Patents

Literature

46results about How to "Strong antibacterial durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of Ag-HA and applications used as anti-bacteria agent

The invention relates to a method for preparing hydroxyapatite loading Ag (HAP-Ag) and an application as an antimicrobial. The preparation method thereof mainly includes the following steps: hydrothermal reaction step, that is adding the hydroxyapatite to the mixed solution of the silver nitrate and the cerous nitrate, wherein the concentration of both the silver nitrate and the cerous nitrate is 0.01mol / L-0.2mol / L, the reaction temperature is 30 DEG C - 60 DEG C and the reaction time is 2-5 hours; the steps of depositing, sucking and filtrating, drying, and grinding. The novel preparation method of the HAP-Ag and the application as the antimicrobial have remarkable antimicrobial products with high durability, long-term antimicrobial effect, convenient usage, no toxin and harmlessness, so as to be applicable to pregnant women and babies.

Owner:朱鹏播

Antibacterial fabric finishing agent and its preparation method

InactiveCN1730807AHas broad-spectrum antibacterial abilityOvercome the disadvantages of poor killing effectFibre treatmentMedicineColor changes

The present invention discloses one kind of antiseptic fabric finishing size and its preparation process. The antiseptic fabric finishing size consists of antiseptic agent 1-3 wt%, dispersant 0.05-0.15 wt%, adhesive 10-20 wt%, thickener 2-2.5 wt%, and color change inhibitor 0.08-0.2 wt%, except water. The antiseptic fabric finishing size has broad-spectrum antiseptic effect and the fabric finished with the antiseptic fabric finishing size has lasting antiseptic effect and has 97.5 % of the antiseptic effect maintained after washing for 50 times. The added color change inhibitor can prevent the color change of fabric effectively while raising the antiseptic effect.

Owner:NORTHWEST UNIV(CN)

Preparation method of chitosan copper fibers

InactiveCN105887242ANo pollution in the processHigh coordination coefficientElectroconductive/antistatic filament manufactureFlame-proof filament manufactureFiberAir filter

The invention discloses a preparation method of chitosan copper fibers. The preparation method is characterized in that certain weight of copper salt is added into the raw material to allow chitosan and metal copper ions to perform coordination complexation so as to generate the complex of the chitosan and the copper ions, and wet spinning is used to obtain the chitosan copper fibers. The prepared chitosan copper fibers are high in specific surface area, high in antibacterial performance, excellent in antistatic and flame-retardant performance and applicable to fields such as textile and garments, disposable hygienic materials and air filter materials. The preparation method is simple in process, high in process condition controllability, and easy in material structure and performance control.

Owner:TIANJIN ZHONGSHENG BIO ENG CO LTD

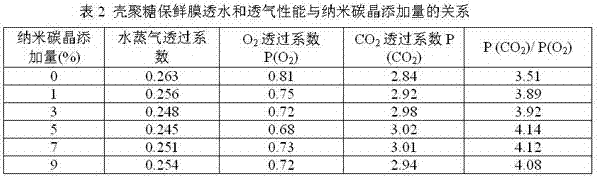

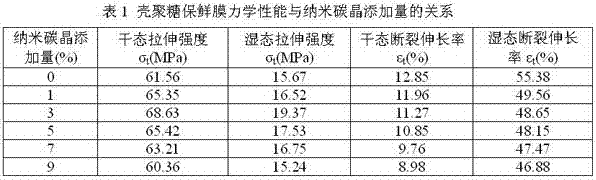

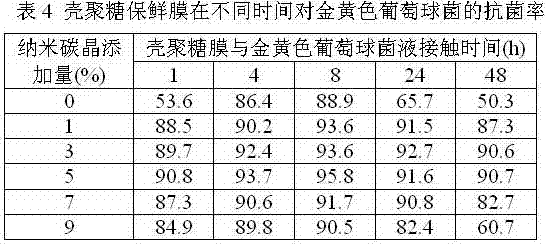

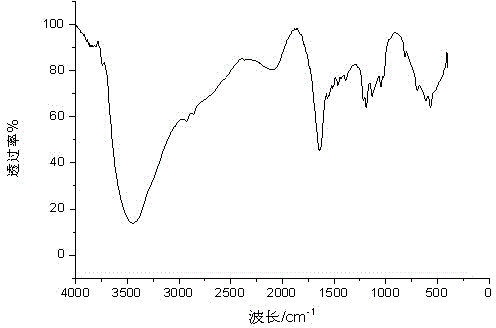

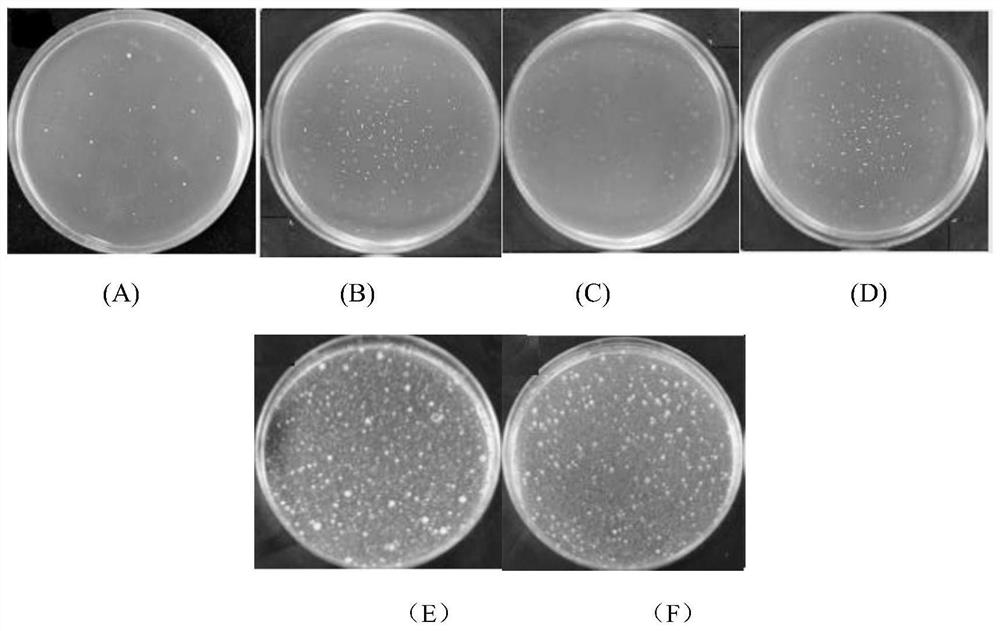

Preparation method of chitosan composite preservative film

The invention discloses a preparation method of a chitosan composite preservative film. The preparation method comprises the following steps: dissolving chitosan in an acetic acid solution, heating to 50 to 65DEG C, and stirring until the chitosan is completely dissolved, so as to obtain a solution A; dispersing modified nano carbon crystal in the solution A, wherein the adding amount of the modified nano carbon crystal is 1 to 9 percent; then adding a plasticizer which accounts for 0.2 to 1 percent of the volume of the solution A, and carrying out stirring, ultrasonic dispersion, standing and ultrasonic degassing for 10 to 15 minutes to obtain a solution B; casting the solution B to form a film, standing and drying at the drying temperature of 35 to 55DEG C; then putting into 0.01 to 0.02mol / L of NaOH solution, soaking for 0.5 to 1 hour, flushing with distilled water, uncovering the film and drying in the sun to obtain the composite preservative film. The chitosan composite preservative film disclosed by the invention has relatively low water vapor permeability, so that excessive loss of water in fruits and vegetables is avoided; the chitosan composite preservative film has relatively good sterilizing function and strong antibacterial durability, i.e., an obvious sterilizing effect can be realized within one hour, and the antibacterial rates for escherichia coli and staphylococcus aureus after 48 hours still can reach 90 percent or above, so the preservation time of the fruits and the vegetables is prolonged.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

Preparation method of antibacterial polyester fabrics

The invention discloses a preparation method of antibacterial polyester fabrics and belongs to the technical field of textile materials. The preparation method comprises the following steps: after sequentially carrying out continuous modification treatment on polyester fabric original samples including clothing, tablecloth and curtains by virtue of a Na2CO3 solution, a mixed solution of alizarin red and sodium cyclamate, a mixed solution of aniline, hydrochloride and ammonium persulfate, a mixed solution of DL-mercaptosuccinic acid and D-penicillamine and a nano-silver solution, putting the treated polyester fabric original samples into a silver tetrafluoroborate aqueous solution, carrying out reaction at room temperature for 30 minutes, washing the product by a great deal of water, and drying at the temperature of 40 DEG C to obtain the antibacterial polyester fabrics. The antibacterial polyester fabrics prepared by the preparation method have the broad-spectrum antibacterial property, are good in antibacterial effect particularly on staphylococcus aureus, bacillus subtilis, Escherichia coli and pseudomonas aeruginosa, are strong in persistence and have the single-strain inhibitory rate reaching 95-99.7 percent after being washed for 30 times.

