Preparation method of delustering agent for chinlon chemical fibers

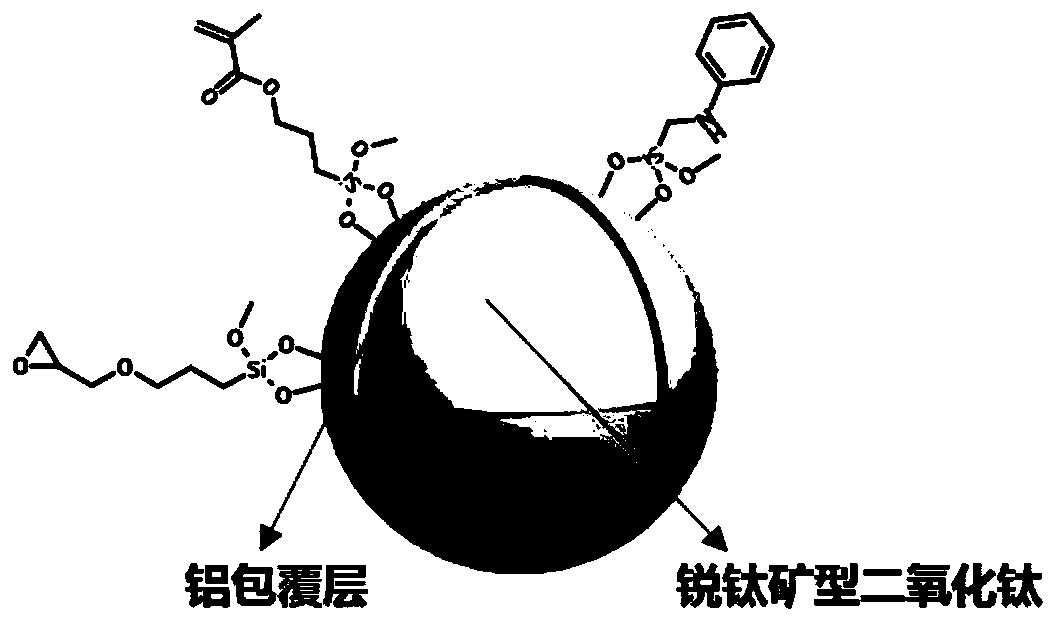

A matting agent, chemical fiber technology, applied in chemical instruments and methods, fiber types, fiber processing and other directions, can solve the problem of difficult aluminum cladding layer compactness and uniformity, unfavorable to improve the mechanical properties of nylon fiber, unfavorable nylon fiber dyeing fastness. It is easy to recycle and reuse, reduce photocatalytic activity, and maintain dispersion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Particle size refinement and homogenization of anatase titanium dioxide: Weigh 100g of primary titanium dioxide at room temperature and disperse it in 150g of absolute ethanol, stir for 10min with magnetic force, add 0.5g of hexamethylenediamine, and continue stirring for 20min to obtain a mixture Uniform titanium dioxide slurry, and then slowly add the slurry into the grinder, adjust the spindle speed to 2500r / min, grind for 30min, dry the resulting slurry in an 80°C blast oven and grind it for later use.

