An empty stomach vertical wall combined square rectangular storage bin

A square and rectangular combined technology, applied in the field of warehousing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

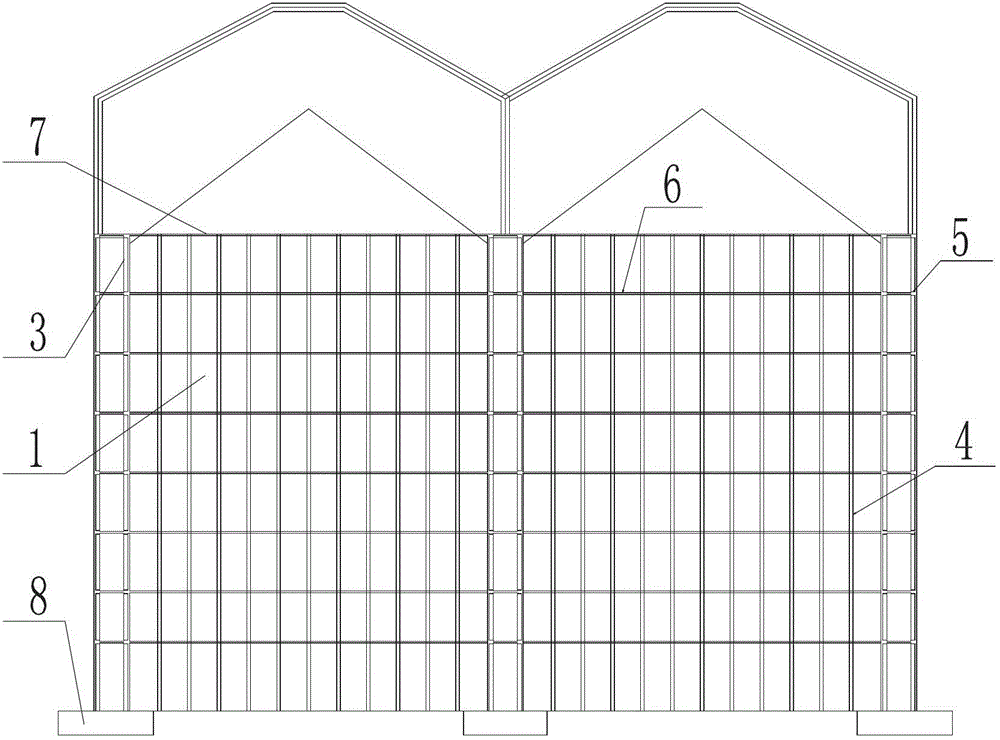

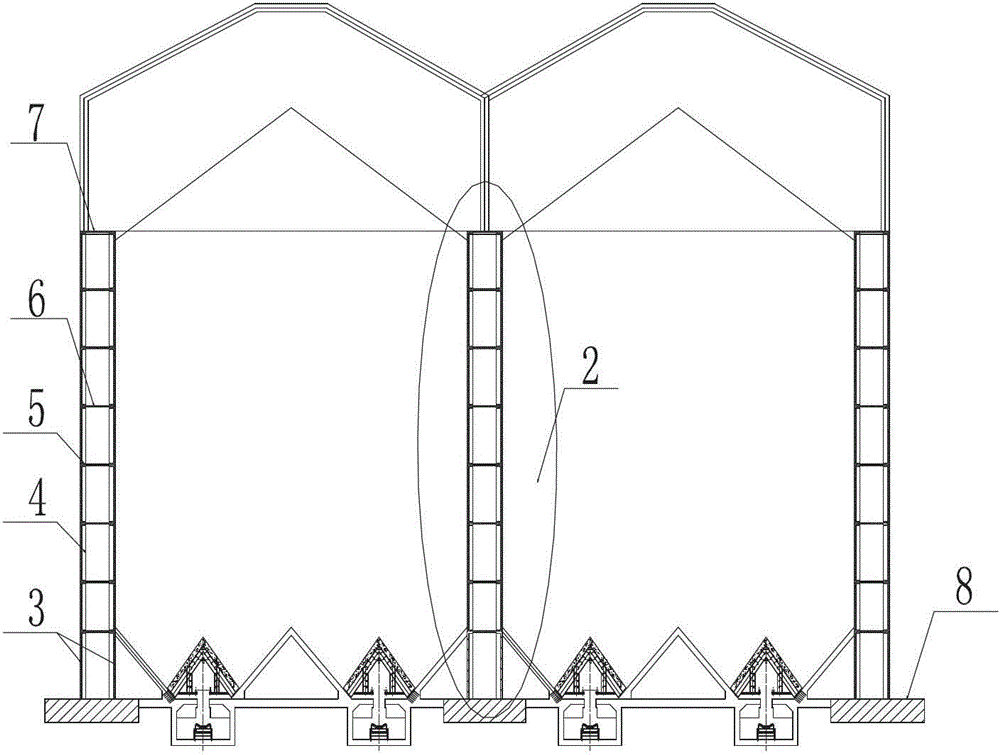

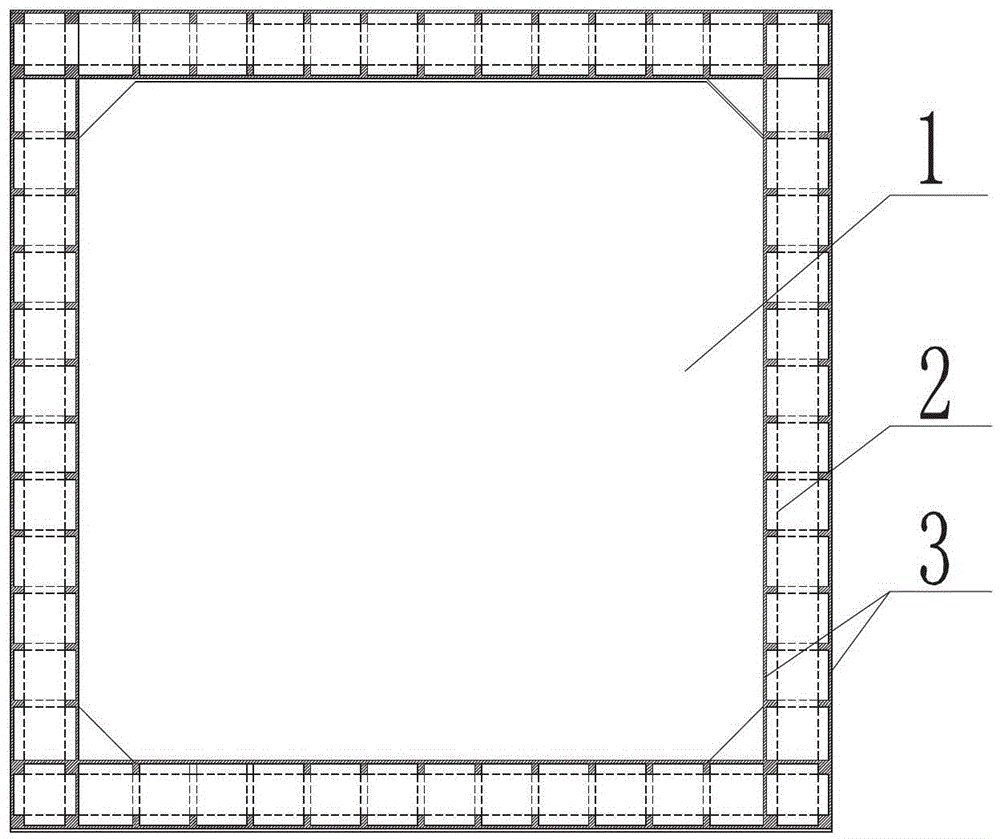

[0027] Embodiment 1 of the present invention: as figure 1 , figure 2 and image 3 As shown, a fasting vertical wall combined square rectangular storage bin includes a square rectangular storage bin 1, and the square rectangular storage bin 1 is composed of four fasting type side wall walls 2, and both sides of the fasting type side wall wall 2 are provided with walls Plate 3, the top of the fasting side wall 2 is provided with a cover plate 7, and the bottom of the fasting side wall 2 is connected to the bottom foundation 8 of the warehouse. The lengths of four hollow type side walls 2 constituting the square rectangular storage bin 1 are equal.

[0028] The inner side of the wall panel 3 is provided with a vertical stiffening support column 4 and a horizontal stiffening support beam 5 . The cover plate 7 is a four-sided through-connection structure. The hollow side wall 2 adopts hollow walls of equal thickness in the vertical direction.

[0029] Such as Figure 4 As sh...

Embodiment 2

[0031] Embodiment 2 of the present invention: as figure 1 , figure 2 and image 3 As shown, a fasting vertical wall combined square rectangular storage bin includes a square rectangular storage bin 1, and the square rectangular storage bin 1 is composed of four fasting type side wall walls 2, and both sides of the fasting type side wall wall 2 