Patents

Literature

47 results about "Pale color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The definition of pale is someone or something light in color or washed out. An example of pale is your face when you are sick and the color goes from your cheeks. An example of pale is a yellow that is not bright or vibrant. To pale is to lose the color from your face.

Flame-retardant thermoplastic resin compositions and their injection moldings

InactiveUS6465555B1Improve flame retardant performanceGood molding effectHeat resistancePolycarbonate

Owner:IDEMITSU KOSAN CO LTD

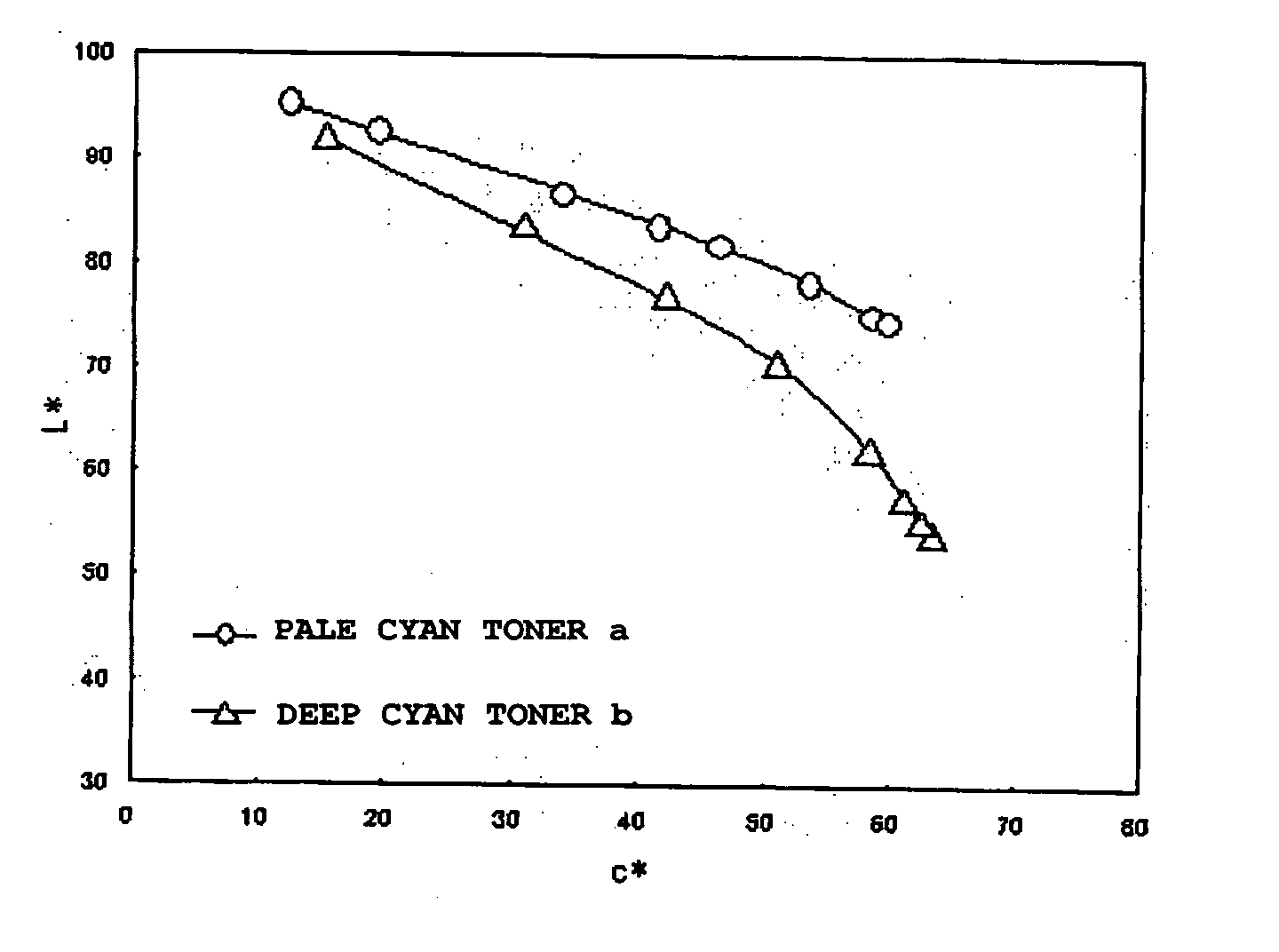

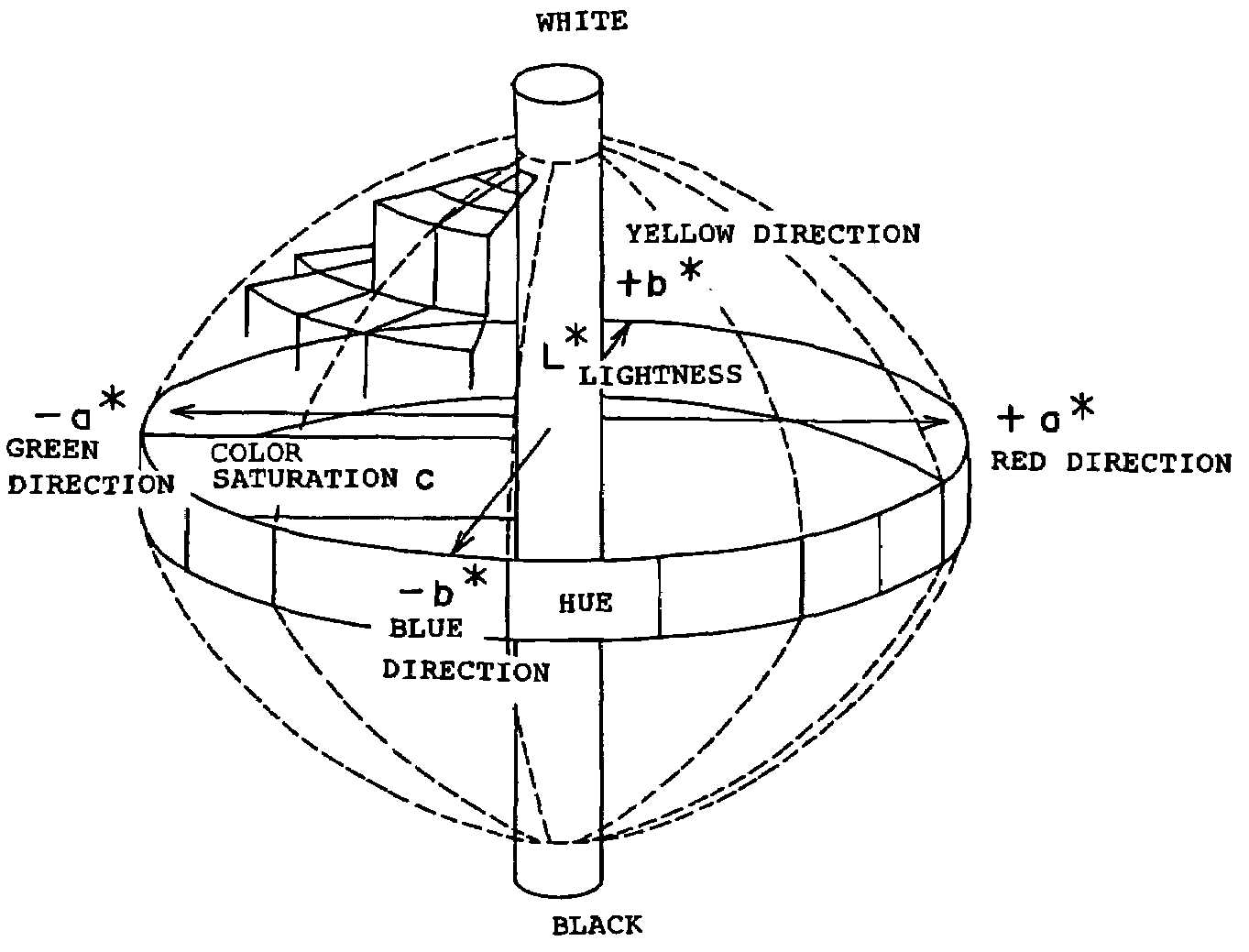

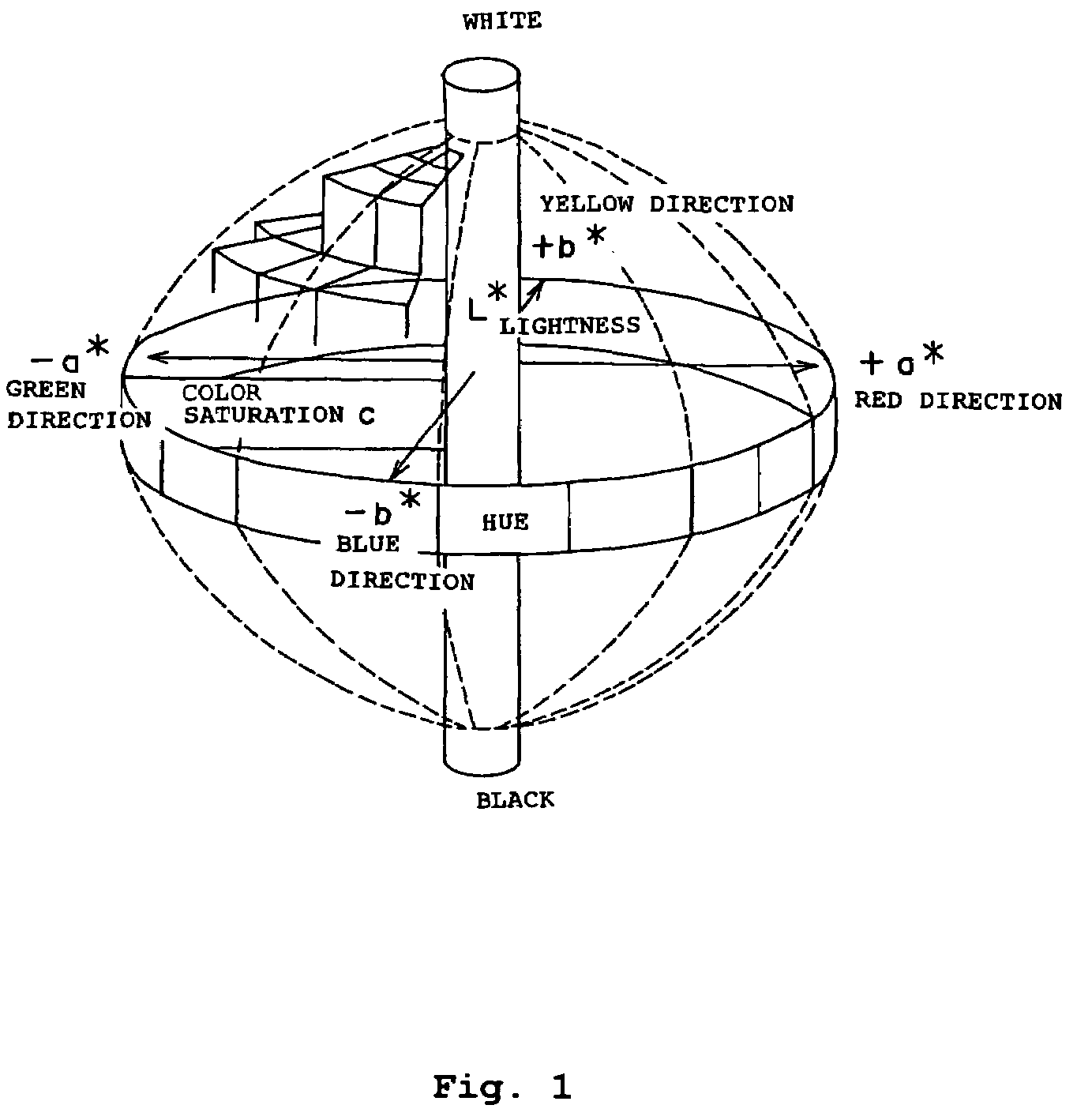

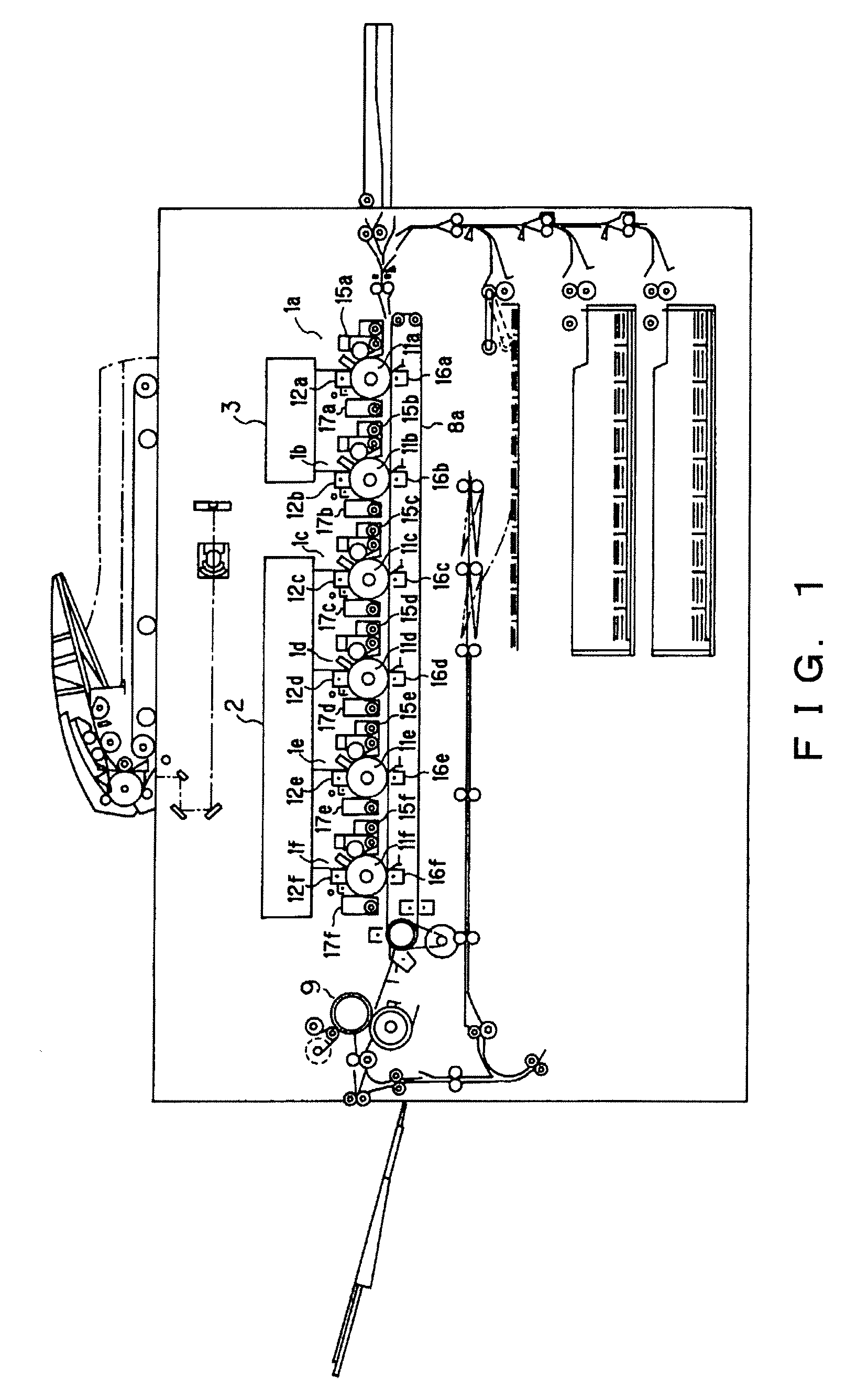

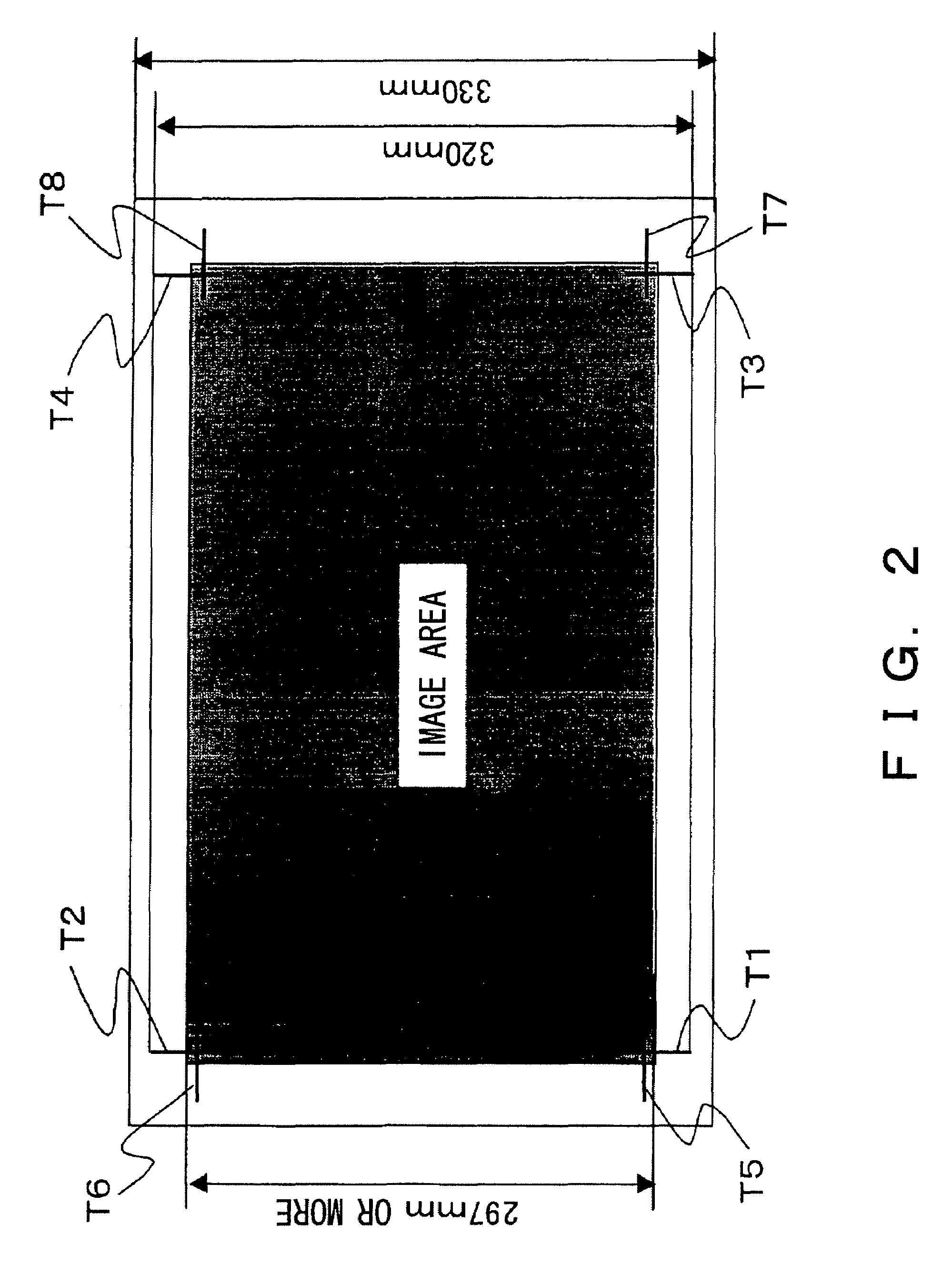

Toner kit, deep-color cyan toner, pale-color cyan toner, and image forming method

InactiveUS20050106481A1Quality improvementReduce graininessDevelopersElectrographic process apparatusHigh densityDark color

