Fly ash based composite material as well as preparation method and application thereof

A composite material and fly ash technology, which is applied in the field of fly ash-based composite materials and its preparation, can solve the problems of affecting application, easy loss, and poor long-lasting antibacterial performance, and achieve high antibacterial activity, increase added value, Good long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

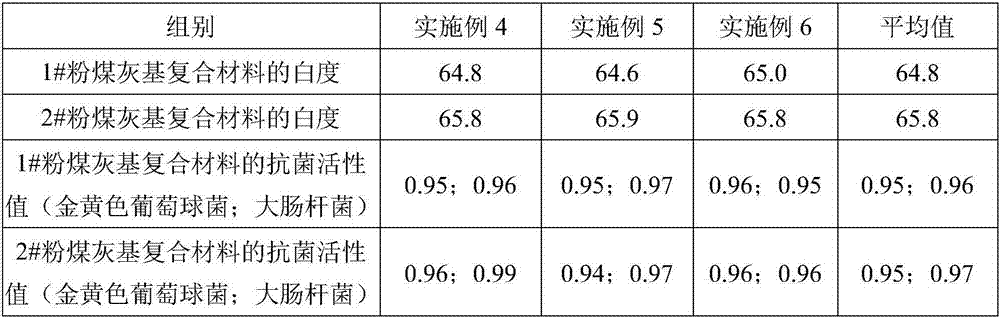

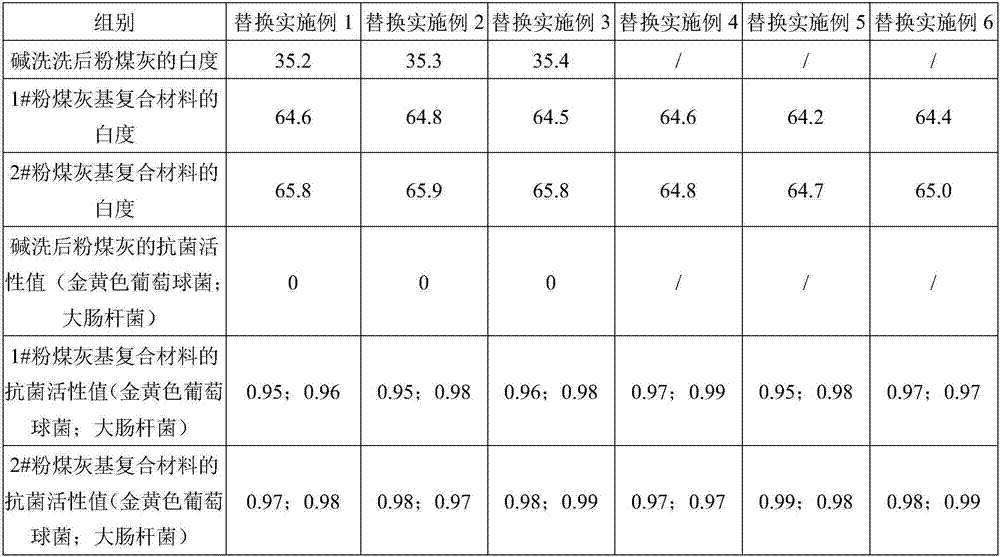

Examples

Embodiment 1

[0026] A method for preparing a fly ash-based composite material, comprising the following steps:

[0027] (1) With fly ash as raw material, the raw material is added to 0.5mol / L hydrochloric acid for pickling, then the pickled raw material is washed with water until the pH value of the eluate reaches 7, and then to the washed Add ethylene glycol, sodium polyacrylate and alkylphenol polyoxyethylene ether to the raw material, the mass ratio of raw material to ethylene glycol, sodium polyacrylate and alkylphenol polyoxyethylene ether is 100:8:2.5:0.6, wet process Grinding until the particle size of the raw material is ≤25 microns (this process is also a dispersion process), and finally a base material slurry with a solid content of 50% is prepared;

[0028] (2) Add a saturated solution of zinc sulfate to the base material slurry first, then slowly add (to reduce the crystallization rate) a saturated solution of barium chloride dropwise at 55°C under stirring conditions, the mate...

Embodiment 2

[0030] A method for preparing a fly ash-based composite material, comprising the following steps:

[0031] (1) With fly ash as raw material, the raw material is added to 0.1mol / L hydrochloric acid for pickling, then the pickled raw material is washed with water until the pH value of the eluate reaches 6, and then to the washed Add ethylene glycol, sodium polyacrylate and alkylphenol polyoxyethylene ether to the raw material, the mass ratio of raw material to ethylene glycol, sodium polyacrylate and alkylphenol polyoxyethylene ether is 100:5:0.5:0.1, wet process Grinding until the particle size of the raw material is ≤25 microns, and finally preparing a base material slurry with a solid content of 45%;

[0032] (2) Add a saturated solution of zinc sulfate to the substrate slurry first, then slowly add a saturated solution of barium chloride dropwise at 50°C under stirring conditions, the solid-liquid ratio of the substrate slurry to the saturated solution of zinc sulfate is 3g / ...

Embodiment 3

[0034] A method for preparing a fly ash-based composite material, comprising the following steps:

[0035] (1) With fly ash as raw material, the raw material is added to 1mol / L hydrochloric acid for pickling, then the pickled raw material is washed with water until the pH value of the eluate reaches 8, and then the washed raw material is added Add ethylene glycol, sodium polyacrylate and alkylphenol polyoxyethylene ether, the mass ratio of raw material to ethylene glycol, sodium polyacrylate and alkylphenol polyoxyethylene ether is 100:10:3:1, wet grinding Treat until the particle size of the raw material is ≤25 microns, and finally prepare a substrate slurry with a solid content of 55%;

[0036] (2) Add a saturated solution of zinc sulfate to the substrate slurry first, then slowly add a saturated solution of barium chloride dropwise at 60°C under stirring conditions, the solid-liquid ratio of the substrate slurry to the saturated solution of zinc sulfate is 10g / 40mL , the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com