Irradiation-resistant hot melt adhesive and preparation method thereof

A technology for radiation-resistant rubber and hot melt adhesive, applied in the field of hot sol, can solve the problems of reduced adhesion and hot melt adhesive failure, and achieves the effect of maintaining adhesion performance, low production energy consumption, and avoiding product purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Raw material components and dosage:

[0049] Ethylene-vinyl acetate (trade name EVA150) 15g,

[0050] Ethylene-vinyl acetate (trade name EVA210) 20g,

[0051] Dimer acid type polyamide resin (trade name H-120) 30g,

[0052] Butyl rubber (trade name 268) 7g,

[0053] EPDM rubber (4551A) 5g,

[0054] Terpene resin (trade name T100) 20g,

[0055] Microcrystalline wax 1g,

[0056] Tetrakis[β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (trade name Antioxidant 1010) 1g,

[0057] Tributyl citrate 1g.

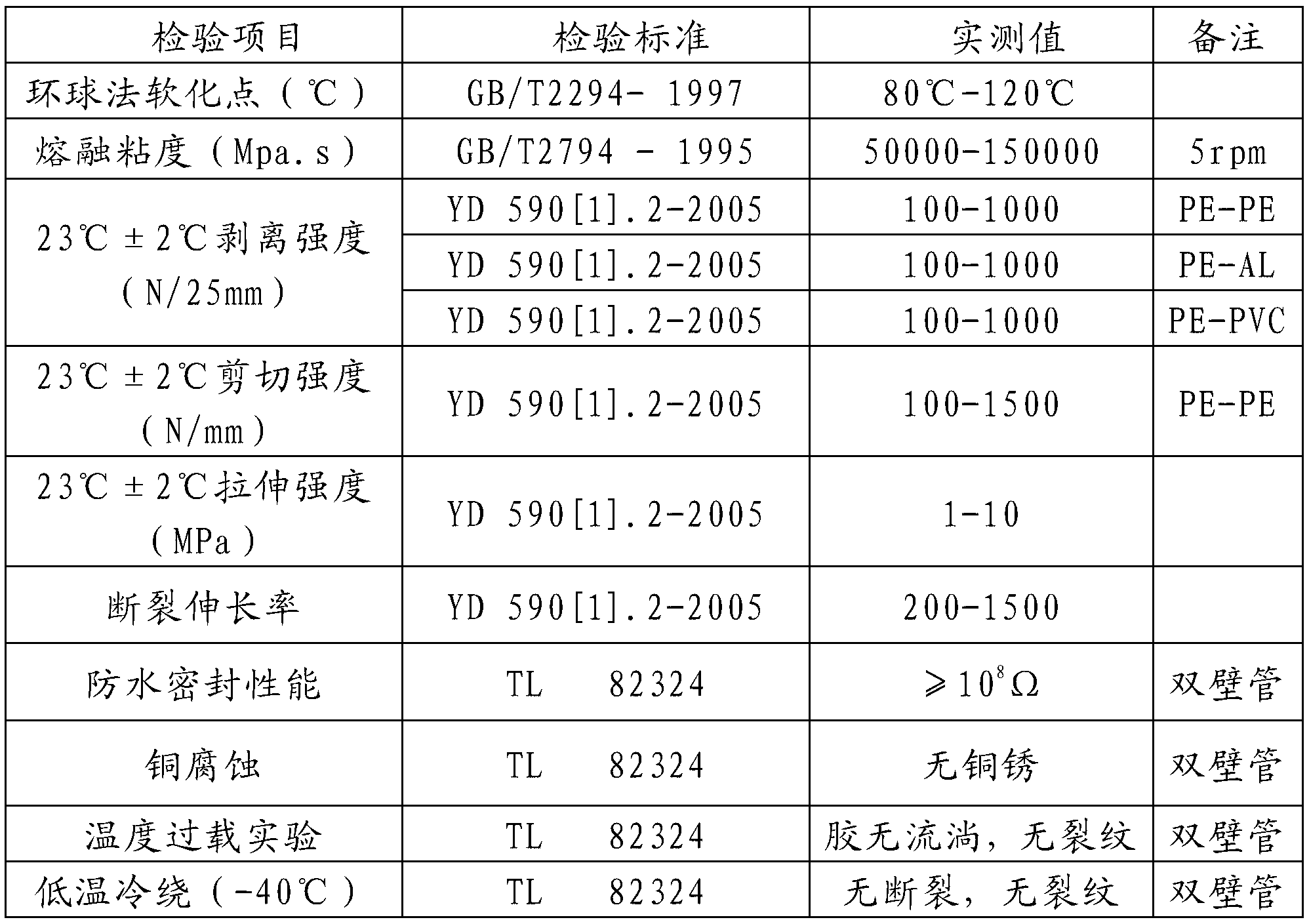

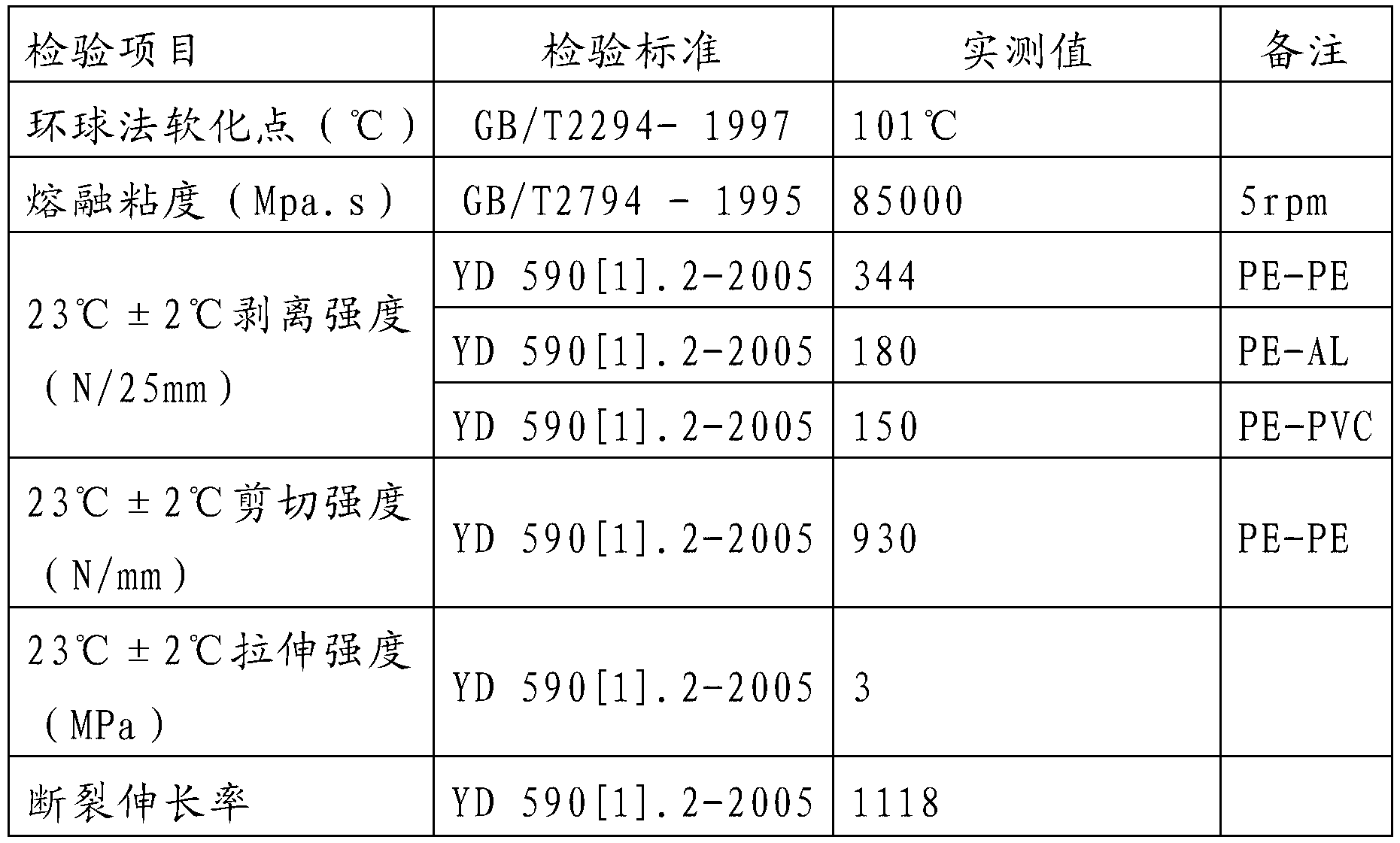

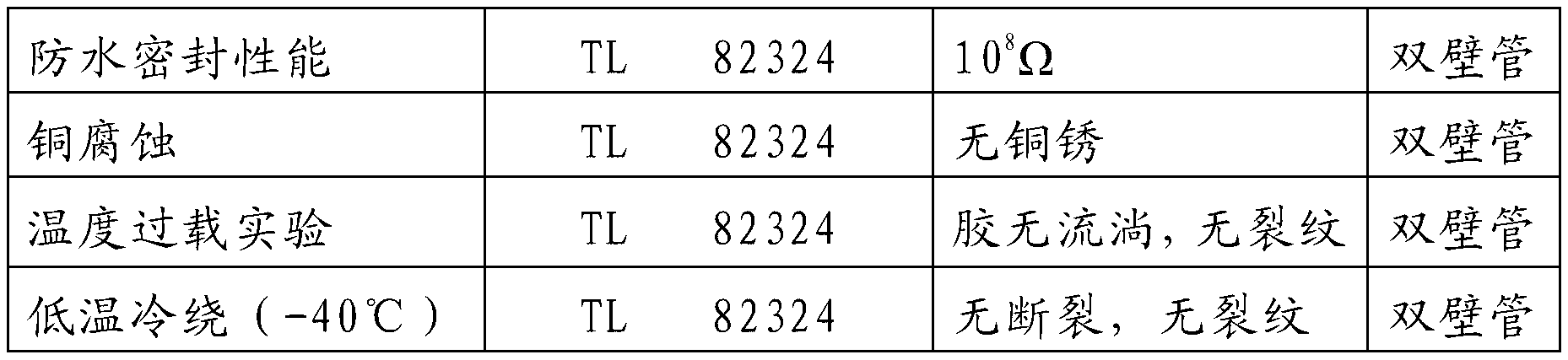