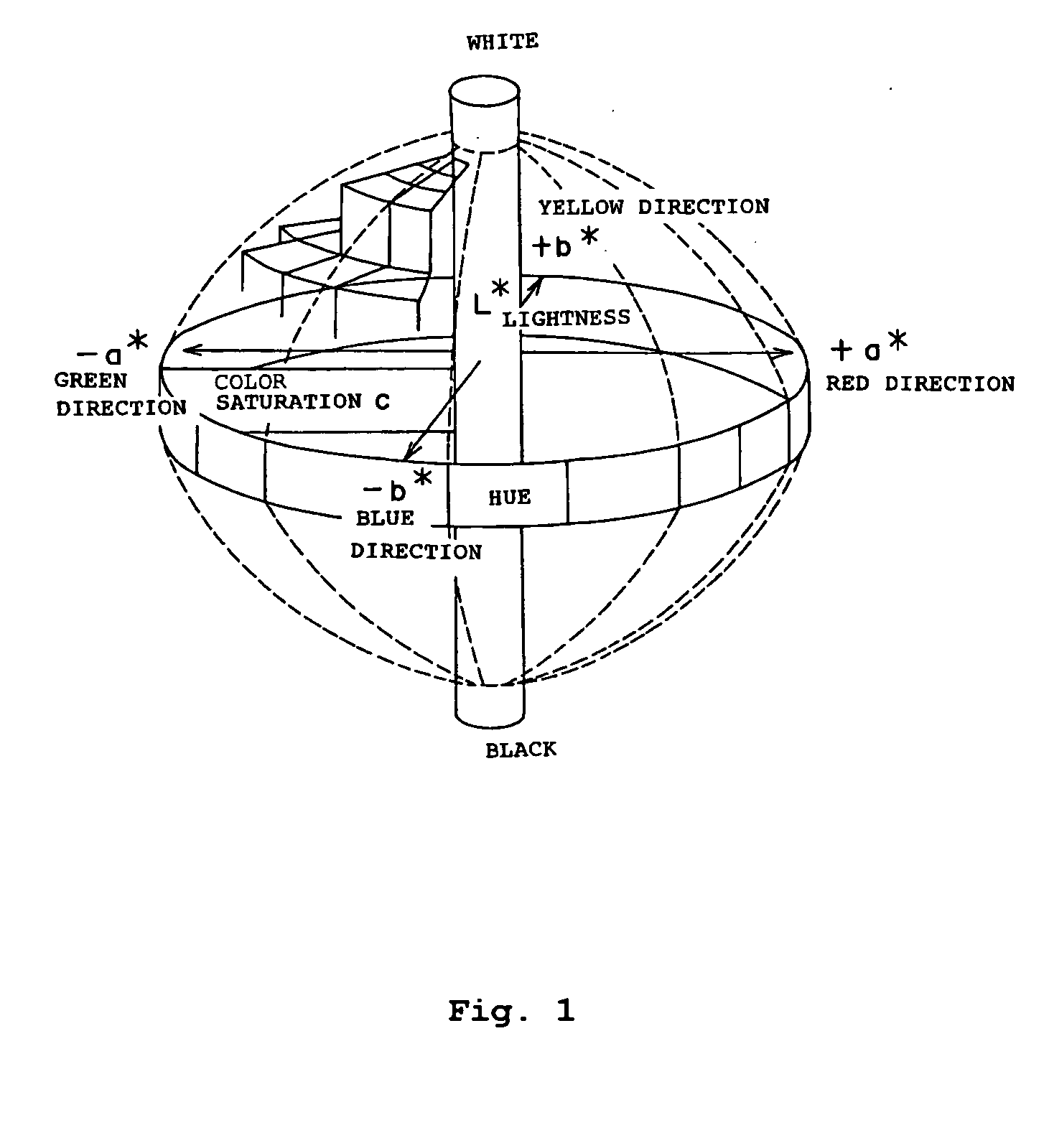

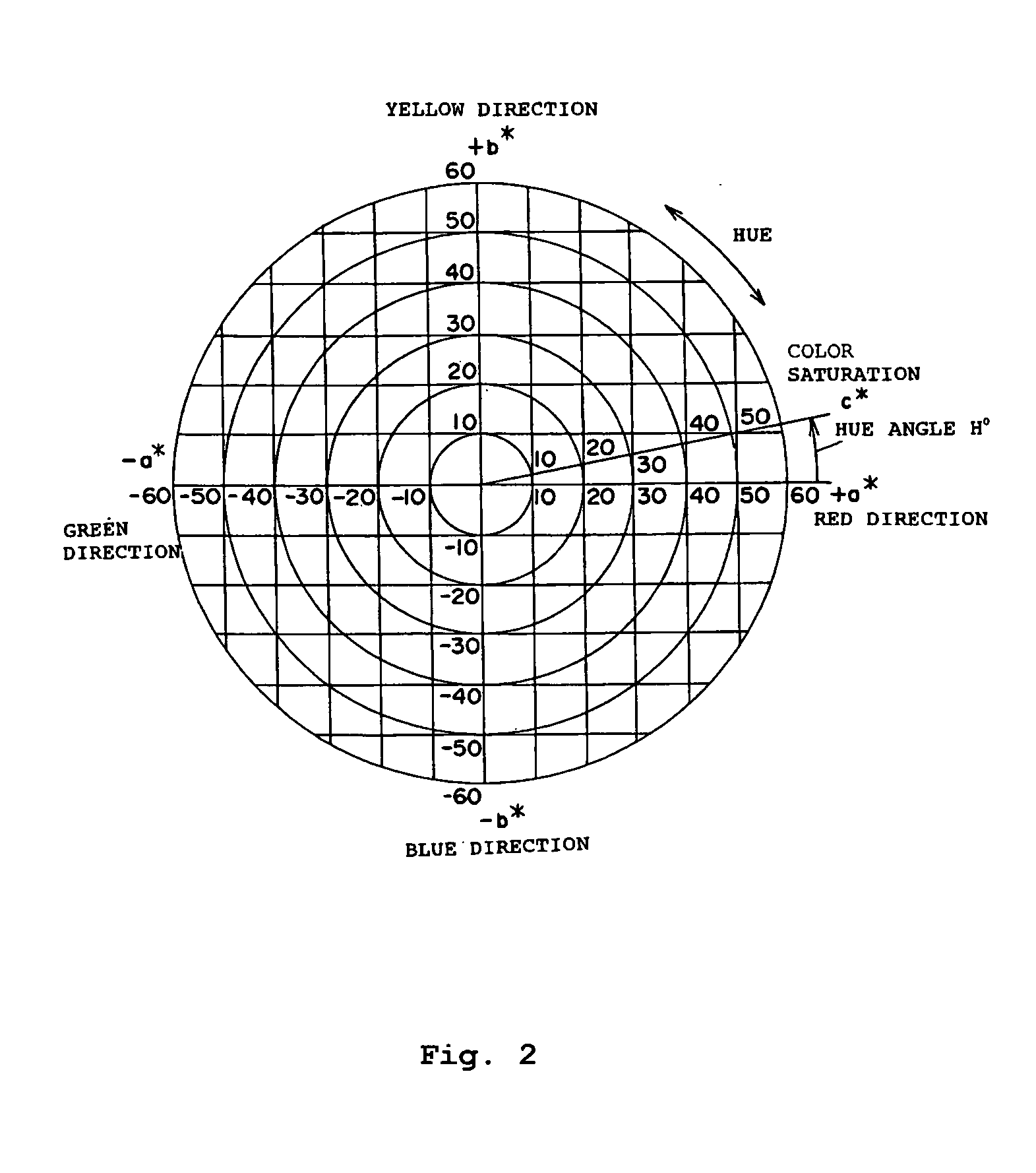

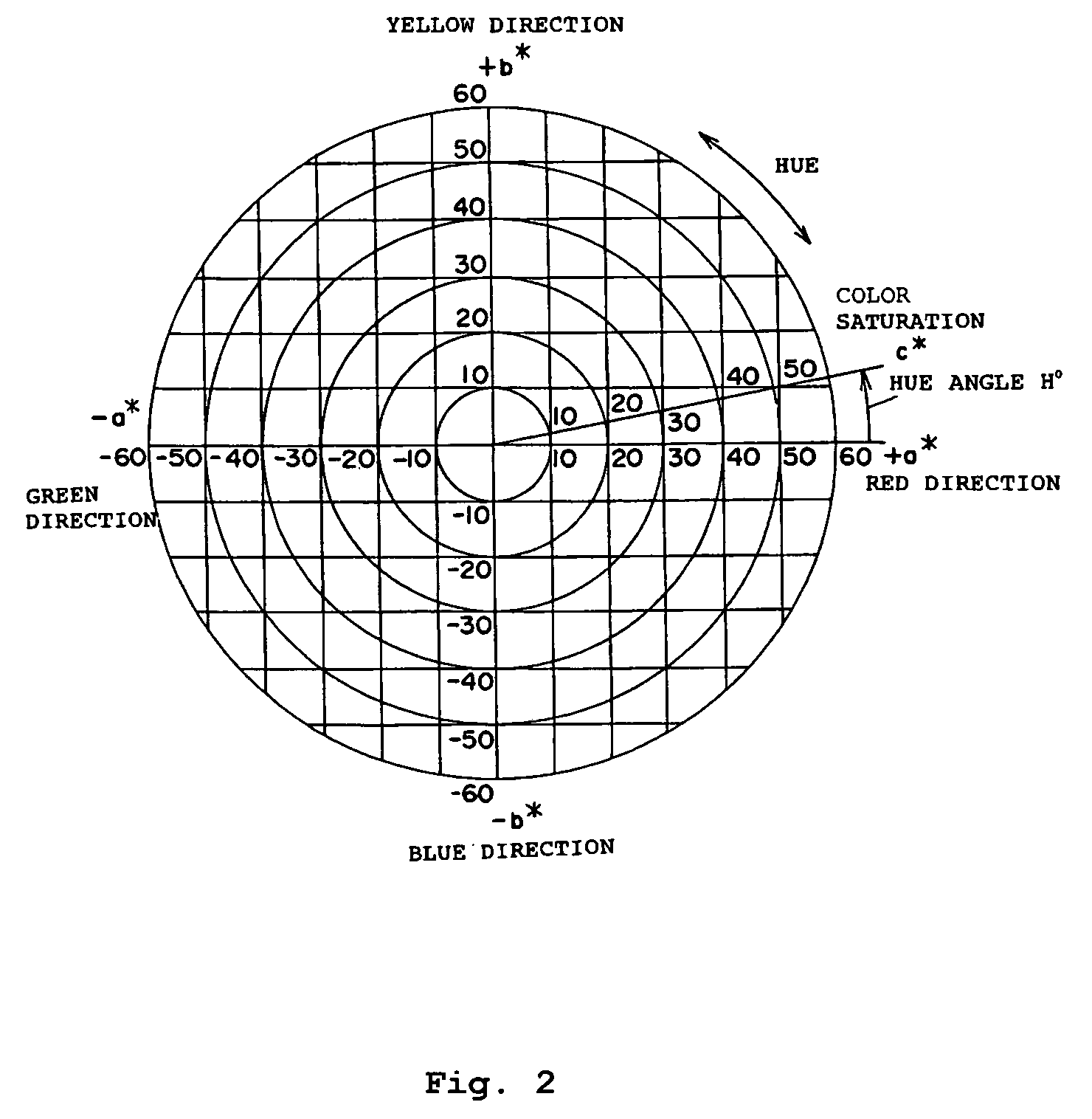

The present invention provides: a toner kit having a deep toner and a pale toner which are separated from each other, wherein: the deep toner and the pale toner satisfy prescribed conditions for an L*a*b* color coordinate system where a* represents a hue in the red-green direction, b* represents a hue in the yellow-blue direction, and L* represents a lightness; the pale toner and the deep toner to be used in the toner kit; and a method for forming an image using the toner kit. Thus, the present invention can form a high quality image, while suppressing graininess and roughness over the areas covering from the low density area to the high density area.

Owner:CANON KK

Method for extracting and separating procyanidine

A method for extracting and separating procyanidine comprises the steps of: separating the coat from the kernel of grape seeds or seabuckthorn seeds; crushing the seed coat into 10 meshes to 80 meshes; adding the crushed seed coat into alkali-water solution, alkali-alcohol-water solution or alkali-acetone-water solution with the pH value of 9 to 14 according to the solid-liquid ratio of 1g:1-10ml, conducting extraction for 1 hour to 10 hours at the temperature of 10 DEG C to 50 DEG C and then filtration; repeatedly extracting and filtering a filter cake until the filtrate is colorless or pale color; merging the filtrate and concentrating the filtrate till the weight of the filtrate is 0.5 time to 2 times of the weight of the seed coat raw materials; extracting the concentrated liquid with organic solvent and separating the liquid for obtaining an organic phase and a water phase; neutralizing the water phase with acid and adding methanol or ethanol with the volume of 1 time to 10 times, stirring, standing and filtrating; evaporating the filtrate, washing the obtained solid with water and then drying the solid for obtaining an oligomeric procyanidine product; and washing the filter cake with water and then drying the filter cake for obtaining the high-polymerization procyanidine. The invention has the advantages of less raw material input quantity, high product purity, high extraction rate, green environmental protection, simple process, and convenient industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

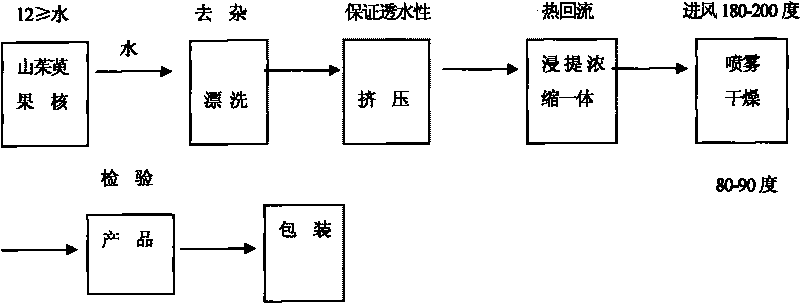

Method for extracting vegetable tannin extract from dogberry kernels

InactiveCN101701135AReduce manufacturing costSolve the growing shortageTanning treatmentNatural resin processLiquid ratioCornus officinalis

The invention discloses a method for extracting vegetable tannin extract from dogberry kernels, which is implemented by collecting and cleaning dogberry kernels, removing impurities, draining, squeezing with a pair of rollers for smashing, extracting vegetable tannin extract liquid by extraction technique and concentrating (wherein feed liquid ratio is 1:4-5, extraction temperature is no higher than 90 DEG C, concentration of concentrated solution is 18-20 baume degrees, and temperature is 60-70 DEG C), and spray drying to obtain the dogberry tannin extract. Due to adopting discarded dogberry kernels as the raw material in tannin extract production, the invention solves the increasingly grave shortage of tannin extract raw material, provides a new raw material for tannin extract production, re-develops and re-utilizes the discarded dogberry kernels, thus avoiding wasting resources, mitigating environment pollution, and effectively reducing cost of tannin extract. The extraction technique adopted in the invention can effectively extract active ingredient of tannin in dogberry kernels and retain the pale color thereof. the invention has simple technique, high practicability, high product quality, wide application, and high conversion rate, and develops a new tannin extract variety---dogberry tannin, which has good quality and low price.

