Exothermic composition and exothermic article using composition, and method for producing exothermic article

A heat-generating composition and heat-generating body technology, applied in chemical instruments and methods, heat-generating devices, heat-exchanging materials, etc., can solve the problems of composition functions such as deterioration of heat-generating performance, high viscosity, and deterioration of fluidity, etc., to prevent Production loss and non-uniformity and quality failure, prevention of deterioration, excellent effects in shape retention and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

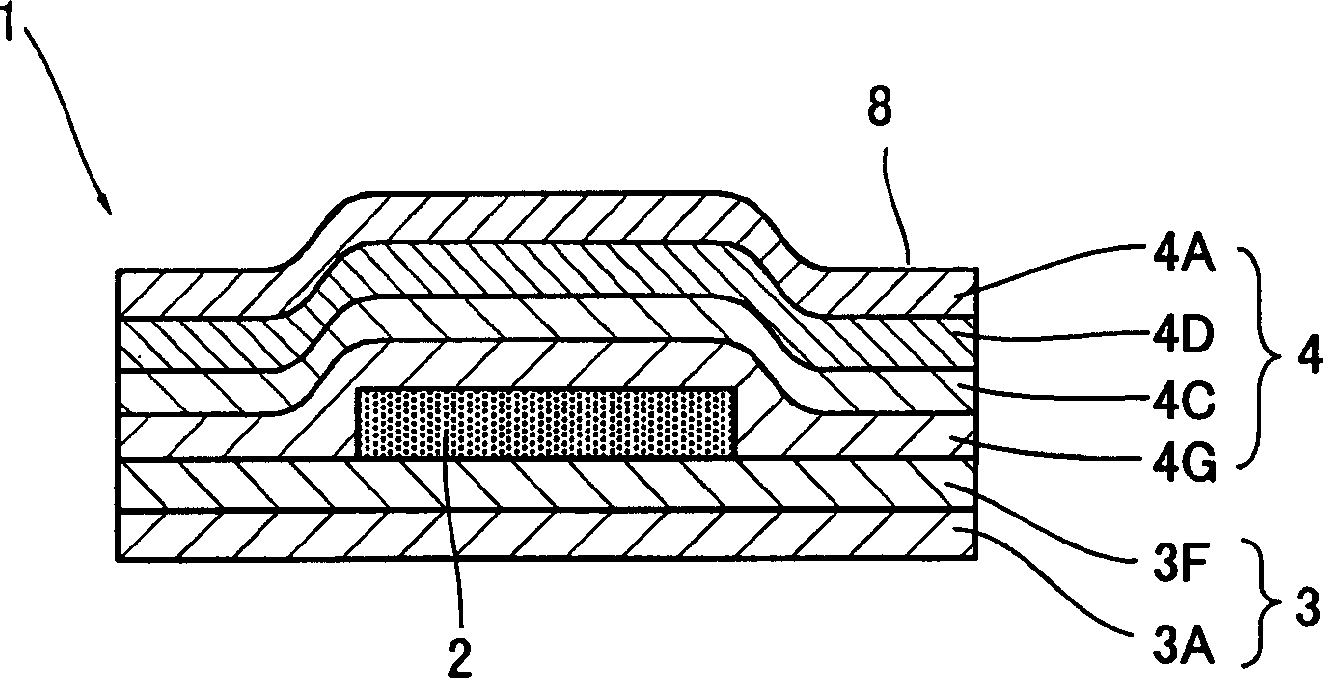

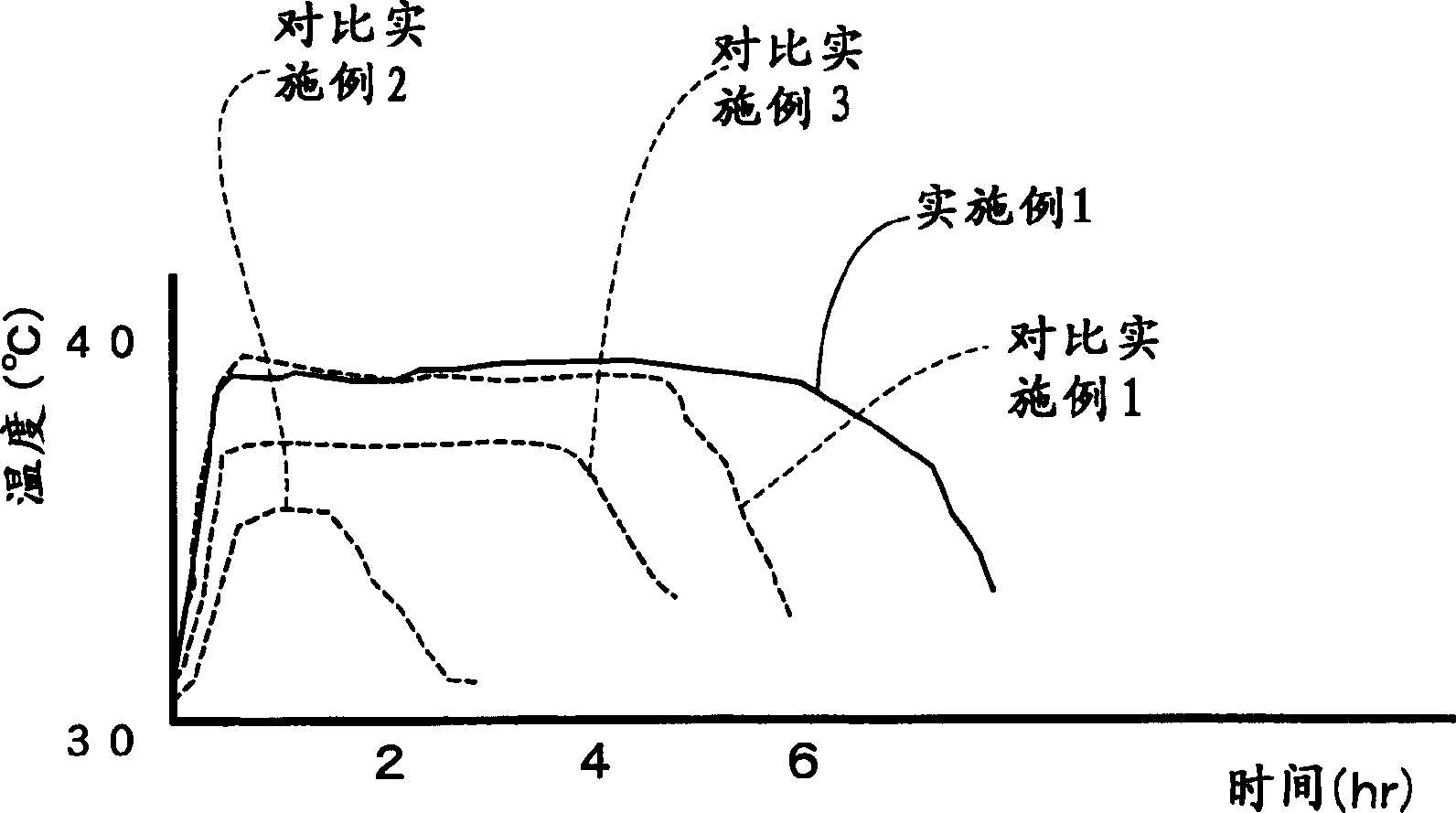

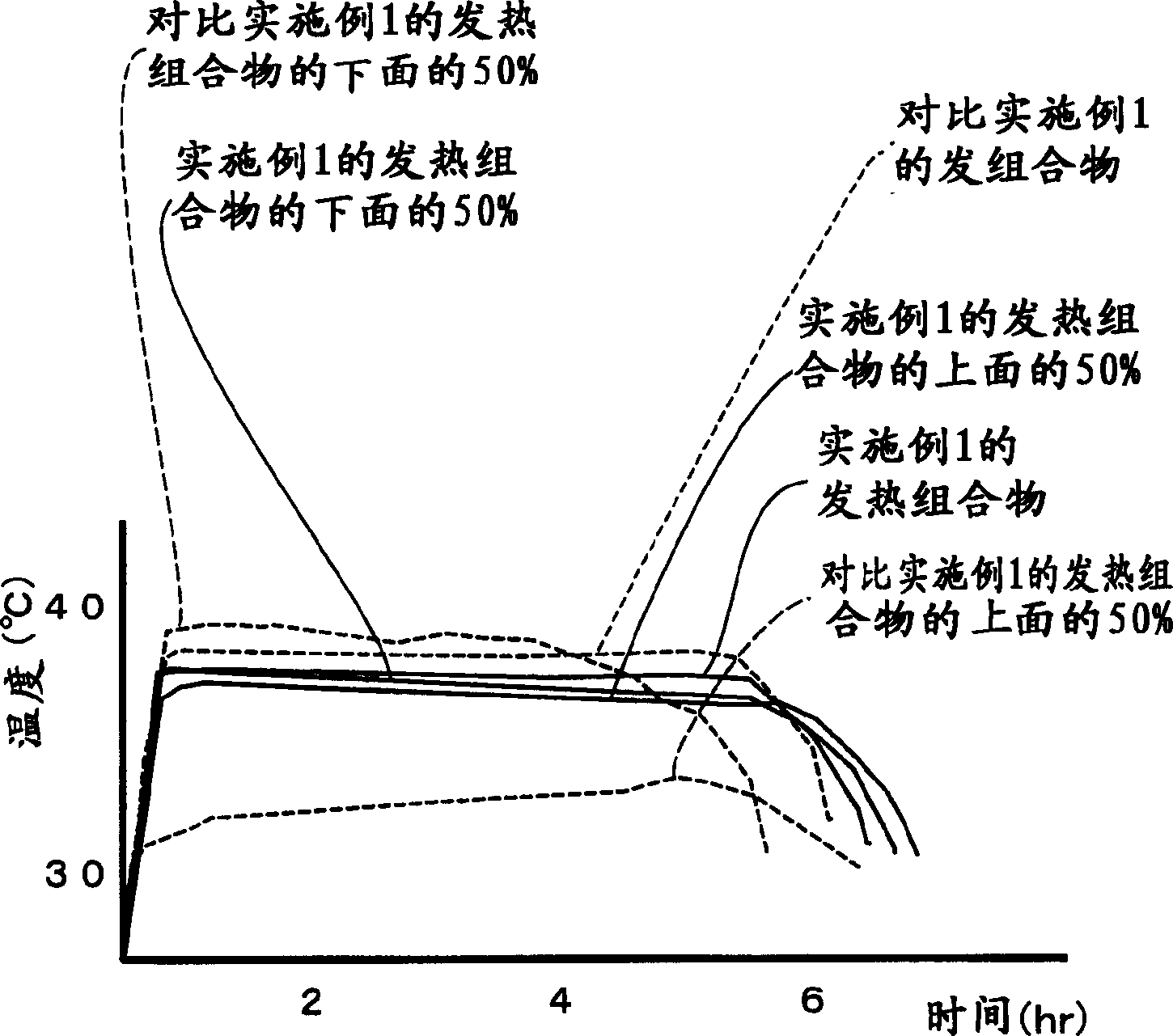

[0458] figure 1 It is a cross-sectional view of the heating element 1 of Example 1 of the present invention. A mold not shown in the figure was set on the base material 3 having dimensions of 85 mm in length and 65 mm in width, the exothermic composition 2 was placed in the mold, and a mold not shown in the figure was used. The scraper plate is molded by through-die molding to laminate the heat-generating composition 2 on the base material 3, which is also covered with a film-shaped covering material 4 having substantially the same size as the base material 3, sealing its periphery 8, sealing The width was 7 mm, and the heating element 1 was obtained.

