Preparation method of cobalt blue ceramic glaze special-use ink

A ceramic glaze and blue technology, applied in the direction of ink, application, household utensils, etc., can solve the problems of poor storage stability and achieve the effect of improving storage stability, avoiding aggregation, and avoiding agglomeration and settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

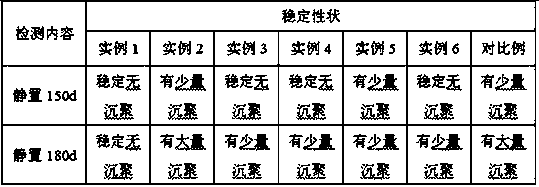

Examples

example 1

[0025] In parts by weight, successively take 10 parts of nanometer graphene oxide, 4 parts of sodium polystyrene sulfonate, 3 parts of glutaraldehyde, 3 parts of carbon fiber, 100 parts of deionized water, and first mix graphene oxide, carbon fiber, polystyrene Sodium ethylene sulfonate and deionized water are mixed, ultrasonically dispersed, then glutaraldehyde is added, and the temperature is 75°C, the stirring speed is 300r / min, and the reaction is heated and stirred for 3 hours, then left to stand, vacuum-dried, and ground to obtain Modified graphene oxide; in parts by weight, successively take 50 parts of copper nitrate and 300 parts of water, pour them into a beaker, stir and mix and dissolve with a glass rod for 30 minutes to obtain a mixed slurry, and add 10 parts of the mixed slurry to the mixed slurry. % modified graphene oxide, and then move the beaker containing the mixed slurry into a digital display speed measuring constant temperature magnetic stirrer, and at a t...

example 2

[0027] In parts by weight, successively get 20 parts of aluminum chloride hexahydrate, 120 parts of water, 20 parts of cobalt chloride hexahydrate, 8 parts of phospholipids, 5 parts of polyols, 5 parts of stabilizers, and 5 parts of esters. Aluminum chloride hexahydrate and water were placed in a three-necked flask, stirred and mixed for 60 minutes at a speed of 500r / min, then added dropwise to the three-necked flask with ammonia water with a mass fraction of 20% to adjust the pH to 7.2, and then added to the three-necked flask Add cobalt chloride hexahydrate, stir and mix for 60 minutes at a speed of 800r / min, then add phospholipids, polyols, stabilizers, and esters into a three-necked flask, and stir and mix for 60 minutes at a speed of 800r / min , that is, special ink for cobalt blue ceramic glaze. The emulsifier is emulsifier OP-10. The phospholipid is milk phospholipid. The polyol is polybutylene adipate diol. The stabilizer is methyl tin mercaptide. The ester substanc...

example 3

[0029] According to parts by weight, take 50 parts of copper nitrate and 300 parts of water successively, pour them into a beaker, stir and mix and dissolve with a glass rod for 30 minutes to obtain a mixed slurry, and then move the beaker containing the mixed slurry into a digital speed measuring constant temperature magnetic stirrer , at a temperature of 55°C and a stirring speed of 500r / min, drop ammonia water with a mass fraction of 20% into the beaker through the dropping funnel at a rate of 5mL / min, adjust the pH of the mixed slurry in the beaker to 7.2, and then add the mixed slurry Gellan gum with a mass of 0.2 times and an emulsifier with a mass of 0.03 times the mixed slurry were continuously stirred and mixed at a constant temperature for 60 minutes, the stirring was stopped, and the temperature was kept and aged for 4 hours to obtain an aged liquid, and the obtained aged liquid was transferred to a rotary evaporator, The temperature is 80°C, the pressure is 500kPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com