Owner:RUANCHUAN CHUANGUAN VEGETABLE TANNIN EXTRACT

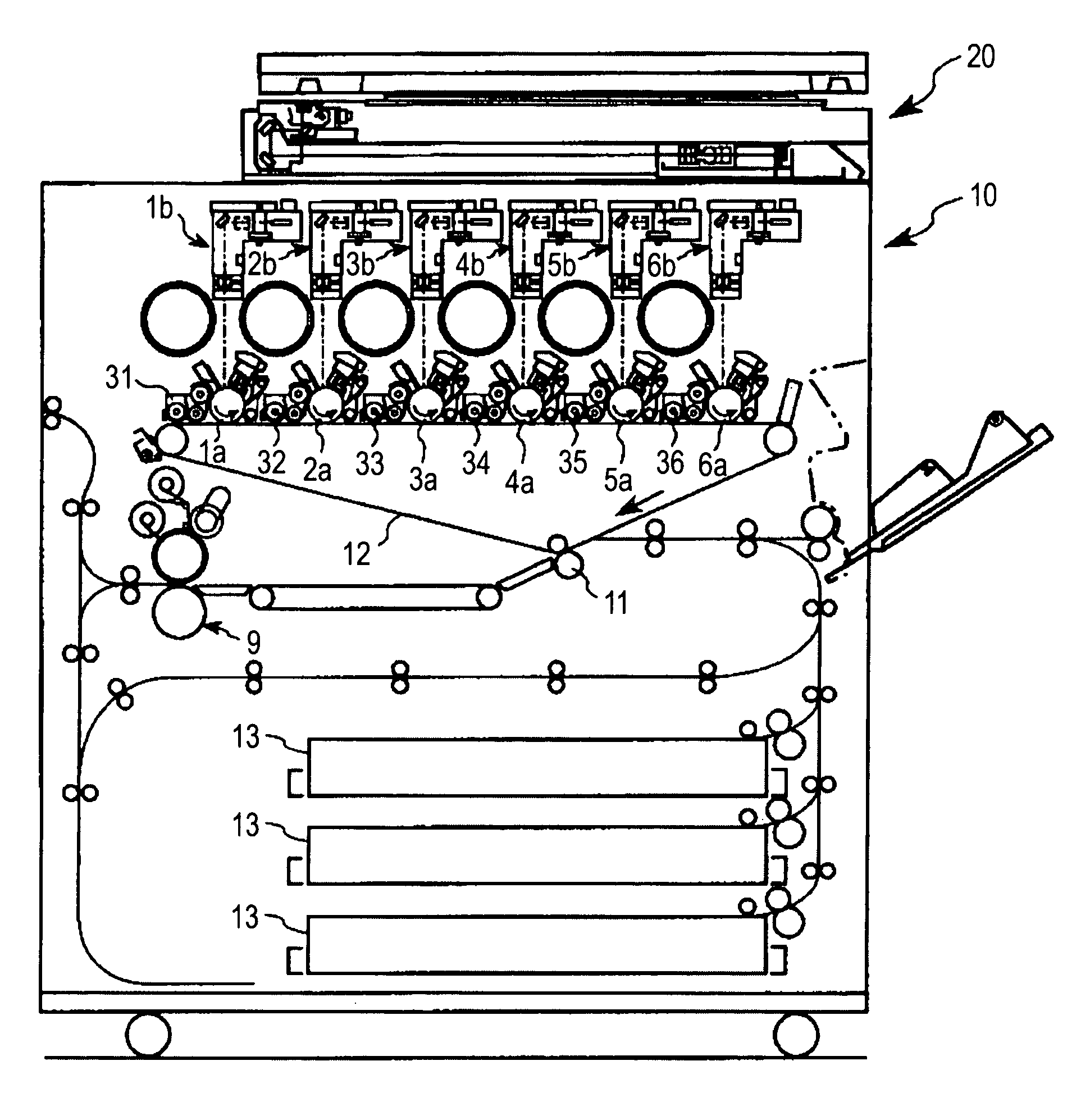

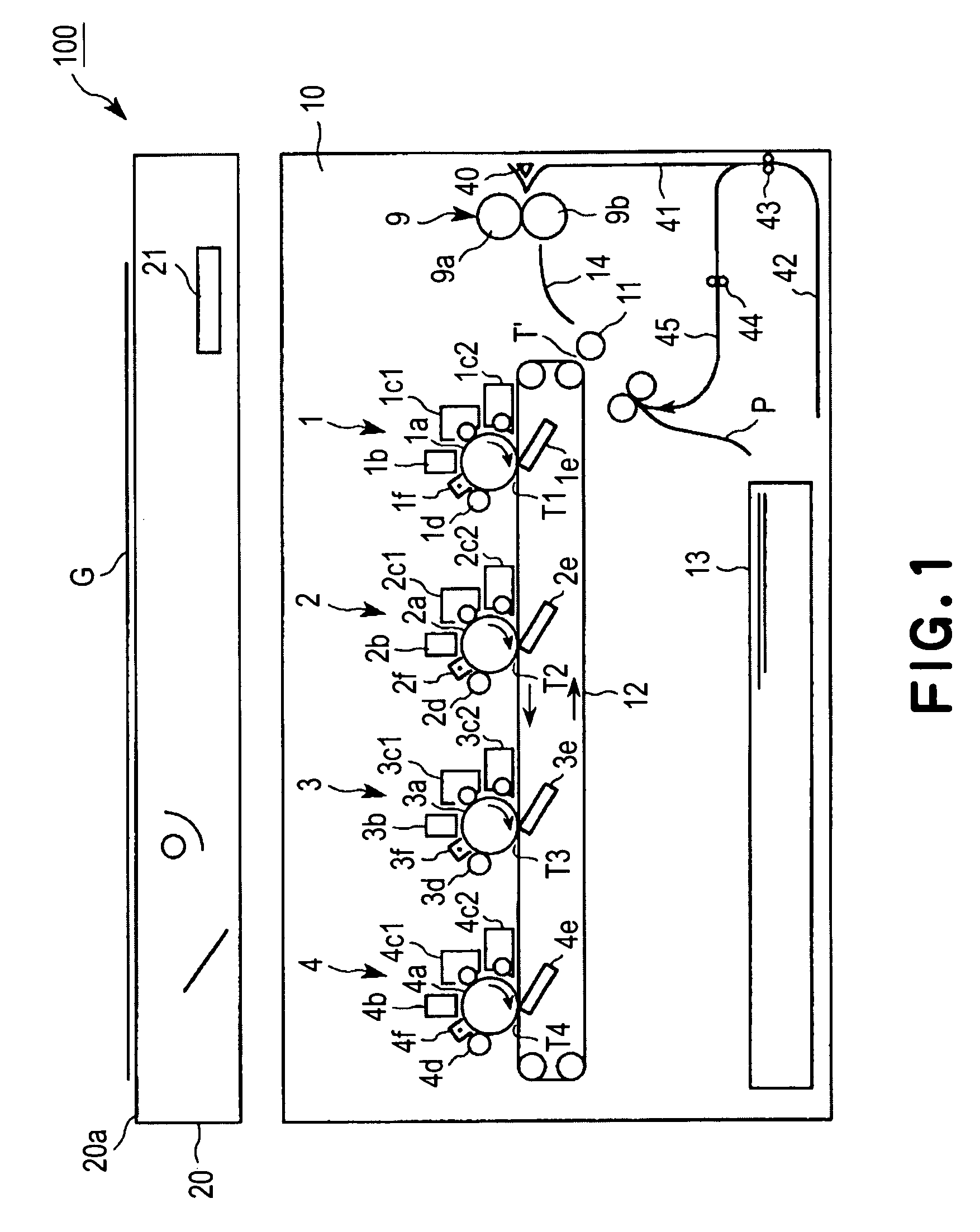

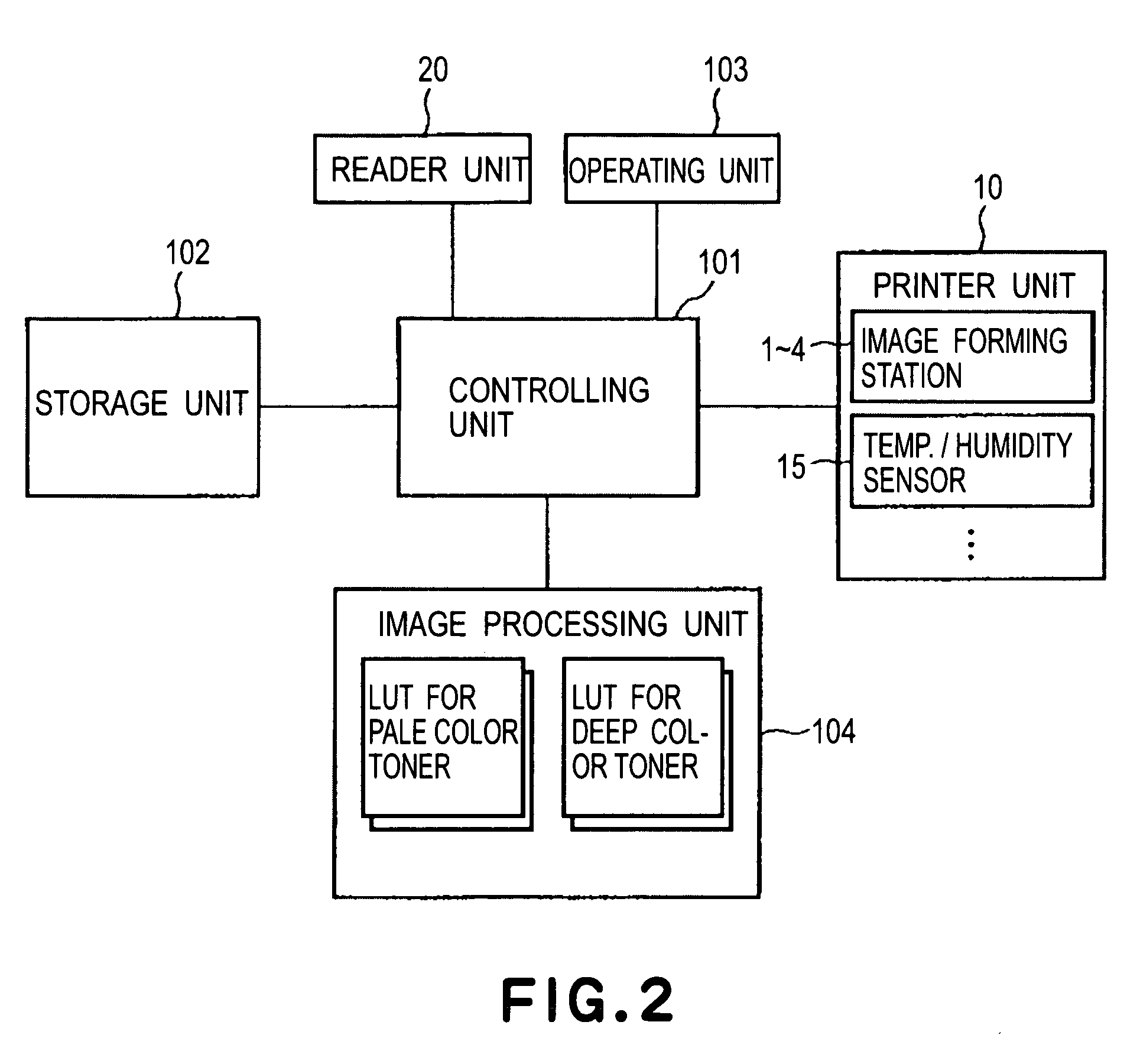

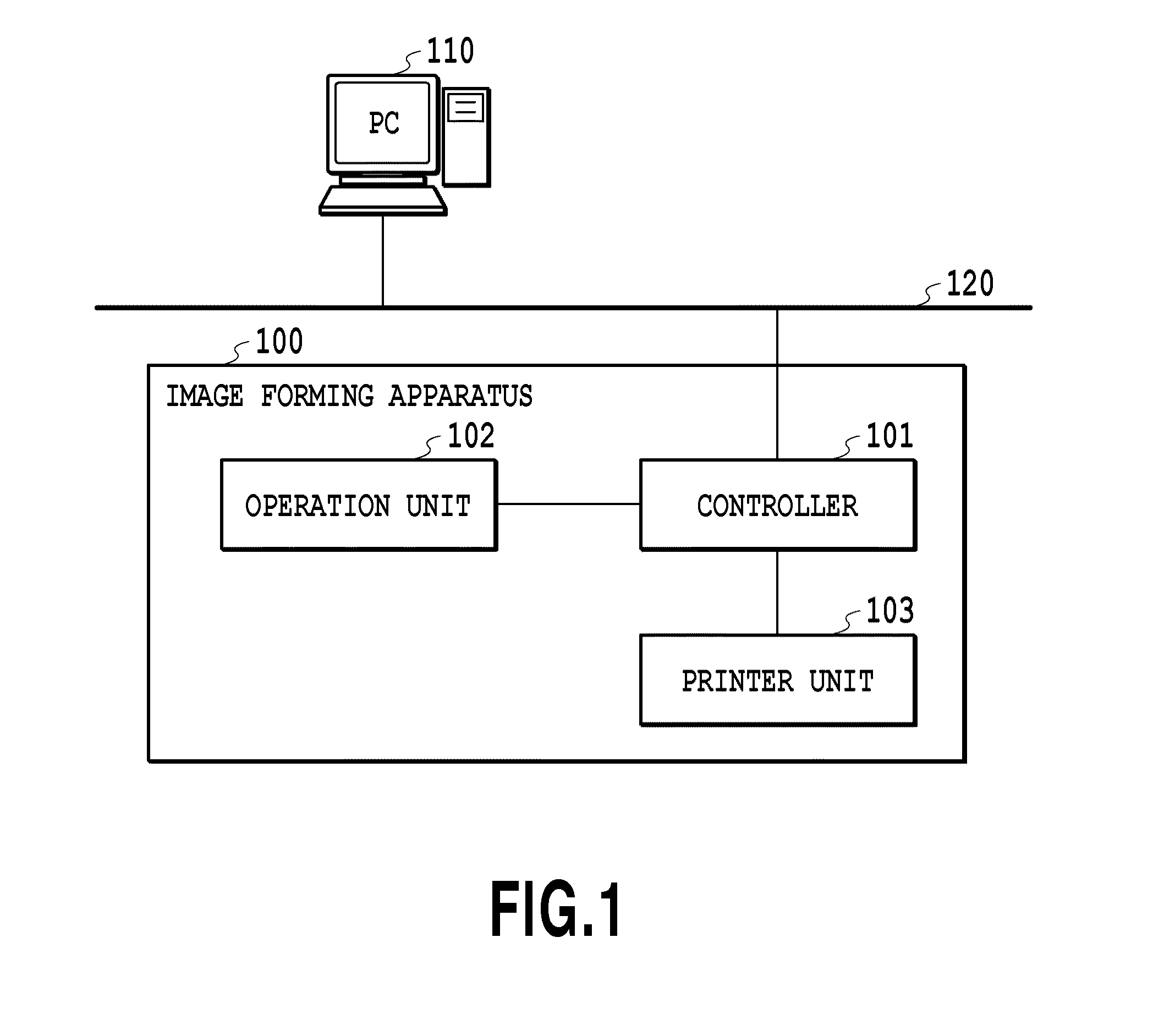

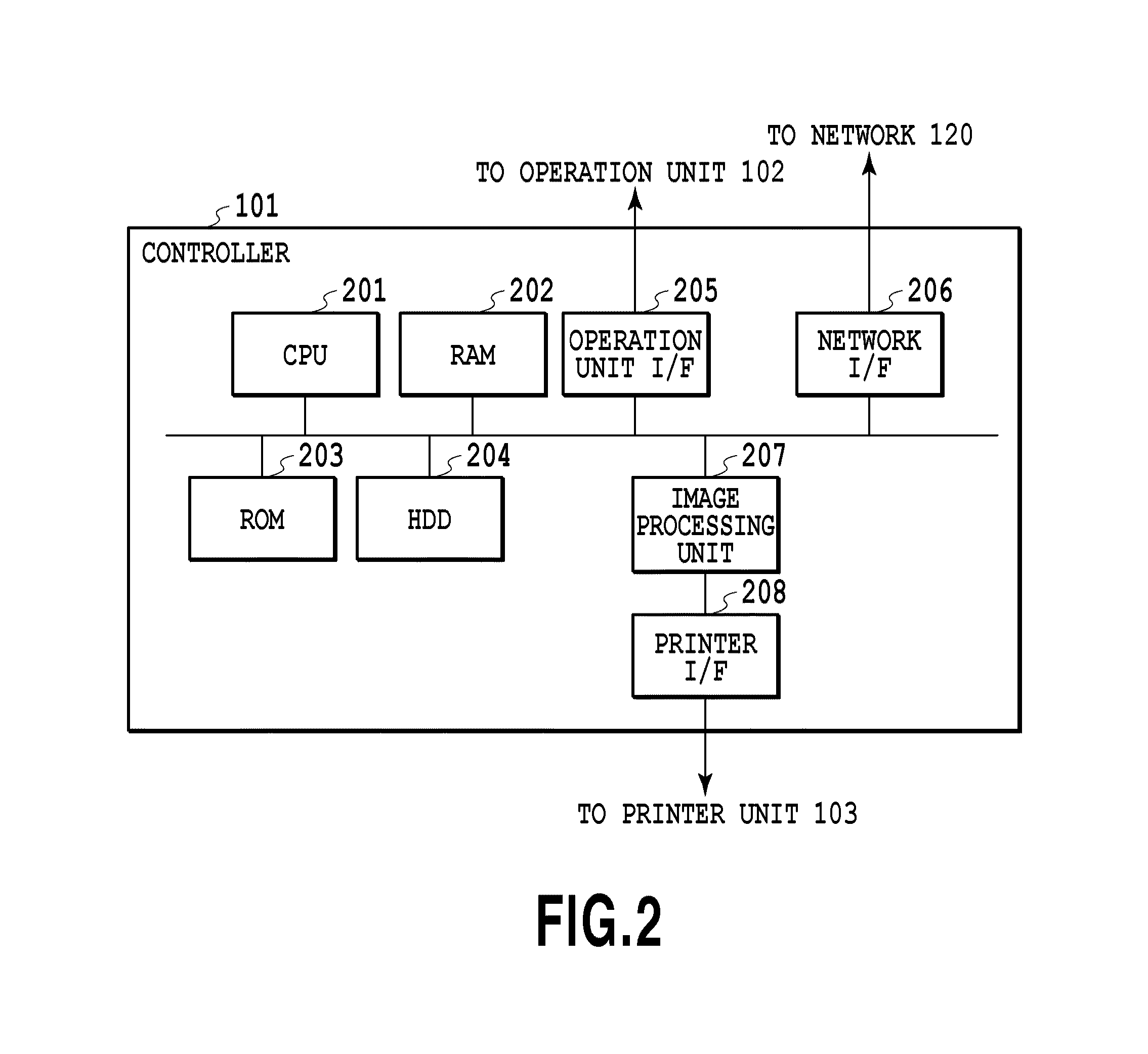

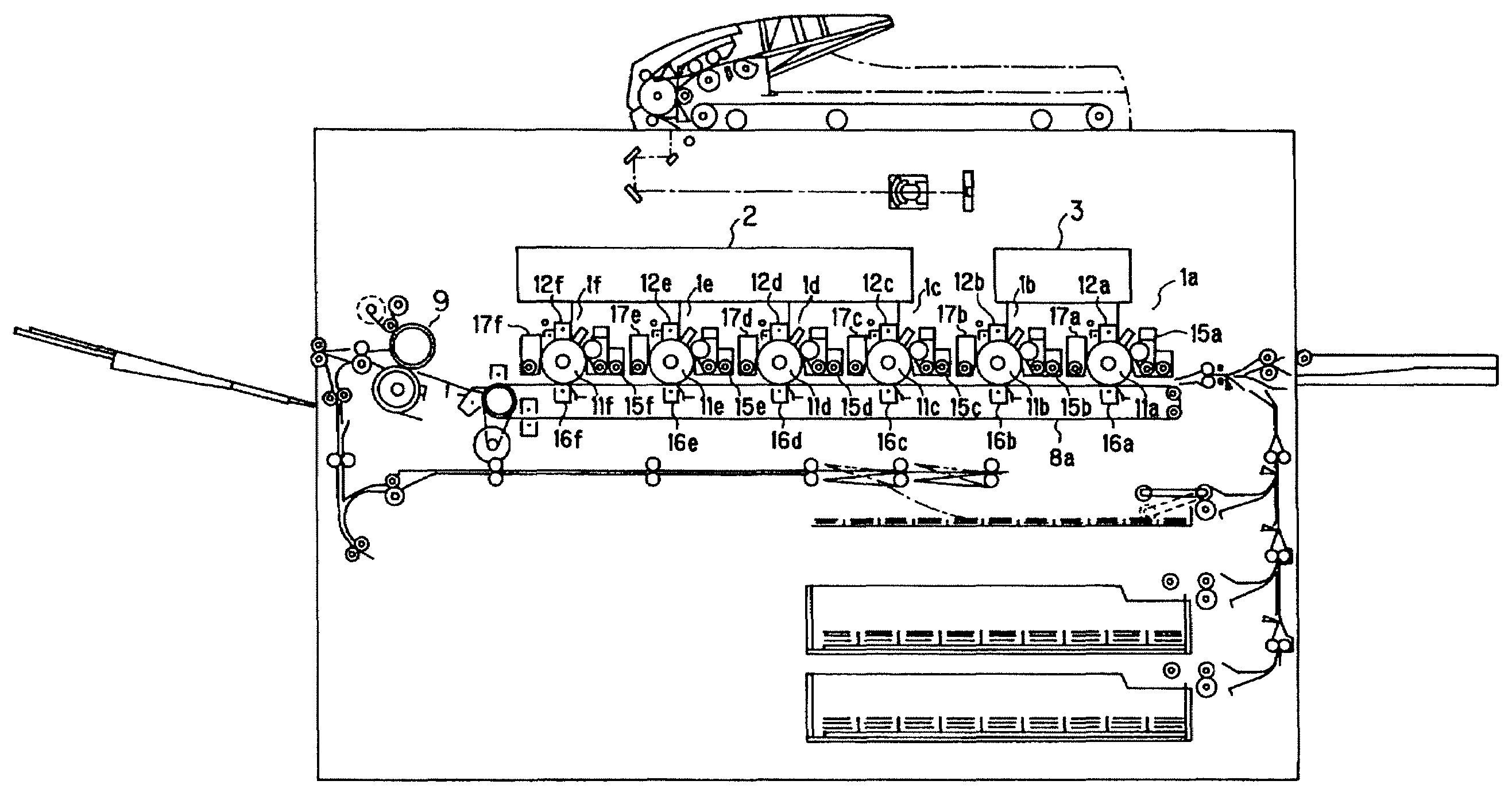

Image forming apparatus featuring a changeable mixing ratio of deep and pale color toners

InactiveUS7130550B2Prevent image deteriorationLow color requirementDevelopersElectrographic process apparatusImage formationDark color

An image forming apparatus includes image forming means for forming a superposed image on an image bearing member by using at least toners which have an identical hue and different color densities; transfer means for electrostatically transferring the superposed image on the image bearing member onto a transfer material; and changing means for changing a mixing ratio between the toners which have an identical hue and different color densities depending on information on a water content of the transfer material, thereby to prevent a deterioration of an image, particularly a halftone image even in the case where the image is formed under a specific image forming condition, such as in a low humidity environment, liable to cause image deterioration due to a discharge phenomenon in the vicinity of a transfer portion.

Owner:CANON KK

Normal-pressure cation-dyeable polyester, textile product made from the same, and production method for the same

InactiveUS20090131628A1Quality improvementEfficient productionMonocomponent polyetheresters artificial filamentMonocomponent copolyesters artificial filamentSulfonatePolyester

A normal-pressure cation-dyeable polyester is provided which contains an isophthalic acid component having a metal sulfonate group in a predetermined proportion based on the total of acid components present in the polyester, and contains a polyalkylene glycol having an average molecular weight of 150 to 600 in a predetermined proportion based on the polyester, wherein the proportion of diethylene glycol based on the total of glycol components and a terminal carboxyl group concentration are each set within a predetermined range. The polyester is stable in quality and excellent in dark- and pale-color light fastness when used for textile products.

Owner:KB SEIREN LTD

Toner kit, deep-color cyan toner, pale-color cyan toner, and image forming method

InactiveUS7288356B2Quality improvementReduce graininessDevelopersElectrographic process apparatusHigh densityDark color

Owner:CANON KK

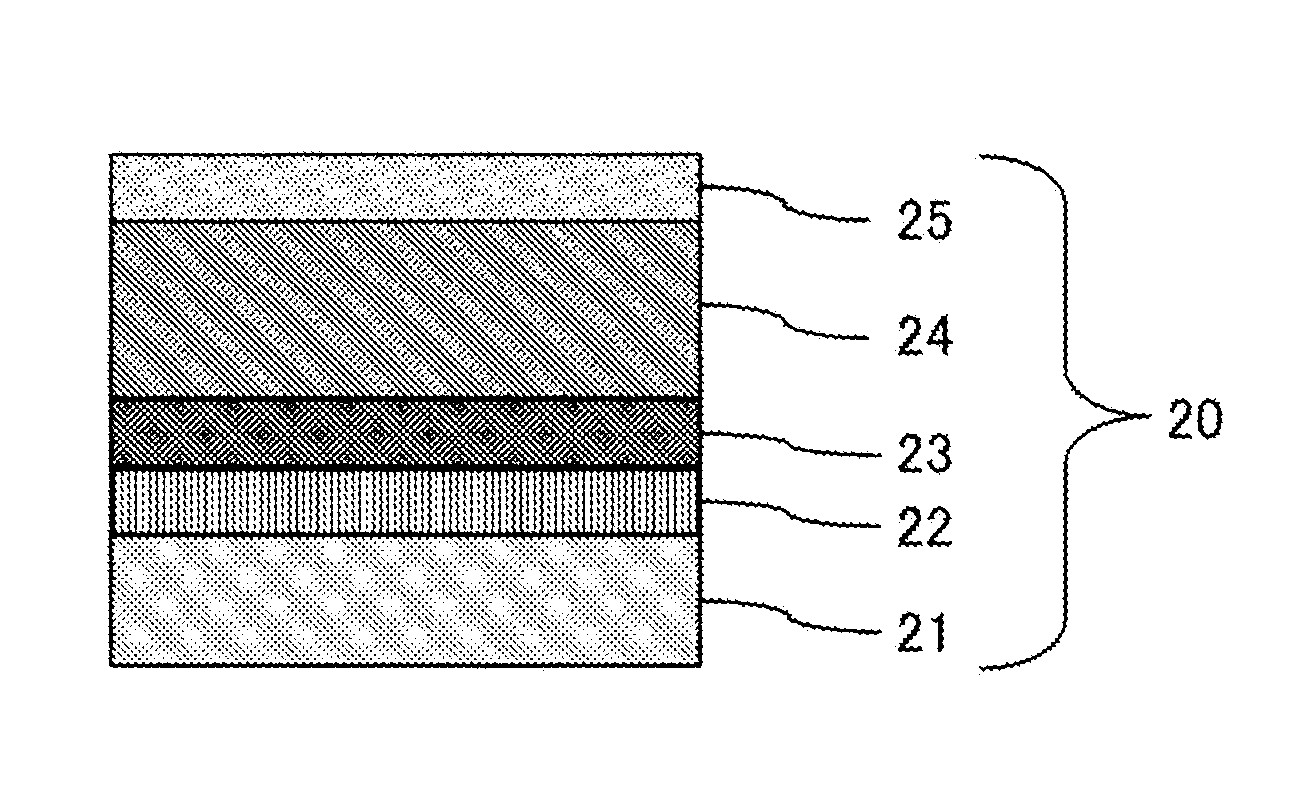

Thermosensitive recording medium and recording method

ActiveUS20090215622A1Excellent effect in maintaining pure whiteSuitable for useAblative recordingThermographyConductive polymerLeuco dye

The present invention provides a thermosensitive recording medium including a white plastic support, a thermosensitive recording layer containing a binder resin as a binding agent, a colorless or pale color leuco dye and a color developer for heat-developing the leuco dye, a protective layer, and a back layer containing an electron-conductive needle filler and an ion-conductive polymer, wherein the thermosensitive recording layer is disposed on the white plastic support, the protective layer is disposed on the thermosensitive recording layer, and the back layer is disposed on a side of the white plastic support opposite to the side where the thermosensitive recording layer is disposed.