Owner:MAANSHAN JINZI TEXTILE OMAMENT +1

Preparation method for anti-microbial cotton material

InactiveCN105178012AReasonable compositionImprove antibacterial propertiesFibre treatmentYtterbium fluoridePolymer science

The invention relates to a preparation method for an anti-microbial cotton material. Cotton fibers are placed in a finishing liquid comprising amino-terminated hyperbranched polymers, micromolecule functional agents, ytterbium fluoride and nano-titanium dioxide, dipping treatment is carried out, and anti-microbial cotton fibers are obtained. The cotton fibers finished through the method has good hand feeling, air permeability and fastness to washing and has strong anti-microbial endurance. Treatment is convenient, the method is simple, and operation is easy.

Owner:SUZHOU KEMIAO NEW MATERIAL

Efficient antibacterial chitosan fiber and preparation method thereof

InactiveCN105839226AImprove antibacterial propertiesImprove anti-static effectWet spinning methodsArtifical filament manufactureFiberFiltration

The invention discloses an efficient antibacterial chitosan fiber and a preparation method thereof. The method comprises the following steps: dissolving chitosan with certain viscosity and certain degree of deacetylation, copper salt and urea which are utilized as raw materials in dilute acetic acid in a certain mass ratio, so as to prepare a spinning solution; filtering and defoaming; spraying out from a spinneret plate; then performing coagulating bath solidification, tensioning, washing and drying processes, thereby obtaining the efficient antibacterial chitosan fiber. The method is simple in preparation process, high in technological condition controllability and easily controllable in material structure and performance; the prepared material has a high specific surface area, high antibacterial property and excellent antistatic property and flame resistance, and can be applied to the field of spinning, medical treatment and public health, filtration materials and the like.

Owner:TIANJIN ZHONGSHENG BIO ENG CO LTD

Reactive antimicrobial additive and preparation method thereof

InactiveCN104650298AImprove antibacterial propertiesStrong antibacterial durabilityFungicidesDisinfectantsPolymer sciencePolyhexamethylene guanidine

The invention discloses a reactive antimicrobial additive and a preparation method thereof. The reactive antimicrobial additive is modified polyhexamethylene guanidine hydrochloride and is prepared from the following raw materials in parts by weight: 2-6 parts of polyhexamethylene guanidine hydrochloride and 5-20 parts of a vinyl monomer. According to the preparation method, the vinyl monomer and polyhexamethylene guanidine hydrochloride are subjected to a direct reaction or a condensation reaction so as to obtain the product. The direction reaction comprises the following operating steps: dissolving polyhexamethylene guanidine hydrochloride and vinyl monomer in dimethyl sulfoxide, heating, directly reacting, thereby obtaining the reactive antimicrobial additive; and the condensation reaction comprises the following operating steps: dissolving the vinyl monomer in water or dimethyl sulfoxide, adding a condensing agent and an activating agent into the solution to realize activating, adding polyhexamethylene guanidine hydrochloride for reacting, thereby obtaining the reactive antimicrobial additive. The reactive antimicrobial additive has broad-spectrum high-efficiency antibacterial performance and can be fixedly arranged on a high polymer matrix used for manufacturing antibacterial materials in a chemical bond mode, so that the antimicrobial is prevented from being taken by a human body and the antibacterial effect is maintained for a long time.

Owner:米尔斯(北京)文化发展股份有限公司

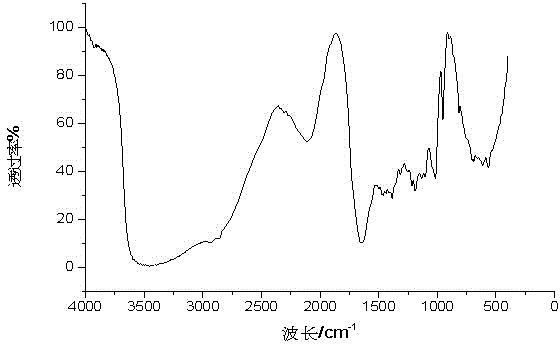

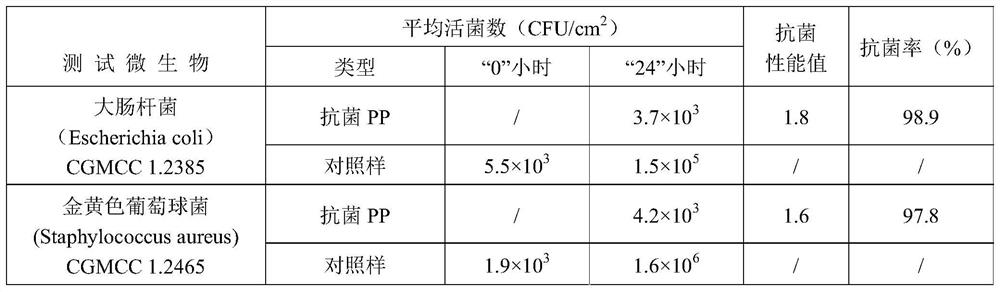

A kind of antibacterial powder and its preparation method and use

ActiveCN110547302BImprove antibacterial propertiesStrong antibacterial durabilityBiocideFungicidesSilicic acidEthyl ester

The invention relates to an antibacterial powder, and a preparation method and an application thereof. The antibacterial powder is prepared by using oxide of silicon as a carrier which is loaded withsilver-copper-zinc composite metal elements. The preparation method comprises the following steps: with soluble silver salt, soluble zinc salt and soluble copper salt as raw materials, controlling a pH of a system with an excess complexing agent to 4 to 5, then adding an isopropanol solution containing ethyl orthosilicate under an ice bath condition, slowly raising a temperature, controlling the hydrolysis rate of tetraethyl orthosilicate, drying a solution by distillation, placing a solid into a muffle furnace, and carrying out calcination at 400 to 500 DEG C so as to obtain an antibacterialpowder. The antibacterial powder provided by the invention has a basic particle size of less than 10 um, is low in cost and superior in antibacterial performance, contains a variety of antibacterial metal ions, and can be extensively applied in antibacterial addition and application of various materials like plastics.

Owner:晋大纳米科技(厦门)有限公司

Waterproof finishing agent and preparation method and application method thereof

InactiveCN110409181AGood film formingImprove waterproof performanceBiochemical fibre treatmentLiquid repellent fibresMoisture permeabilityMaterials science

