Strong acid-base resistant composite ceramic anticorrosive coating and preparation method thereof

A technology of composite ceramics and anti-corrosion coatings, applied in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve the problems of high construction humidity requirements, complex construction technology, and many coating times, and achieve Better curing effect, less precipitation and layering, and high coating density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0056] A strong acid-alkali resistant composite ceramic anti-corrosion paint, comprising A component and B component, which can be coated after mixing the A component and the B component according to a certain ratio during use.

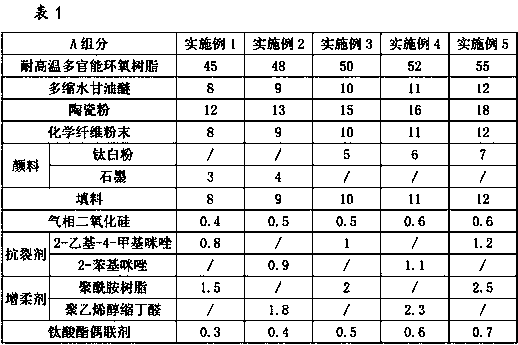

[0057] In parts by weight, the content of each component in the A component is as shown in Table 1:

[0058]

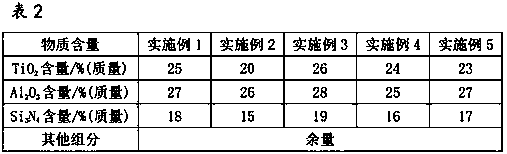

[0059] Among them, the maximum particle size of the ceramic powder is ≤5μm, the chemical composition contains titanium dioxide, aluminum oxide and silicon nitride, and the following conditions are met:

[0060] a. The mass percentage content of titanium dioxide is ≥20%;

[0061] b. The mass percentage of aluminum oxide is ≥ 25%;

[0062] c. The mass percentage content of silicon nitride is ≥15%.

[0063] The chemical composition of ceramic powder used in each embodiment is specifically shown in the following table:

[0064]

[0065] The chemical fiber powder used in each embodiment is pulverized from chemical fiber with high chemical...

Embodiment 6

[0070] A preparation method for strong acid and alkali resistant composite ceramic anticorrosion coating, comprising the steps of:

[0071] Step 1. In parts by weight, weigh 12 parts of ceramic powder, 8 parts of chemical fiber powder, 3 parts of graphite, 8 parts of filler, 0.4 part of fumed silica, 0.8 part of 2-ethyl-4-methylimidazole, poly After mixing 1.5 parts of amide resin and 0.3 part of titanate coupling agent, stir evenly to obtain a mixed material 1; the ceramic powder, chemical fiber powder and filler used are the same as in Example 1;

[0072] Step 2, mixing 45 parts of high-temperature-resistant multifunctional epoxy resin and 8 parts of polyglycidyl ether, and then stirring evenly to obtain the mixture material 2;

[0073] Step 3. Add the mixture material 1 obtained in step 1 to the mixture material 2 obtained in step 2 under stirring conditions, and stir for more than 3.5 hours to obtain component A;

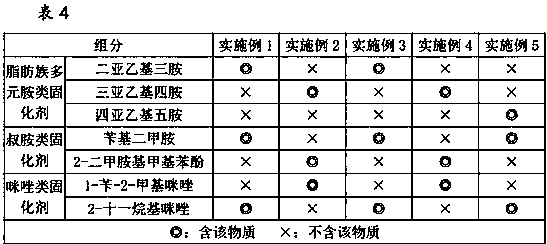

[0074] Step 4: Weigh diethylenetriamine, benzyldimethylam...

Embodiment 7

[0076] A preparation method for strong acid and alkali resistant composite ceramic anticorrosion coating, comprising the steps of:

[0077] Step 1. In parts by weight, weigh 13 parts of ceramic powder, 9 parts of chemical fiber powder, 4 parts of graphite, 9 parts of filler, 0.5 part of fumed silica, 0.9 part of 2-phenylimidazole, polyvinyl butyral 1.8 parts and 0.3 parts of titanate coupling agent were mixed and stirred evenly to obtain a mixed material 1; the ceramic powder, chemical fiber powder and filler used were the same as in Example 2;

[0078] Step 2. Mix 48 parts of high-temperature-resistant multifunctional epoxy resin and 9 parts of polyglycidyl ether, and then stir evenly to obtain the mixture material 2;

[0079] Step 3. Add the mixture material 1 obtained in step 1 to the mixture material 2 obtained in step 2 under stirring conditions, and stir for more than 3.5 hours to obtain component A;

[0080] Step 4: Weigh triethylenetetramine, 2-dimethylaminomethylphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com