[0459] Heat generating composition 2 is formed by mixing a stabilizer for preventing water separation with a heat generating composition containing metal powder as a main component, and 6 parts by mass of sodium chloride (NaCl) as a metal chloride, 50 parts by mass of water, As carbon components, 5 parts by mass of activated ...

Embodiment 2

[0489] In the same manner as in Example 1, by using the exothermic composition obtained in Example 1 to obtain Figure 5 The heating element 1 shown in , only changes the base material and cover material.

[0490] As the base material 3, an air-impermeable laminated film is used which is a release film 3I formed of a polyester film with a thickness of 100 μm, an adhesive layer 3H with a thickness of 30 μm, and a polyethylene film with a thickness of 50 μm from the exposed surface. A composite laminated nonwoven fabric 3C of a film 3A, a polyethylene resin 3E having a thickness of 40 μm, and a water-absorbent cotton nonwoven fabric is formed.

[0491] As the covering material 4, a laminated film prepared in the following manner was used: a polyester nonwoven fabric 4A (30 g / m in unit weight) having kneaded therein fibers of an anion-generating agent containing feldspar as a main component was used. 2 ) and polyethylene porous membrane 4D with a thickness of 40 μm, in this orde...

Embodiment 3

[0497] Figure 6It is a sectional view of the heating element 1 according to the third embodiment of the present invention. The heat generating body 1 is formed in such a manner that the heat generating composition 2 having the same composition as in the preceding examples has a water-absorbing polymer (without cyclic anhydride and co-derived acid) uniformly spread on both surfaces thereof. and salt N-vinylacetamide polymer cross-linked product) 7 and 7A, the amount of water-absorbing polymer is 0.5 parts by mass per surface, and this exothermic composition 2 is laminated on a film-shaped base material 3, on which It was covered with a film-shaped covering material 4 having a web-shaped hot-melt adhesive 4G provided thereon, and then its periphery 5 was sealed by heat sealing with a sealing width of 7 mm.

[0498] That is, the heating element 1 of this example has the same shape as the heating element 1 of Example 1, which is a rectangular shape with a length of 85 mm and a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water sorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com