Cross four-angle-steel type bending constraint support

A buckling constraint, cross-shaped technology, applied in building components, earthquake-proof and other directions, can solve the problems of large additional load of core units, limited promotion and use range, and high requirements for manufacturing accuracy, saving installation time, easy industrial production, on-site Easy to assemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

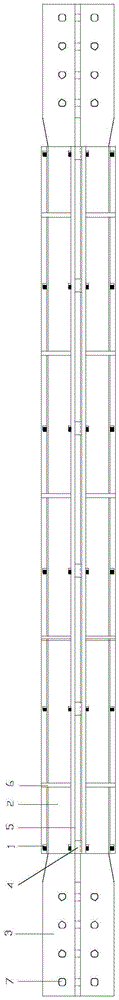

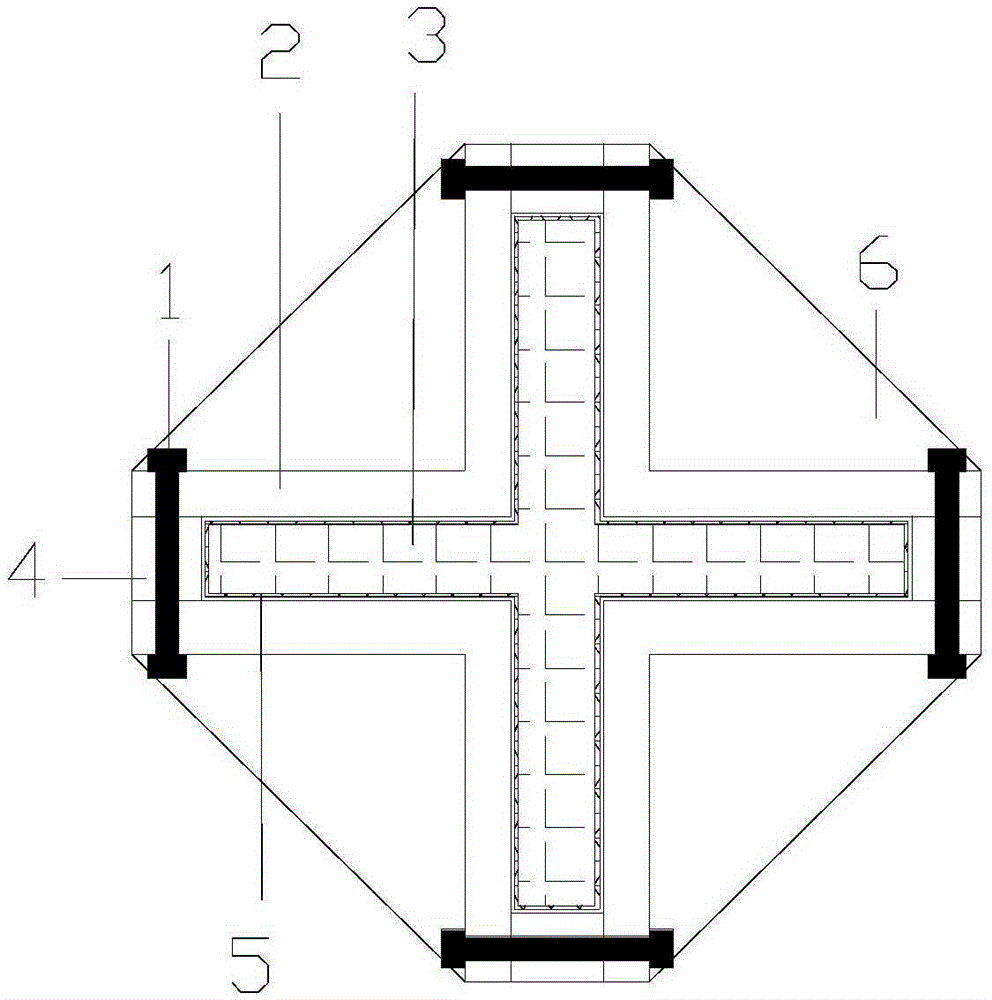

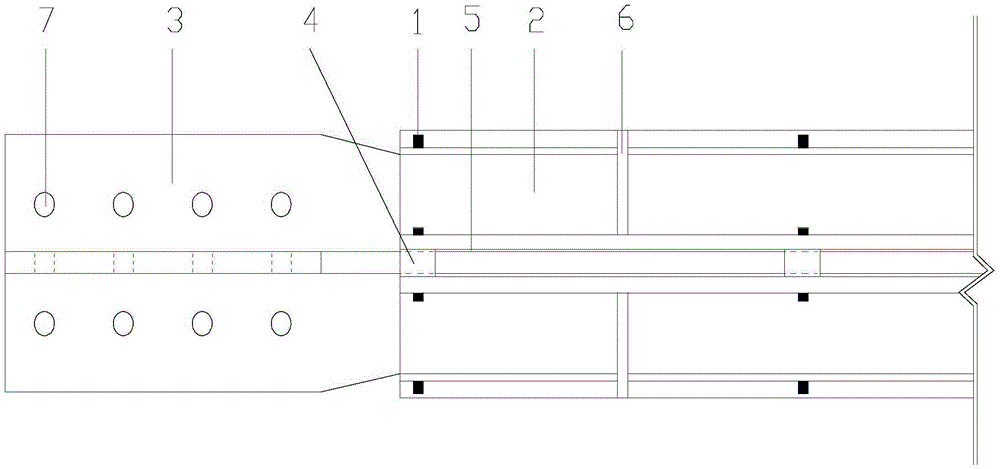

[0022] like figure 1 , figure 2 , image 3 As shown, a cross-shaped four-angle steel-type buckling-constrained support includes a "ten"-shaped core material 3, and a non-adhesive material layer 5 is sprayed on the outside of the "ten"-shaped core material 3, and the setting of the non-adhesive material layer 5 It can ensure that the "ten"-shaped core material 3 has enough relative movement when it is under tension and compression, so as to reduce frictional resistance. The non-adhesive material can be epoxy resin; the "ten"-shaped core material 3 is arranged on four angle steel 2 inside, the two ends of the "ten"-shaped core material 3 protrude from the angle steel 2 and are arranged outside the angle steel 2, and the "ten"-shaped core material 3 outside the angle steel 2 is provided with a friction-type high-strength bolt hole 7; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com