Method for preparing graphene through mechanical stripping and application of method

A mechanical exfoliation and graphene technology, applied in the field of graphene, can solve the problems of unstable quality of graphene, unfavorable for large-scale promotion, inability to realize exfoliation, etc., and achieve the effect of good exfoliation effect, fewer defects and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present embodiment has prepared a kind of graphene, and specific process is:

[0039] (1) Sodium α-alkenyl sulfonate, sodium fatty alcohol polyoxyethylene ether sulfate, coconut oil diethanolyl amide, polyethylene glycol 5000, and water are prepared in a mass ratio of 4:4:8:15:69 to prepare foam agent aqueous solution;

[0040] (2) Artificial graphite is uniformly pre-dispersed in the foaming agent aqueous solution of above-mentioned configuration, obtains artificial graphite pre-dispersion liquid, and its concentration is 10mg / mL;

[0041] (3) Add the artificial graphite pre-dispersion into the pin sand mill, the particle size of the grinding medium is 0.5mm, the filling amount is 80%, the stirring speed is 1500rmp, and the stirring time is 2h;

[0042] (4) by washing with water, and treating at a centrifugal speed of 1000rmp for 10min to obtain a graphene supernatant, that is, to obtain graphene.

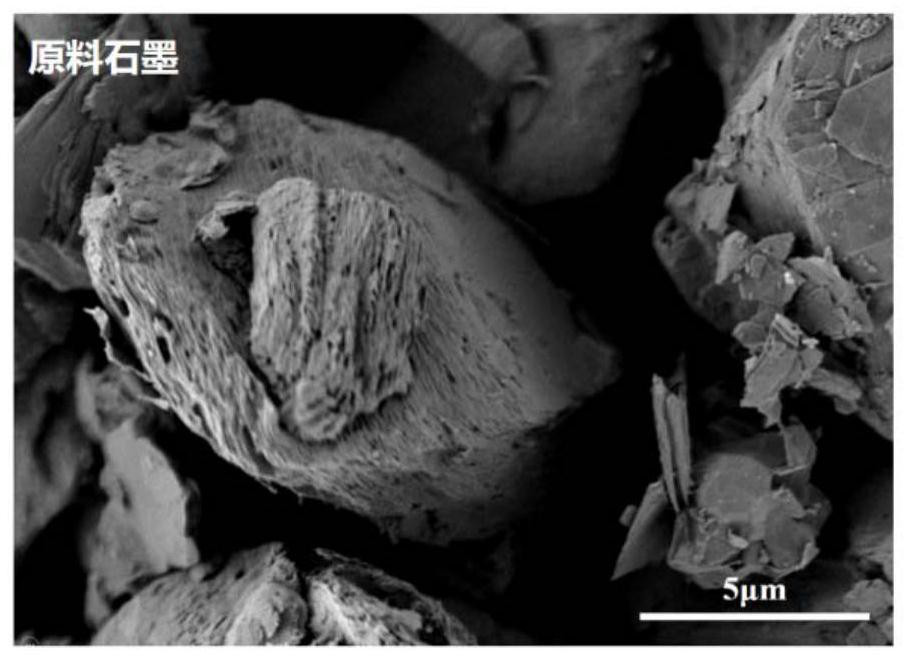

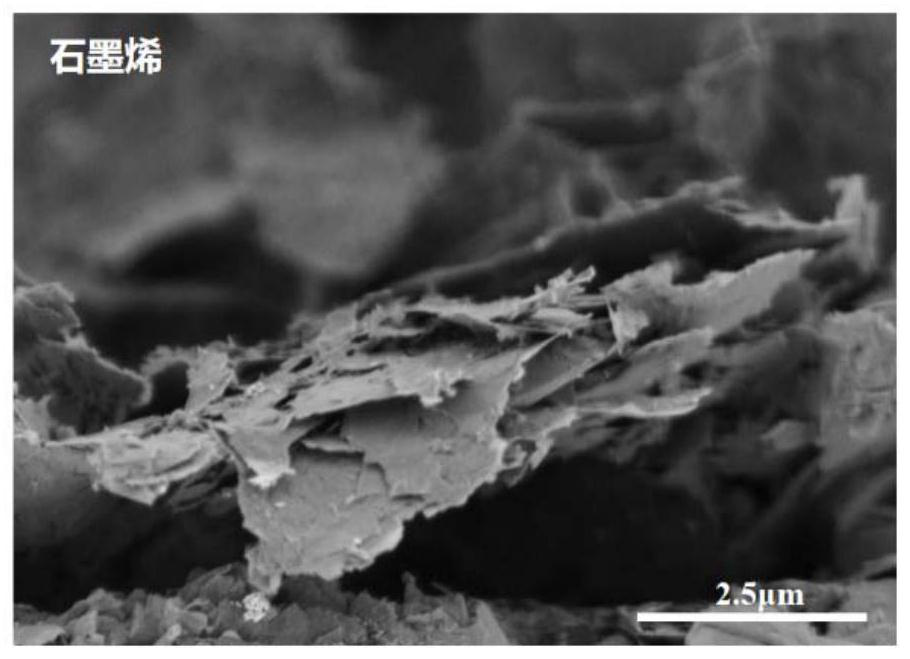

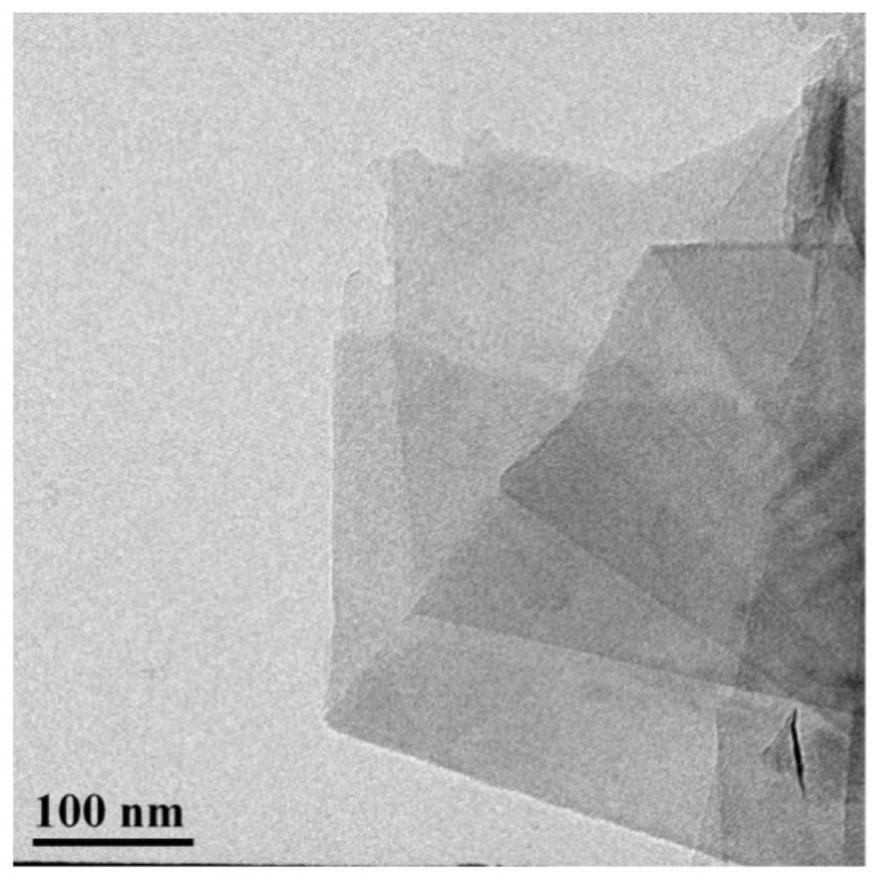

[0043] from figure 1 From the SEM morphology of the raw graphit...

Embodiment 2

[0047] The present embodiment has prepared a kind of graphene, and specific process is:

[0048] (1) Sodium α-alkenyl sulfonate, sodium fatty alcohol polyoxyethylene ether sulfate, coconut oil diethanolyl amide, polyethylene glycol 4000, and water are prepared in a mass ratio of 5:2.5:7.5:15:70 to prepare foam agent aqueous solution;

[0049] (2) The graphite flakes are uniformly pre-dispersed in the aqueous foam solution of the above-mentioned configuration to obtain graphite flakes pre-dispersed liquid, the concentration of which is 10mg / mL;

[0050] (3) Add flake graphite pre-dispersion liquid into pin sand mill, grinding medium particle size 0.3mm, filling capacity 80%, stirring speed 1500rmp, stirring time 2h;

[0051] (4) by washing with water, and treating at a centrifugal speed of 2000rmp for 7 minutes to obtain the graphene supernatant, that is, to obtain graphene.

Embodiment 3

[0053] The present embodiment has prepared a kind of graphene, and specific process is:

[0054] (1) Sodium α-alkenyl sulfonate, sodium fatty alcohol polyoxyethylene ether sulfate, coconut oil diethanolyl amide, polyethylene glycol 3000, and water are prepared into foam according to the mass ratio of 3:2:5:15:75 agent aqueous solution;

[0055] (2) Uniformly pre-disperse the expandable graphite in the above-mentioned aqueous foam solution to obtain an expandable graphite pre-dispersion, the concentration of which is 10 mg / mL;

[0056] (3) Add the expandable graphite pre-dispersion into the pin sand mill, the particle size of the grinding medium is 0.8mm, the filling amount is 80%, the stirring speed is 1000rmp, and the stirring time is 3h;

[0057] (4) by washing with water, and treating at a centrifugal speed of 2500rmp for 5min to obtain the graphene supernatant, namely to obtain graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com