Owner:RICOH KK

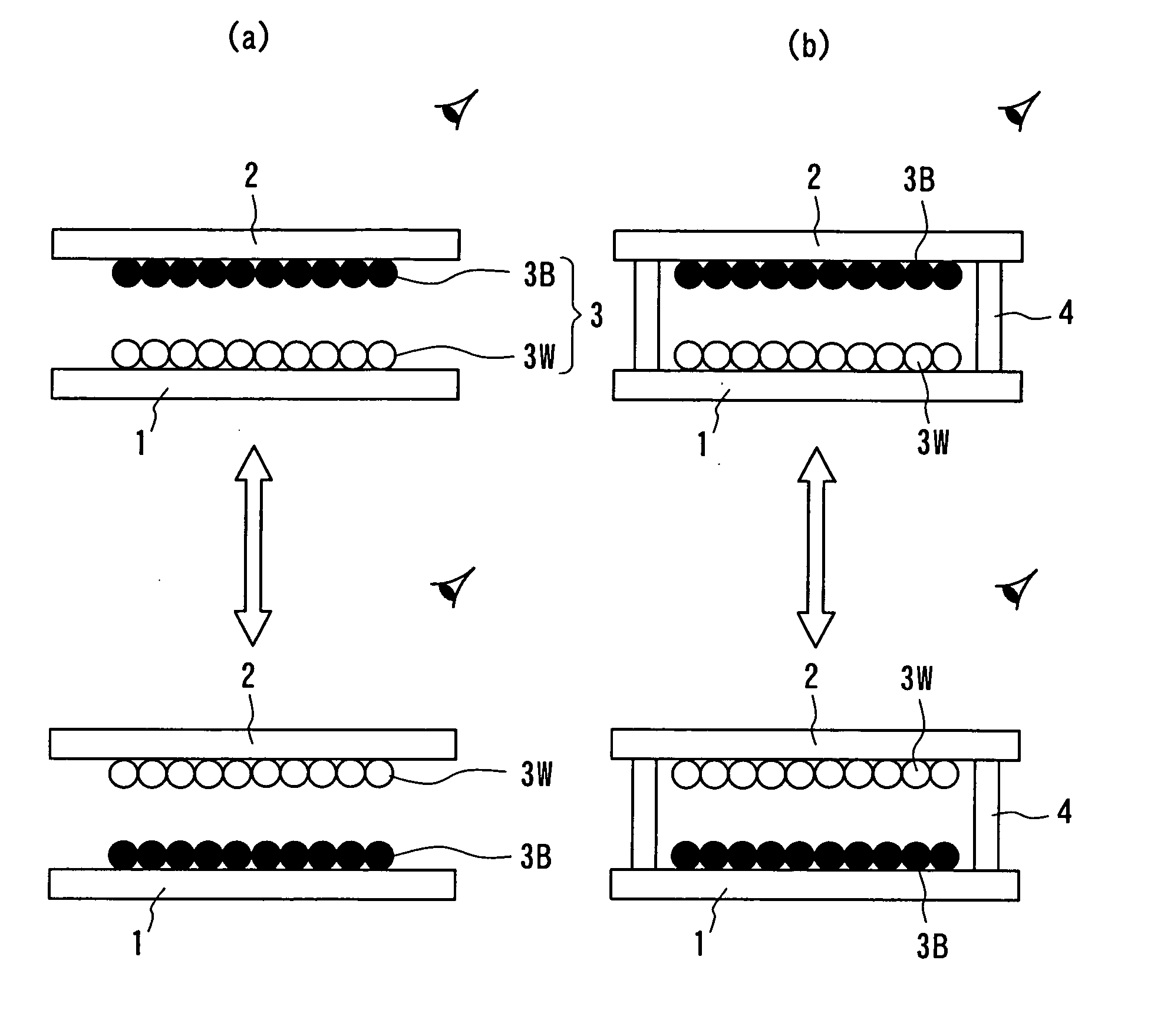

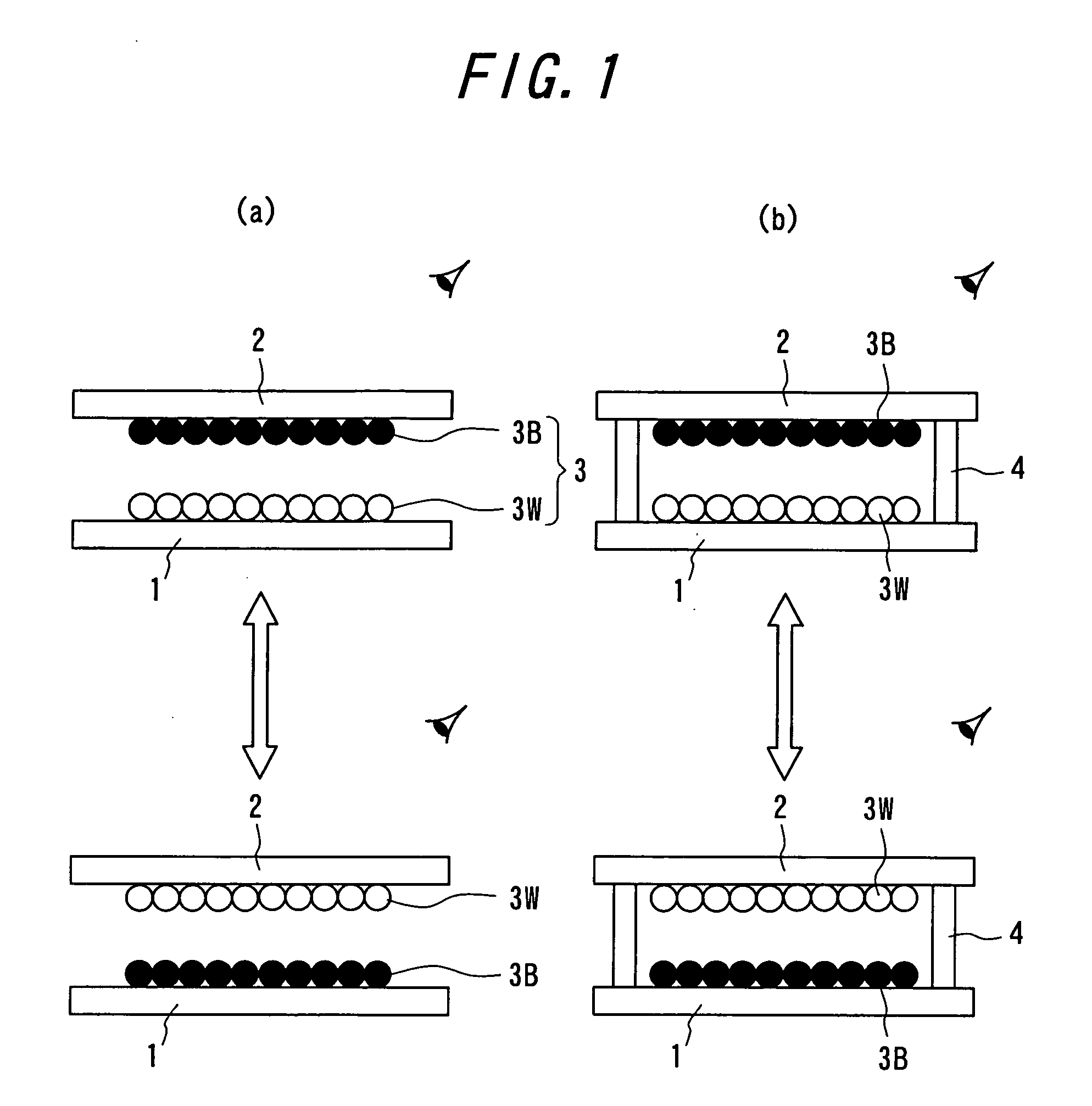

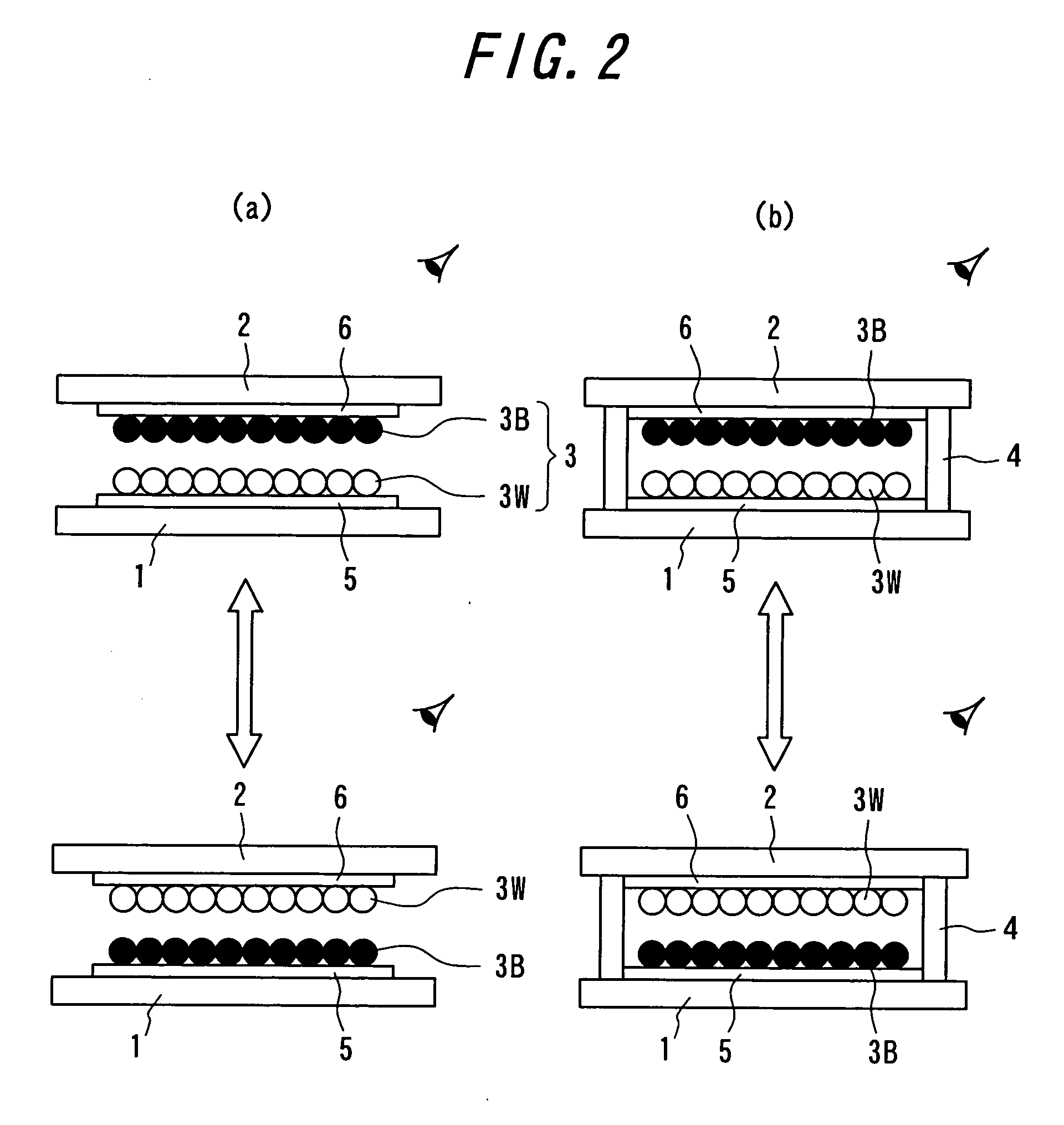

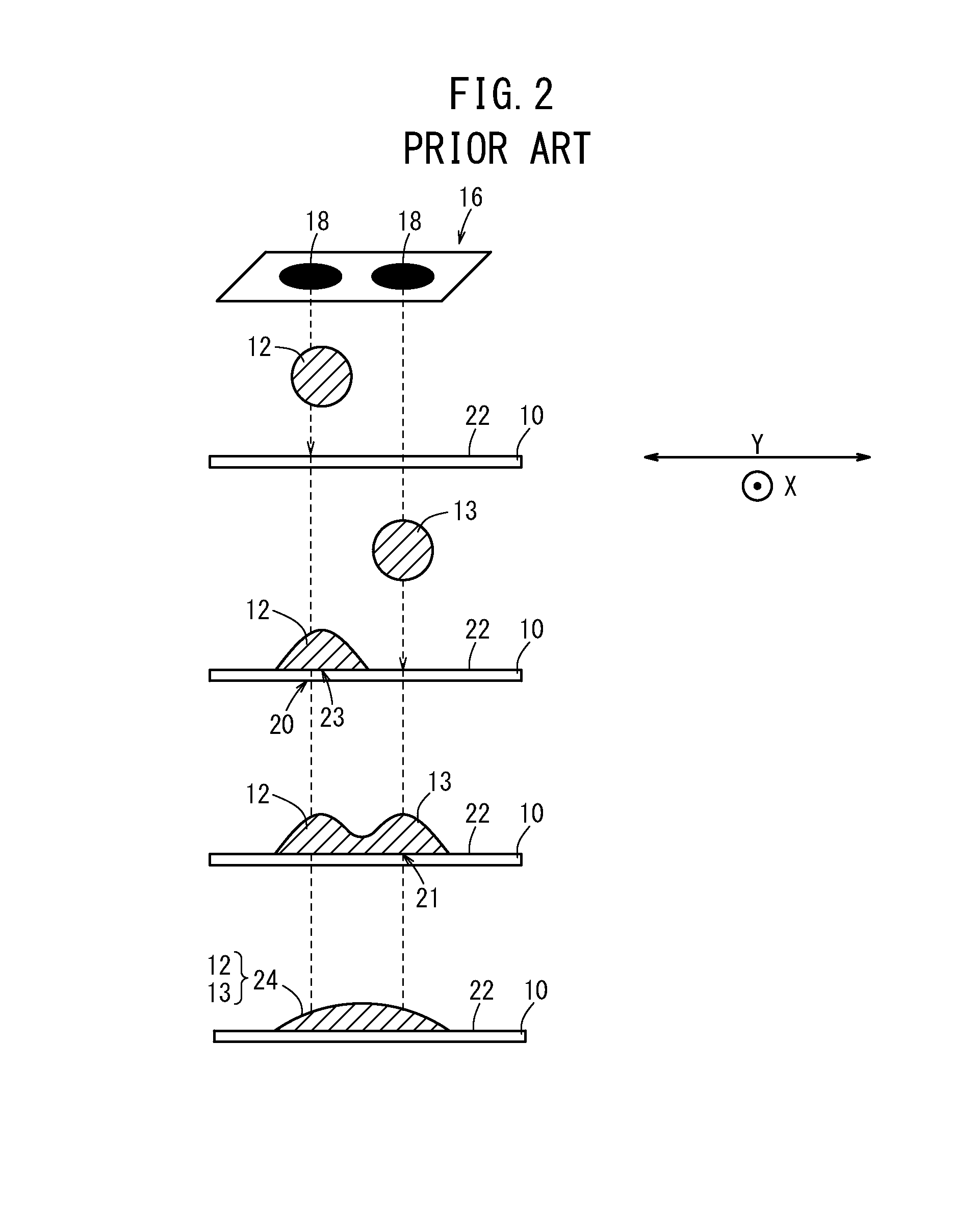

Method of manufacturing image display panel and image display panel

InactiveUS20070029931A1Improve adhesionPromote resultsAlternating current plasma display panelsCold-cathode tubesResistAdhesive

A method of manufacturing an image display panel, having one or more cells formed in an isolated manner from one another by partition walls and accommodating image display media and a plurality of image display elements, in which the image display media are sealed between opposed two substrates, at least one of the two substrates being transparent, and, in which the image display media, to which an electrostatic field is applied, are made to move so as to display an image, characterized in that the improvement comprises the steps of: (1) manufacturing a substrate with the partition walls on one substrate; applying an adhesive mixture obtained by mixing a photo-curing resin and a heat-hardening resin on the partition walls; and then connecting the other substrate to the partition walls through the adhesive mixture, the steps of: (2) manufacturing a substrate with the partition walls by forming the partition walls on one substrate; performing a washing by a dry treatment with respect to the thus manufactured substrate with the partition walls; applying an adhesive on the partition walls; and connecting the other substrate to the partition walls through the adhesive, or the steps of: (3) manufacturing the partition walls on one substrate by means of a pale color resist; applying an adhesive colored by a dark color on the partition walls; and connecting the other substrate to the partition walls through the adhesive.

Owner:BRIDGESTONE CORP

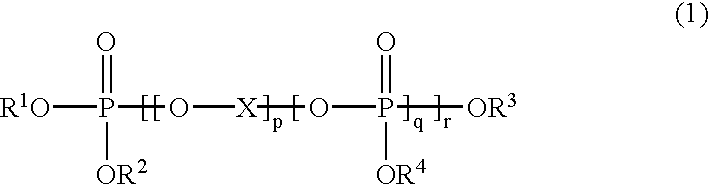

Amphoteric phosphate fat-liquoring agent containing silicon and preparation method thereof

The invention relates to the technical field of leather and chemical industries, in particular to a silicone-containing amphoteric phosphate fatliquor and a preparation method thereof. The invention aims at providing the silicone-containing amphoteric phosphate fatliquor and the preparation method thereof so as to overcome the problem of affecting the leather color, the physical health of operators and non-ideal fatliquoring effect in the prior art. In order to achieve the purpose, the technical proposal is as follows: the silicone-containing amphoteric phosphate fatliquor is prepared by compounding the following raw materials based on parts by weight: 30-50 parts of polyether-modified polysiloxane phosphobetaine, 20-30 parts of phosphorylated castor oil, 20-40 parts of sulfited fish oil and 0.2-5.0 parts of aliphatic alcohol polyethenoxy ether phosphate. The silicone-containing amphoteric phosphate fatliquor has pale color, does not affect the leather color, has no irritating odor and poses no threat to the physical health of the operators. The fatliquoring leather has the advantages of leather fullness, fine grain surface, elasticity and softness and strong slipperiness; and the fatliquor has good fatliquoring effect.

Owner:SHAANXI UNIV OF SCI & TECH

Novel natural rubber drying method

The invention relates to a method for producing natural rubber. The novel method for drying natural rubber is based on the basic principle of friction heat generation, uses a barrel / screw extrusion mechanism to apply a force to a bulk gel of rubber to further expulse free water, and then compresses the rubber by the relative movement of the screw and the barrel, a mechanical friction is carried out for rubber granules in a drying device to raise the temperature and pressure of the rubber through self mechanical friction of rubber against the mechanics; after the energy repertory of rubber arrives at a certain level, a principle of adiabatic flash is used to achieve the separation of water from natural rubber within the mechanics, thereby accomplishing the drying of natural rubber. A friction heat generation method is adopted by the invention to convert the mechanical energy to heat energy to heat the rubber, and then make temperature thereof rise without intermediate process of energy transmission, thereby shortening the time needed by baking technology by more than 120 times, significantly improving the quality of the rubber, and producing a rubber with a pale color nearing the natural color.

Owner:NATURAL RUBBER TECH HK CO LTD

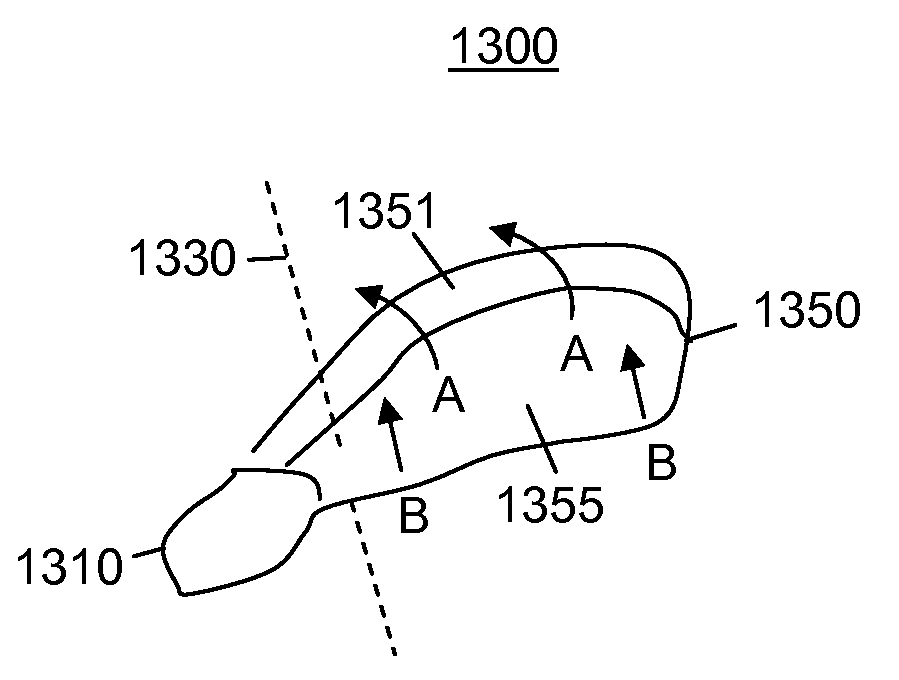

Rice petals

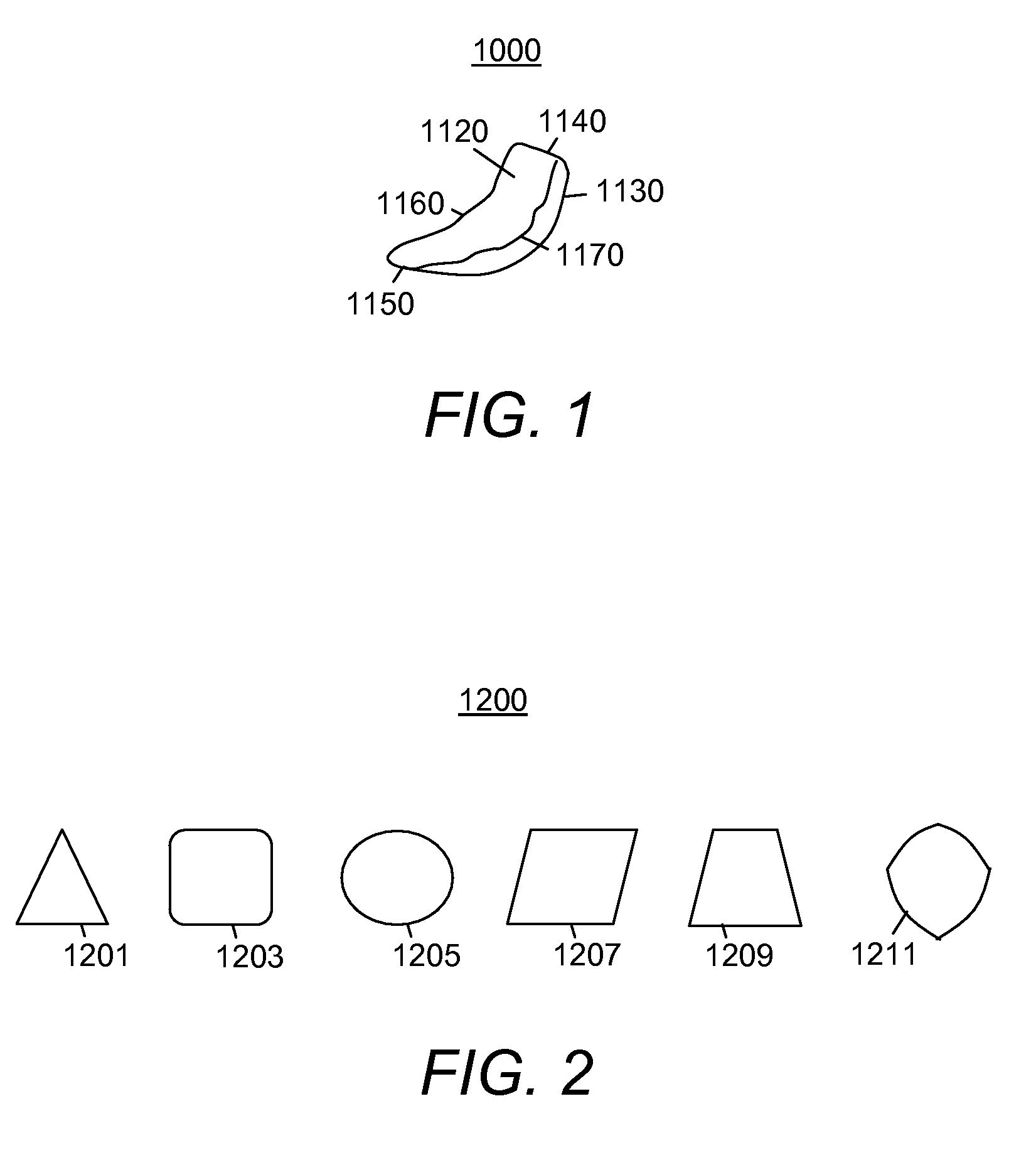

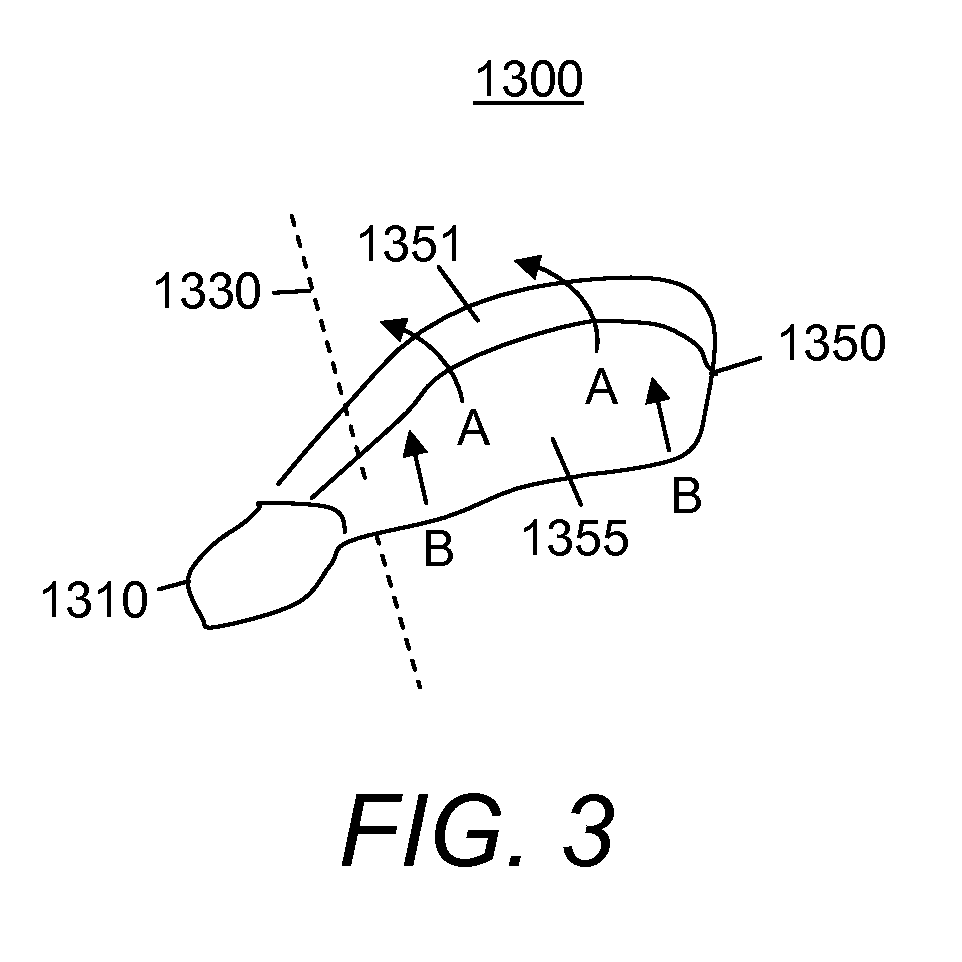

Environmentally-friendly materials 1000 intended to be tossed into the air are constructed of water soluble materials which dissolve in the rain. These may also be made of materials which birds and squirrels may eat without doing them any harm. One preferred material, based upon its density and rigidity is rice papers. The materials are cut into pieces 1000 which are sized and shaped to resemble flower petals, confetti 1200 or a petal 1300 made to spiral down to the ground like a falling maple seed. The rice petals 1000, 1200, 1300 have a pale color to reduce the chances that they will stain the ground or other surfaces. These are designed to be used in areas which restrict throwing flower petals, which cause staining, rice, which harms wildlife, or confetti which must be cleaned up. The rice petals 1000, 1200, 1300 do not stain, may be eaten by wildlife and biodegrade in the environment. Since the material of the rice petals may be made of rice, they preserve the tradition of throwing rice at celebrations.

