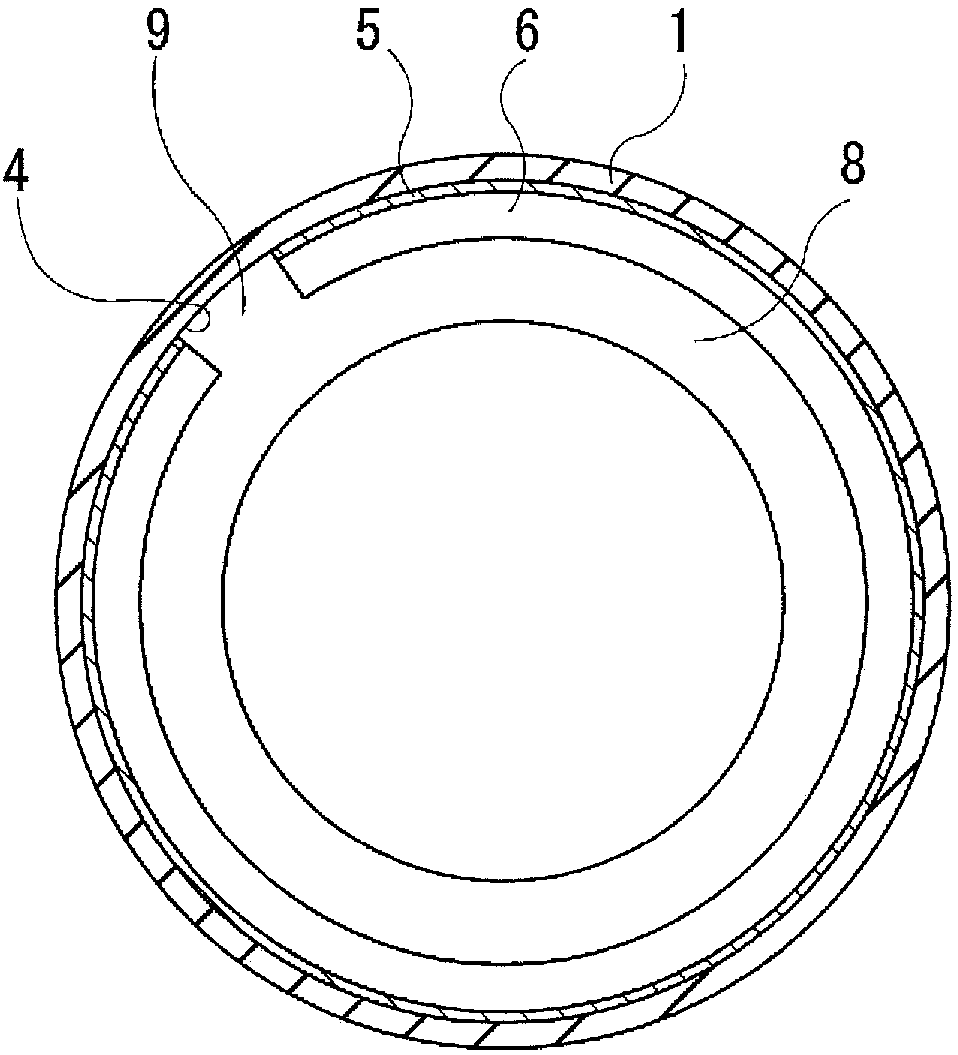

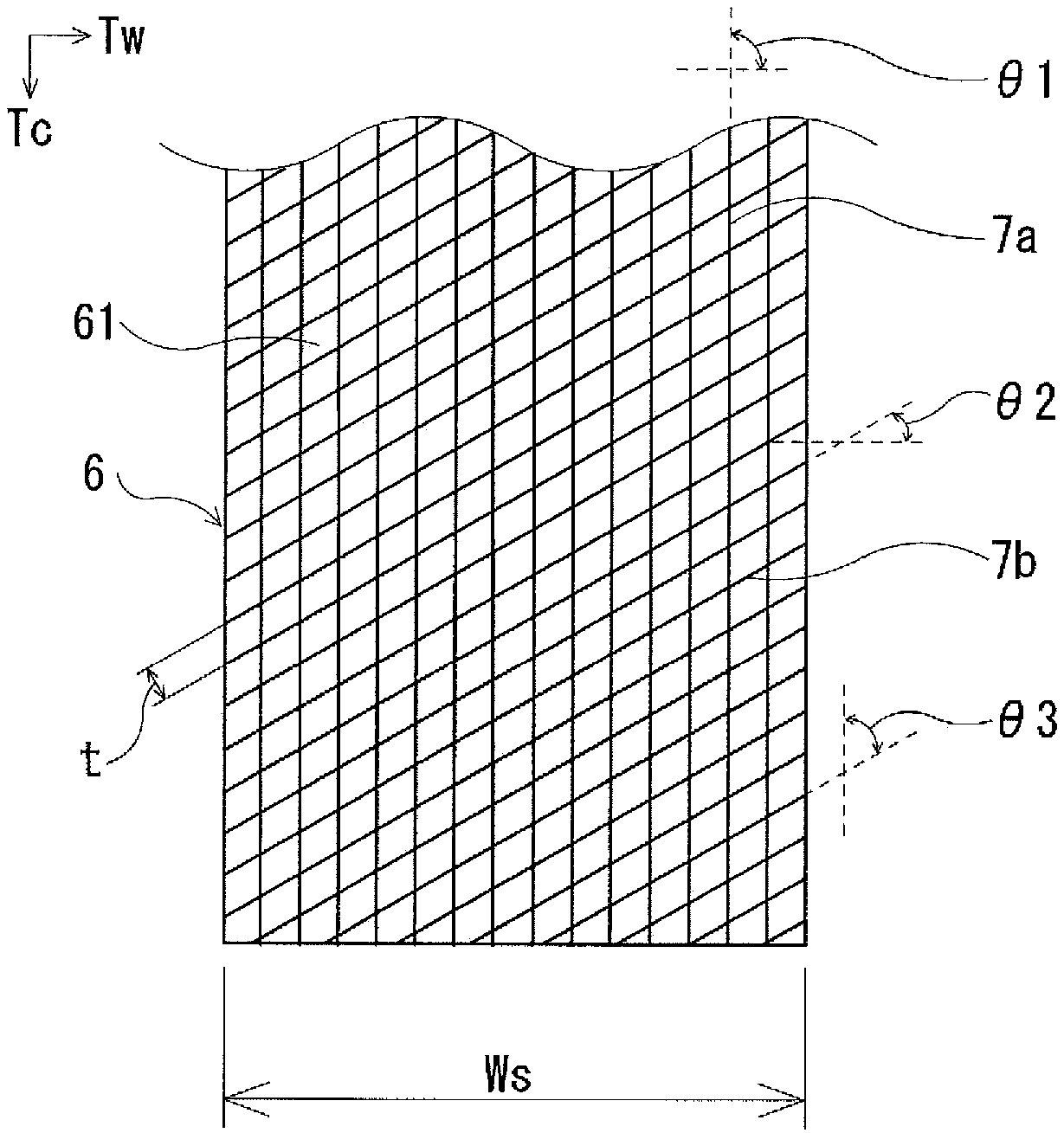

[0041] The tires of Examples 1 to 20 were manufactured. The pneumatic tires had a tire size of 275 / 35ZR20 and were provided with: a tread portion extending in the tire circumferential direction and formed in a ring shape; a pair of sidewall portions disposed on both sides of the tread portion and a pair of bead portions arranged on the inner side in the tire radial direction of these sidewall portions, the pneumatic tire is bonded with a belt-shaped sound-absorbing member on the inner surface of the tread portion along the tire circumferential direction, wherein the belt-shaped sound-absorbing member has A plurality of slots extending in two directions intersecting each other.

[0042] In Examples 1 to 20, the presence or absence of notches, the angle θ1 of the first notch with respect to the tire width direction, and the angle of the second notch with respect to the tire width direction are determined as shown in Tables 1-1 and 1-2. θ2, the groove interval (interval t / width W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com