Color curable composition and method of preparing the same, color filter and method of producing the same, and solid-state image pick-up device

A technology for color filters and camera devices, applied in the fields of filters, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the problem of incomplete dissolution of dyes, difficult to confirm the dissolution of dye powders, and long costs for dye powder dissolution. Time and other issues to achieve the effect of promoting preparation and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The method for producing a colored curable composition according to the present invention includes a process of preparing a dye solution by dissolving at least one dye in an organic solvent, a process of preparing a pigment dispersion liquid by dispersing at least one pigment using a dispersant, and The process of mixing a dye solution with a pigment dispersion.

[0035]

[0036] First, a process of dissolving at least one dye in an organic solvent to form a dye solution is described.

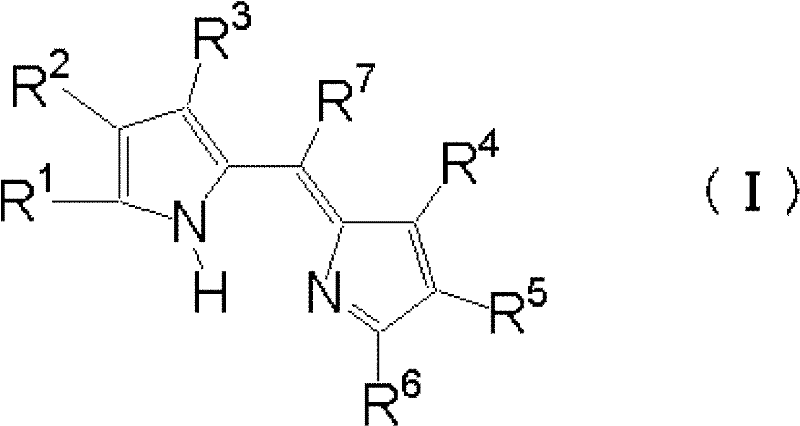

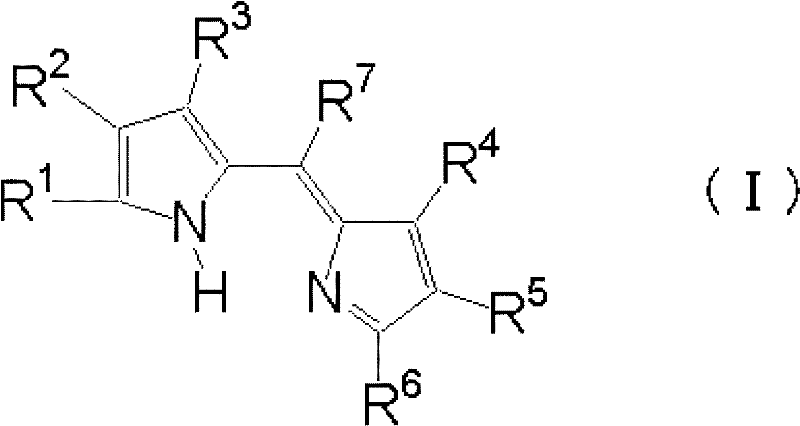

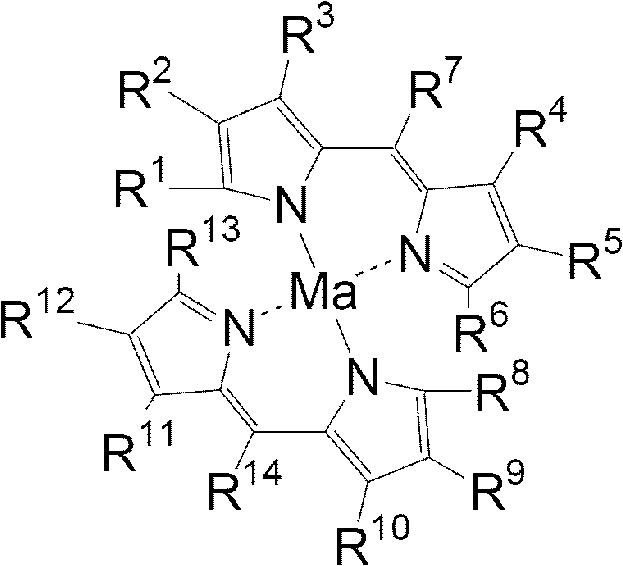

[0037] The dye used in the present invention is not particularly limited, and known dyes that have been used for color filters can be used. Examples thereof include dyes described in JP-A No. 64-90403, JP-A No. 64-91102, JP-A No. 1-94301, JP-A No. 6-11614, Japanese Patent No. 2592207, U.S. Patent No. 4,808,501, U.S. Patent No. 5,667,920, U.S. Patent No. 5,059,500, JP-A No. 5-333207, JP-A No. 6-35183, JP-A No. 6-51115, JP-A No. 6-194828, JP-A No. 8 -211599, JP-A No. 4-249549, JP-A No....

Embodiment 1

[0391] (1) Preparation of dye solution

[0392] 0.183 parts of the specific complex (Exemplary Compound Ia-3 given above) was added to 1.133 parts of cyclohexanone, and the resulting mixture was stirred at normal temperature for 60 minutes using a mixing rotor (manufactured by AS ONE Corporation), A dye solution is obtained as a result.

[0393] (2) Preparation of pigment dispersion

[0394] First, Pigment Blue 15:6 (HELIOGEN L6700F (trade name) manufactured by BASF Corporation) was refined as follows.

[0395] In detail, ingredients of the following composition were put into a double-arm kneader, and kneaded at 80° C. for 30 hours. After that, the obtained mixture was added to 100 parts of a 1% aqueous hydrochloric acid solution having a temperature of 80° C., and stirred for 1 hour. Thereafter, the resulting product was filtered, washed with hot water, dried, and pulverized, as a result of which a fine pigment of Pigment Blue 15:6 was obtained.

[0396] - Pigment blue 15...

Embodiment 2 to 8 and comparative example 2 to 8

[0446] In addition to changing the type of dye and the type and composition ratio of organic solvents as shown in Table 1, and changing the amount of solvent to give the solid content shown in Table 1, in the same way as the above method A (for coloring can be Preparation of Curing Composition) The colored curable compositions of Examples 2 to 8 were obtained in the same manner. In addition to changing the type of dye and the type and composition ratio of organic solvents as shown in Table 1, and changing the amount of solvent to give the solid content shown in Table 1, in the same way as the above method B (for coloring can be The colored curable compositions of Comparative Examples 2 to 8 were obtained in the same manner as in Preparation of Curable Compositions). As described above, since the amount of the organic solvent is changed, the solid content of the colored curable composition is changed. Using each of the obtained colored curable compositions, dispersion stabilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com