Owner:BAKER JENNIFER

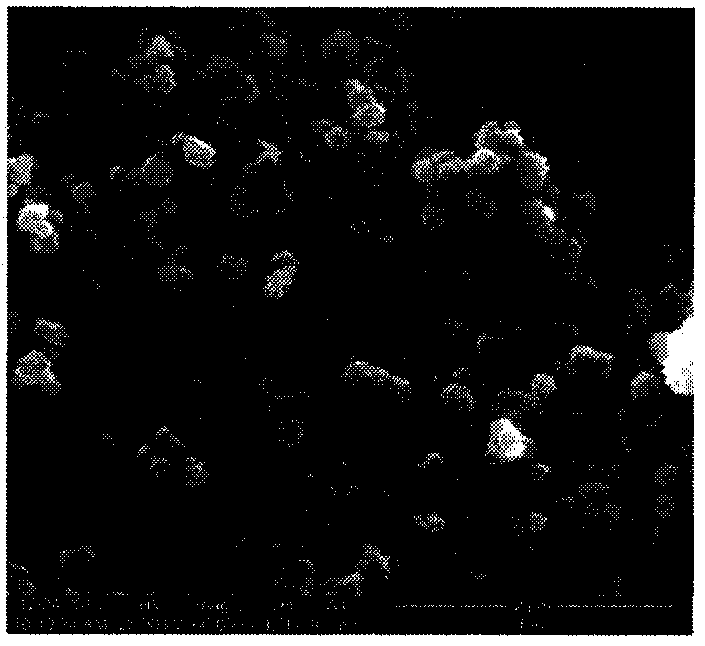

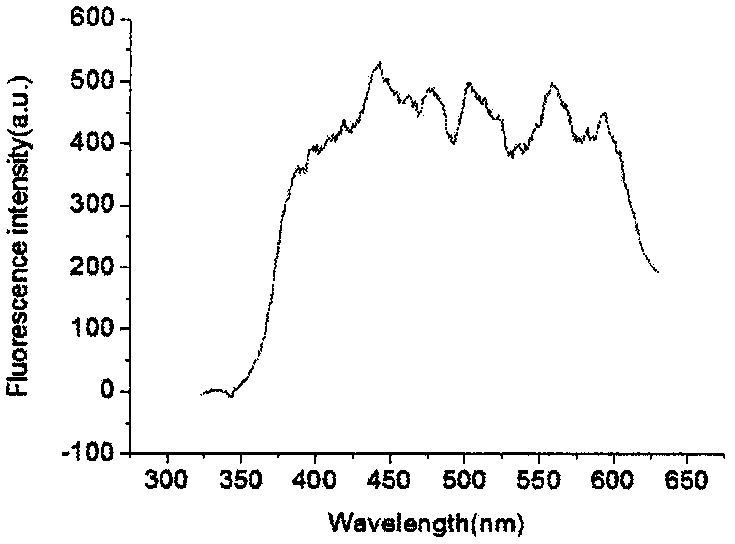

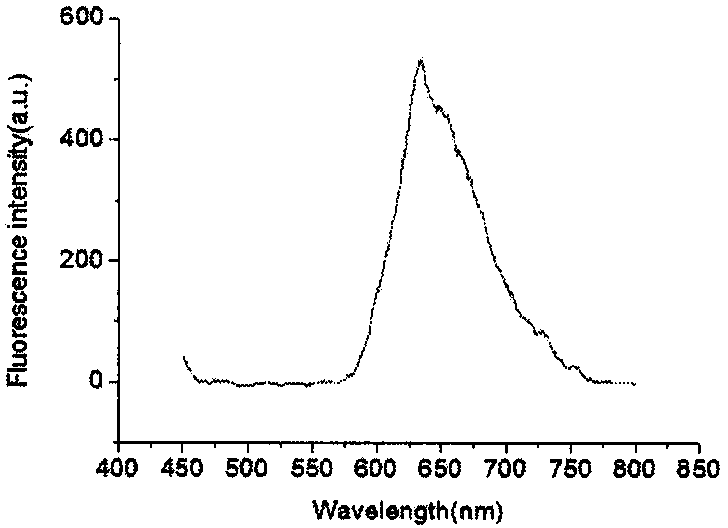

Nanometer titanium dioxide fluorescent powder and preparation method thereof

InactiveCN104388084AOvercoming the problem of inconspicuous contrastThe background is less stickyPerson identificationLuminescent compositionsFluorescencePerylene

The invention relates to a nanometer titanium dioxide fluorescent powder, and the fluorescent powder is perylene diimide-coated nanometer titanium dioxide. The disclosed nanometer titanium dioxide fluorescent powder is a light-pink particle under natural light, is fine in powder, and can be selectively adsorbed on a fingerprint when being used to develop the potential fingerprint through brushing, phenomena of powder adhering to or retained on background are less, and the developed fingerprint shows clear and coherent lines. When being observed under natural light, the fingerprint lines show light pink, and under excitation of blue-green light, the fluorescent powder is excited and emits high-intensity fluorescent light, the fingerprint lines show orange red when being observed through an orange filter lens, good contrast can be obtained on various objects, and the problem is overcome that the contrast is not obvious when a white titanium dioxide powder is used to develop a light-color object.

Owner:CHINESE PEOPLE'S PUBLIC SECURITY UNIVERSITY

Cover for deflecting light and minimizing heat absorption by a body

InactiveUS20090133325A1Minimizing heat absorbedNot hasten its decayClimate change adaptationGreenhouse cultivationPale colorEngineering

Disclosed is a cover devised to be positioned on a body, especially sod, in order to deflect light and to minimize the build up of heat under the cover, while retaining moisture so as to not to hasten the decay of the body. This cover comprises an inner surface which contacts the body, and an outer surface, wherein the inner surface is of an opaque dark color to minimize heat build up and the outer surface is of an opaque pale color to deflect light. The inner and outer surfaces are produced by co-extrusion. As such, the cover is specifically designed to increase the shelf-life of sod, especially during its storage and transportation.

Owner:WORKMAN PACKAGING

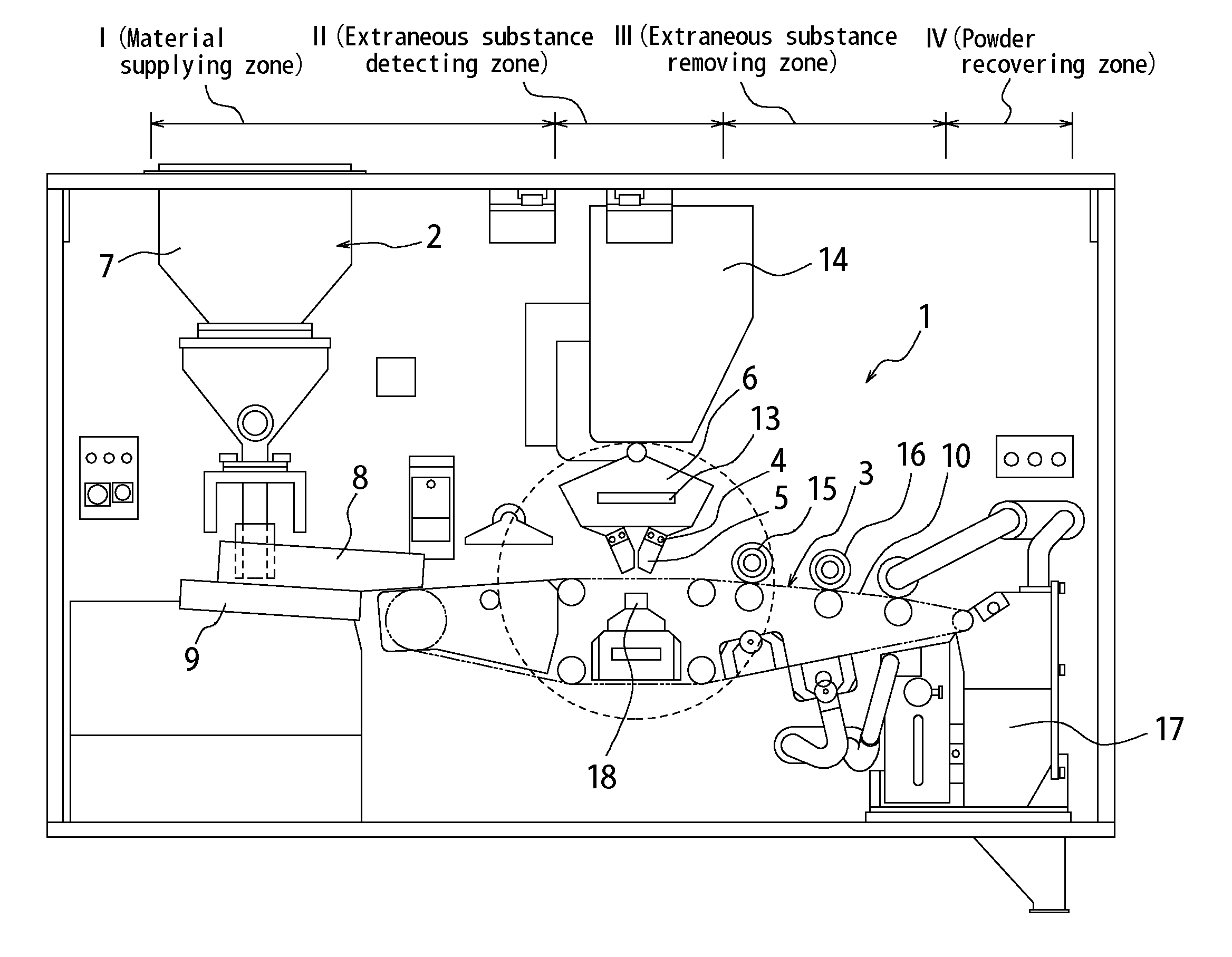

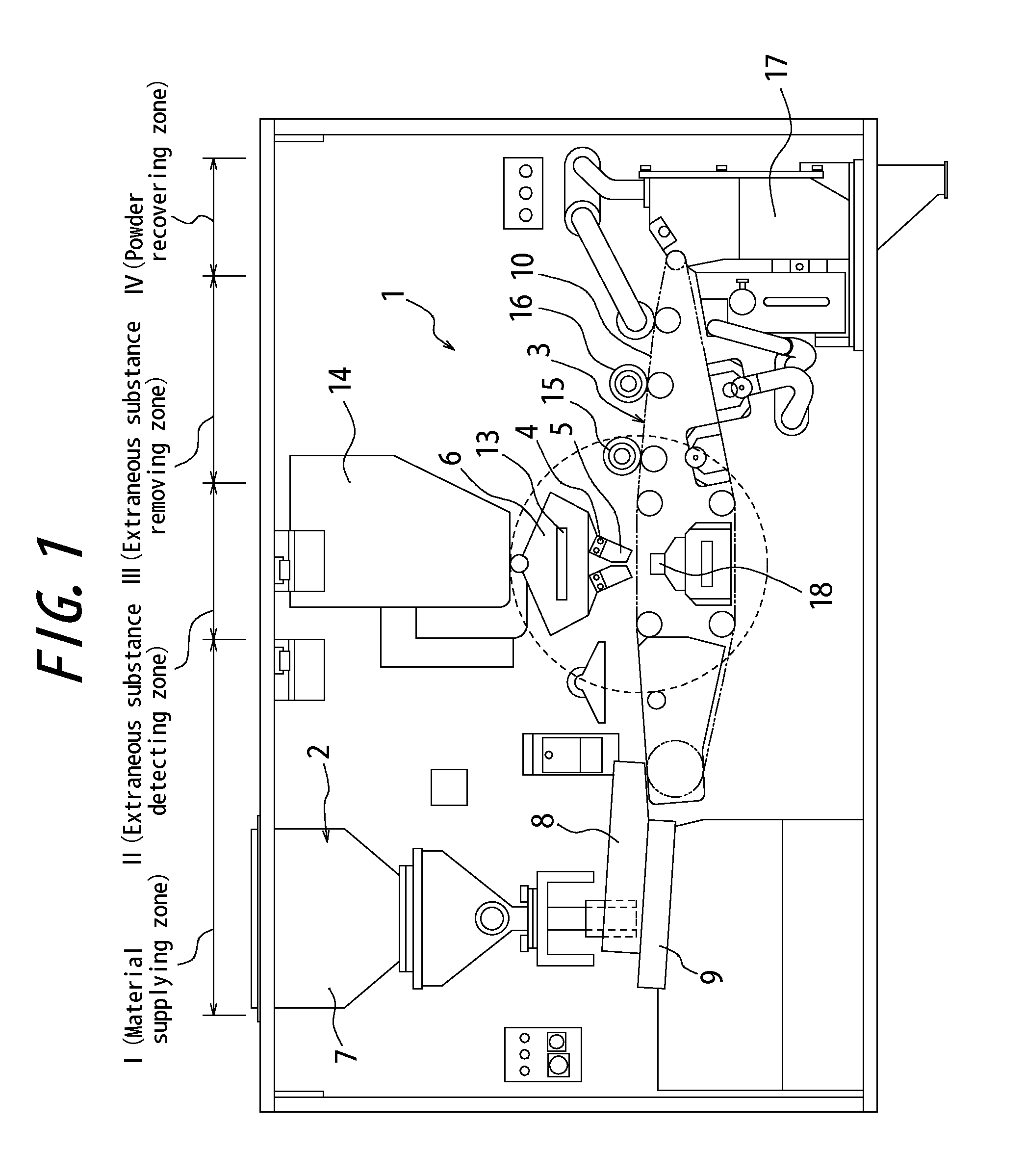

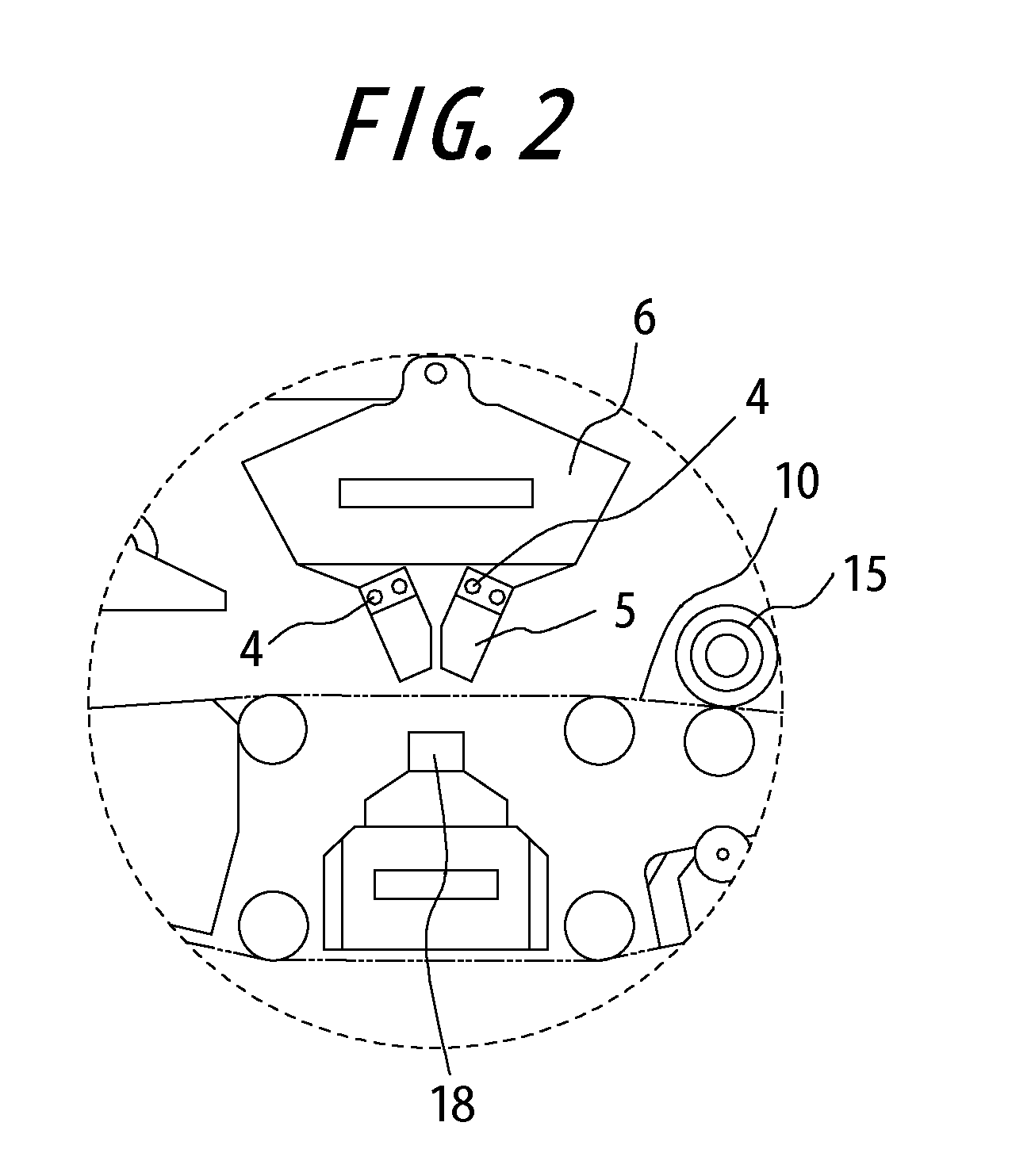

Method and apparatus for detecting colored foreign particles in quartz powder material

ActiveUS8164750B2Shading correctionImprove accuracyRadiation pyrometryColor measuring devicesQuartzForeign body

Owner:SUMCO CORP

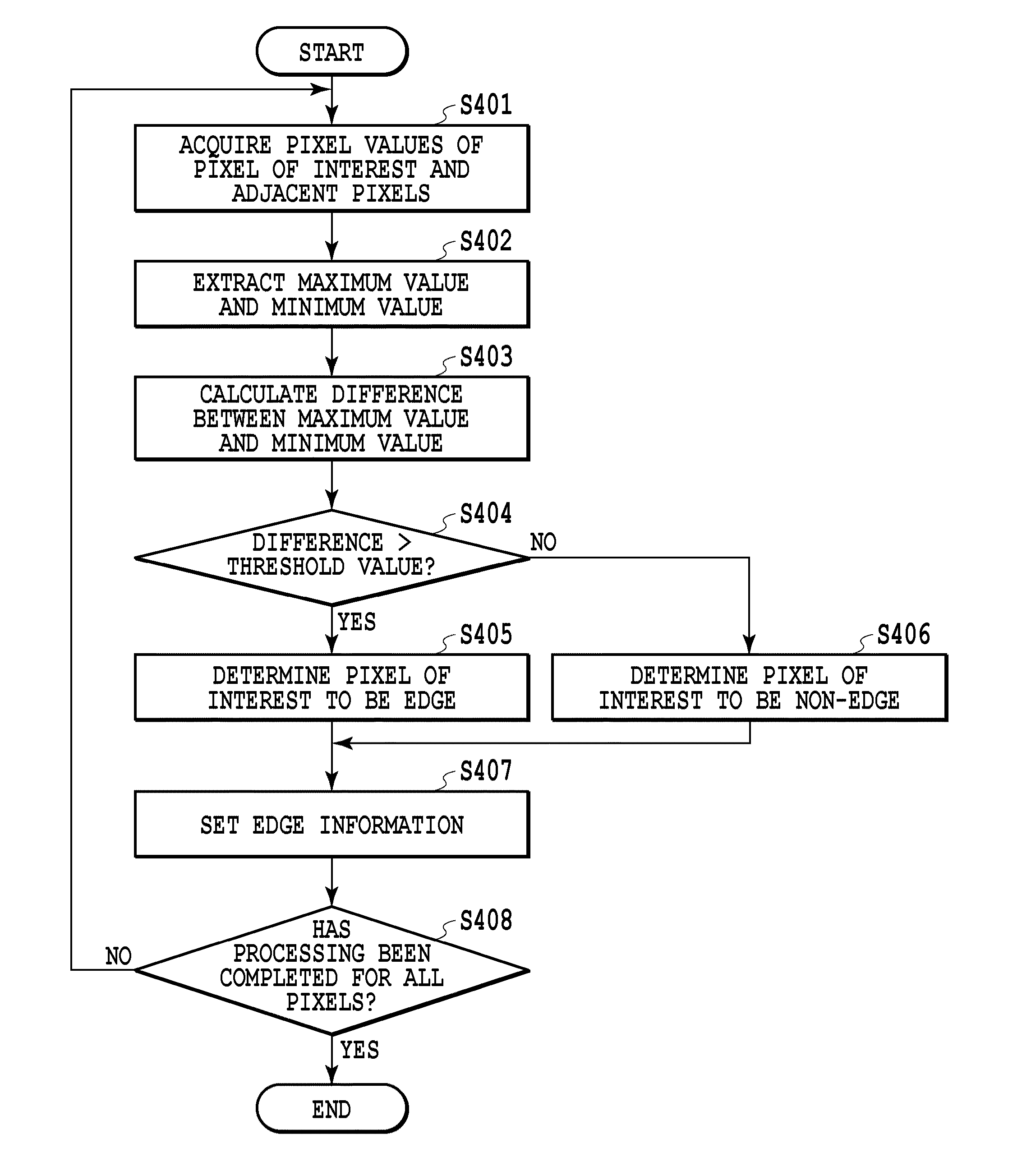

Image processing apparatus, image processing method, and storage medium

ActiveUS20160048099A1Curb consumptionLow densityDigitally marking record carriersDigital computer detailsGraphicsImaging processing

In the conventional toner save processing, in the case where the color of each element, such as a character, a graphics, and an image, constituting an image is a pale color or bright color, visual recognizability will be degraded even by maintaining the density of an edge portion of each element. An image processing apparatus that performs color material save processing to perform color printing while suppressing a color material consumption compared to that at the time of normal printing, includes an edge detection unit configured to detect an edge pixel constituting an edge of an object within input image data, and a density adjustment unit configured to convert the color of a detected edge pixel into an achromatic color and to decrease the density of the color of a non-edge pixel, which is a pixel other than the edge pixel of the object.

