Breathable waterproof anti-ultraviolet fabric and preparation method and application thereof

An anti-ultraviolet, fabric technology, applied in the field of outdoor fabrics, can solve the problems of anti-ultraviolet, such as waterproof, waterproof, anti-ultraviolet or single breathable, can not be breathable, etc., to achieve excellent lasting antibacterial effect, strengthen anti-ultraviolet performance. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

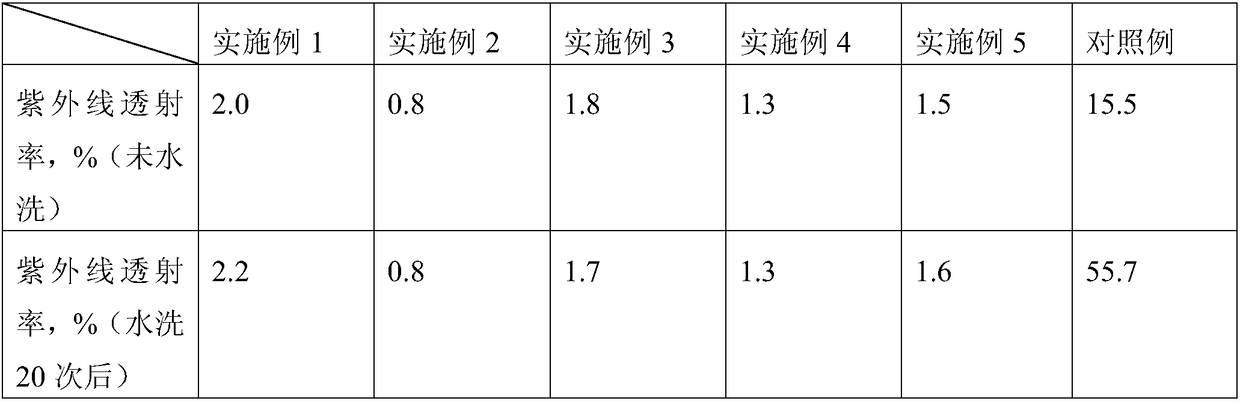

Examples

Embodiment 1

[0027] Weigh 100 parts of PVC and 0.1 part of anti-ultraviolet absorber UV-531, mix evenly and melt blend at 170°C to obtain UV-modified PVC; weigh 40 parts of UV-modified PVC, 40 parts of polypropylene and 20 parts of polyester , after mixing evenly, the anti-ultraviolet gray fabric is obtained through high-speed melt spinning, weaving and finishing at 190°C; the nano-silver is coated on the surface of the anti-ultraviolet gray fabric by vacuum sputtering method, and the breathable, waterproof and anti-ultraviolet fabric of the present invention is obtained a.

Embodiment 2

[0029] Weigh 100 parts of PVC and 10 parts of anti-ultraviolet absorber UV-326, mix them uniformly and melt blend at 190°C to obtain UV-modified PVC; weigh 50 parts of UV-modified PVC, 40 parts of polypropylene and 15 parts of polyester , after mixing evenly, high-speed melt spinning, weaving, and finishing at 180°C to obtain an anti-ultraviolet gray fabric; the nano-silver is coated on the surface of the anti-ultraviolet gray fabric by vacuum sputtering to obtain the breathable, waterproof, and anti-ultraviolet fabric B of the present invention .

Embodiment 3

[0031] Weigh 90 parts of PVC and 0.1 part of anti-ultraviolet absorber UV-327, mix them uniformly and melt blend at 180°C to obtain UV-modified PVC; weigh 40 parts of UV-modified PVC, 35 parts of polypropylene and 20 parts of polyester , after mixing evenly, high-speed melt spinning, weaving, and finishing at 185°C to obtain an anti-ultraviolet gray cloth; the nano-silver is coated on the surface of the anti-ultraviolet gray cloth by magnetron sputtering to obtain the breathable, waterproof, and anti-ultraviolet fabric of the present invention c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com