Preparation method of environment-friendly healthy coating

A technology of health and paint, applied in the field of paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method for an environmentally friendly and healthy paint, comprising the following steps:

[0025] (1) Add lithium salt with a molar mass of 1 times the cation exchange capacity of bentonite and water with a mass of 40 times that of bentonite to bentonite, mix well, stir at 40°C for 4 hours to carry out cation exchange reaction, and then filter with suction to filter the residue Then add the same amount of lithium salt and water, repeat the exchange process twice, then filter with suction, wash with distilled water, and dry at 50°C to obtain lithium-based bentonite; organic cations and water with a mass 50 times that of bentonite, mixed evenly, stirred at 40°C for 5 hours to carry out organic cation exchange reaction, then suction filtered, washed with distilled water and dried at 50°C, pulverized to obtain preliminary treated organobentonite; The preliminarily treated organobentonite is heated at 150°C for 10 hours to allow lithium ions to enter the lamel...

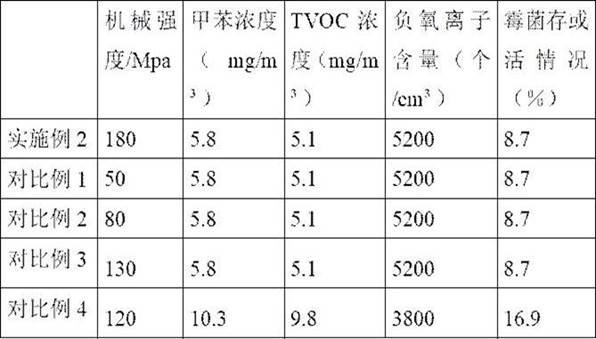

Embodiment 2

[0035] A preparation method for an environmentally friendly and healthy paint, comprising the following steps:

[0036] (1) Add lithium salt with a molar mass 3 times the cation exchange capacity of bentonite and water with a mass 60 times that of bentonite to bentonite, mix well, stir at 60°C for 6 hours to carry out cation exchange reaction, and then filter with suction to filter the residue Then add the same amount of lithium salt and water, repeat the exchange process 4 times, then filter with suction, wash with distilled water, dry at 80°C to obtain lithium-based bentonite; organic cations and water with a mass of 100 times that of bentonite, mixed evenly, stirred at 80°C for 7 hours to carry out organic cation exchange reaction, then suction filtered, washed with distilled water and dried at 80°C, pulverized to obtain preliminarily treated organobentonite; The preliminarily treated organobentonite is heated at 180°C for 20 hours to allow lithium ions to enter the lamella...

Embodiment 3

[0046] A preparation method for an environmentally friendly and healthy paint, comprising the following steps:

[0047] (1) Add lithium salt with a molar mass twice the cation exchange capacity of bentonite and water with a mass 50 times that of bentonite to bentonite, mix well, stir at 40°C for 5 hours to carry out cation exchange reaction, and then filter with suction to filter the residue Then add the same amount of lithium salt and water, repeat the exchange process 3 times, then filter with suction, wash with distilled water, and dry at 60°C to obtain lithium-based bentonite; add the molar amount of lithium-based bentonite to 20% of the cation exchange capacity of bentonite organic cations and water with a mass of 80 times that of bentonite, mixed evenly, stirred at 40°C for 5 hours to carry out organic cation exchange reaction, then suction filtered, washed with distilled water and dried at 50°C, pulverized to obtain preliminary treated organobentonite; The preliminarily...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com