Owner:CANON KK

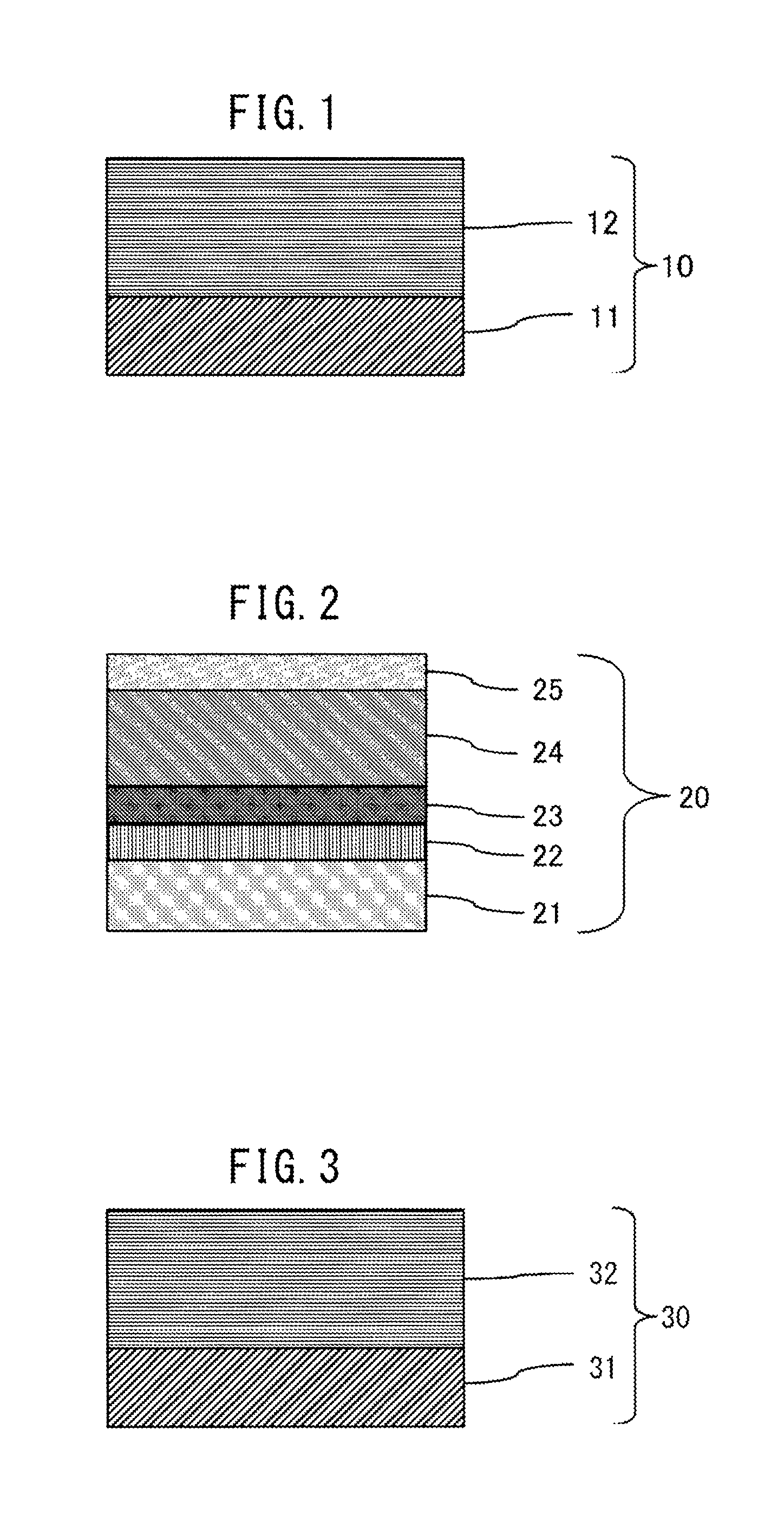

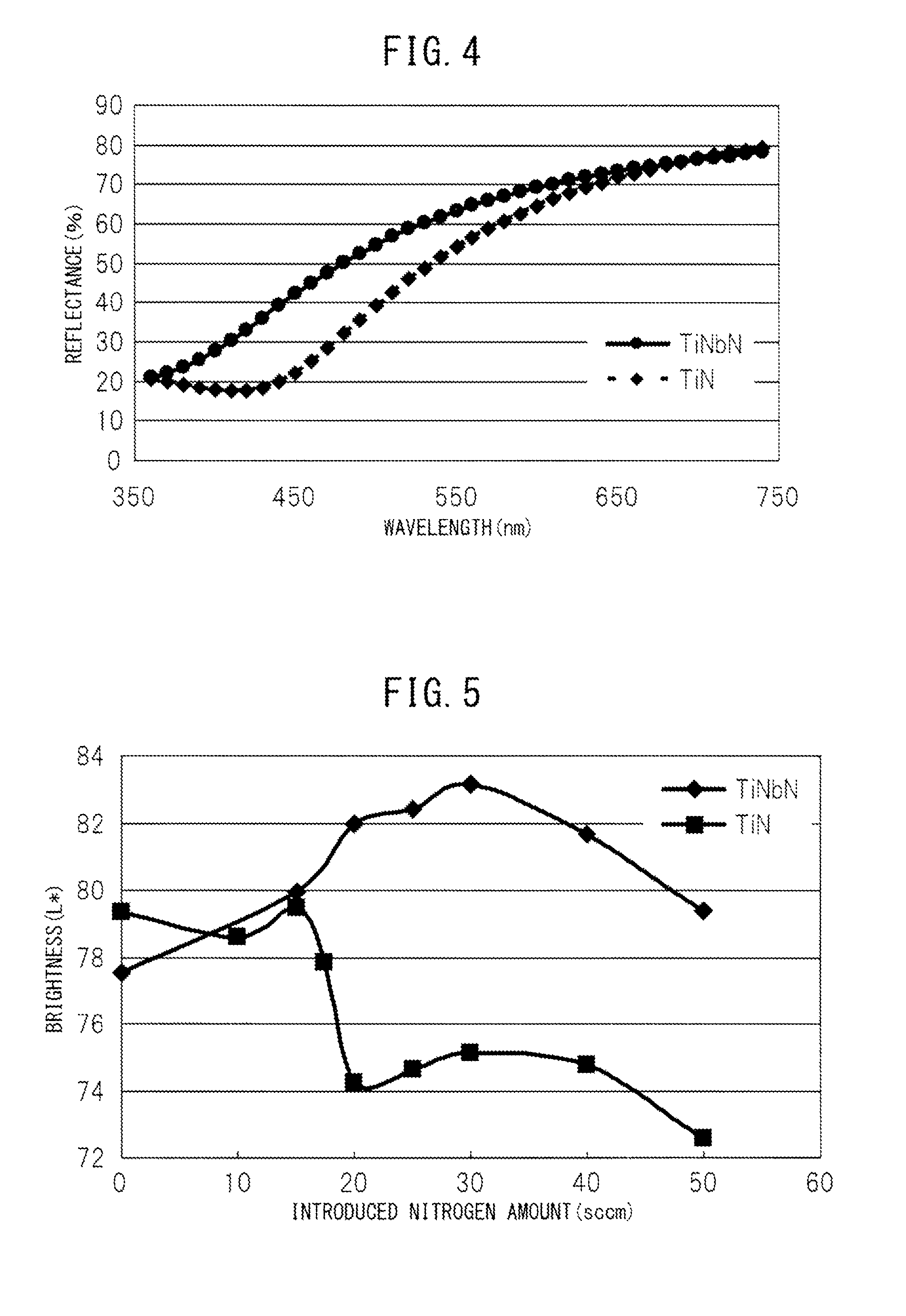

Golden rigid decorative member

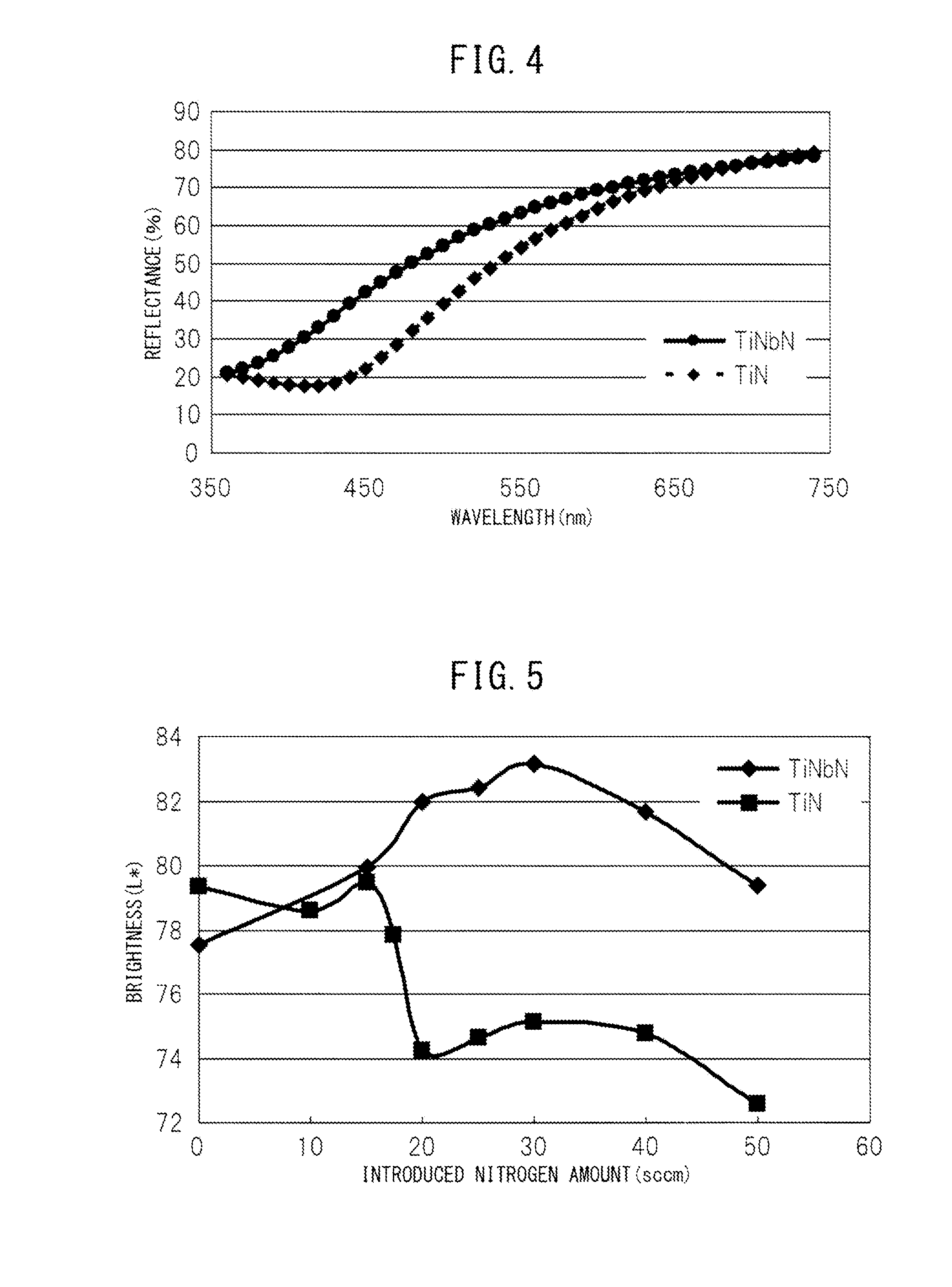

ActiveUS20150044453A1Deterioration of appearance qualityIncrease brightnessNitrogen compoundsVacuum evaporation coatingAlloyGold color

A golden rigid decorative member in which scratch resistance and abrasion resistance are significantly improved and deterioration of appearance quality due to a flaw, abrasion, or the like is suppressed, and which has a pale color with a high quality feel is stably provided. A single layer or several layers of a coating including a reaction compound of an alloy of Ti and one or two or more metals selected from Nb, Ta, and V, and of one or two non-metallic elements mainly including nitrogen and selected from carbon and oxygen are stacked on a base.

Owner:CITIZEN WATCH CO LTD

Thermosensitive recording medium and recording method

ActiveUS8227379B2High whitenessImprove antistatic performanceAblative recordingThermographyConductive polymerLeuco dye

The present invention provides a thermosensitive recording medium including a white plastic support, a thermosensitive recording layer containing a binder resin as a binding agent, a colorless or pale color leuco dye and a color developer for heat-developing the leuco dye, a protective layer, and a back layer containing an electron-conductive needle filler and an ion-conductive polymer, wherein the thermosensitive recording layer is disposed on the white plastic support, the protective layer is disposed on the thermosensitive recording layer, and the back layer is disposed on a side of the white plastic support opposite to the side where the thermosensitive recording layer is disposed.

Owner:RICOH KK

Gradual change type peacock blue glaze ceramic and preparation process thereof

The present invention relates to gradual change type peacock blue glaze ceramic and a preparation process thereof. The gradual change type peacock blue glaze ceramic comprises light-colored glaze on the surface of a ceramic blank body, and dark-colored glaze on the local part of the light-colored glaze. For the gradual change type peacock blue glaze ceramic, the surface of the light-colored glaze is thin and transparent, and has glassy luster; manganese oxide, iron hydroxide, and cobalt are introduced as color agents, so that the light-colored glaze displays slightly light blue; the dark-colored glaze is arranged in the surface of light-colored glaze, is bright, and has a strong glassy texture, the overall ceramic is blue-green; the combined degree of the light-colored glaze and the dark-colored glaze is high; the combined part is smooth, and free of cracking; and the overall color of the ceramic can be adjusted according to the thickness of the dark-colored glaze, from shallow to deep, to form a variety of lines, thus forming a unique artistic effect. The gradual change type peacock blue glaze ceramic is stable in effect, can be produced in a large quantity, increases the yield, reduces the production cost of materials, and improve the economic efficiency and market competitiveness.

Owner:德化县如瓷生活文化有限公司

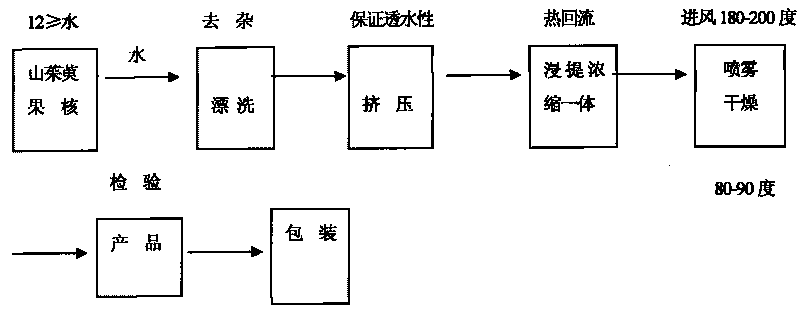

Image forming apparatus

InactiveUS7427999B2Reduced footprintReduce impactInking apparatusElectrographic process apparatusColor imageOptical property

A first optical scanning device for scanning image data of colors (yellow, magenta, cyan and black) which serve as the basic for formation of color image employs an optical system having optical characteristic stable to changes in temperature in common, the optical system being incorporated in a single optical box. Inexpensive resin material is employed for its lens in a second optical scanning device for scanning image data of pale color or a special color having a large tolerance amount to color deviation or spot diameter. Further, an inexpensive second optical scanning device saving space is formed by reducing the optical path length.

Owner:CANON KK

Golden rigid decorative member

ActiveUS9469765B2Deterioration of appearance qualityIncrease brightnessVacuum evaporation coatingSputtering coatingNitrogenAlloy

A golden rigid decorative member in which scratch resistance and abrasion resistance are significantly improved and deterioration of appearance quality due to a flaw, abrasion, or the like is suppressed, and which has a pale color with a high quality feel is stably provided. A single layer or several layers of a coating including a reaction compound of an alloy of Ti and one or two or more metals selected from Nb, Ta, and V, and of one or two non-metallic elements mainly including nitrogen and selected from carbon and oxygen are stacked on a base.

Owner:CITIZEN WATCH CO LTD

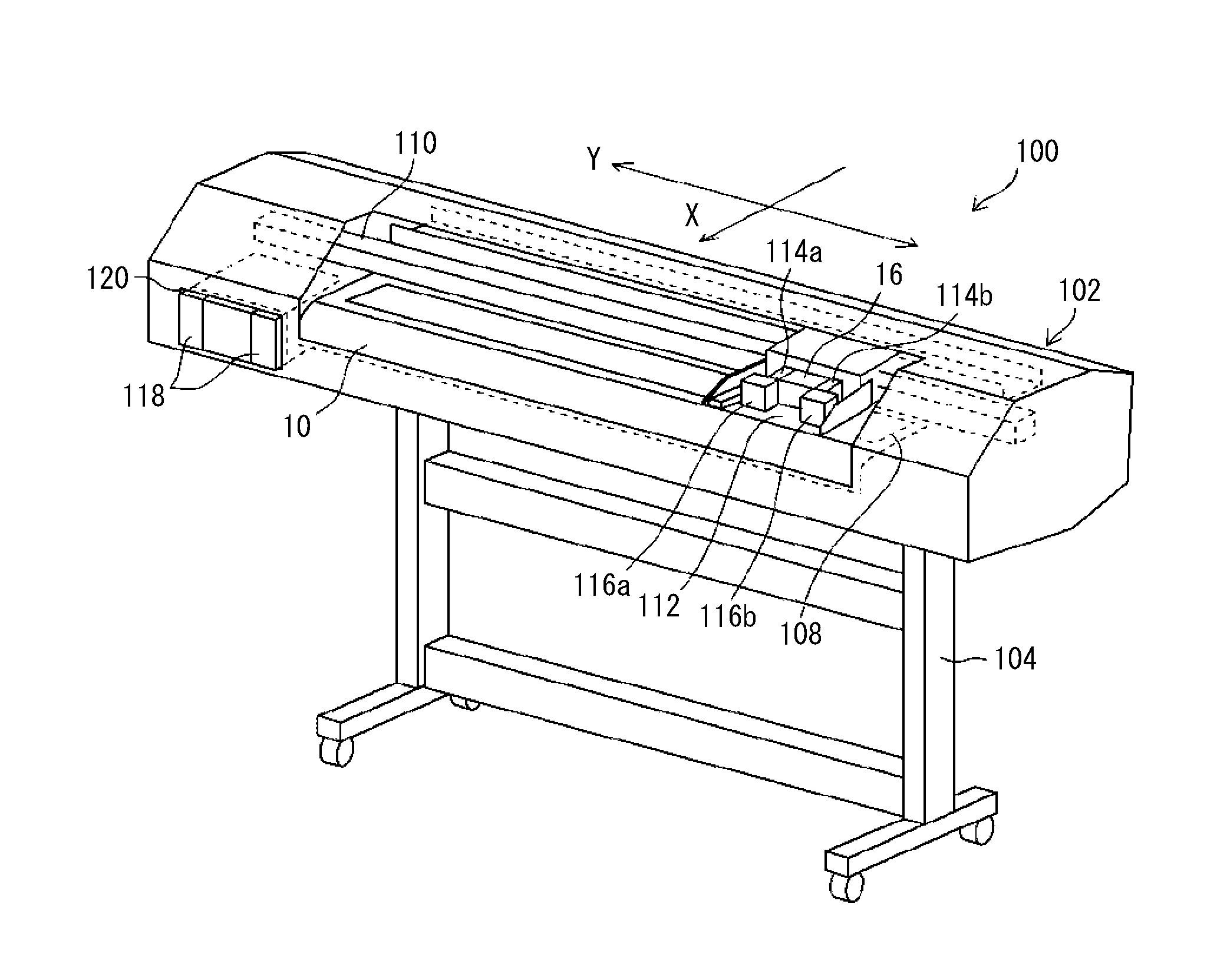

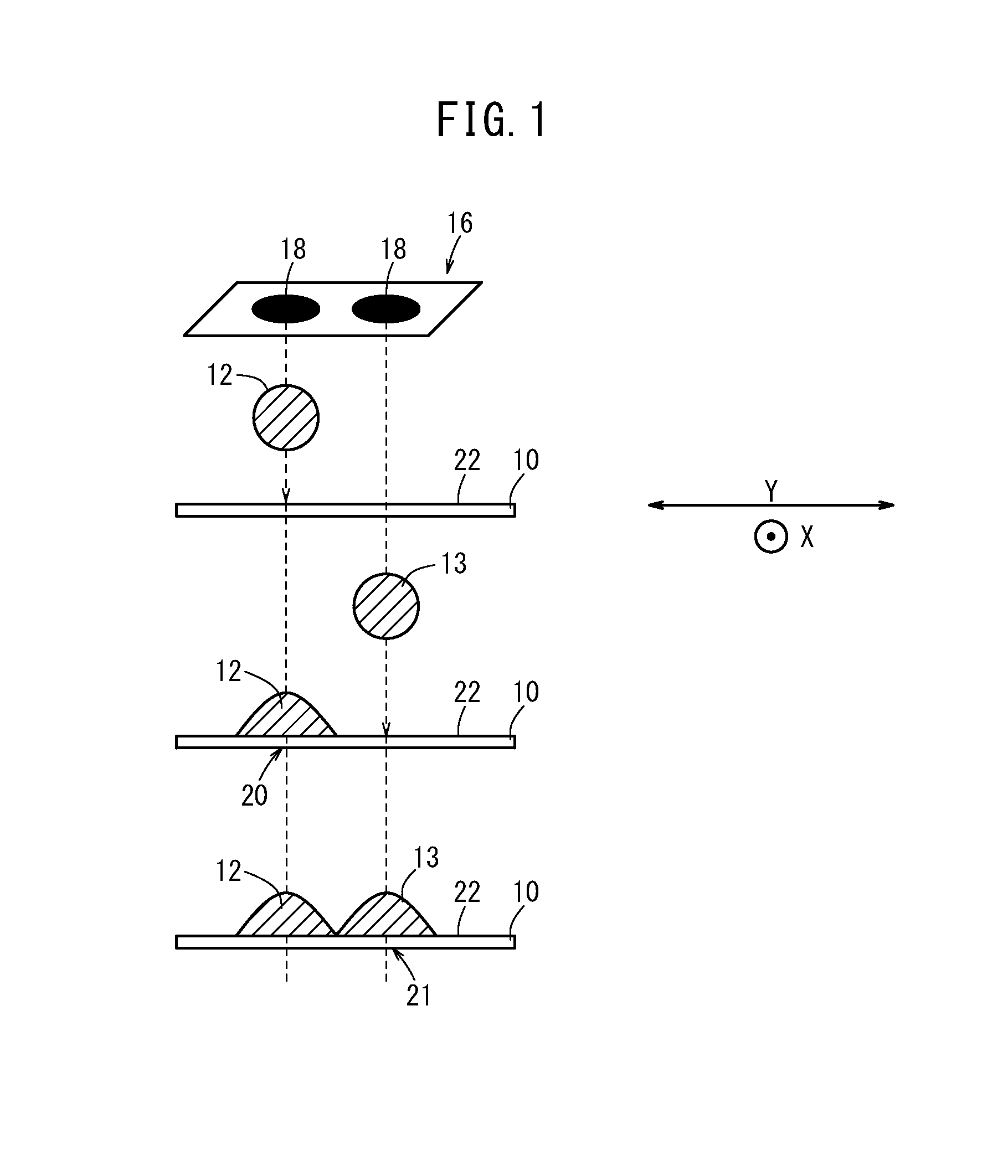

Image producing apparatus and image producing method

ActiveUS20140098152A1Easy to controlReduce appearanceOther printing apparatusControl signalComputer science

A control signal is generated, so that if dots, which are formed in a transverse direction across a recording medium, are classified into plural groups depending on a plurality of timings, then preceding dots, which belong to a group having an earliest timing, are formed in a pale color. A head drive circuit controls a recording head based on the generated control signal.

Owner:FUJIFILM CORP

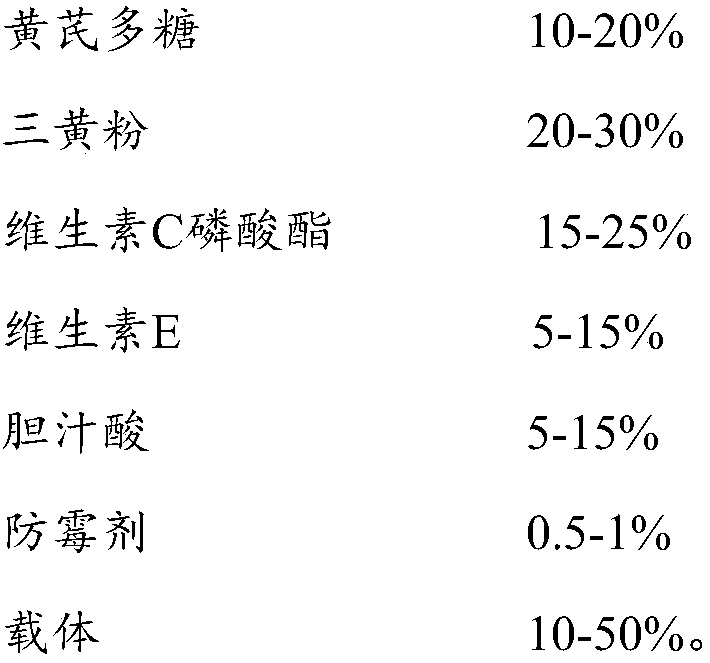

Compound feed additive for freshwater fishes

InactiveCN108271918AImprove immunityImprove stress resistanceClimate change adaptationAnimal feeding stuffDiseaseFood additive

