Prestressed concrete steel bar truss hollow close-splicing laminated two-way plate

A technology of concrete reinforcement and steel truss, applied in the direction of floor slabs, structural elements, building components, etc., which can solve the problems of increased slab thickness and reinforcement, which is not conducive to cost saving, and large material consumption, so as to save the amount of steel bars and reduce the amount of concrete , good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

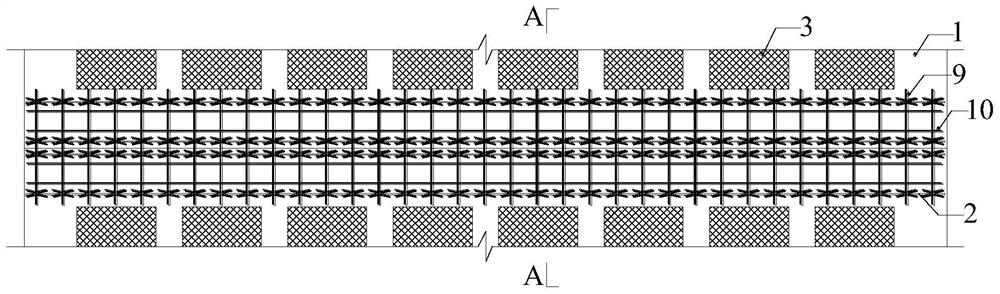

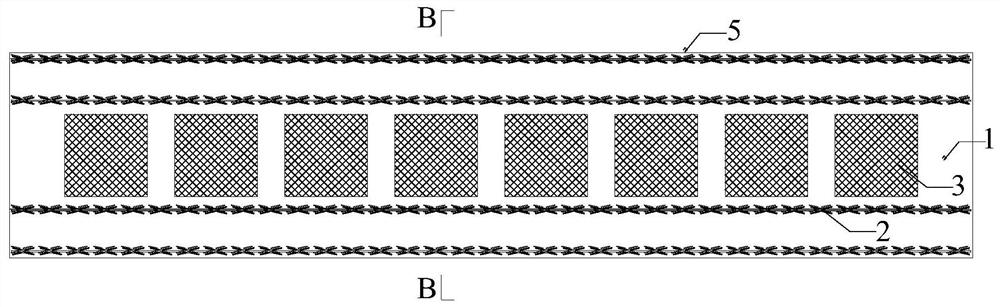

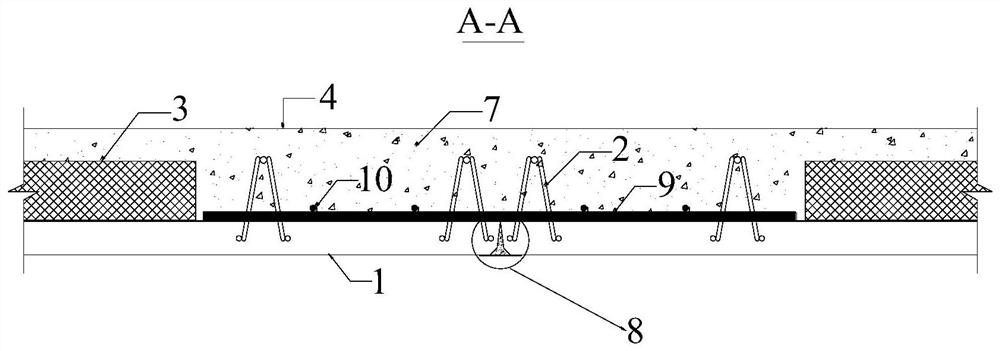

[0027] The prestressed concrete steel truss aerial striped bidirectional plate, such as Figure 1-7 As shown, including at least two parallel set of pre-stress truss prefabricated plates, a seam joint structure and a laminated layer 7, the prestressed truss prefabricated plate including prestressed concrete bottom plate 1 and a steel truss 2, prestressed concrete bottom plate 1 is a rectangular component Shape, the reinforced truss 2 is arranged in the longitudinal direction of the prestressed concrete bottom plate 1, and the lower end of the reinforced truss 2 is embedded in the prestressed concrete bottom plate 1, and the panel surface of the prestressed concrete bottom plate 1 is provided with a space block in its long-term direction. 3, the seam structure is disposed between the adjacent two pre-plate prefabricated plates, the laminated layer 7 is poured on the plate surface of the prestressed truss preform, and the top surface of the laminated layer is formed after pouring.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com