Silver-containing antibacterial thin-layer composite film as well as preparation method and application thereof

A composite membrane and thin-layer technology, which is applied in the field of separation membranes, can solve the problems of poor durability of antibacterial performance on the surface of the membrane, increase the preparation steps, and long post-processing time, etc., to achieve increased durable antibacterial ability, simple preparation method, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

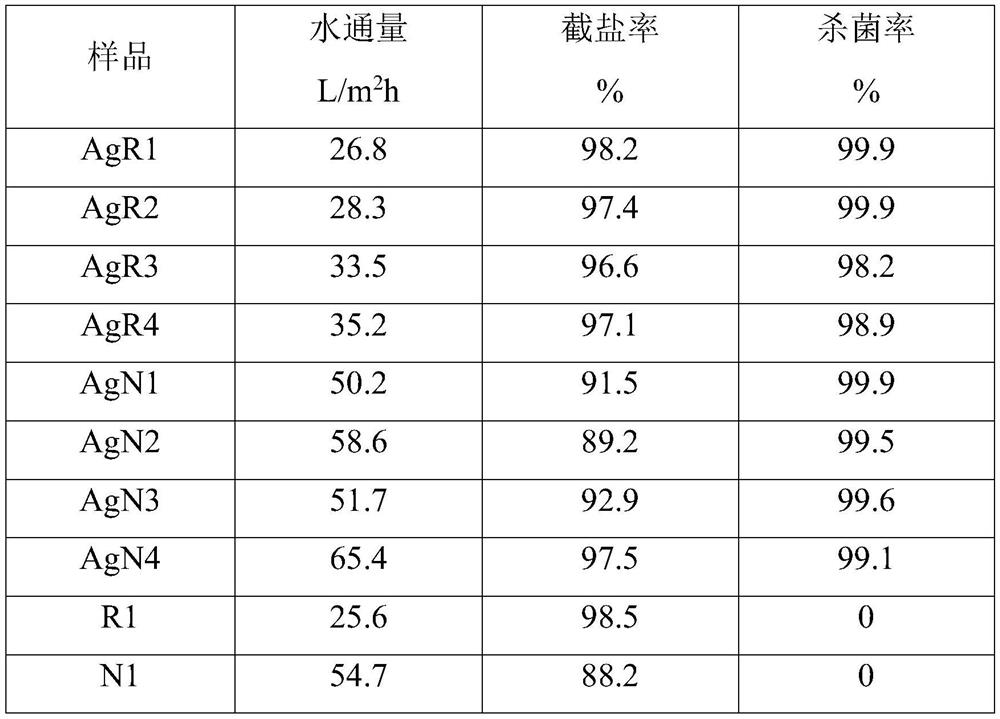

[0057] Add 2 g of ethylenediamine and 100 mL of deionized water to 1 g of silver oxide and stir to obtain an ethylenediamine solution of silver oxide, and add 100 mL of Isopar E to 0.1 g of trimesoyl chloride and stir to obtain a trimesoyl chloride solution. The upper surface of the polysulfone support layer is contacted with the ethylenediamine solution containing silver oxide, and the liquid is discharged after contacting at 25°C for 30s; then, the upper surface of the support layer is contacted with the trimesoyl chloride solution, and the liquid is drained after contacting for 30s at 25°C ; Then, put the film into an oven and heat it at 70°C for 3 minutes to obtain the composite film AgR1. X-ray photoelectron spectroscopy test shows that the mass content of silver element on the composite film surface is 5.5wt%. Wherein, the average thickness of the polyamide separation layer is 218nm.

[0058] Soak the obtained composite membrane AgR1 in water for 24 hours, and then test...

Embodiment 2

[0060] Add 1 g of ethylenediamine and 100 mL of deionized water to 3 g of silver sulfate and stir to obtain an ethylenediamine solution of silver sulfate, and add 100 mL of Isopar G to 0.1 g of trimesoyl chloride and stir to obtain a trimesoyl chloride solution. Contact the upper surface of the polysulfone support layer with an ethylenediamine solution containing silver sulfate, and drain the liquid after contacting it for 60 seconds at 25°C; then, contact the upper surface of the support layer with a trimesoyl chloride solution, and drain the liquid after contacting it for 30 seconds at 25°C ; Then, put the film into an oven and heat it at 100°C for 2 minutes to obtain the composite film AgR2. X-ray photoelectron spectroscopy test shows that the mass content of silver element on the composite film surface is 8.1wt%. Wherein, the average thickness of the polyamide separation layer is 195 nm.

[0061] Soak the obtained composite membrane AgR2 in water for 24 hours, and then te...

Embodiment 3

[0063] 0.5 g of ethylenediamine and 100 mL of deionized water were added successively to 0.1 g of silver carbonate and stirred to obtain an ethylenediamine solution of silver carbonate, and 100 mL of Isopar E was added to 0.05 g of trimesoyl chloride and stirred to obtain a solution of trimesoyl chloride. Contact the upper surface of the above polysulfone support layer with ethylenediamine solution containing silver carbonate, and drain the liquid after contacting it at 25°C for 60 seconds; then, contact the upper surface of the support layer with trimesoyl chloride solution, and drain it after contacting it for 60 seconds at 25°C ; Then, put the film into an oven and heat it at 70°C for 4min to obtain the composite film AgR3. X-ray photoelectron spectroscopy test shows that the mass content of silver element on the composite film surface is 0.8wt%. Wherein, the average thickness of the polyamide separation layer is 182 nm.

[0064] The obtained composite membrane AgR3 was so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com