Owner:四川北大威生物科技有限公司

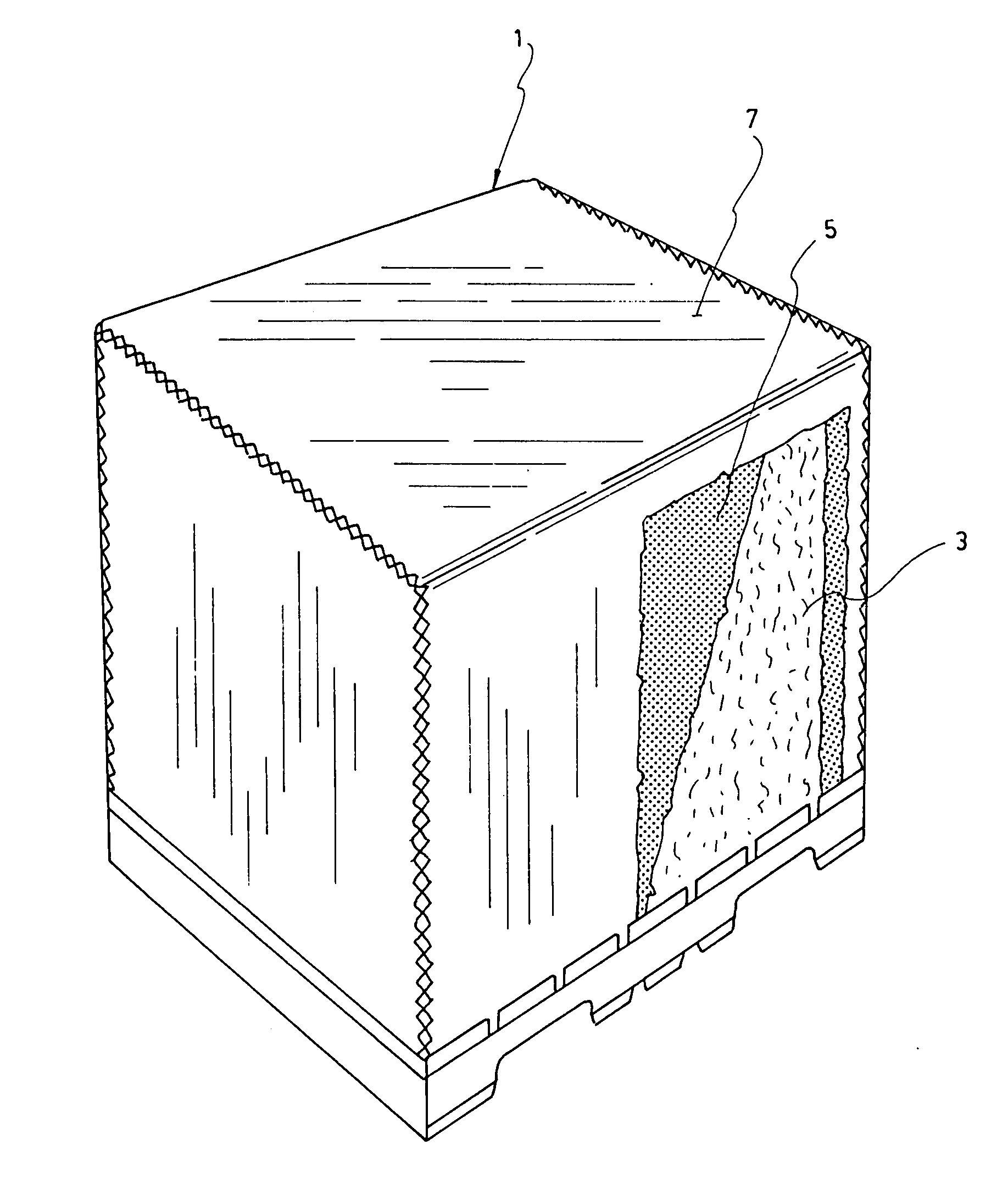

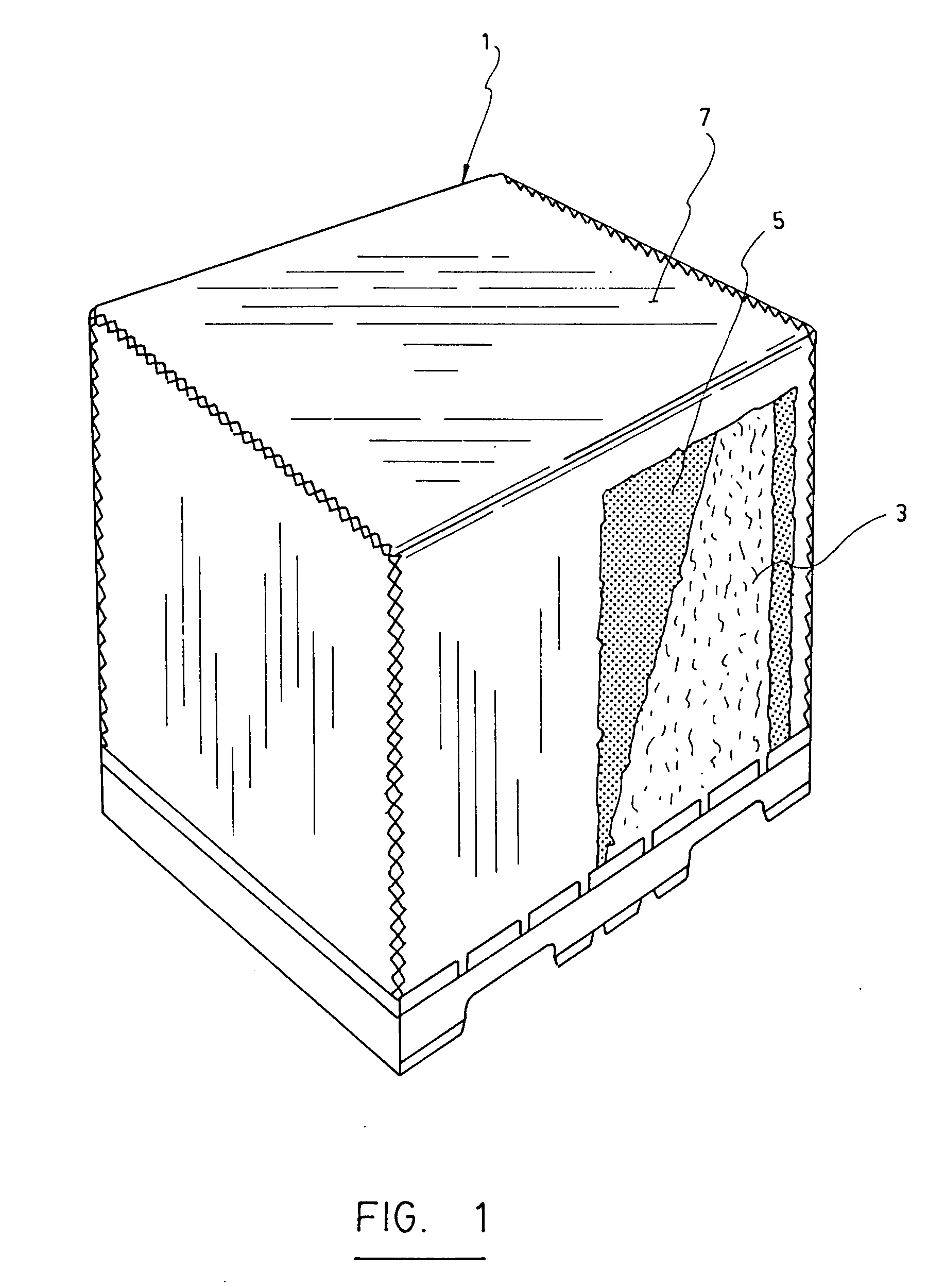

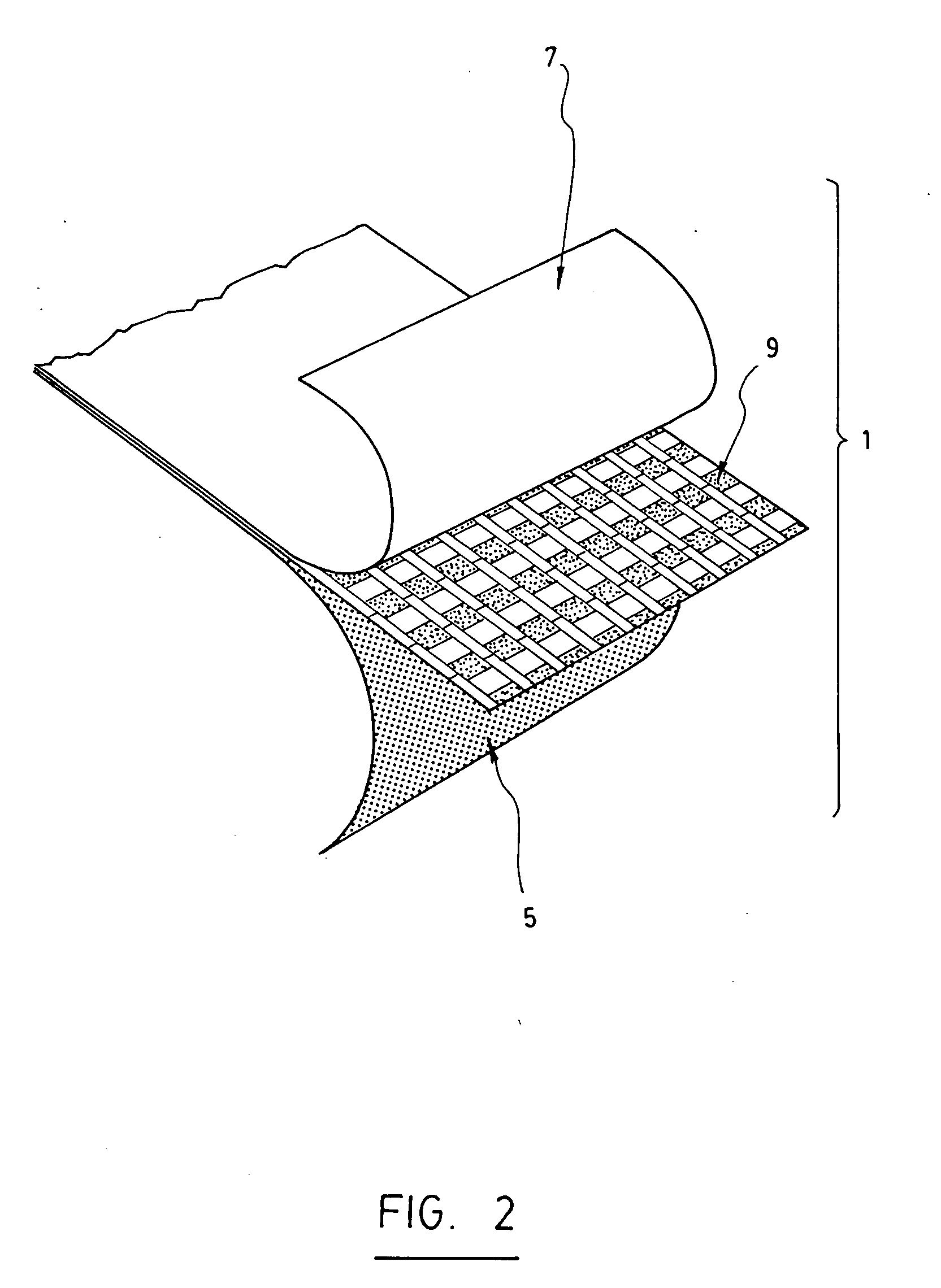

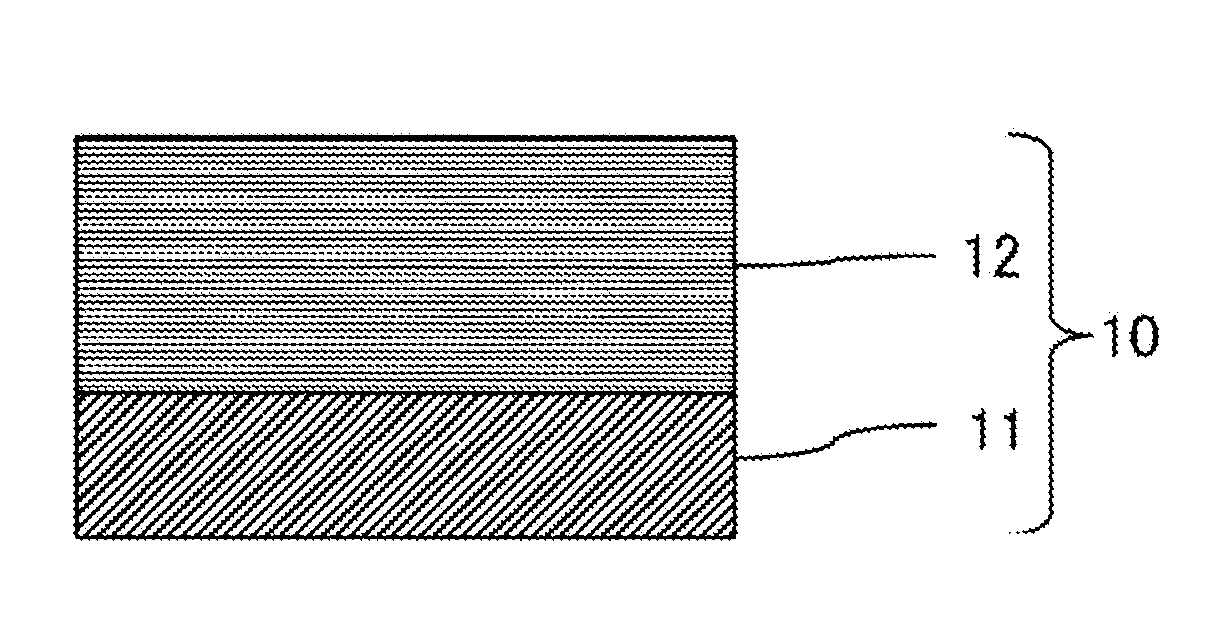

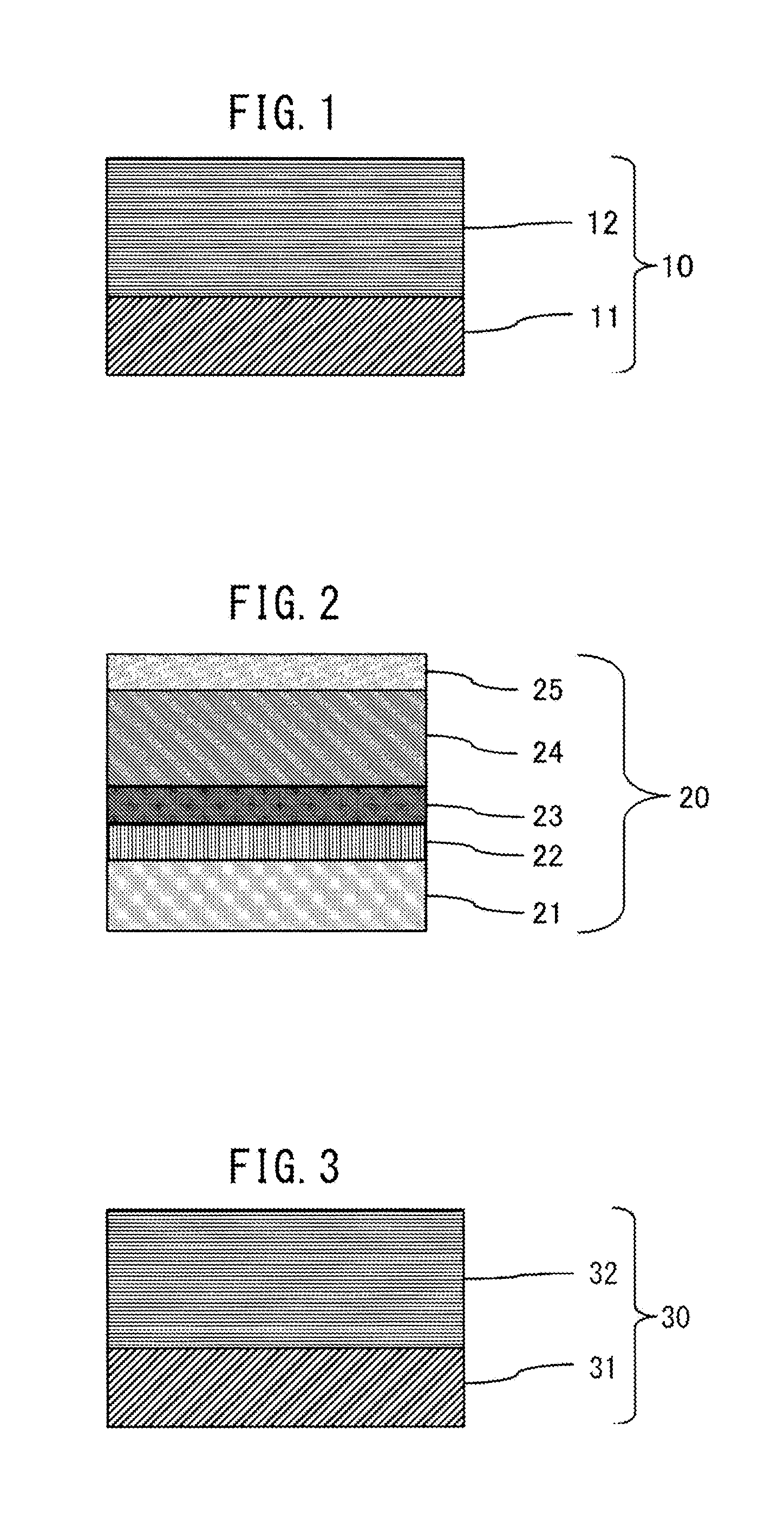

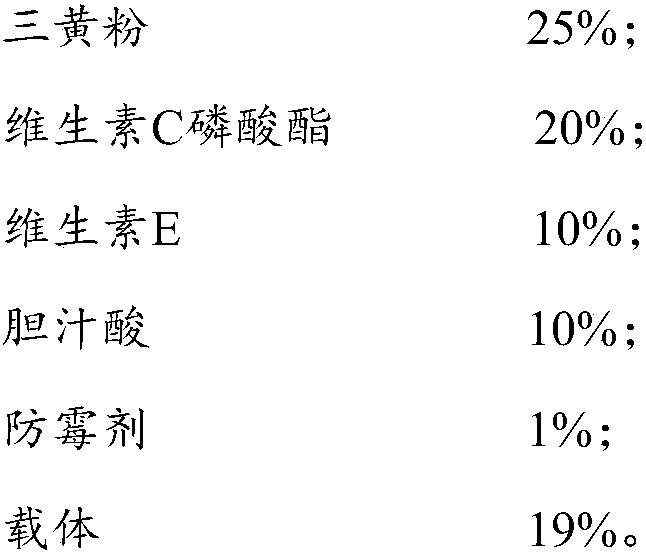

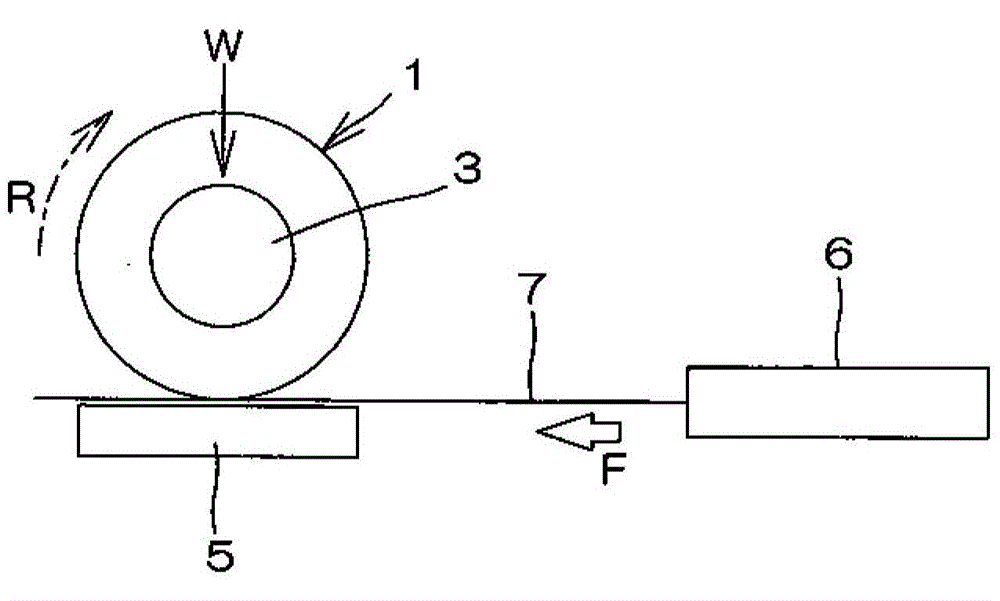

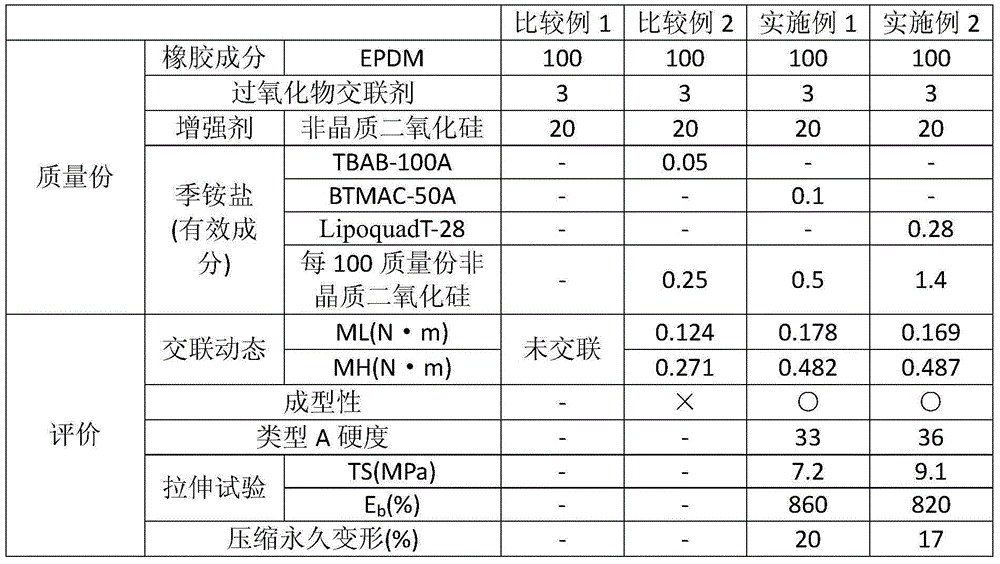

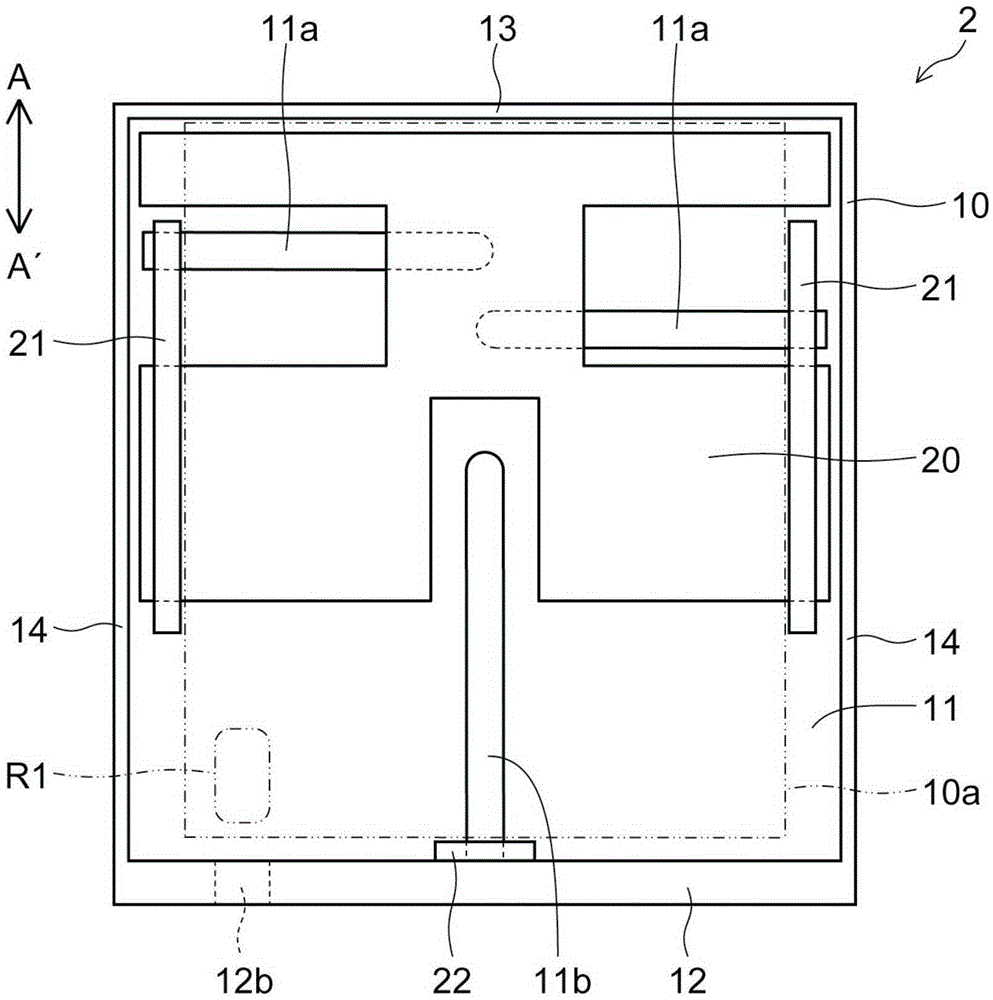

Rubber composition and rubber molded article using the same

To provide a novel rubber composition containing at least EPDM as a rubber component, manufactured by using a peroxide crosslinking agent as a crosslinking agent and blending at least amorphous silica as a reinforcer, capable of being colored with pale colors such as white or any colors other than black and capable of forming a rubber molded article excellent in mechanical property because above described crosslink of EPDM is not inhibited, and the rubber molded article formed by using the rubber composition. A rubber composition contains at least a rubber component containing EPDM, a peroxide crosslinking agent and amorphous silica and further quaternary ammonium salt of 0.3 pt.mass or more based on 100 pts.mass of the amorphous silica is blended. A rubber molded article 1 consists of the above described rubber composition.

