Method for in-situ generation of Ti7Al5Si12 reinforced brazing seam from foamed titanium

An in-situ generation, foamed titanium technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of large residual stress, poor wettability, and large difference in thermal expansion coefficient, and achieve reduced residual stress and thermal expansion. The effect of reducing the coefficient and reducing the thermal expansion coefficient difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for in-situ generation of Ti7Al5Si12 reinforced aluminum-based brazing seam from titanium foam, the specific steps are as follows:

[0050] Step 1, select aluminum-based solder, the main component of the solder is Al-Si alloy, and the shape is powder, paste, foil, strip or ring;

[0051] Step 2, carry out DSC test on the aluminum-based solder, and measure its liquidus as T;

[0052] Step 3, prepare the base metal, titanium foam and brazing material before welding;

[0053] Step 4, pre-weld assembly in a furnace;

[0054] Step 5, vacuumize, set the welding temperature and holding time, set or not set the pressure, and start welding;

[0055] Step 6, cooling with the furnace to complete the welding.

[0056] In step 1, preferably, the mass fraction of Si element in the aluminum-based solder is 8-20%, and the balance is Al and a small amount of other alloying elements.

[0057] In step 2, the liquidus temperature T ≥ 550°C obtained by the DSC test.

[0058] I...

Embodiment 2

[0076] A method for in-situ generation of Ti7Al5Si12 reinforced aluminum-based brazing seam from titanium foam, the specific steps are as follows:

[0077] Step 1, select aluminum-based solder, the main component of the solder is Al-Si alloy, and the shape is powder, paste, foil, strip or ring;

[0078] Step 2, carry out DSC test on the aluminum-based solder, and measure its liquidus as T;

[0079] Step 3, prepare the base metal, titanium foam and brazing material before welding;

[0080] Step 4, pre-weld assembly in a furnace;

[0081] Step 5, vacuumize, set the welding temperature and holding time, set or not set the pressure, and start welding;

[0082] Step 6, cooling with the furnace to complete the welding.

[0083] In step 1, preferably, the mass fraction of Si element in the aluminum-based solder is 12-14%, and the balance is Al and a small amount of other alloying elements.

[0084] In step 2, the liquidus temperature T ≥ 550°C obtained by the DSC test.

[0085] ...

Embodiment 3

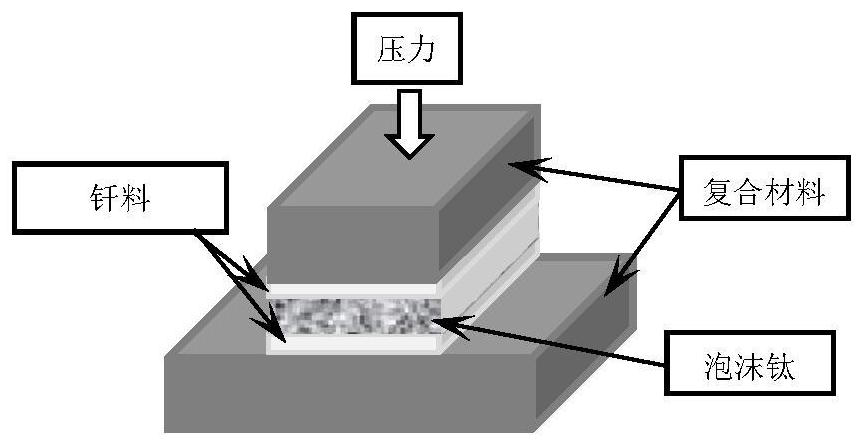

[0101] Example 3. Prepare Al-Si10.5-Mg0.1 powder solder, according to figure 1 Assembly drawing shown for 70% SiC p / Al composite material sample, AlSiMg solder and foamed titanium were assembled, the welding temperature was 700 °C, the holding time was 1 h, and the welding pressure was 10 MPa.

[0102] Specific steps: use Al, Si, Mg pure metal powder, prepare brazing filler metal according to the ratio of Al-Si10.5-Mg0.1, and prepare brazing filler metal after stirring, ball milling and drying; cut the foamed titanium into small pieces, The surface of the composite material to be welded is ground with a water mill, and then the surface of the sample to be welded that has been roughly ground is finely ground with 280, 400 and 600 sandpapers in turn. The samples were ultrasonically cleaned with absolute ethanol, and then dried in cold air for use; press figure 1 Fill the prepared powder brazing filler metal and foam titanium between the surfaces of the samples to be welded, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com