Rubber composition and rubber molded article using the same

A rubber composition and rubber molding technology, applied in the field of rubber moldings, can solve the problems of inability to cross-link, hinder EPDM cross-linking, and inability to obtain mechanical properties of rubber moldings, etc., and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

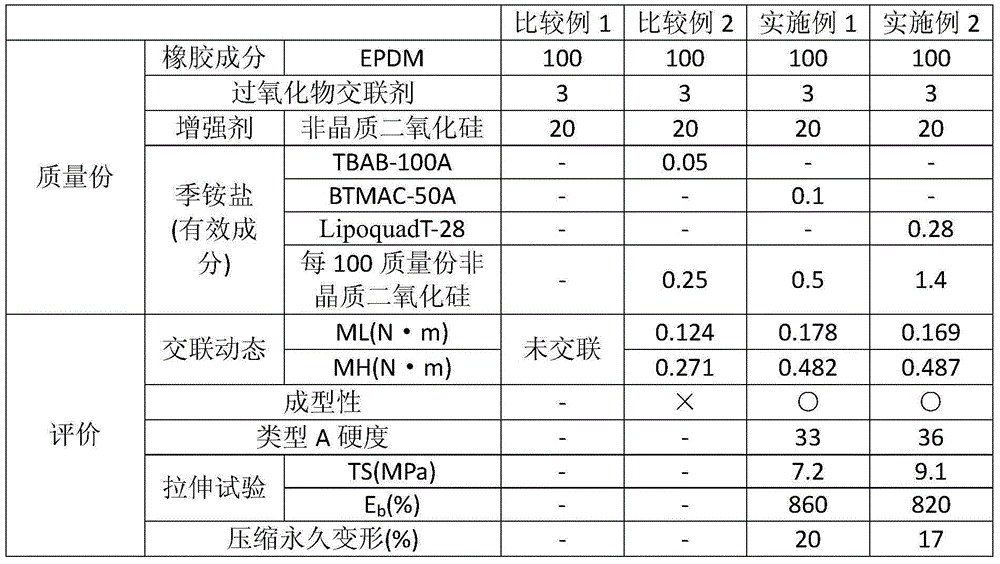

Embodiment 1

[0103] (Preparation of rubber composition)

[0104] Oil-extended EPDM (Esprene 670F manufactured by Sumitomo Chemical Co., Ltd., ethylene content: 66% by mass, diene content: 4.0% by mass, oil extension: 100 phr) was used as a rubber component.

[0105] In 200 parts by mass of this oil-extended EPDM (solid content (EPDM): 100 parts by mass), 3 parts by mass of dicumyl peroxide (Percumyl (registered) manufactured by NOF Corporation) as a peroxide crosslinking agent was blended. Trademark) D), 20 parts by mass of amorphous silica (Nipsil (registered trademark) VN3 manufactured by Tosoh Silicon Chemical Co., Ltd., wet-process silica), and 0.2 parts by mass of benzyltri A 50% aqueous solution of butylammonium chloride (BTMAC-50A manufactured by Lion Specialty Chemical Co., Ltd.) was kneaded using a 3L kneader and an open mill to prepare a rubber composition.

[0106] Regarding the compounding ratio of the active ingredient (benzyltributylammonium chloride) in the above aq...

Embodiment 2

[0108] As a quaternary ammonium salt, a 28% aqueous solution (Lipoquad T28 manufactured by Lion Specialty Chemical Co., Ltd.) of 1 part by mass of alkyl (C12-C16) trimethylammonium chloride was blended, and the same as in Example 1 In the same manner, a rubber composition was prepared.

[0109] Regarding the compounding ratio of the active ingredient (alkyl (C12-16) trimethylammonium chloride) in the above aqueous solution, the compounding ratio is 0.28 per 100 parts by mass of the solid content (EPDM) in the oil-extended EPDM The compounding ratio is 1.4 parts by mass per 100 parts by mass of amorphous silica.

Embodiment 3

[0111] As a quaternary ammonium salt, except that 0.5 parts by mass of powdered tetrabutylammonium bromide (TBAB-100A manufactured by Lion Specialty Chemical Co., Ltd.) was compounded, the rubber composition was prepared in the same manner as in Example 1. things.

[0112] Regarding the compounding ratio of the above-mentioned tetrabutylammonium bromide, the compounding ratio is 0.5 parts by mass per 100 parts by mass of solid matter (EPDM) in oil-extended EPDM, and the compounding ratio is 0.5 parts by mass per 100 parts by mass of amorphous dioxide Silicon, the compounding ratio is 2.5 parts by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com