Owner:SUMITOMO RUBBER IND LTD

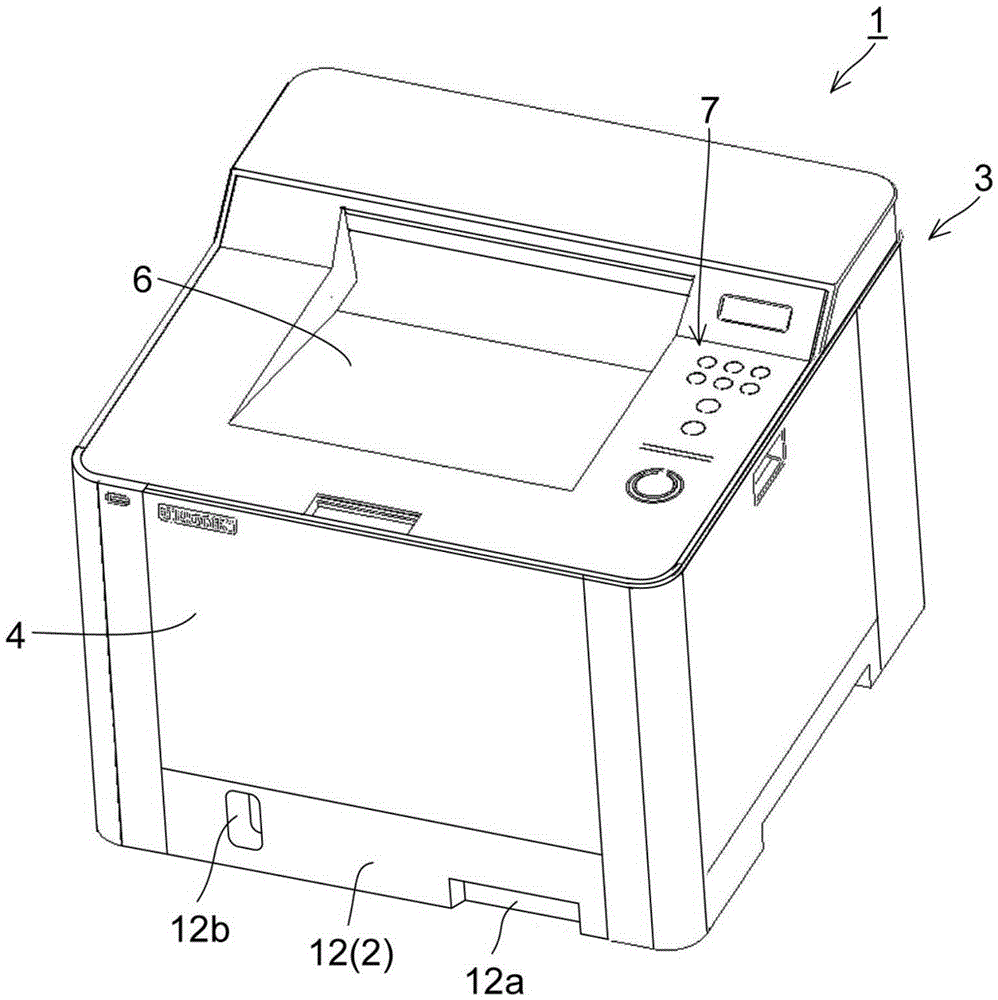

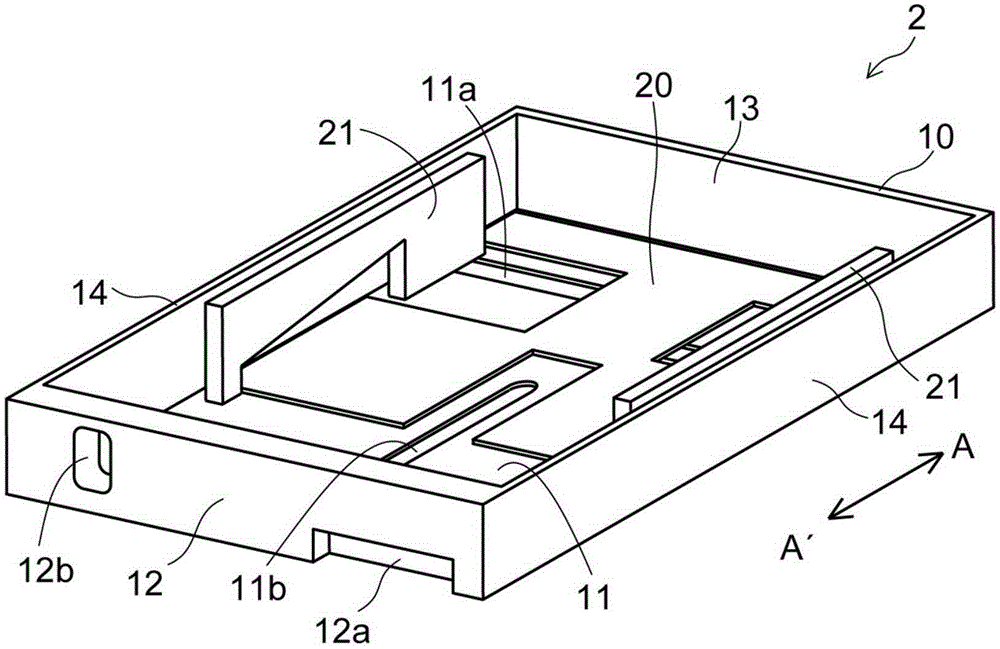

Sheet feeding cassette and image forming apparatus including the same

ActiveCN105692262AReliable confirmationReliable identificationElectrographic process apparatusArticle separationImage formationEngineering

The invention provdes a sheet feeding cassette and an image forming apparatus including the same. The sheet feeding cassette includes a storage region, a front portion, and a bottom portion. On the storage region, a sheet is stored. The front portion is disposed on a downstream side with respect to the storage region in a drawing direction. On the bottom portion, the sheet is placed. In the front portion, an opening is formed through which the storage region is visible. Within the storage region, the bottom portion is formed in white or a pale color. At least a part of the visible region in the storage region is formed to be different in lightness by three or more in Munsell value from a light-color part of the bottom portion, the light-color part being formed in white or the pale color.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Erasing tool

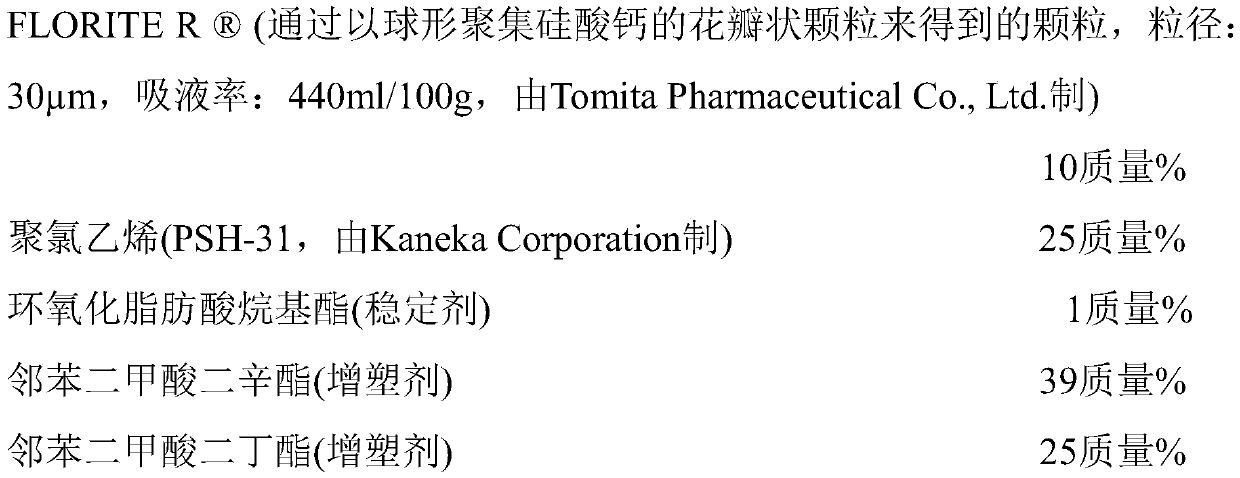

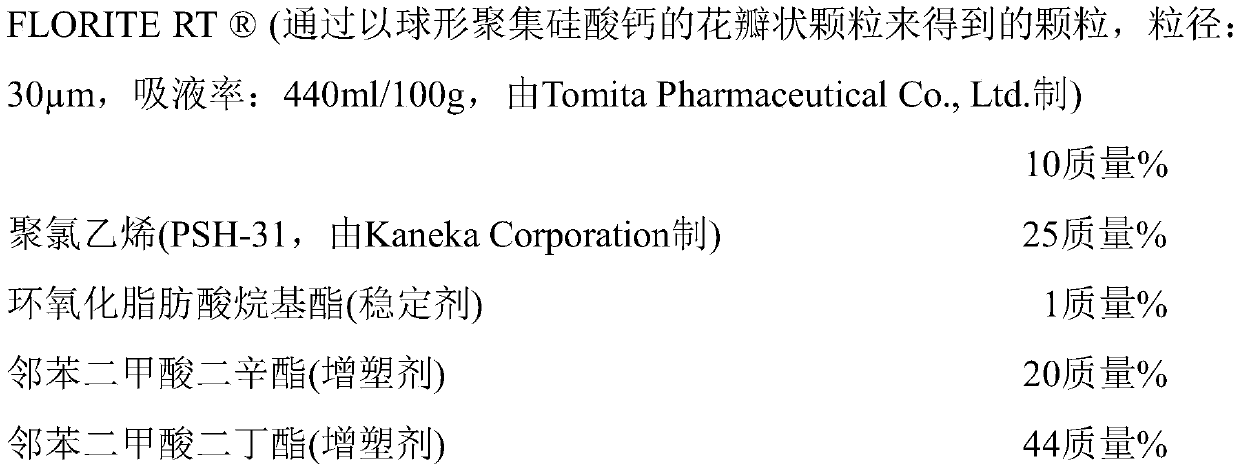

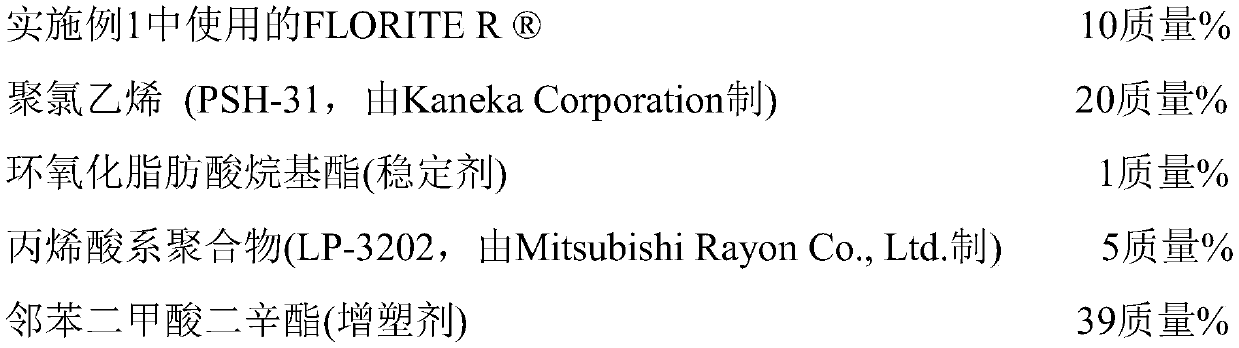

Provided is a highly translucent erasing tool that does not generate leavings, instantly shows an adsorption degree of even a pale color or the like of a color pencil lead or the like, and enables reliable erasure. The erasing tool is characterized by including a secondary aggregate having petaloid particles as primary particles, wherein an average particle diameter is 1 to 100 [mu]m.

Owner:MITSUBISHI PENCIL CO LTD

Blanket flower type formula with wine red as bottom color and printing process of blanket flower type formula

The invention relates to a blanket flower type formula with wine red as a bottom color and a printing process of the blanket flower type formula. According to the blanket flower type formula, ingredients of a flower dark color part, a flower neutral color part, a flower tint part, a flower heart part, a leaf deep color part, a leaf intermediate color part, a leaf tint part, a deep bottom color part, an intermediate bottom color part and a light bottom color part are included and are different. By adopting the printing process matched with the blanket flower type formula, the problems of unstable quality and unattractive appearance of a blanket are solved, so that the produced blanket is uniform in color, bright in color, strong in layering sense, and attractive in flower type, and conforms to aesthetic demands of people.

Owner:SUQIAN SHENLONG HOME TEXTILE

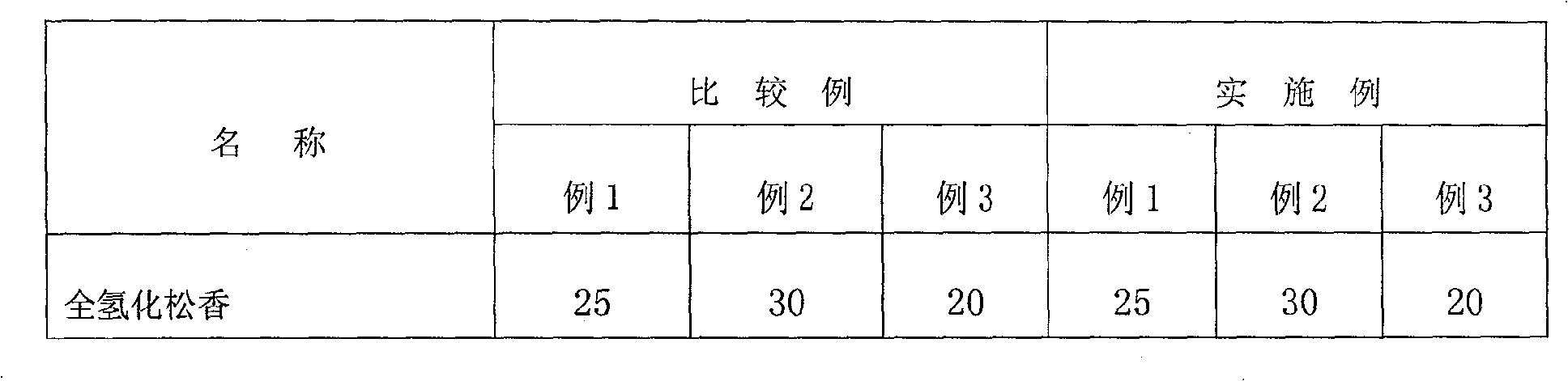

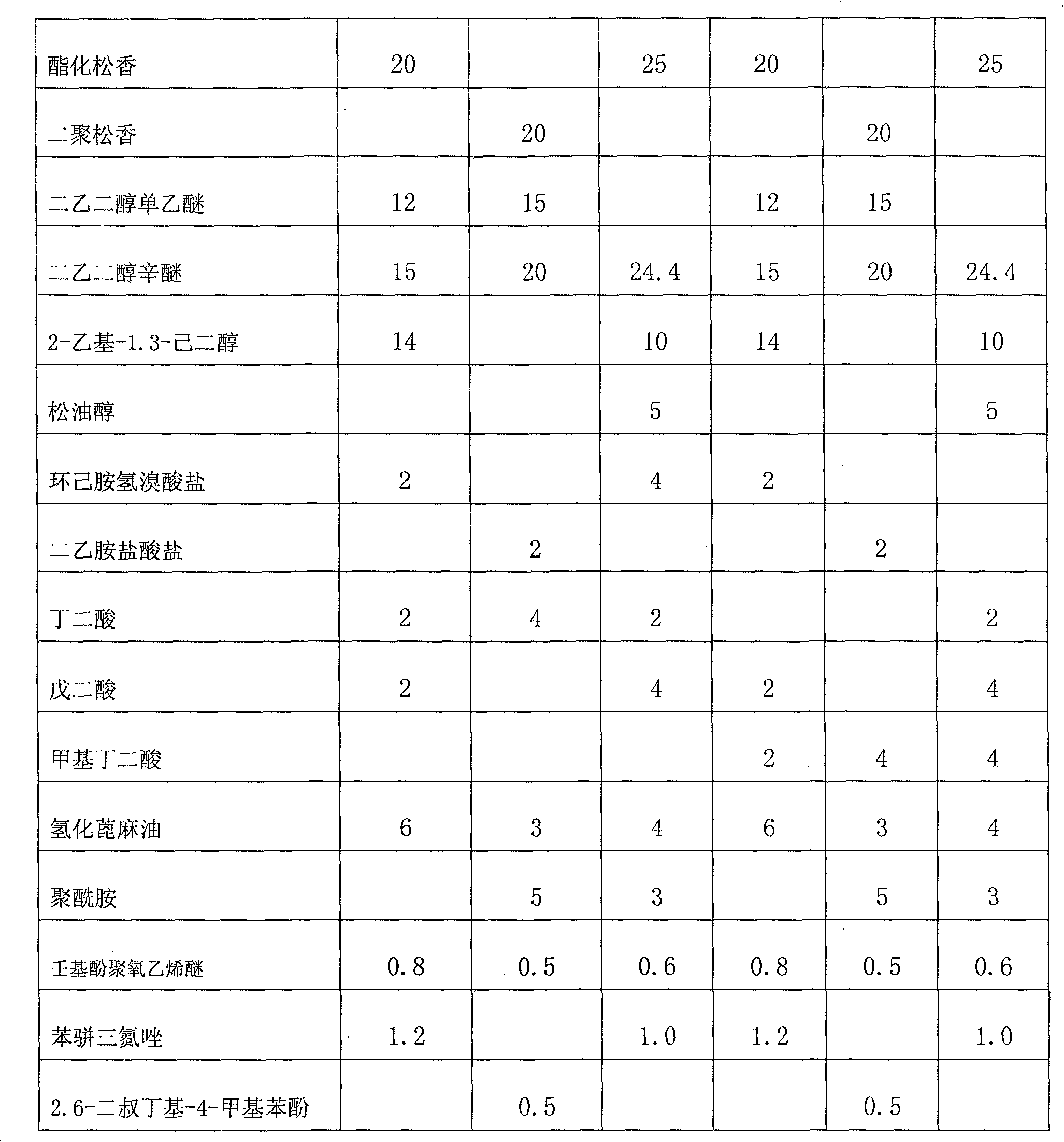

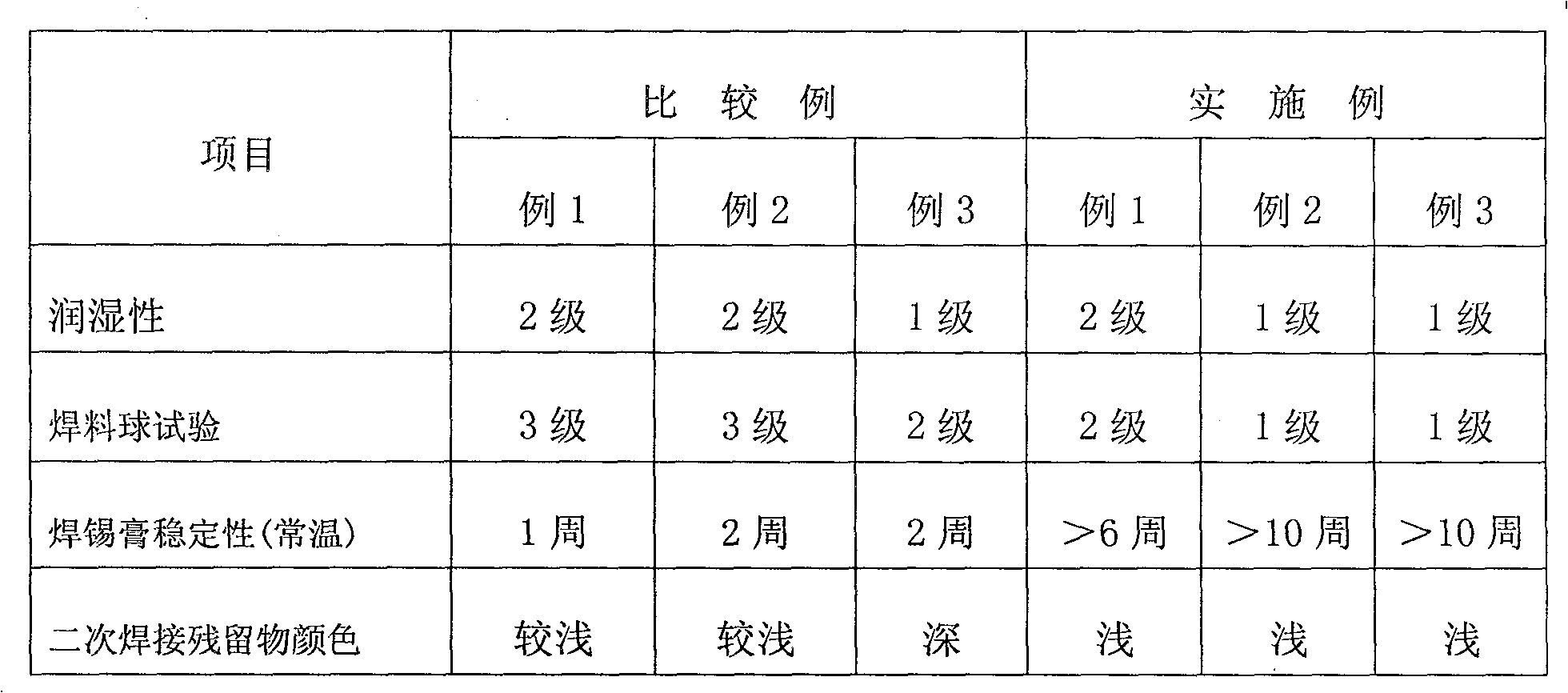

SMT no-lead tinol

InactiveCN100571962COvercoming lead problemsImprove wettabilityWelding/cutting media/materialsSoldering mediaHydrobromideActive agent

Owner:SHENZHEN UNIBRIGHT TECH

Grey fabric dirt removing method used in terylene bags and suitcases light color/bright color dyeing

InactiveCN108277667AFlat surfaceFull clothDry-cleaning apparatus for textilesDyeing processThermal expansionEngineering

The invention relates to a grey fabric dirt removing method used in terylene bags and suitcases light color / bright color dyeing. The grey fabric dirt removing method used in terylene bags and suitcases light color / bright color dyeing comprises following steps: 1, 3g / L of an oil removing agent and 3g / L of caustic soda are introduced into a desizing water-washing combined trough, the temperature isincreased to 100 DEG C, and grey fabric full width is introduced into the desizing water-washing combined trough for wetting, thermal expansion, and emulsification; and 2, three times of hot water rolling washing and one time of cold water rolling washing are carried out. The treatment time is short; speed is fast; dirt and oil spots can be removed completely; dyeing finished products obtained viatreatment possesses following advantages: the cloth surface is more flat, and the color is more bright.

Owner:宜兴市新伟隆印染有限公司

Colour painting method of exerciser rod body

InactiveCN1559812AStrong textureSmooth linesSpecial artistic techniquesArtistic surface treatmentSports equipmentEngineering

Owner:VISION SPORTS ENTERPRISE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com