Efficient antibacterial and antiviral two-in-one odorless radiation curable coating and preparation method thereof

A radiation-curing and anti-virus technology, applied in the field of coatings, can solve problems such as no mention of LED radiation curing methods, unproven antibacterial and anti-virus efficiency, complex manufacturing process, etc., to achieve long-lasting anti-bacterial and anti-virus effects, good long-lasting anti-bacterial properties, Reduce the effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

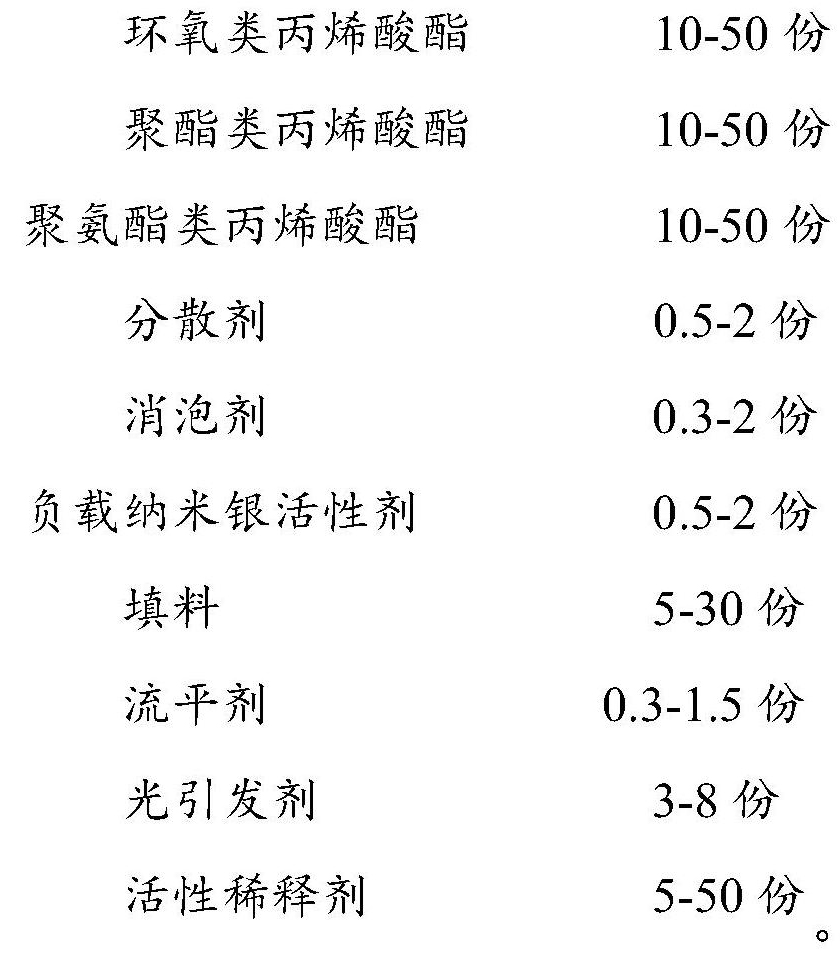

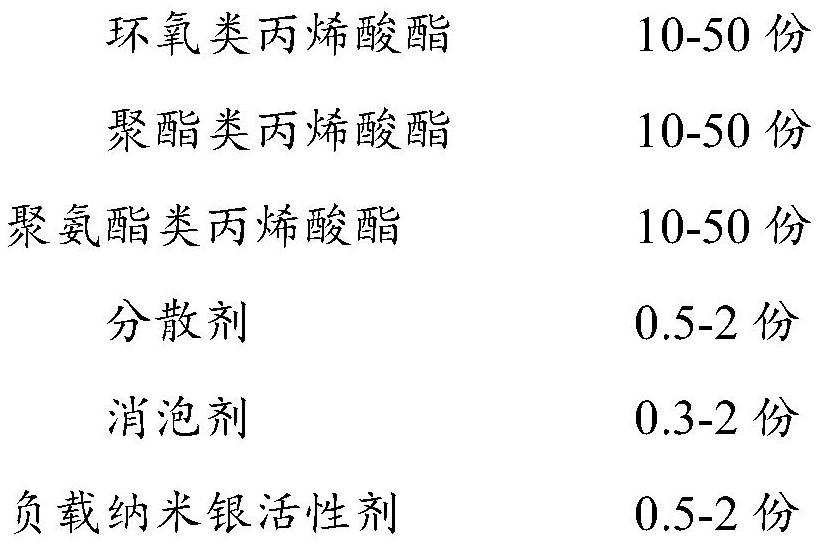

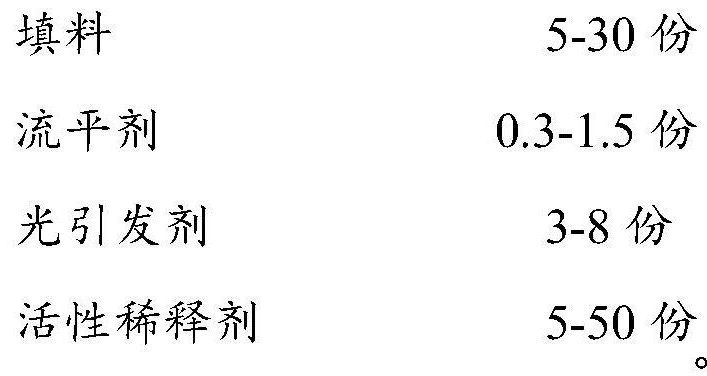

[0028] A high-efficiency antibacterial and antiviral two-in-one odor-cleaning radiation-cured transparent coating, the preparation method of which is as follows:

[0029]

[0030] A method for preparing a high-efficiency antibacterial and antiviral two-in-one odor-cleaning radiation-cured transparent coating comprises the following steps:

[0031] A method for preparing a high-efficiency antibacterial and antiviral two-in-one deodorizing radiation-cured coating, comprising the following steps:

[0032] Put epoxy acrylate, polyester acrylate, polyurethane acrylate, dispersant and defoamer into a clean dispersion cylinder, and then disperse for 10 minutes at a speed of 1000r / min;

[0033] Then add the loaded nano-silver active agent and filler, and then disperse for 30 minutes at a speed of 1200r / min until the fineness is ≤25μm and there is no oil shrinkage;

[0034] Finally, add leveling agent, photoinitiator and reactive diluent, and disperse for 15 minutes at a rotation s...

Embodiment 2

[0038] A high-efficiency antibacterial and antiviral two-in-one odor-cleaning radiation-cured white paint, the preparation method of which is as follows:

[0039]

[0040]