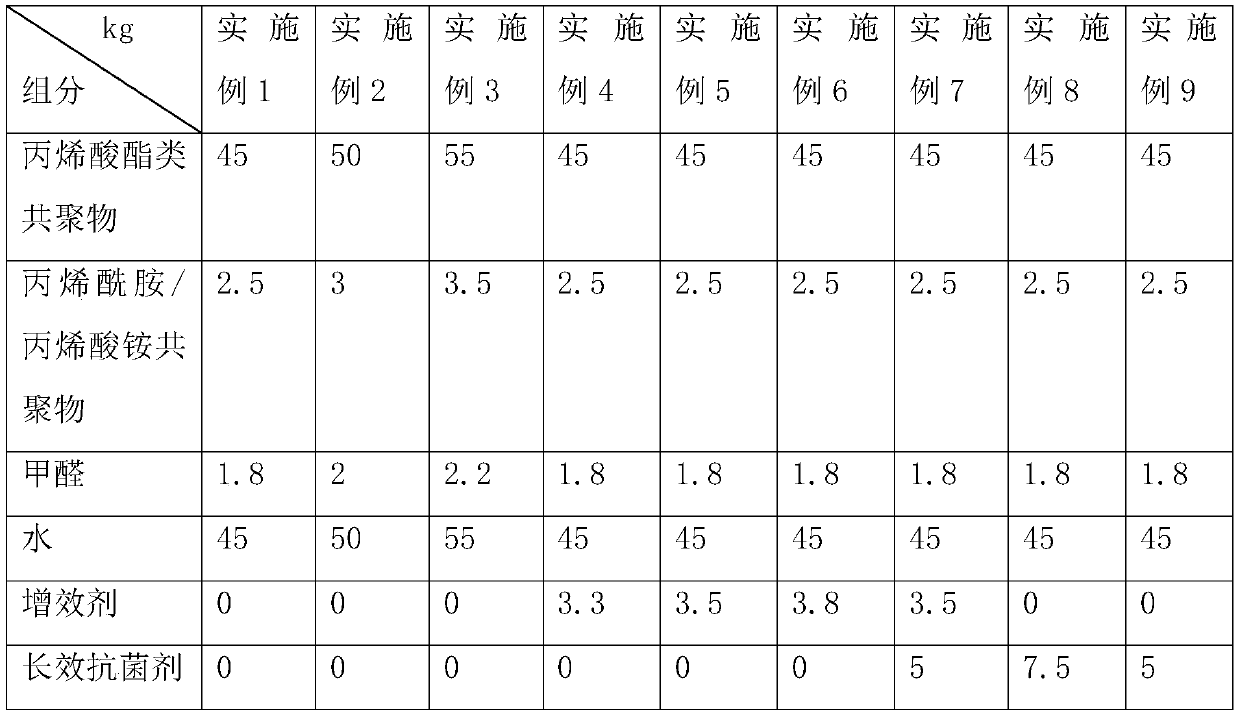

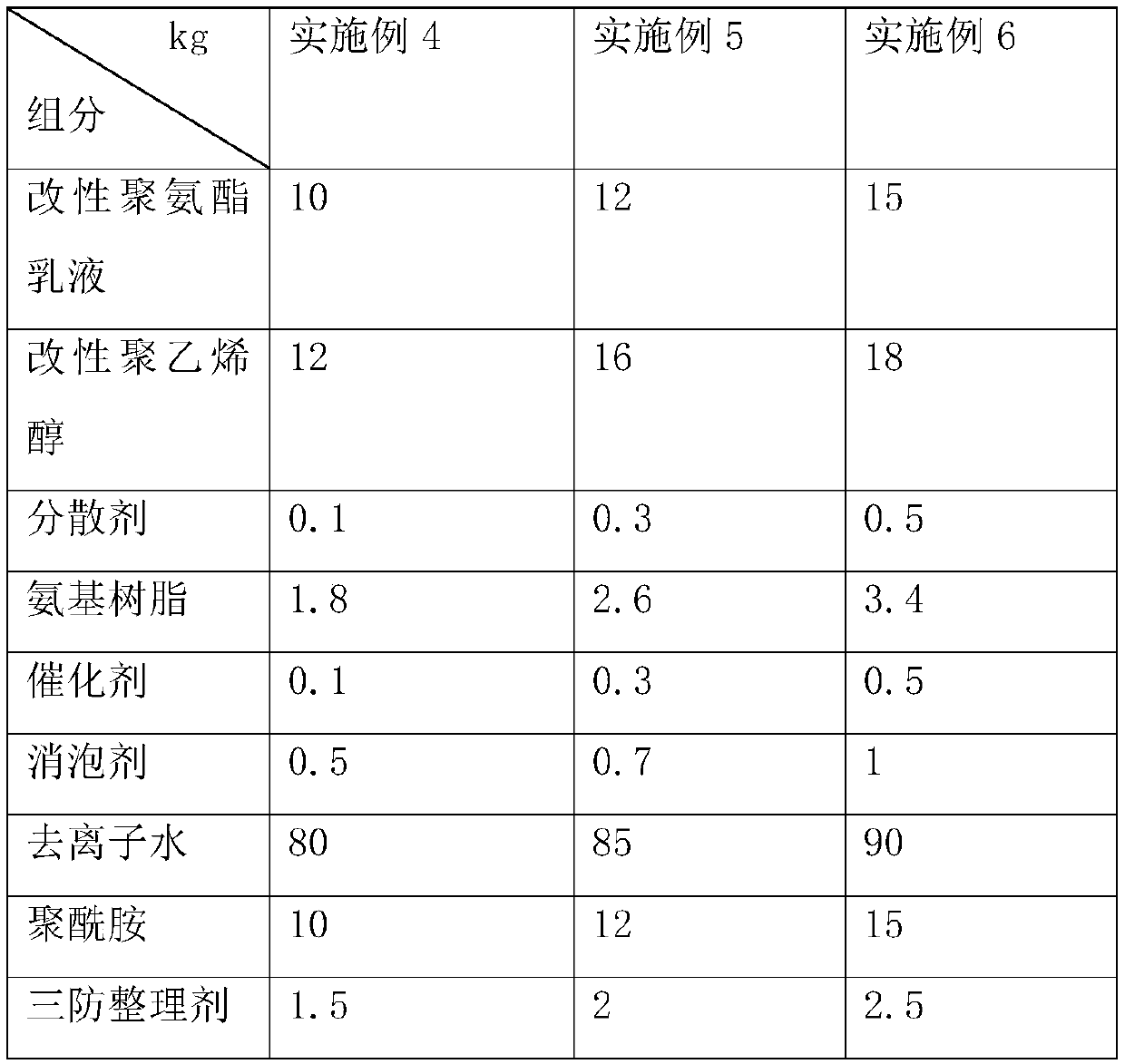

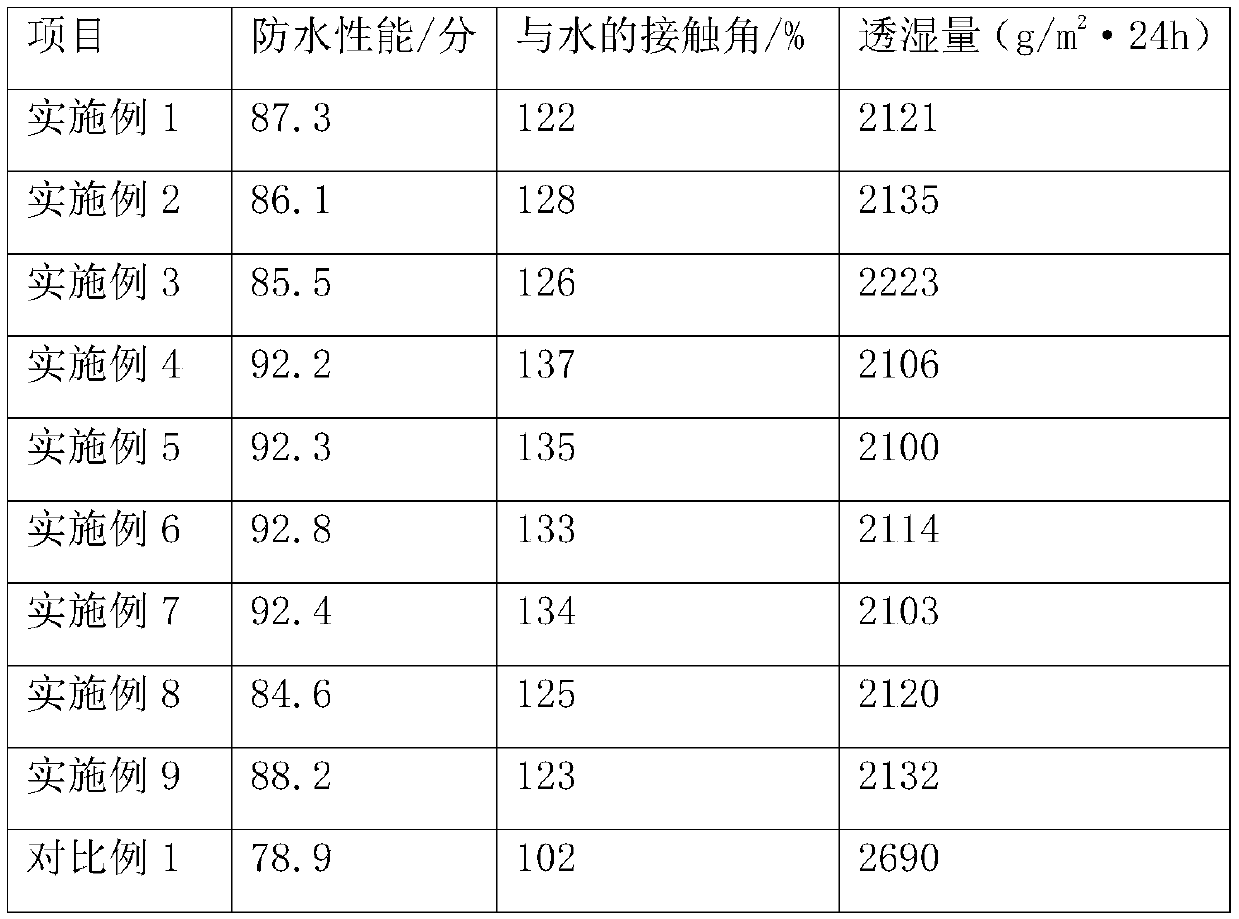

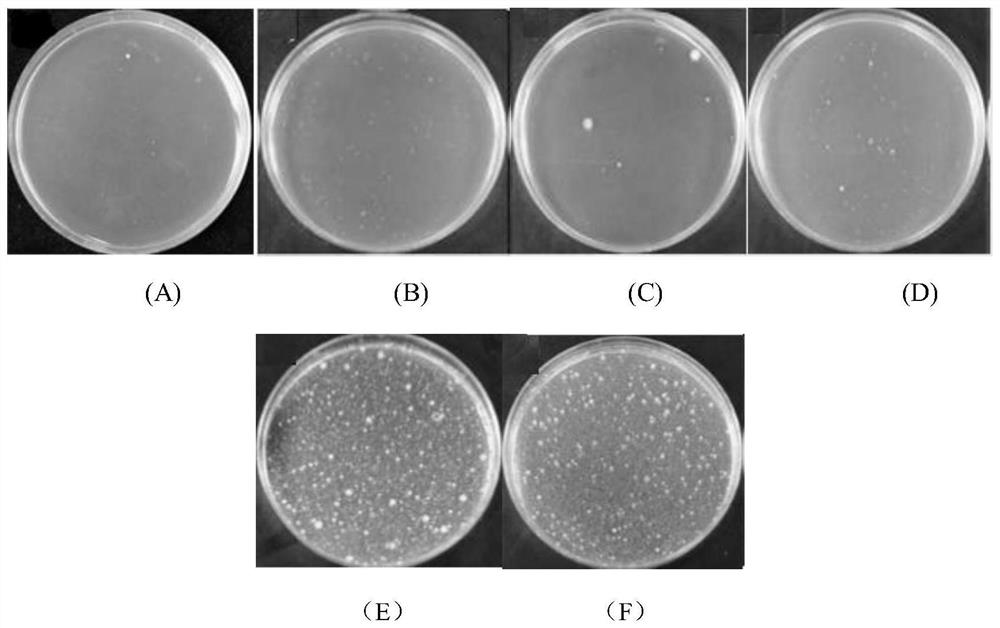

The invention discloses a waterproof finishing agent and a preparation method and application method thereof. the waterproof finishing agent is prepared from, by weight, 45-55 parts of an acrylate copolymer, 2.5-3.5 parts of an acrylamide / ammonium acrylate copolymer, 1.8-2.2 parts of formaldehyde and 45-55 parts of water. The waterproof finishing agent can make the surface elasticity of a waterproof curtain for a bathroom good and soft, and has the advantages of being good in waterproof performance, low in breathability and moisture permeability, and excellent in antibacterial performance.

Owner:三赢家居用品(河源)有限公司

Processing technique of antibacterial polyurethane filament

InactiveCN107299408AEasy to produceIncrease productivityMonocomponent synthetic polymer artificial filamentArtifical filament manufactureChemistryMelt spinning

The invention discloses a processing technique of an antibacterial polyurethane filament. The processing technique comprises the following steps: a, cleaning thermoplastic polyurethane chips, drying, mixing the dried thermoplastic polyurethane chips and an antibacterial agent and adding the mixture into a screw extruder for fusing and mixing; b, adding a cross-linking agent at a metering segment of the extruder or behind the extruder before entering a mixer; c, spraying a melt spinning material, spinning and performing winding formation with a spinneret plate, so as to obtain a finished product. The technological process of production comprises: cleaning of the chips, drying, extruding, mixing, spinning, drafting, cooling, oiling and winding. The antibacterial agent is copper powder which is nanoscale copper powder. The processing technique has the beneficial effects of being simple in production, high in production efficiency, low in investment, relatively good in antibacterial property of a product, relatively strong in antibacterial endurance, stable in quality and easy in popularization.

Owner:太仓佩利斯高分子材料有限公司

Preparation method of durably antibacterial air-jet vortex spun covering yarn

ActiveCN113174664AImprove physical and mechanical propertiesStrong antibacterial durabilityContinuous wound-up machinesMonocomponent synthetic polymer artificial filamentYarnPolymer science

