Modification method of nano white carbon black

A nano-silica, modification technology, applied in the direction of fibrous fillers, dyeing polymer organic compounds, etc., can solve the problems of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of monomer pre-emulsion: put 100 parts of styrene, 1 part of sodium dodecylbenzene sulfonate, 100 parts of deionized water, 1.0 part of sodium hydroxide, and 0.01 part of potassium persulfate into the reactor. When the temperature was raised to 40°C, the reaction was stirred for 30 minutes to prepare a styrene pre-emulsion liquid a.

[0040] (2) Preparation of mixed polar monomer mixture: Take 100 parts of methyl methacrylate (MMA) and 15 parts of acrylamide into the reactor and stir and mix for 5 minutes; then add 50 parts of deionized water and 1 part of hydrogen. Sodium oxide was stirred and mixed for 10 minutes to form a mixed polar monomer mixture a (pH of the mixture a=7.2).

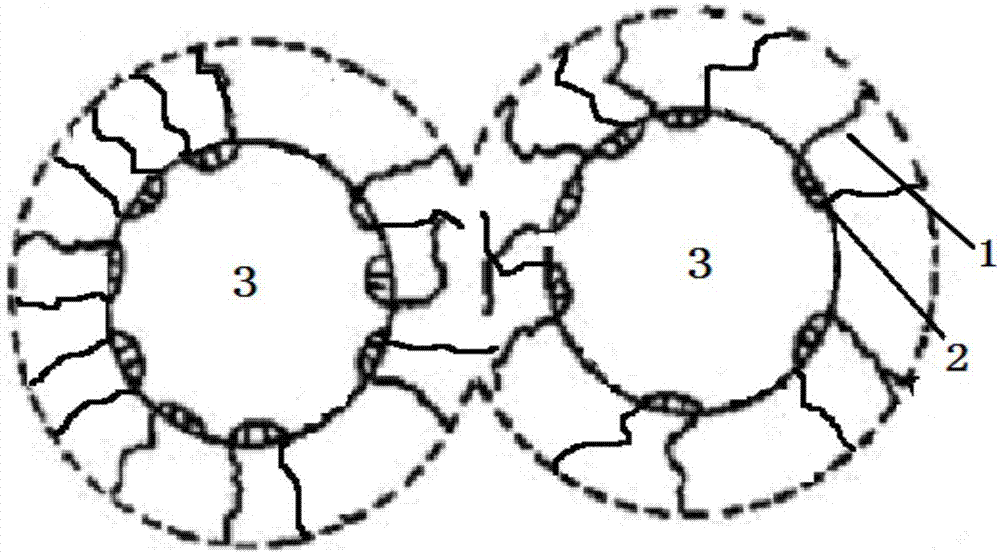

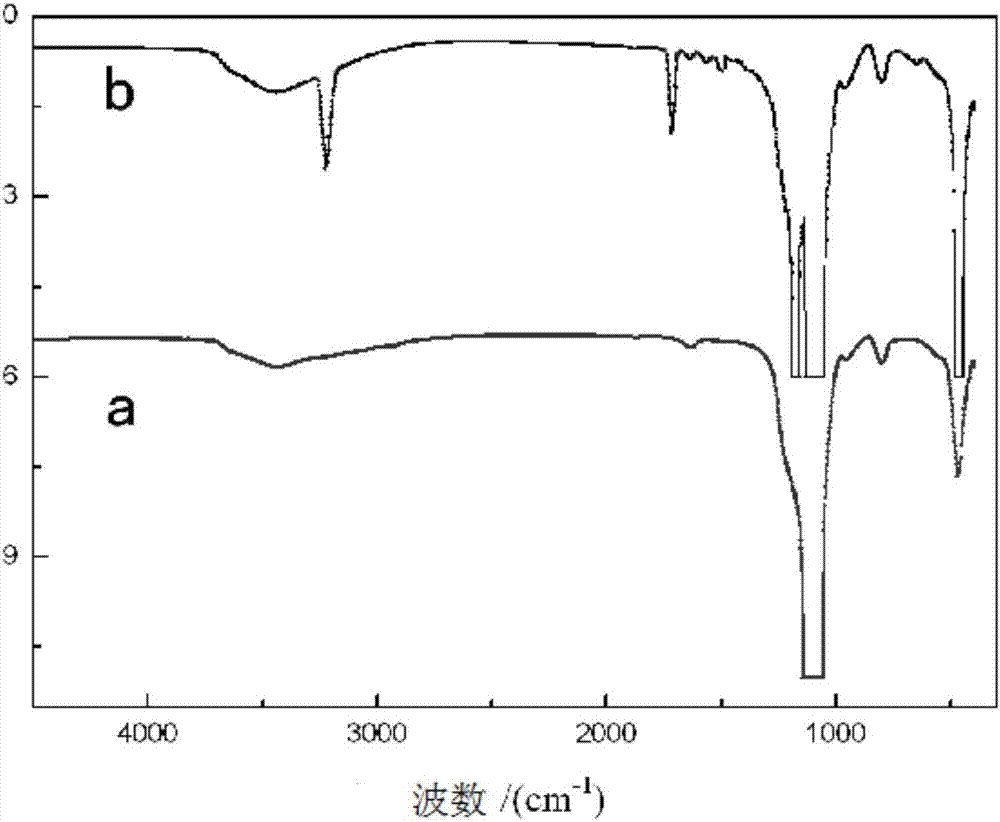

[0041] (3) Preparation of modified nano-silica: take 100 parts of nano-silica (40nm) and 5 parts of polar monomer mixture a, 200 parts of deionized water, and 1.0 part of sodium hydroxide into the polymerization kettle and stir. Mix for 10 minutes; then add 1 part of sodium dodec...

Embodiment 2

[0043] (1) Preparation of monomer pre-emulsion: the same as in Example 1.

[0044] (2) Preparation of mixed polar monomer mixture: the same as in Example 1.

