Water-based antibacterial and antiviral anionic polyurethane resin and preparation method thereof

A polyurethane resin and anti-virus technology, which is applied in the field of water-based antibacterial and anti-virus anionic polyurethane resin and its preparation, can solve the problems of production pollution, complex synthesis technology, and no bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

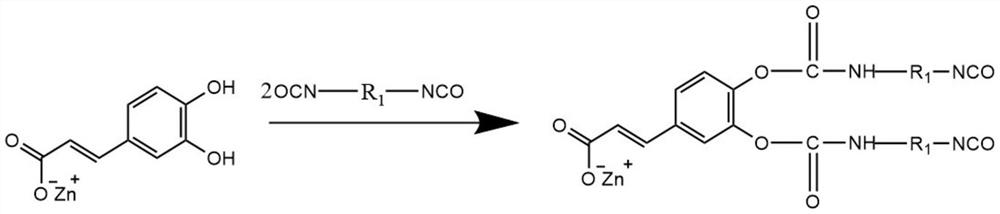

Method used

Image

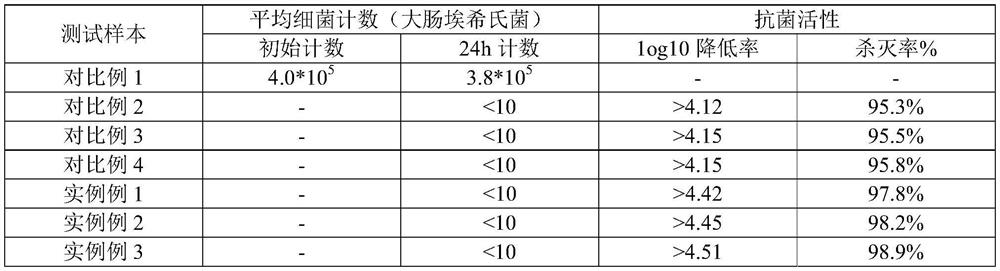

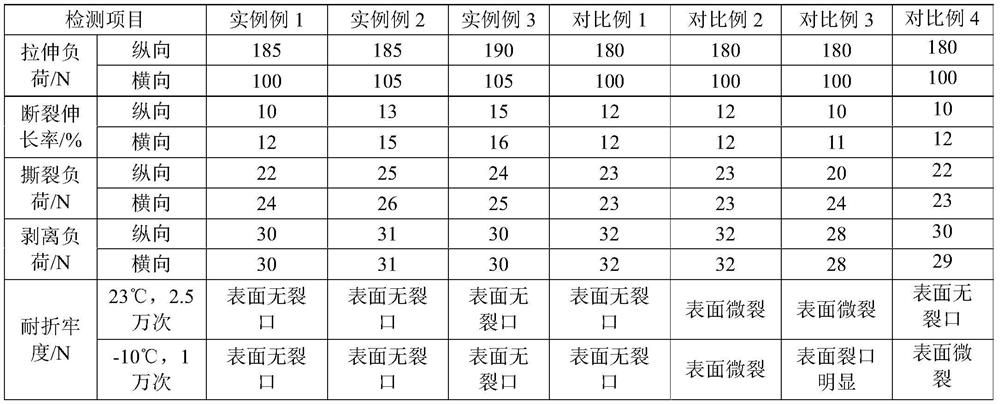

Examples

Embodiment 1

[0043] A kind of preparation method of waterborne antibacterial and antiviral anionic polyurethane resin

[0044] S1. Add 3g of caffeic acid and 1.5g of zinc hydroxide into a beaker filled with 10g of 50-60°C water and mix them, and stir evenly to obtain 14.5g of caffeic acid zinc solution with ph=9.

[0045] S2. Put 300g of polycarbonate polyol into a 1000mL four-necked flask equipped with a thermometer, agitator, and reflux condenser, raise the temperature to 110°C, dehydrate for 1h under a vacuum of >-0.09MPa, cool down to 60°C, and add 14.5g of zinc caffeate solution, stirred evenly, put in 70g of isophorone diisocyanate, and reacted at 90°C for 2h. The temperature was lowered to 70° C., 5 g of small molecule chain extender ethylene glycol was added, and the reaction was continued at 70° C. for 1 hour. Cool down to <50°C, add catalyst organic bismuth 0.5g and acetone 40ml, stir and raise the temperature to 75°C for 4h. Then cool down to 20°C, add 80ml of acetone, and sti...

Embodiment 2

[0049] A kind of preparation method of waterborne antibacterial and antiviral anionic polyurethane resin

[0050] S1. Add 4g of caffeic acid and 1.75g of zinc hydroxide into a beaker filled with 10g of 50-60°C water and mix, and stir evenly to obtain 15.75g of caffeic acid zinc solution with ph=8.7.

[0051] S2. Put 310g of polytetrahydrofuran ether polyol into a 1000mL four-necked flask equipped with a thermometer, a stirrer, and a reflux condenser, raise the temperature to 110°C, dehydrate under a vacuum >-0.09MPa for 1h, cool down to 60°C, and add 15.75g of zinc caffeate solution was stirred evenly, then 72g of isophorone diisocyanate was added, and reacted at 90°C for 2h. The temperature was lowered to 70°C, 6g of small molecule chain extender ethylene glycol was added, and the reaction was continued at 70°C for 1 hour. Cool down to <50°C, add catalyst organic bismuth 0.7g and acetone 40ml, stir and raise the temperature to 75°C for 4h. Then cool down to 20°C, add 80ml o...

Embodiment 3

[0055] A kind of preparation method of waterborne antibacterial and antiviral anionic polyurethane resin

[0056] S1. Add 4.5g of caffeic acid and 1.9g of zinc hydroxide into a beaker filled with 10g of 50-60°C water and mix, and stir evenly to obtain 16.4g of caffeic acid zinc solution with ph=8.8.

[0057] S2. Put 315g of polytetrahydrofuran ether polyol into a 1000mL four-necked flask equipped with a thermometer, a stirrer, and a reflux condenser, raise the temperature to 110°C, dehydrate under a vacuum >-0.09MPa for 1h, cool down to 60°C, and add 16.4g of zinc caffeate solution was stirred evenly, and then 56g of hexamethylene diisocyanate was added, and reacted at 90°C for 2h. The temperature was lowered to 70°C, 7.8g of small molecule chain extender 1,4-butanediol was added, and the reaction was continued at 70°C for 1 hour. Cool down to <50°C, add catalyst organic bismuth 0.8g and acetone 40ml, stir and raise the temperature to 75°C for 4h. Then cool down to 20°C, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com