Hydrophobic durable antibacterial polypropylene composite material and preparation method thereof

An antibacterial polypropylene and composite material technology, which is applied in the field of polypropylene composite materials, can solve the problems of antibacterial materials such as difficult antibacterial effect, antibacterial agent failure, and antibacterial agent difficulty, etc., to achieve easy removal, good stain resistance, and good self-cleaning sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a hydrophobic and durable antibacterial polypropylene composite material, the specific steps of its preparation method are as follows:

[0033] (1) Weigh 98 parts of polypropylene resin, 0.4 parts of antibacterial agent, 2 parts of silicone oil, and 0.8 parts of auxiliary agent according to the weight ratio, and stir and mix in a mixer for 5 minutes.

[0034] (2) Add the above-mentioned mixed materials into a twin-screw extruder, melt, extrude, granulate, and dry to obtain a durable antibacterial hydrophobic self-cleaning polypropylene composite material. The rotational speed of the twin-screw extruder is 400 rpm, and the processing temperature is 200°C.

[0035] The antibacterial rate of Escherichia coli and Staphylococcus aureus of the prepared hydrophobic and durable antibacterial polypropylene composite material is 95%; the antibacterial attenuation period of the durable antibacterial polypropylene composite material is 4 months. The hydrop...

Embodiment 2

[0037] This embodiment provides a hydrophobic and durable antibacterial polypropylene composite material, the specific steps of its preparation method are as follows:

[0038] (1) Preparation of hydrophobic functional masterbatch

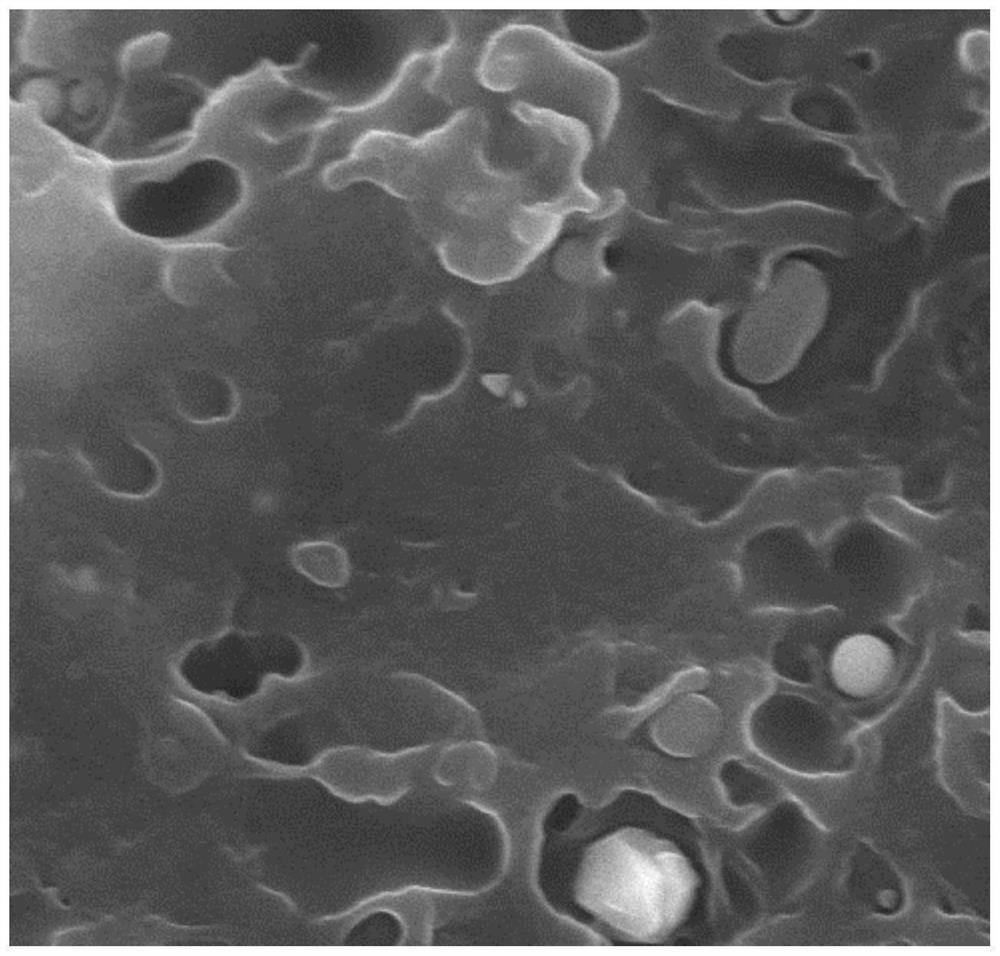

[0039] Mix polyethylene, ethylene-octene copolymer, PTFE and hydrophobic agent in a mixer for ten minutes and wait until they are uniform, then put the mixed material into a twin-screw extruder, and undergo melting, extrusion, granulation, The hydrophobic functional masterbatch is obtained by drying, and its SEM image is as follows figure 1 shown.

[0040]Among them, the mass ratio of polyethylene, ethylene-octene copolymer, PTFE and hydrophobic agent is: 100:17:10:15; the speed of the twin-screw extruder is 400 rpm, and the processing temperature is 180°C;

[0041] (2) Weigh 93 parts of polypropylene resin, 0.4 part of antibacterial agent, 5 parts of hydrophobic functional masterbatch, 2 parts of silicone oil and 0.8 part of auxiliary agent accor...

Embodiment 3

[0045] This embodiment provides a hydrophobic and durable antibacterial polypropylene composite material, the specific steps of its preparation method are as follows:

[0046] (1) Preparation of hydrophobic functional masterbatch

[0047] Mix polyethylene, ethylene-octene copolymer and hydrophobic agent in a mixer for ten minutes and wait until they are uniform, then put the mixed material into a twin-screw extruder, and process it through melting, extrusion, granulation, and drying. Obtain hydrophobic functional masterbatch.

[0048] Among them, the mass ratio of polyethylene, ethylene-octene copolymer, PTFE and hydrophobic agent is: 100:17:10:15; the speed of the twin-screw extruder is 400 rpm, and the processing temperature is 180°C;

[0049] (2) Weigh 93 parts of polypropylene resin, 0.8 parts of antibacterial agent, 2 parts of silicone oil, 5 parts of functional hydrophobic masterbatch and 0.8 parts of auxiliary agent according to the weight ratio, stir and mix in the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com