Method for preparing antibacterial masterbatches by using discarded and/or waste plastic as raw materials

A technology of waste plastics and antibacterial masterbatch, which is applied in the field of waste and/or waste plastics, which can solve the problems of easy loss of antibacterial properties, poor thermal stability, and increased costs, so as to improve durable antibacterial performance, enhance thermal stability, and reduce loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

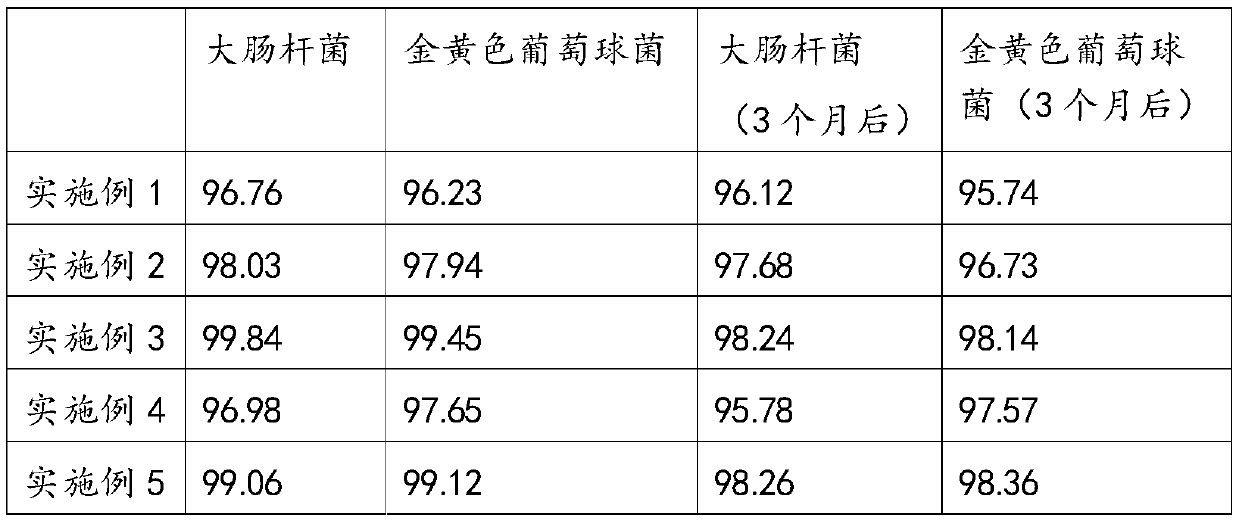

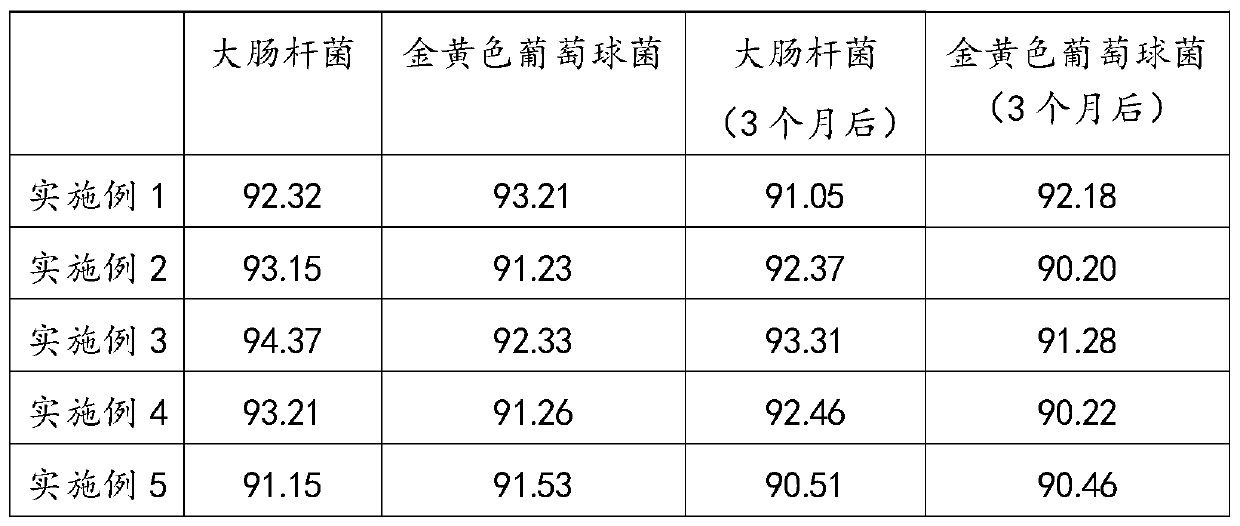

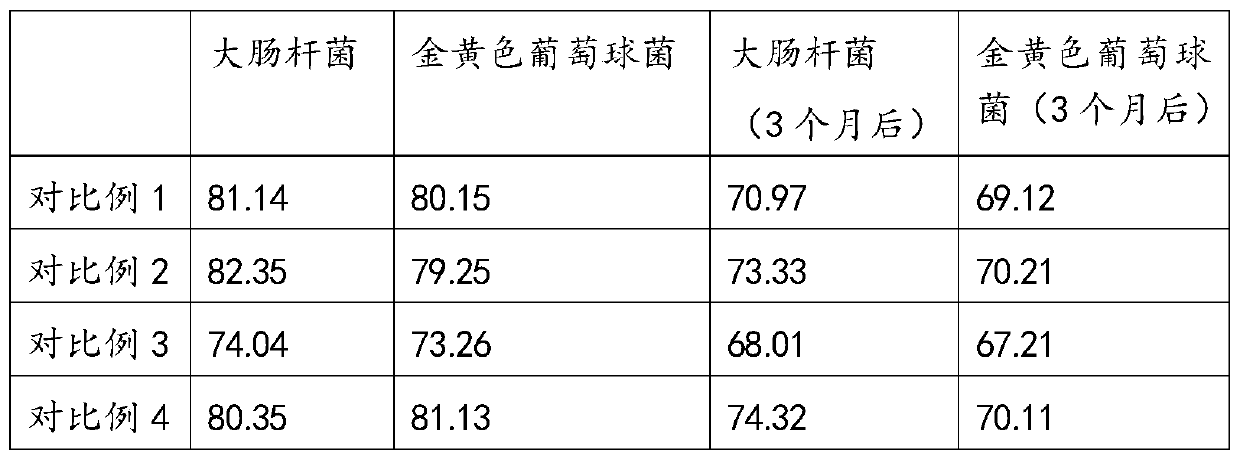

Examples

Embodiment 1

[0051] The above-mentioned method for preparing antibacterial masterbatch with waste plastics as raw material comprises the following steps:

[0052] (1) Sorting and cleaning 100 parts of waste PE materials with a melt index of 20, and drying them at 90°C; they were firstly crushed to 20 mesh, then finely crushed to 60 mesh, and then twin-screw extruded at 150°C out to obtain waste plastic masterbatch;

[0053] (2) Add 0.75 parts of chlorinated maleic acid-modified polyethylene and 1.5 parts of paraffin to the waste plastic masterbatch obtained by extrusion as the first surface modifier, and modify it at 90°C at a speed of 1200rpm / min. properties, and then mix the obtained modified product with about 700 meshes of fly ash loaded with antibacterial agents, then add 3.5 parts of sodium tripolyphosphate and 3 parts of stearic acid as the second surface modifier, and then heat it at 140 ° C Process at a speed of 600rpm / min, the temperature during twin-screw extrusion is 170°C, th...

Embodiment 2

[0061] In embodiment 2, the fly ash loaded with antibacterial agent is the fly ash loaded with zinc oxide and quaternary ammonium salts, and its ratio is:

[0062] The weight ratio of zinc oxide and fly ash is 1:3;

[0063] The weight ratio of quaternary ammonium salts and fly ash is 1:12.

Embodiment 3

[0064] In embodiment 3, the fly ash loaded with antibacterial agent is the fly ash loaded with zinc oxide, and its ratio is:

[0065] The weight ratio of zinc oxide and fly ash is 1:3.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com