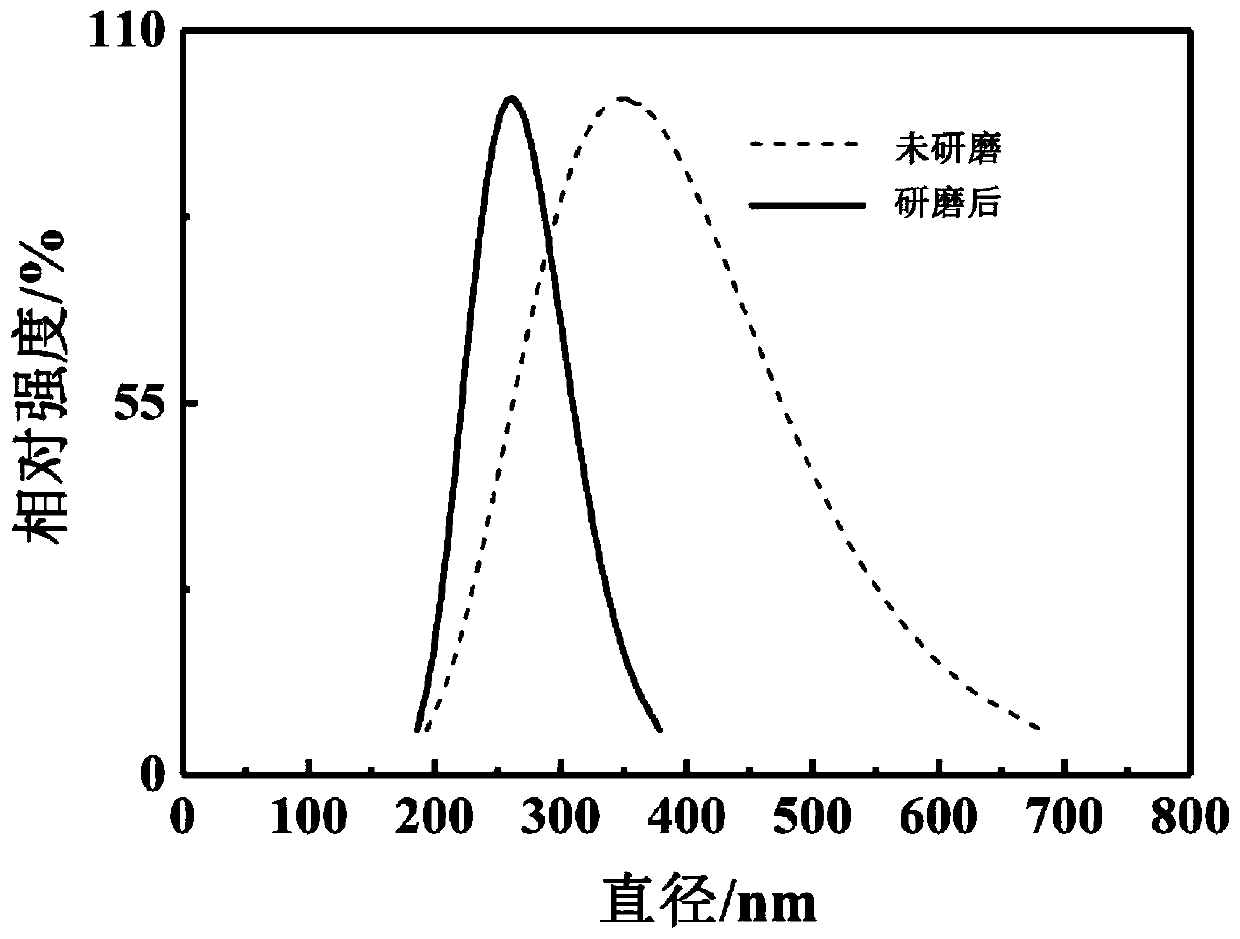

[0047] figure 2 It is the particle size distribution curve of anatase titanium dioxide before and after grinding, and the results show that the particle size distribution of the ultrafine powder after grinding is 0.2-0.4 μm and the particle size distribution is concentrated.

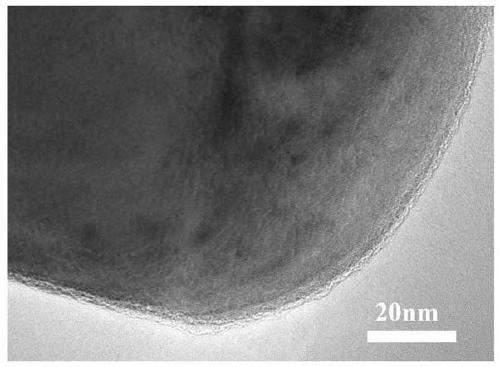

[0048] (2) Preparation of aluminum-coated titanium dioxide: Weigh 20 g of the ultrafine powder obtained in step (1), disperse it in 30 g of absolute ethanol, add 1.0 g of caprolactam, sti...

Embodiment 2

[0055] (1) Anatase titanium dioxide particle size refinement and homogenization treatment: Weigh 100g of titanium dioxide primary product at room temperature and disperse it in 400g of absolute ethanol, magnetically stir for 10min, add 0.3g caprolactam, continue to stir for 20min to obtain a homogeneous mixture Titanium dioxide slurry, and then slowly add the slurry into the grinder, adjust the spindle speed to 2000r / min, grind for 40min, dry the resulting slurry in a blast oven at 80°C and grind it for later use.

[0056] (2) Preparation of aluminum-coated titanium dioxide: Weigh 20 g of the ultrafine powder obtained in step (1), disperse it in 80 g of absolute ethanol, add 0.2 g of caprolactam, stir magnetically for 10 min to obtain a slurry, and disperse the slurry ultrasonically for 20 min; then Put it in an oil bath and heat it to 80°C with a stirring rate of 300r / min. Add 2.404g of aluminum isopropoxide and stir for 15 minutes. A mixed solution with a pH of 8.5 was adjus...

Embodiment 3

[0063] (1) Anatase titanium dioxide particle size refinement and homogenization treatment: Weigh 100g of titanium dioxide primary product at room temperature and disperse it in 300g of absolute ethanol, magnetically stir for 10min, add 0.4g of adipic acid, continue stirring for 20min to obtain a mixture Uniform titanium dioxide slurry, then slowly add the slurry into the grinder, adjust the spindle speed to 2200r / min, grind for 35min, dry the resulting slurry in a blast oven at 80°C and grind it for later use.

[0064] (2) Preparation of aluminum-coated titanium dioxide: Weigh 20 g of the ultrafine powder obtained in step (1), disperse it in 70 g of absolute ethanol, add 0.6 g of caprolactam, stir magnetically for 10 min to obtain a slurry, and ultrasonically disperse the slurry for 30 min; then Put it in an oil bath and heat it to 70°C, with a stirring rate of 400r / min, add 1.603g of aluminum isopropoxide, and stir for 15 minutes, then evenly add anhydrous ethanol and deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com