The invention relates to a preparation method of durably antibacterial air-jet vortex spun covering yarn. The method comprises the steps that viscose staple fiber is made into a viscose cotton roll according to opening and cleaning procedures; through a cotton carding procedure, nanofiber containing an antibacterial agent is sprayed to a cotton web conveying device which is additionally arranged after carding and before bundling and sliver forming, viscose drawn slivers are obtained through horn mouth bundling and two-pass drawing, then the viscose drawn slivers are fed into an air-jet vortex spinning machine, polyamide filaments are fed into the space between a front roller and a second roller through a filament guide device, and vortex spinning is carried out. The covering yarn prepared by the method has good antibacterial durability, and the vortex spun covering yarn can integrate the advantages of high strength and wear resistance of polyamide core filaments, is good in yarn evenness and high in spinning efficiency, and has good economic value.

Owner:DONGHUA UNIV +1

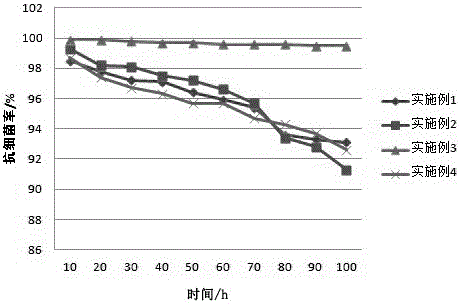

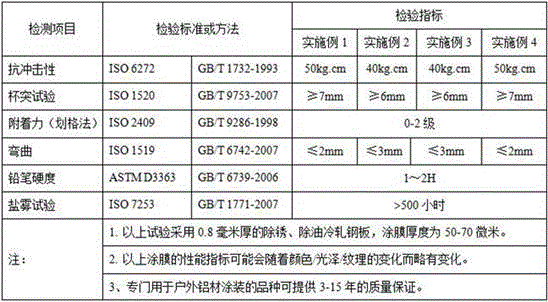

Polyurethane system antibacterial powder paint, preparation method of polyurethane system antibacterial powder paint and coating

InactiveCN107523115AImprove antibacterial propertiesStrong antibacterial durabilityAntifouling/underwater paintsPaints with biocidesTitaniumPolyester resin

The invention discloses polyurethane system antibacterial powder paint, which is prepared from the following raw materials in parts by weight: 45 to 55 parts of hydroxy polyester resin, 6 to 12 parts of isocyanate curing agents, 0.1 to 2.5 parts of antibacterial agents, 20 to 28 parts of titanium pigment, 10 to 15 parts of precipitated barium sulfate, 0.5 to 1.5 parts of flatting agents, 0.2 to 0.5 part of benzoin and 0.5 to 1 part of optical brighteners. The invention also discloses a preparation method of the polyurethane system antibacterial powder paint and a coating. After the polyurethane system antibacterial powder paint is used, the characteristics of stable antibacterial effect and long-period effective antibacterium are realized; the adaptation to the addition of different kinds of antibacterial agents can be realized.