are provided with walls Plate 3, the top of the fasting side wall 2 is provided with a cover plate 7, and the bottom of the fasting side wall 2 is connected to the bottom foundation 8 of the warehouse. The lengths of four hollow type side walls 2 constituting the square rectangular storage bin 1 are equal.

[0032] The outer side of the wall panel 3 is provided with a vertical stiffening support column 4 and a horizontal stiffening support beam 5 . The cover plate 7 is a four-sided through-connection structure. The hollow side wall 2 adopts hollow walls with equal or variable thickness in the vertical direction.

[0033] Such as ...

Embodiment 3

[0036] Embodiment 3 of the present invention: as figure 1 , figure 2 and image 3 As shown, a fasting vertical wall combined square rectangular storage bin includes a square rectangular storage bin 1, and the square rectangular storage bin 1 is composed of four fasting type side wall walls 2, and both sides of the fasting type side wall wall 2 are provided with walls Plate 3, the top of the fasting side wall 2 is provided with a cover plate 7, and the bottom of the fasting side wall 2 is connected to the bottom foundation 8 of the warehouse. The lengths of four hollow type side walls 2 constituting the square rectangular storage bin 1 are equal.

[0037] The inner side of the wall panel 3 is provided with a vertical stiffening support column 4 and a horizontal stiffening support beam 5 . The cover plate 7 is a four-sided through-connection structure. The hollow side wall 2 adopts hollow walls with equal or variable thickness in the vertical direction.

[0038] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com