Barium titanate chemico-mechanical polishing aqueous composition and its application

A water-based composition, chemical mechanical technology, applied in the polishing composition containing abrasives, surface polishing machine tools, grinding/polishing equipment, etc., can solve the problems that need to be improved, so as to improve the polishing removal rate and reduce chemical corrosion function, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

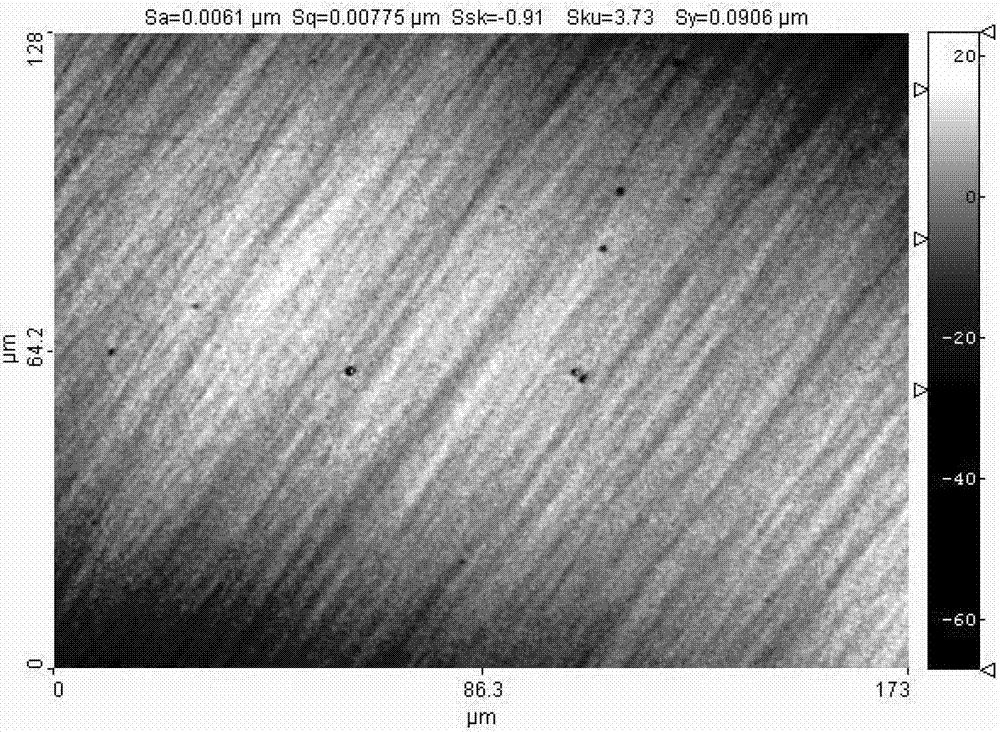

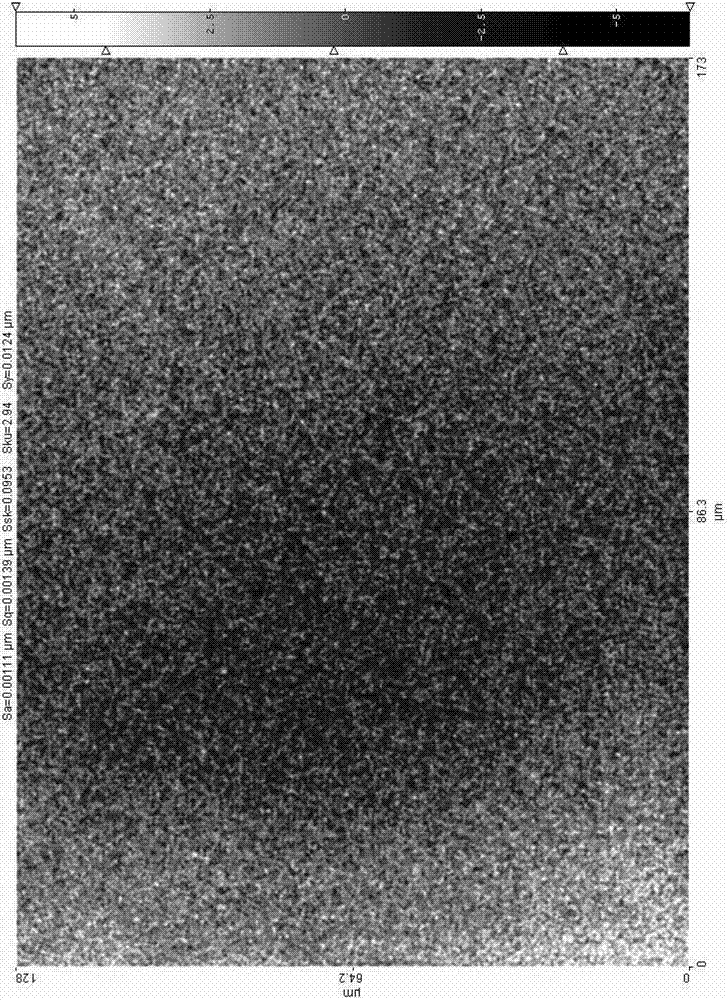

Image

Examples

Embodiment 1

[0036] Add 20 grams of citric acid and 1 gram of polyvinyl alcohol into 400 grams of deionized water successively, stir to dissolve, evenly stir slowly and add 480 grams of 25% 50nm aluminum oxide hydrosol, then calibrate its pH value to 10.5, finally add water to make up 1000 grams and stir evenly, then polish the polishing sample under 1.0Psi pressure. The results show that the polishing removal rate MRR is 204.0nm / min, and the surface roughness Sa is 4.98nm.

Embodiment 2

[0038] Add 20 grams of citric acid and 1 gram of polyvinyl alcohol into 400 grams of deionized water in sequence, stir to dissolve, and then slowly stir and add 400 grams of 30% 50nm silica hydrosol, and then use NaOH to calibrate its pH value to 10.5 , and finally add water to make up 1000 grams and stir evenly, and then polish the polished sample under a pressure of 1.0Psi. The results show that the polishing removal rate MRR is 120.6nm / min, and the surface roughness Sa is 2.37nm.

Embodiment 3

[0040] Add 20 grams of citric acid, 10 grams of ammonium fluoride and 1 gram of polyvinyl alcohol into 400 grams of deionized water in sequence, stir to dissolve, and then slowly stir and add 400 grams of 30% 50nm silica hydrosol, and then use NaOH Calibrate its pH value to 10.5, and finally add water to make up 1000 grams, stir evenly, and then polish the polishing sample under a pressure of 1.0 Psi. The results show that the polishing removal rate MRR is 152.3nm / min, and the surface roughness Sa is 2.18nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com