[0058] Preparation method: Weigh each component according to the above-mentioned amount, add it to a twin-screw extruder for mixing, the mixing temperature is 140°C, mix twice, use circulating water to cool the hob and cut into pellets to obtain radiation-resistant hot melt Adhesive products, use the packaging box to store the hot melt adhesive obtained after granulation. The obtained radiation-resistant hot melt adhesive product had a softenin...

Embodiment 2

[0067] Raw material components and dosage:

[0068] Ethylene-vinyl acetate (trade name EVA210) 10g,

[0069] Ethylene-vinyl acetate (trade name EVA450) 10g,

[0070] Dimer acid type polyamide resin (trade name LR-PA-170) 40g,

[0071] Butyl rubber (trade name 268) 10g,

[0072] EPDM rubber (3722P) 10g,

[0073] Rosin 17g,

[0074] Microcrystalline wax 1g,

[0075] Tetrakis[β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (trade name Antioxidant 1010) 1g,

[0076] Tributyl citrate 1g.

[0077] Preparation method: same as Example 1, except that the mixing temperature is 150°C. The softening point of the obtained radiation-resistant hot-melt adhesive product is 120° C., and the viscosity is 108000 mpa.s.

Embodiment 3

[0079] Raw material components and dosage:

[0080] Ethylene-vinyl acetate (trade name EVA150) 15g,

[0081] Ethylene-vinyl acetate (trade name EVA210) 15g,

[0082] Dimer acid type polyamide resin (trade name H-120) 20g,

[0083] Butyl rubber (trade name 268) 20g,

[0084] EPDM rubber (4551A) 10g,

[0085] Rosin 5g,

[0086] Terpene resin (trade name T100) 4g,

[0087] Polyethylene wax 1g,

[0088] N,N-bis-[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hexamethylenediamine 9g,

[0089] Tributyl citrate 0.5g,

[0090] Acetyl tributyl citrate 0.5g.

[0091] Preparation method: the same as in Example 1, the difference is that before mixing, ethylene-vinyl acetate, butyl rubber and EPDM rubber are put into an internal mixer for banburying and granulation, and the banburying temperature is 80 ℃, and then mixed with other materials for kneading. The obtained radiation-resistant hot melt adhesive product has a softening point of 115°C and a viscosity of 78000mpa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com