[0041] A method for preparing a high-efficiency antibacterial and antiviral two-in-one deodorizing radiation-cured coating, comprising the following steps:

[0042] Put epoxy acrylate, polyester acrylate, polyurethane acrylate, dispersant and defoamer into a clean dispersion cylinder, and then disperse for 5 minutes at a speed of 1200r / min;

[0043] Then add the loaded nano-silver active agent, pigment and filler, and then disperse for 20 minutes at a speed of 1500r / min until the fineness is ≤25μm and there is no oil shrinkage;

[0044] Finally, add leveling agent, photoinitiator and reactive diluent, and disperse for 10 minutes at a rotation speed of 1200r / min.

[0045] The advantage of this embodiment is: even in the case of high content of pigments and fillers, the coating film under this solutio...

Embodiment 3

[0048] A high-efficiency antibacterial and antiviral two-in-one odor-cleaning radiation-cured spray coating, the preparation method of which is as follows:

[0049]

[0050]

[0051] A method for preparing a high-efficiency antibacterial and antiviral two-in-one deodorizing radiation-cured coating, comprising the following steps:

[0052] Put epoxy acrylate, polyester acrylate, polyurethane acrylate, dispersant and defoamer into a clean dispersion cylinder, and then disperse for 7 minutes at a speed of 1100r / min;

[0053] Then add the loaded nano-silver active agent and filler, and then disperse for 25 minutes at a rotation speed of 1300r / min until the fineness is ≤25μm and there is no oil shrinkage;

[0054] Finally, add leveling agent, photoinitiator and reactive diluent, and disperse for 12 minutes at a rotational speed of 1100r / min.

[0055] The advantage of this embodiment is: strong construction tolerance, not only can roll coating construction, spraying construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com