Owner:霍文波 +1

Preparation method of carbon nanosilver/titanium dioxide composite material

InactiveCN107581196AUnlimited usage environmentEnvironment safetyBiocideDisinfectantsNanoparticleCatalytic effect

The invention discloses a preparation method of a carbon nanosilver / titanium dioxide composite material, which comprises the following steps: preparing a nanoparticle carbon suspension A and a mixture B; mixing the nanoparticle carbon suspension A and the mixture B, and adding a mixture C to form a gel; drying and calcining the gel to obtain the nano carbon / titanium dioxide composite powder; adding the nano carbon / titanium dioxide composite powder in a silver nitrate solution, and stirring the materials to obtain a mixture D; continuously stirring the mixture D, dropping dihydrate trisodiumcitrate until the color of the solution is yellow, stopping stirring, and aging the materials to obtain the precipitates, and washing and drying the product to obtain the carbon nanosilver / titanium dioxide composite material. The method is characterized in that through doping modification of carbon nanosilver, the carbon nanosilver / titanium dioxide composite material has catalytic effect under visible light irradiation, which has great practical significance. Under light conditions and dark conditions, the antibacterial persistence of the carbon nanosilver / titanium dioxide composite material is better than that of silver nitrate with concentration being 0.1% and much better than the performance of titanium dioxide in the dark condition, and the carbon nanosilver / titanium dioxide compositematerial has strong antimicrobial performance of silver nitrate and photocatalytic antibacterial performance of titanium dioxide.

Owner:陈磊

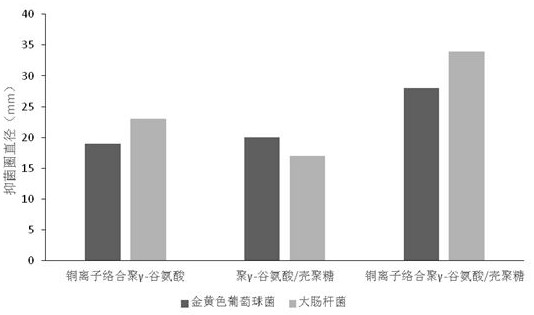

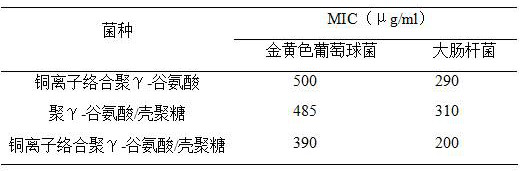

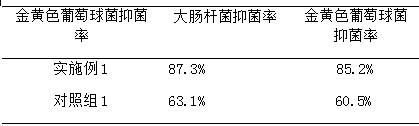

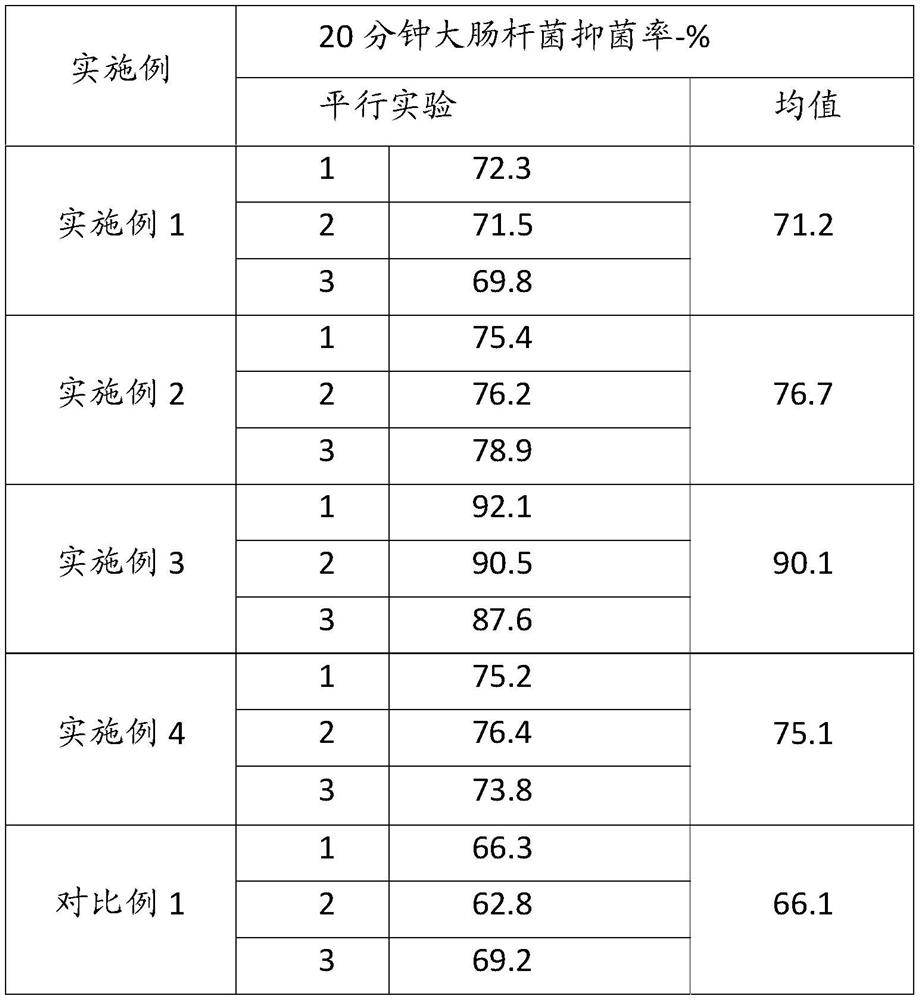

Copper ion complexing poly gamma glutamic acid/chitosan/cotton blended antibacterial knitted fabric and preparation method thereof

The invention belongs to the field of functional textiles, and particularly relates to copper ion complexing poly gamma-glutamic acid(gamma-PGA) / chitosan(CS) / cotton blended antibacterial knitted fabric and a preparation method thereof. According to the knitted fabric, chitosan and poly gamma-glutamic acid are cross-linked, then a copper ammonia complex ion solution is added to prepare a spinning solution, the spinning solution is subjected to wet spinning, then stretching, water washing, after-finishing, water washing and drying are carried out to obtain copper ion complexing poly gamma-glutamic acid / chitosan composite fibers, and the blended antibacterial knitted fabric is prepared from cotton fiber yarn and the composite fibers. In the knitted fabric and the preparation method, carboxylof gamma-PGA and amino of CS have a very high coordination coefficient, and the structure is stable. Poly-gamma glutamic acid can be used as a water-retaining agent and a heavy metal ion adsorbent, and the loading rate of copper ions can be increased. In the knitted fabric and the preparation method, chitosan and the copper ions are combined to resist bacteria and have a synergistic effect, and the finally-prepared knitted fabric has better antibacterial performance, anti-static performance and flame retardance and is high in antibacterial durability.

Owner:QUFU NORMAL UNIV

Processing craft of long-acting antibacterial vinylon filament

InactiveCN107299409AEasy to produceIncrease productivityMonocomponent synthetic polymer artificial filamentArtifical filament manufactureThermoplastic polyurethaneEngineering

The invention discloses a processing craft of a long-acting antibacterial vinylon filament. The processing craft comprises the following steps: a, cleaning and drying a thermoplastic polyurethane slice, mixing with an antibacterial agent, adding into a screw extruder, melting and mixing; b, adding a crosslinking agent on a metering section of the extruder or behind the extruder before entering a mixer; c, spraying out a melt spinning fabric through a spinneret plate, spinning, and winding to finally obtain a finished product. The flow of the production craft is as follows: cleaning the slice, drying, extruding, mixing, spinning, drafting, cooling, applying oil and winding. The antibacterial agent is silver powder, and the silver powder is nanoscale silver powder. The processing craft has the beneficial effects that the production is simple, the production efficiency is high, the investment is low, the antibacterial performance of the product is relatively good, the antibacterial durability is relatively strong, the quality is stable, and the processing craft is easy to popularize.

