Carbon black and ceramic double-phase nanometer composite slurry for preparing metal-based micro-nano powder and preparation method thereof

A nano-composite, metal-based technology, applied in the direction of coating, etc., to achieve the effect of high absorption rate, uniform distribution and strong light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

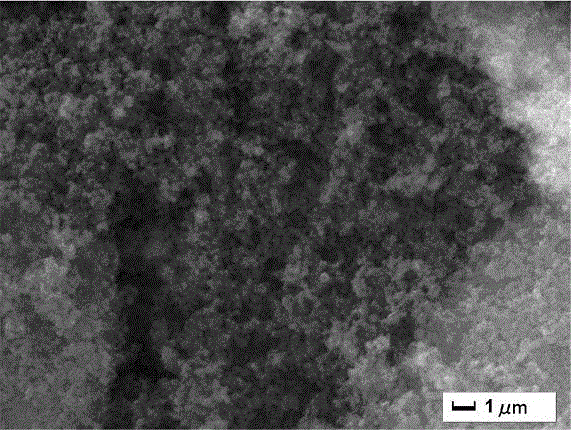

Image

Examples

Embodiment 1

[0024] Materials used in the example: Commercially available ordinary bagged carbon black powder, with an average particle size of 18nm and a tinting strength of 135%, the amount of carbon black powder added accounts for 0.05% of the total mass of the slurry; commercially available ordinary bagged silicon carbide powder , with an average particle size of 30nm and a dark green color. The amount added accounts for 0.3% of the total mass of the slurry, and the rest is absolute ethanol.

[0025] First, the nano-carbon black powder is pretreated by dry ball milling to break the original large aggregate particles, and then mixed with absolute ethanol and stirred until a semi-finished carbon black slurry without obvious solid-liquid layering is obtained. The final semi-finished carbon black slurry is placed in an ultrasonic equipment for constant temperature ultrasonic dispersion. The constant temperature is controlled at 20±5°C, and the dispersion time is 30 to 60 minutes. A single-p...

Embodiment 2

[0027] Materials used in the example: commercially available ordinary bagged carbon black powder, the average particle size is 28nm, the coloring strength is 120%, and the amount of carbon black powder added accounts for 0.1% of the total mass of the slurry; commercially available ordinary bagged tungsten carbide The powder, with an average particle size of 10nm, is gray-black, and its added amount accounts for 0.5% of the total mass of the slurry, and the rest is absolute ethanol.

[0028] First, the nano-carbon black powder is pretreated by dry ball milling to break the original large aggregate particles, and then mixed with absolute ethanol and stirred until a semi-finished carbon black slurry without obvious solid-liquid layering is obtained. The final semi-finished carbon black slurry is placed in an ultrasonic equipment for constant temperature ultrasonic dispersion. The constant temperature is controlled at 20±5°C, and the dispersion time is 30 to 60 minutes. A single-ph...

Embodiment 3

[0030] Materials used in the example: Commercially available ordinary bagged carbon black powder, with an average particle size of 14nm and a tinting strength of 140%, the amount of carbon black powder added accounts for 0.15% of the total mass of the slurry; commercially available ordinary bagged alumina powder , with an average particle size of 50nm and a white color. The amount added accounts for 0.6% of the total mass of the slurry, and the rest is absolute ethanol.

[0031] First, the nano-carbon black powder is pretreated by dry ball milling to break the original large aggregate particles, and then mixed with absolute ethanol and stirred until a semi-finished carbon black slurry without obvious solid-liquid layering is obtained. The final semi-finished carbon black slurry is placed in an ultrasonic equipment for constant temperature ultrasonic dispersion. The constant temperature is controlled at 20±5°C, and the dispersion time is 30 to 60 minutes. A single-phase nano-car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com