Bent groove-shaped steel plate type laminate member

A groove-shaped, laminated board technology, used in building components, building structures, building materials, etc., can solve the problems of low overall rigidity, reduced floor height clearance, and self-heavy weight, so as to improve building quality and reduce its own weight. , the effect of high overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described with reference to the accompanying drawings.

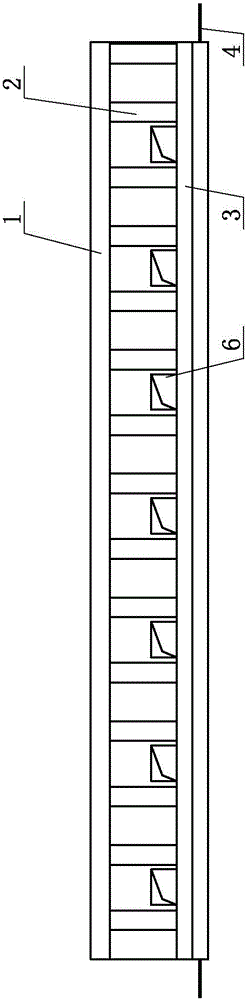

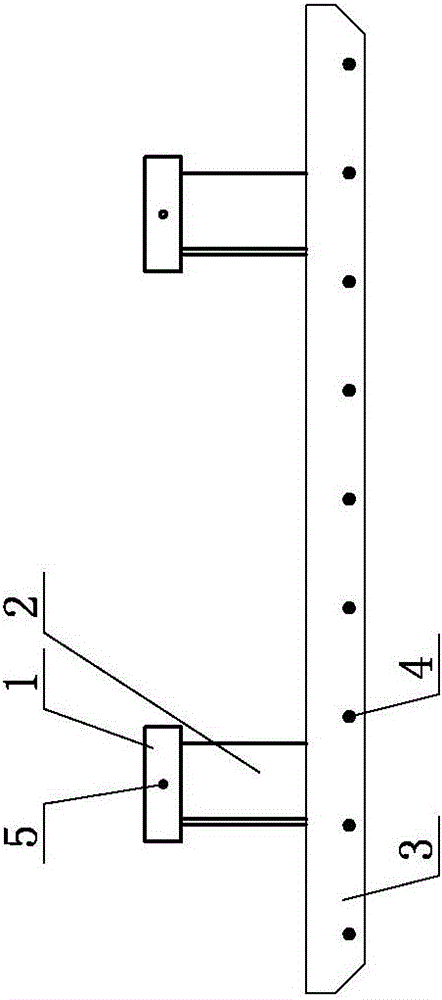

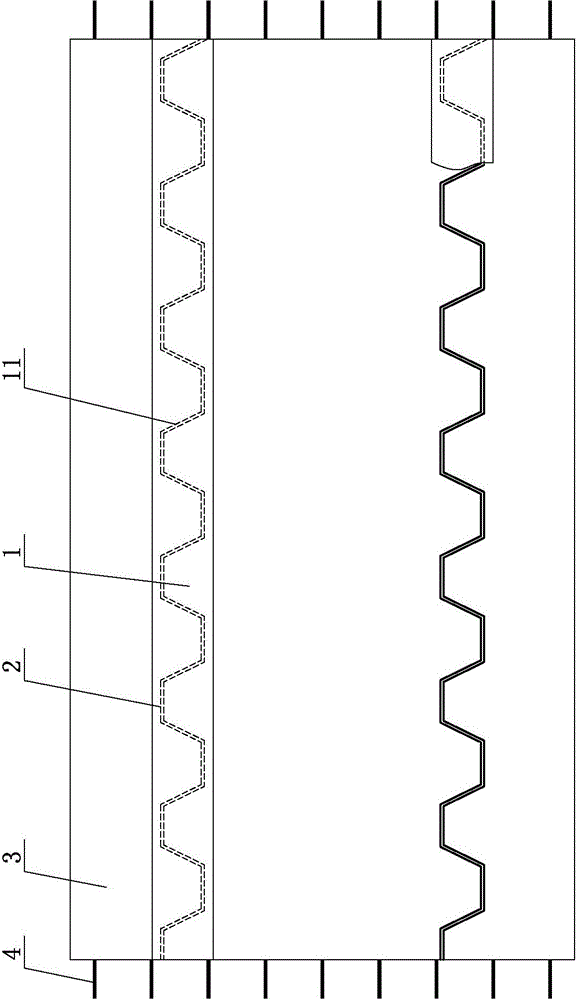

[0008] 3 in the figure is the bottom plate, the bottom plate 3 and the concrete rib 1, the steel plate 2 is arranged on the bottom plate 3, the bottom of the steel plate 2 in the height direction is embedded in the bottom plate 3, the top of the steel plate 2 in the height direction is embedded in the concrete support 1, and the steel plate 2 is bent along the length direction Several grooves 11 are formed, and the opening directions of every two adjacent grooves 11 are opposite, and several through holes 6 are opened in the middle of the steel plate 2 . This combined structure can increase the pressure-bearing performance of the laminated plate member and increase its section moment of inertia. The through hole 6 is a square hole or a round hole, which is convenient for passing multiple steel bars at the same time. It can increase the contact area of the steel bars, and ever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com