Aqueous cutting fluid and aqueous cutting agent

A technology of cutting fluid and cutting slurry, applied in the direction of grinding/polishing equipment, base materials, additives, etc., to achieve the effect of high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

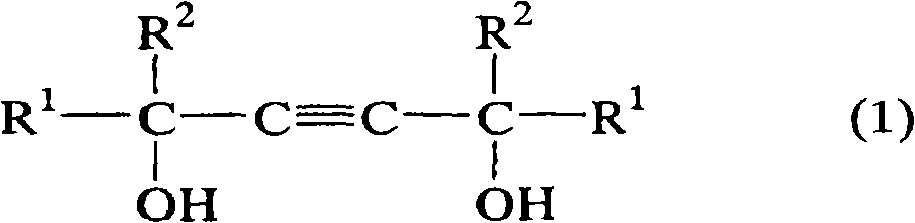

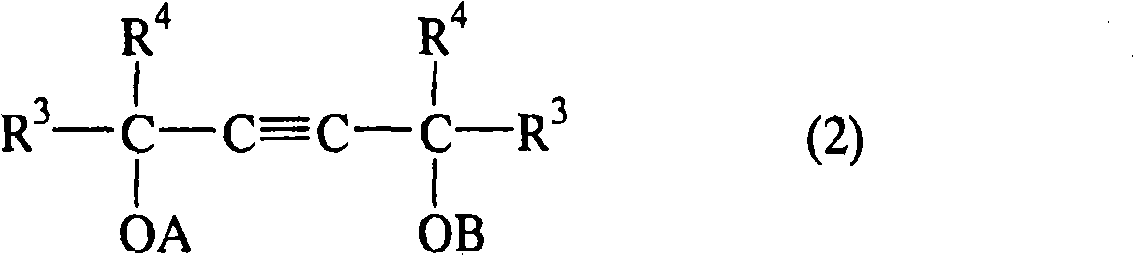

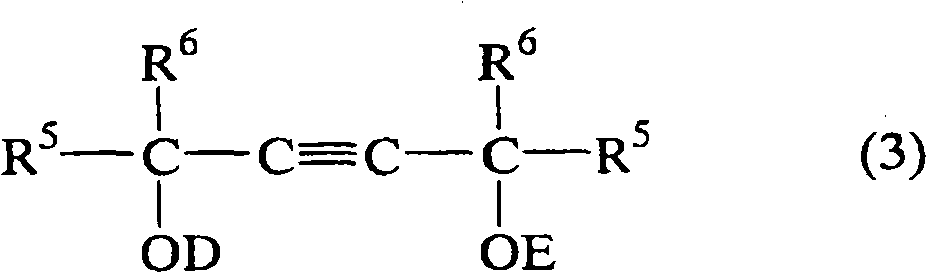

Method used

Image

Examples

Embodiment 1

[0059] A fluid, labeled M-1, was obtained by mixing 13% deionized water, 18% PEG200 and 68% diethylene glycol, and adding 1% acetylenic diol A (2,5,8,11-tetra Methyl-6-dodecyn-5,8-diol ethylene oxide adduct, which added 4 moles of ethylene oxide) in the system. This liquid was mixed with a silicon carbide (SiC) abrasive (Shinano Electronic Refining Co., Ltd., GC#1000, average particle size 11 microns) and stirred until an aqueous slurry for cutting silicon ingots was obtained.

[0060] The determination of the abrasive dispersion stability of the water-based cutting slurry is carried out by measuring the average particle size just after it is prepared and after it has been kept standing for 24 hours. The results are shown in Table 3. The viscosity stability and processing accuracy of the slurry were measured by cutting a silicon ingot under the following conditions. The results are also listed in Table 3.

[0061] Cutting conditions

[0062] Cutting tool: multi wire saw ...

Embodiment 2~11 and comparative Embodiment 1~7

[0081] As described in Example 1, an aqueous cutting fluid (M-2 to M-18) was prepared by mixing and stirring the component amounts as described in Tables 1 and 2. As described in Example 1, this liquid was mixed with silicon carbide abrasive (Shinano Electronic Refining Co., Ltd., GC#1000, average particle size 11 μm) and stirred until an aqueous slurry was obtained.

[0082] The dispersion stability of the prepared aqueous cutting slurry abrasive was evaluated by measuring the average particle size just after preparation and after 24 hours of storage. The results are shown in Tables 3 and 4. The slurry was also evaluated for its viscosity stability and processing accuracy by cutting a silicon ingot under the same conditions as in Example 1. The results are also shown in Tables 3 and 4.

[0083] Table 1

[0084]

[0085] Table 2

[0086]

[0087]

[0088] Alkyne diol A: Ethylene oxide adduct of 2,5,8,11-tetramethyl-6-dodeyn-5,8-diol with 4 moles of ethylene oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com