Reactive antimicrobial additive and preparation method thereof

A technology of antibacterial agents and additives, which is applied in the field of antibacterial agent additives and its preparation, and can solve problems such as drug resistance, no drug resistance, and reduced antibacterial persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

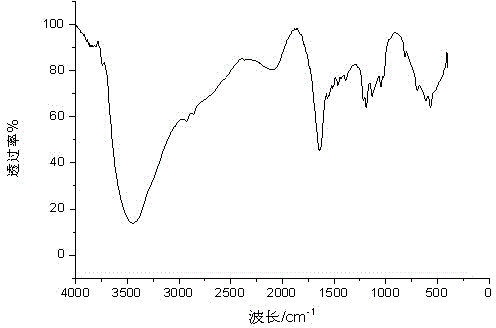

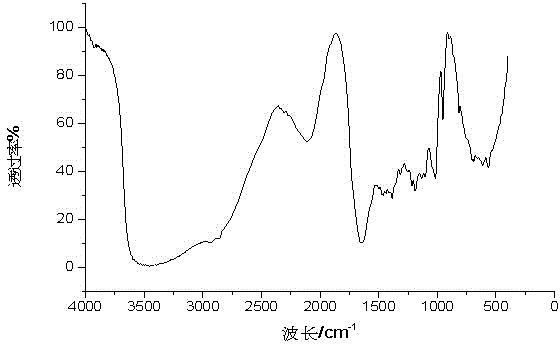

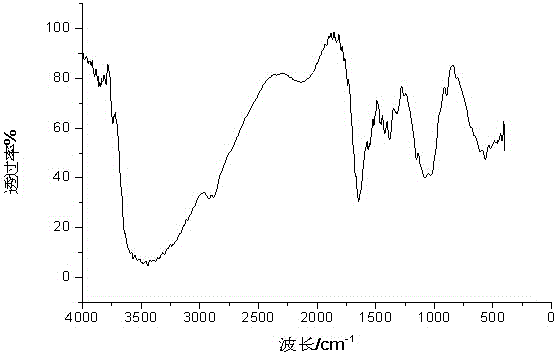

Image

Examples

Embodiment 1

[0042] A kind of reactive antimicrobial agent additive, described reactive antimicrobial agent additive is modified PHMG, calculated in parts by weight, its raw material composition and content are as follows:

[0043]PHMG 2 parts

[0044] Vinyl monomer 20 parts;

[0045] The PHMG is obtained by melt polycondensation at 180° C. with guanidine hydrochloride and hexamethylenediamine in a molar ratio of 1:1;

[0046] The vinyl monomer is acrylic acid.

[0047] The preparation method of above-mentioned a kind of reactive antimicrobial agent additive, the steps are as follows:

[0048] Calculated in parts by weight, add 2 parts of PHMG and 20 parts of acrylic acid to 100 parts of dimethyl sulfoxide and stir to dissolve, then control the temperature at 55°C and the rotation speed at 200r / min for 5.5h. After the reaction, use 400 Parts of organic solvent acetone precipitated the product, and the resulting product was repeatedly washed with acetone for 3 times, and then dried at a ...

Embodiment 2

[0062] A kind of reactive antimicrobial agent additive, described reactive antimicrobial agent additive is modified PHMG, calculated in parts by weight, its raw material composition and content are as follows:

[0063] 5 servings of PHMG

[0064] Vinyl monomer 5 parts;

[0065] The PHMG is obtained by melt polycondensation at 180°C with a molar ratio of guanidine hydrochloride and butylenediamine at 1:1;

[0066] The vinyl monomer is methacrylic acid.

[0067] The preparation method of above-mentioned a kind of reactive antimicrobial agent additive, comprises the steps:

[0068] (1) Calculated in parts by weight, dissolve 5 parts of vinyl monomer in 20 parts of dimethyl sulfoxide, add 0.5 part of activator 1-hydroxybenzotriazole (HOBt) and 0.5 part of condensate The mixture N, N-diisopropylcarbodiimide (DIC) was stirred and activated at room temperature for 1 hour to obtain solution 1;

[0069] The amount of dimethyl sulfoxide used above is calculated by weight ratio, and ...

Embodiment 3

[0076] A kind of reactive antimicrobial agent additive, described reactive antimicrobial agent additive is modified PHMG, calculated in parts by weight, its raw material composition and content are as follows:

[0077] PHMG 4 parts

[0078] 8 parts of vinyl monomer;

[0079] The PHMG is obtained by melt polycondensation at 180°C with a molar ratio of guanidine hydrochloride and octyldiamine in a molar ratio of 1:1;

[0080] The vinyl monomer is a mixture of acrylic acid and methacrylic acid in mass ratio, that is, methacrylic acid:acrylic acid is 1:0.6.

[0081] The preparation method of above-mentioned a kind of reactive antimicrobial agent additive specifically comprises the steps:

[0082] (1) Calculated in parts by weight, decompose 5 parts of methacrylic acid and 3 parts of acrylic acid into 32 parts of dimethyl sulfoxide, add 1.2 parts of activator 1-hydroxybenzotriazole (HOBt) and 1.2 parts of condensing agent N, N-diisopropylcarbodiimide (DIC) were stirred and activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com