Construction method applied to shield tunneling machine receiving well station side wall large steel die

A construction method and receiving well technology, which is applied to vertical shaft equipment, shaft lining, earthwork drilling and mining, etc., can solve problems such as water leakage, influence on construction effect, and influence on concrete integrity, and achieve the effect of ensuring pouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

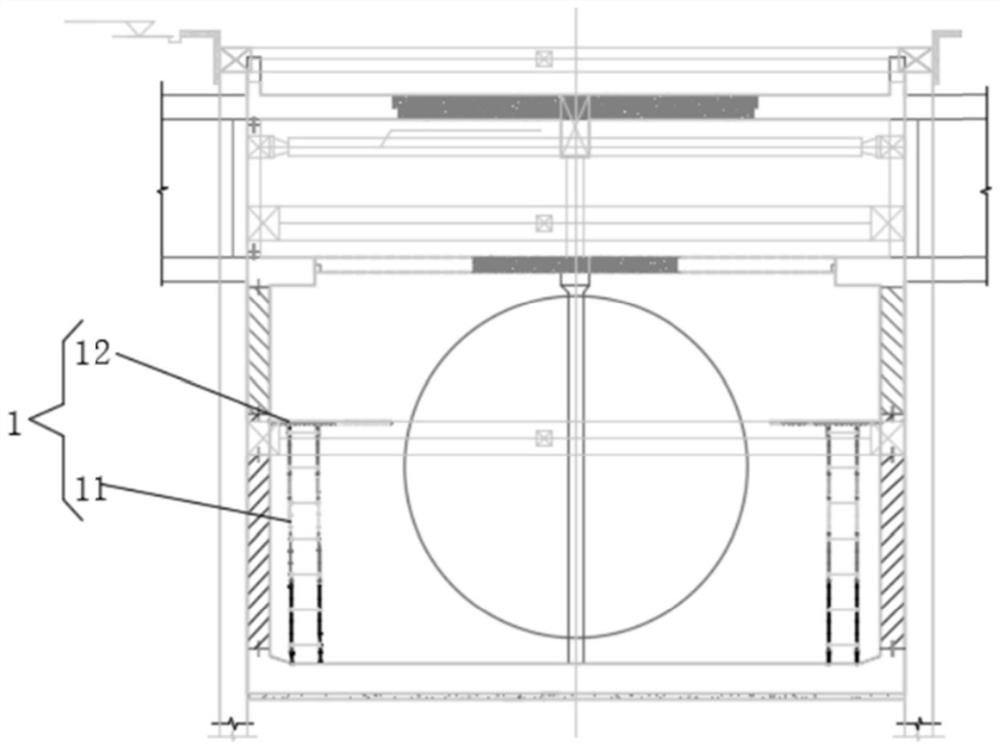

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

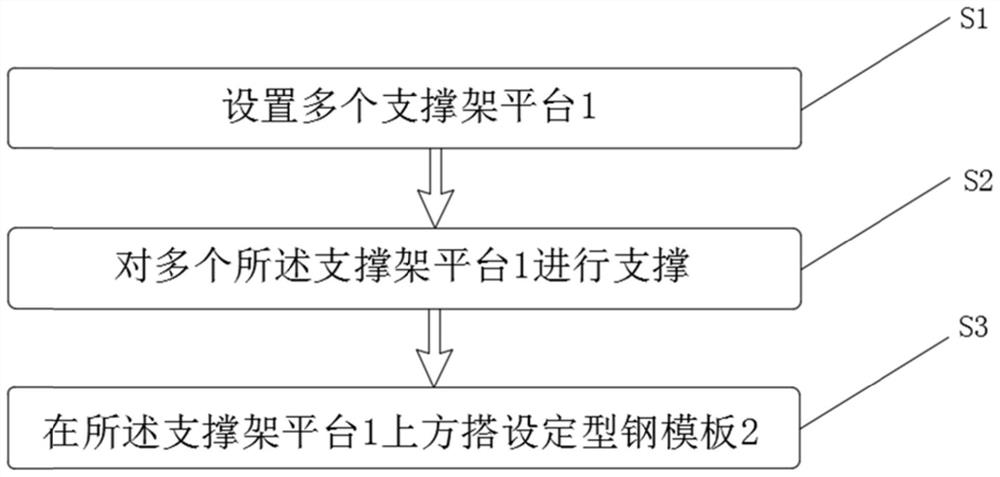

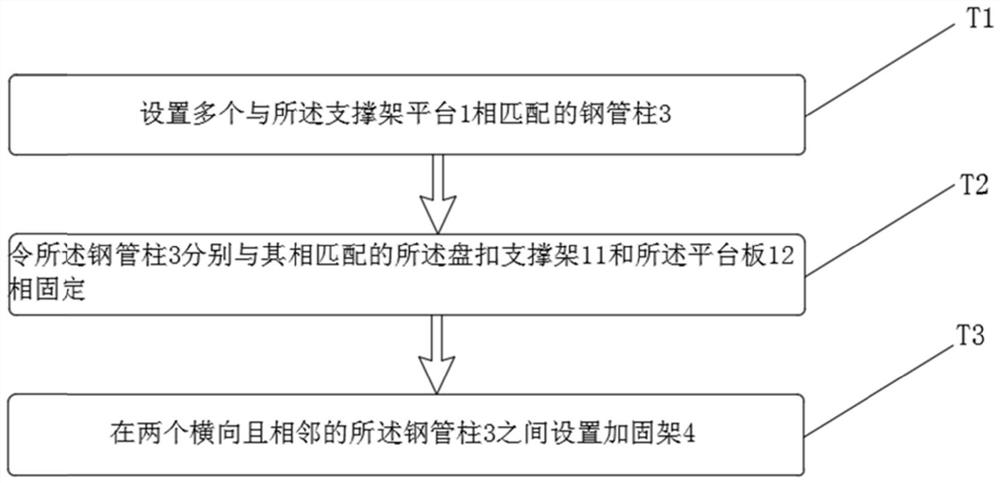

[0027] Please see attached figure 1 with Figure 3-7 , a large steel formwork construction method applied to the side wall of the shield machine receiving well station, comprising the following steps:

[0028] S1, setting a plurality of support frame platforms 1;

[0029] S2. Supporting a plurality of support frame platforms 1;

[0030] S3. Set up a shaped steel formwork 2 above the support frame platform 1 .

[0031] In this embodiment, the support frame platform 1 is built to the required height according to the actual needs, so that it is convenient to carry out construction at a place exceeding eight meters, and since the shaped steel formwork 2 is integrally formed, it will not affect the overall concrete The effect of pouring is guaranteed, and because the shaped steel formwork 2 is made of rigid material, there will be no water leaka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com