[0045] (3) Preparation of modified nano-silica: take 100 parts of nano-silica (40nm) and 10 parts of polar monomer mixture a, 260 parts of deionized water, and 2.0 parts of sodium hydroxide into the polymerization kettle and stir. Mix for 20 minutes; then add 2 parts of sodium dodecylbenzene sulfonate and 2.0 parts of styrene pre-emulsion a, stir and heat up to 65°C, then stir and mix for 25 minutes to form the seed of a composite emulsion centered on nano-silica powder ; Then 15 parts of styrene pre-emulsion a and 0.13 parts of potassium persulfate are added, after 4.0 hours of reaction, 0.2 parts of diethylhydroxylamine are finally added, washed, dehydrated, dried, and ground to obtain modified nano-silica. Sampling analysis: Make standard samples, and see Table 1 for their tested performance.

Embodiment 3

[0047] (1) Preparation of monomer pre-emulsion: the same as in Example 1.

[0048] (2) Preparation of mixed polar monomer mixture: the same as in Example 1.

[0049] (3) Preparation of modified nano-silica: take 100 parts of nano-silica (40nm) and 12 parts of polar monomer mixture a, 270 parts of deionized water, and 2.0 parts of sodium hydroxide into the polymerization kettle and stir. Mix for 20 minutes; then add 3 parts of sodium dodecylbenzene sulfonate and 2.5 parts of styrene pre-emulsion a, stir and heat up to 65°C, then stir and mix for 25 minutes to produce the seed of a composite emulsion centered on nano-silica powder ; Then add 18 parts of styrene pre-emulsion a and 0.13 parts of potassium persulfate, after reaction for 4.0h, finally add 0.2 parts of diethylhydroxylamine, washing, dehydration, drying, grinding to obtain modified nano-silica. Sampling analysis: Make standard samples, and see Table 1 for their tested performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com