Owner:太仓佩利斯高分子材料有限公司

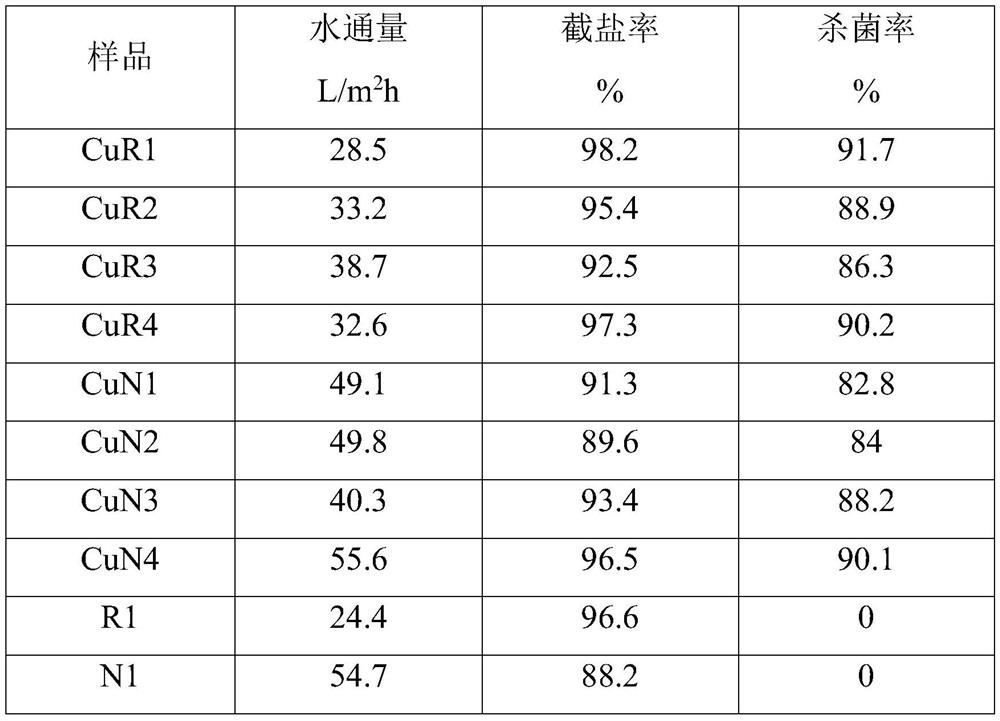

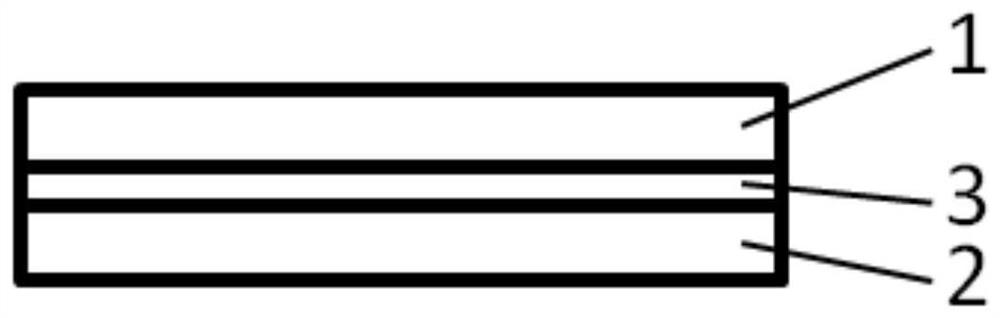

Copper-containing antibacterial thin-layer composite film as well as preparation method and application thereof

PendingCN112516812AImprove long-lasting antibacterial performanceLong-term bactericidal effectMembranesSemi-permeable membranesPolyamideCopper oxide

The invention discloses a copper-containing antibacterial thin-layer composite film as well as a preparation method and application thereof. The composite film comprises an enhancement layer, a supporting layer and a separation layer, wherein the separation layer is located on one surface of the supporting layer, the enhancement layer is located on the other surface of the supporting layer, the supporting layer is a polymer porous membrane, the separation layer is a polyamide separation layer loaded with copper hydroxide, and the mass content of elemental copper in the separation layer is 0.5-10 wt%. The preparation method comprises the following steps: firstly, preparing a polyamine solution and a polyacyl chloride solution of copper hydroxide; and sequentially contacting the supporting layer with the polyamine solution and the polyacyl chloride solution of copper hydroxide, and carrying out heat treatment. The copper-containing antibacterial thin-layer composite film prepared according to the invention has the advantages of lasting antibacterial performance, simple preparation process, suitability for mass production and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multifunctional deodorant health-care mattress shell fabric and manufacturing method thereof

InactiveCN105177807AEasy transferControl body surface moistureSolvent-treatmentMelt spinning methodsPolyesterAdditive ingredient

The present invention discloses a multifunctional deodorant health-care mattress shell fabric and a manufacturing method thereof. Peanut shells are carbonized through special processes and modified, other accessory ingredients is then added, and polyester melt spinning is carried out. The surfaces of the obtained complex fibers are of a multi-micropore structure, a high specific surface area facilitates water transport, and the wet permeability is high. With multi-pore adsorbing effects of peanut shell powdered carbon and attapulgite, bacteria body surface moisture can be effectively controlled, a moist environment where bacteria live is thus damaged, growth of the bacteria is restrained, and the deodorization performance of the mattress shell fabric can also be raised. Compared with functionally finished mattress shell fabrics in the prior art, the health-care mattress shell fabric manufactured by the present invention is good in antibacterial endurance and simple in process.

Owner:屠明鑫

Processing process of antibacterial polyester filaments

InactiveCN107385552AEasy to produceIncrease productivityMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterCross-link

The invention discloses a processing process of antibacterial polyester filaments. The processing process comprises the following steps: (a) slicing thermoplastic polyurethane, cleaning, drying, then mixing with an antibacterial agent, adding into a screw extruder, melting and mixing; (b) adding a cross-linking agent at a metering section of the extruder or after entering the extruder and before entering a mixer; and (c) spraying melt-spun materials by using a spinneret plate, spinning, winding and forming, thus finally obtaining a finished product. The production process comprises the procedures of slicing and cleaning, drying, extruding, mixing, spinnereting, drawing, cooling, oiling and winding. The antibacterial agent is copper powder which is nanoscale copper powder. The processing process disclosed by the invention has the beneficial effects that the production is simple, the production efficiency is high, the investment is low, and the product is better in antibacterial performance, stronger in antibacterial persistence, stable in quality and easy in promotion.

Owner:太仓佩利斯高分子材料有限公司

A kind of preparation method of antibacterial polyester fabric

ActiveCN104499271BHas broad-spectrum antibacterial propertiesStrong persistenceFibre typesPolyesterPenicillamine

The invention discloses a preparation method of antibacterial polyester fabrics and belongs to the technical field of textile materials. The preparation method comprises the following steps: after sequentially carrying out continuous modification treatment on polyester fabric original samples including clothing, tablecloth and curtains by virtue of a Na2CO3 solution, a mixed solution of alizarin red and sodium cyclamate, a mixed solution of aniline, hydrochloride and ammonium persulfate, a mixed solution of DL-mercaptosuccinic acid and D-penicillamine and a nano-silver solution, putting the treated polyester fabric original samples into a silver tetrafluoroborate aqueous solution, carrying out reaction at room temperature for 30 minutes, washing the product by a great deal of water, and drying at the temperature of 40 DEG C to obtain the antibacterial polyester fabrics. The antibacterial polyester fabrics prepared by the preparation method have the broad-spectrum antibacterial property, are good in antibacterial effect particularly on staphylococcus aureus, bacillus subtilis, Escherichia coli and pseudomonas aeruginosa, are strong in persistence and have the single-strain inhibitory rate reaching 95-99.7 percent after being washed for 30 times.

Owner:MAANSHAN JINZI TEXTILE OMAMENT +1

Processing process of long-acting antibacterial polyester filament yarn

InactiveCN107385553AEasy to produceIncrease productivityMelt spinning methodsMonocomponent polyesters artificial filamentThermoplastic polyurethaneAntibacterial agent

The invention discloses a processing process of a long-acting antibacterial polyester filament yarn. The processing process comprises the following steps: (a) cleaning and drying thermoplastic polyurethane slices, mixing the thermoplastic polyurethane slices with an antibacterial agent, adding the mixture into a screw extruder, and carrying out fusion and mixing; (b) adding a cross-linking agent in a metering stage of the extrusion or after the mixture is added into the extruder before entering a mixer; and (c) spraying out a fused spinning material by virtue of a spinneret plate, and carrying out spinning and winding formation. The product process comprises the following flows: slice cleaning, drying, extrusion, mixing, yarn spinning, traction, cooling, oiling and winding. The antibacterial agent is nano-scale silver powder. The processing process has the beneficial effects that the production is simple, the production efficiency is high, the investment is low, the product is relatively good in antibacterial performance, relatively strong in antibacterial durability, stable in quality and easy to popularize.

Owner:太仓佩利斯高分子材料有限公司

Antibacterial coating slurry and use method thereof

InactiveCN108059895APrevents antimicrobial discolorationHas long-acting broad-spectrum antibacterial abilitySucessive textile treatmentsAntifouling/underwater paintsFiberEmulsion

The invention discloses antibacterial coating slurry for a fiber fabric and a use method of the antibacterial coating slurry. The antibacterial coating slurry comprises the following components in percent by weight: 1.5%-3.5% of an antibacterial agent, 0.1%-0.15% of a dispersant, 15%-25% of a waterborne acrylic emulsion, 5%-6.5% of a thickening agent, 0.1%-0.2% of a color fixing agent, and the balance of water, and the sum of the content of each component is 100%, wherein the antibacterial agent is a submicron-grade TiO2-Ag antibacterial agent. Aiming at overcoming the defects of the prior art, the invention provides an antibacterial finishing slurry composition which can be used for antibacterial treatment of fabrics, so that an antibacterial fabric with broad-spectrum antibacterial capability is obtained, and the prepared antibacterial fabric is effectively prevented from discoloration.

Owner:JIANGSU NEW REBA TECH CO LTD

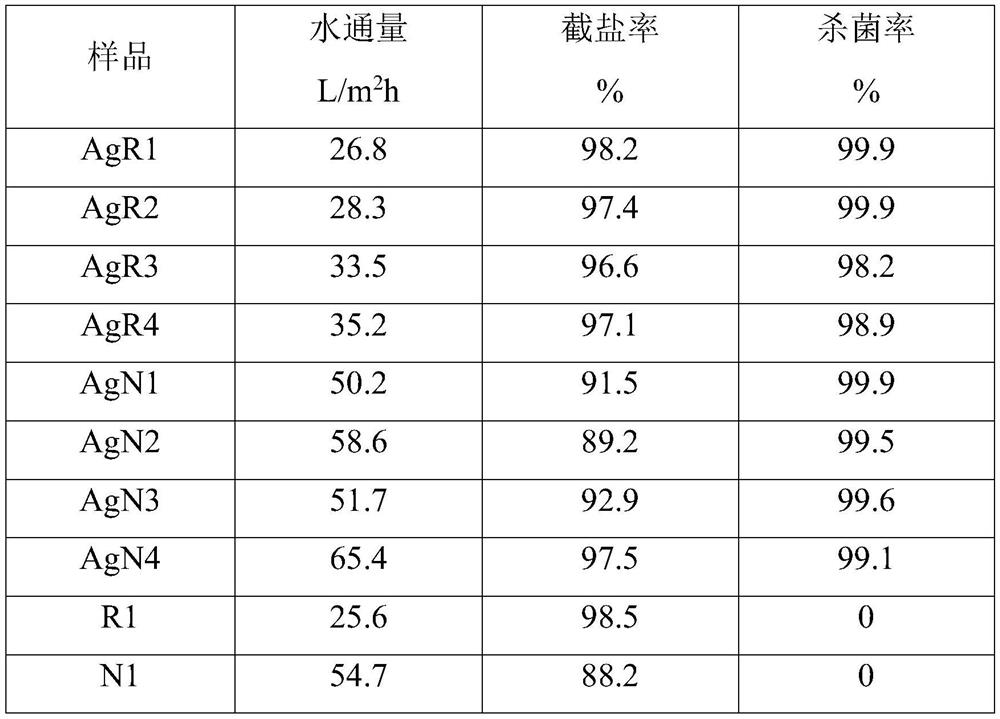

Silver-containing antibacterial thin-layer composite film as well as preparation method and application thereof

PendingCN112516811AImprove long-lasting antibacterial performanceLong-term bactericidal effectMembranesSemi-permeable membranesPolyamideMass content

The invention discloses a silver-containing antibacterial thin-layer composite film as well as a preparation method and application thereof. The composite film comprises an enhancement layer, a supporting layer and a separation layer, wherein the separation layer is located on one surface of the supporting layer, the enhancement layer is located on the other surface of the supporting layer, the supporting layer is a polymer porous membrane, and the separation layer is a polyamide separation layer loaded with a silver-containing compound, wherein the mass content of the elemental silver in theseparation layer is 0.1-10 wt%. The preparation method comprises the following steps: firstly, preparing a polyamine solution and a polyacyl chloride solution of a silver compound; and sequentially contacting the supporting layer with the polyamine solution and the polyacyl chloride solution containing the silver compound, and carrying out heat treatment. The silver-containing antibacterial thin-layer composite film prepared according to the invention has the advantages of lasting antibacterial performance, simple preparation process, suitability for mass production and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

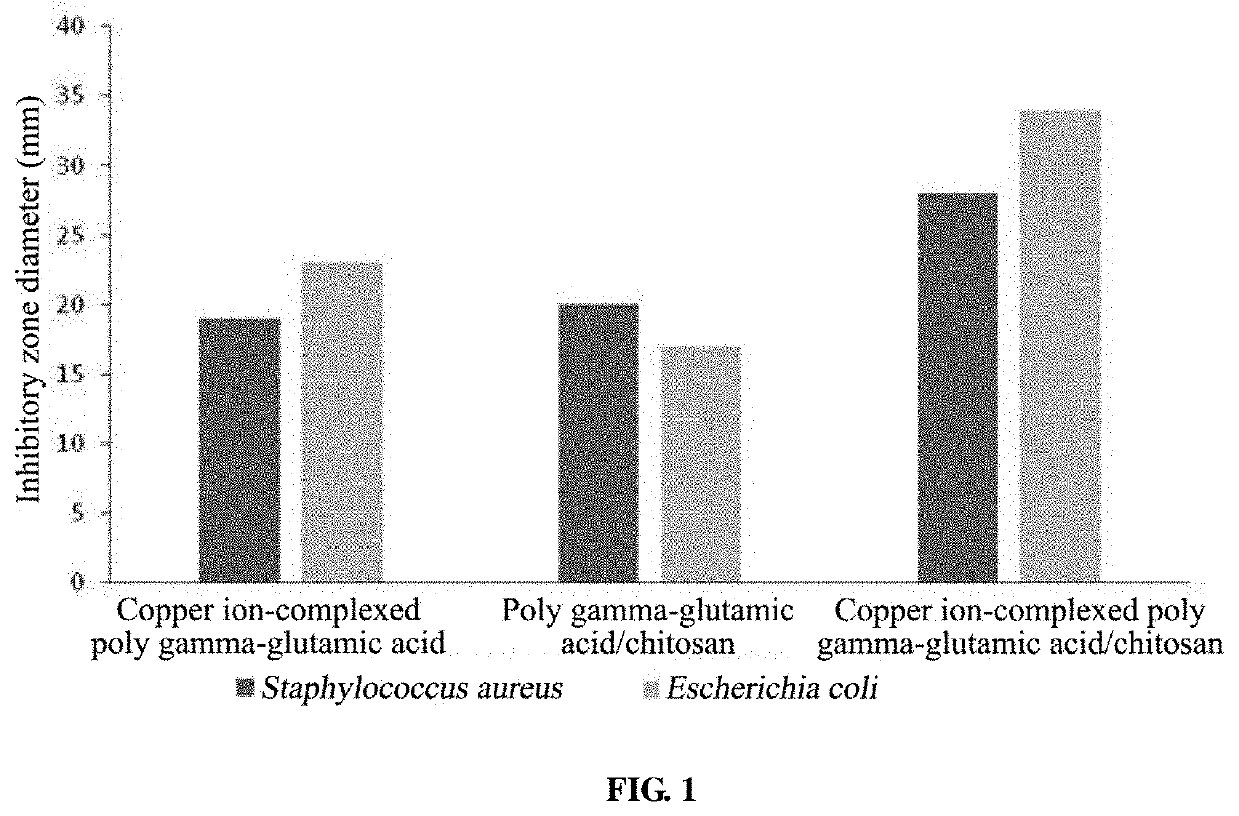

Copper ion-complexed poly gamma-glutamic acid/chitosan/cotton blended antibacterial knitted fabric and preparation method thereof

ActiveUS20220090303A1High antibacterial activityHigh load rateBiocideWarp knittingYarnPolymer science

A copper ion-complexed poly gamma-glutamic acid (γ-PGA) / chitosan (CS) / cotton blended antibacterial knitted fabric and a preparation method includes chitosan that is crosslinked with poly gamma-glutamic acid, then a copper-ammonia complex ion solution is added to prepare a spinning solution. The spinning solution is wet spun and then stretched, washed with water, finished, washed with water, and dried to get copper ion-complexed poly gamma-glutamic acid / chitosan composite fibers. The blended antibacterial knitted fabric is then prepared by using cotton fiber yarns and the composite fibers. There is a very high coordination coefficient between carboxyl groups of gamma-PGA and amino groups of CS, so the structure is stable. Poly-gamma glutamic acid can be used as water-retaining agent and heavy metal ion adsorbent, which can increase the loading rate of copper ions.

Owner:QUFU NORMAL UNIV

Nano silver durable antibacterial cloth permeated by semiconductor and preparing method thereof

InactiveCN106319938AHigh antibacterial activityImprove antibacterial propertiesBiochemical treatment with wool-protecting/anti-moth agentsHigh pressureAtmospheric pressure

The invention discloses nano silver durable antibacterial cloth permeated by semiconductor and preparing method thereof. The invention applies the semiconductor permeation in the preparing of nano silver antibacterial solution and obtains nano silver antibacterial cloth from cloth through high pressure airless spray, squeezing and drying. The antibacterial cloth is obtained by semiconductor permeation. The invention comprises the steps of spraying the nano silver antibacterial solution with high pressure airless spray system, spraying with high pressure airless sprayer, evening up with pressure roller and drying. The invention can efficiently kill more than 650 kinds of bacterial, with sterilization rate reaching 99.9%. The invention also has good killing effect for white candida that is hard to be killed by general nano silver. As the invention improves the permeation and adhesive force and the washing resistance of nano silver antibacterial cloth enhances, the antibacterial effect is durable.

Owner:厦门博正科技有限公司

Preparation method for composite regenerated cellulose fibers

InactiveCN108505144ANot easy to fall offGuaranteed long-term antimicrobial performanceBiochemical fibre treatmentConjugated cellulose/protein artificial filamentsIn situ polymerizationFiltration

The invention discloses a preparation method for composite regenerated cellulose fibers. The aniline monomer is first added into the regenerated cellulose solution. Then by adopting in-situ polymerization, polyaniline molecules are generated on the regenerated cellulose in the solution. Spinning solution is attained after filtration, vacuum degassing; polyaniline-regenerated cellulose composite fibers are attained after the spinning solution is sprayed through a spinneret hole, coagulated and shaped in coagulation bath, stretched, crimped, finalized and dried. The composite regenerated cellulose fibers are prepared by dipping the polyaniline-regenerated cellulose composite fibers in silver nitrate solution and then in glucose solution. The preparation method for the composite regenerated cellulose fibers has the advantages of good antibacterial effect, strong antibacterial persistence and high mechanical properties, which can effectively improve the comfort and functionality of textiles.

Owner:WUHU CHUANGYUAN NEW MATERIALS CO LTD

Health mattress fabric capable of alleviating fatigue and improving sleep quality, and making method thereof

InactiveCN104988597ABig gapStrong sound and heat insulationMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterAdsorption effect

The invention discloses a health mattress fabric capable of alleviating fatigue and improving sleep quality. In the invention, wine brewer's grains are charred through a special technology, the charred wine brewer's grains are modified, other effective assistants and polyester are added, melt spinning is carried out to obtain a composite fiber, the internal gap of the composite fiber is large to realize strong sound and heat insulation functions, and the porous adsorption effect of wine brewer's grain carbon powder and negative ion powder can effectively control the water of the surface of bacteria in order to destroy the moist survival environment of the bacteria and inhibit the growth of the bacteria. Compared with functional finishing mattress fabrics in the prior art, the health mattress fabric produced in the invention has the advantages of strong antibacterial endurance, simple production process, comfortableness, environmental protection, fatigue alleviation, sleep quality improvement and long service life.

Owner:安徽月娇家具有限公司

Stain-proof and dust-proof type health-care mattress fabric and preparation method thereof

InactiveCN105064068AEasy transferControl body surface moistureMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterSurface moisture

The invention discloses stain-proof and dust-proof type health-care mattress fabric. According to the fabric, coffee grounds are carbonized with a special process, are modified and are added with other effective assistants and polyester for melt spinning, acquired complex fiber has a microporous structure on the surface, the higher specific surface area is more beneficial to moisture transport, and the wet permeability is high; further, by means of the microporous adsorption effect of coffee ground carbon fine powder and animal bones, the bacterial surface moisture can be effectively controlled, then the moist environment for bacterium survival is damaged, and the bacterium growth is inhibited; compared with functional finishing mattress fabric in the prior art, the prepared health-care mattress fabric has the advantages of high antibacterial endurance, stain-proof and dust-proof performance, dimensional stability, pilling resistance, high elasticity and the like, moreover, the production is simple and easy, the cost is low, and organic unification of artistry and economic practicality is really achieved.

Owner:安徽月娇家具有限公司

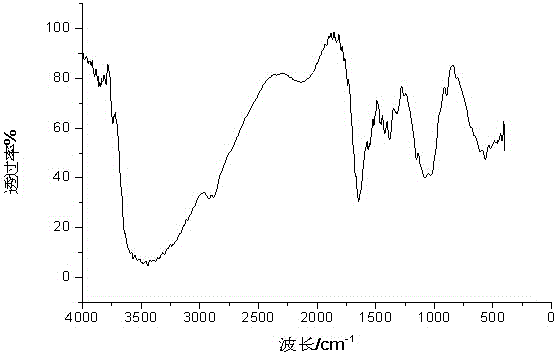

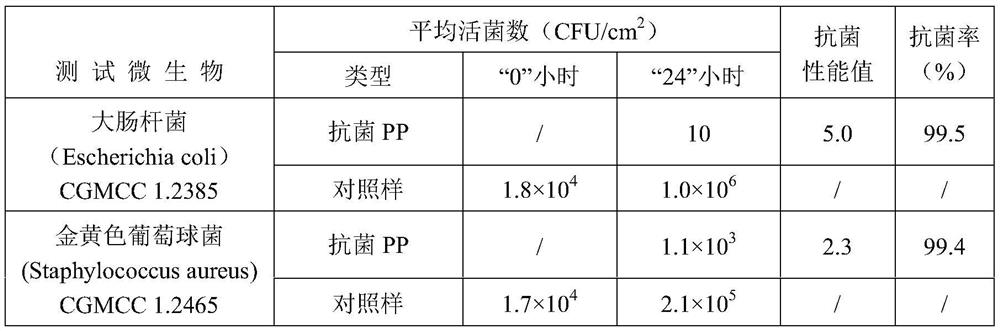

Anti-oxidation and antimicrobial polypropylene material and preparation method thereof

InactiveCN104927203AImprove antioxidant capacityGood antibacterial effectAntioxidantUltraviolet lights

The invention discloses an anti-oxidation and antimicrobial polypropylene material and a preparation method thereof. The anti-oxidation and antimicrobial polypropylene material comprises polypropylene, filling agents, flexibilizer, antioxidants, antibacterial agents, dispersing agents and ultraviolet light absorbing agents and is prepared through blend extrusion granulation. Compared with traditional polypropylene material and a preparation method, the anti-oxidation and antimicrobial polypropylene material and the preparation method thereof have the obvious advantages that a finished product has the advantages of good in anti-oxidation property and antibacterial effect and strong in antibacterial permanence; the preparation method is scientific and systematic, loss in the preparation process is reduced, and the operation and industrial production are easy; the mechanical property is good, and the anti-oxidation and antimicrobial polypropylene material can be applied to small household appliances and kitchen and bathroom appliances.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

Antibacterial paper for daily use

PendingCN112553958AAntibacterial effectDelay drug resistancePaper/cardboardPaper/cardboard layered productsMedicineSkin contact

The invention belongs to the technical field of paper for daily use, and particularly relates to antibacterial paper for daily use. The antibacterial paper for daily use comprises at least two layersof base paper and a composite layer arranged between the two layers of base paper, wherein the composite layer comprises laminated glue and an antibacterial agent, and the antibacterial agent comprises a silver ion antibacterial agent. The antibacterial agent in the embodiment of the invention comprises the silver ion antibacterial agent, is good in antibacterial effect, low in drug resistance andhigh in antibacterial durability, does not make direct contact with the skin of a user and is high in safety.

Owner:GOLD HONG YE PAPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com