Preparation method of durably antibacterial air-jet vortex spun covering yarn

A technology of vortex spinning and core-spun yarn, which is applied in the direction of continuous winding spinning machine, spinning machine, open-end spinning machine, etc., can solve the problem of poor antibacterial durability, and achieve good antibacterial properties and high spinning efficiency. , powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

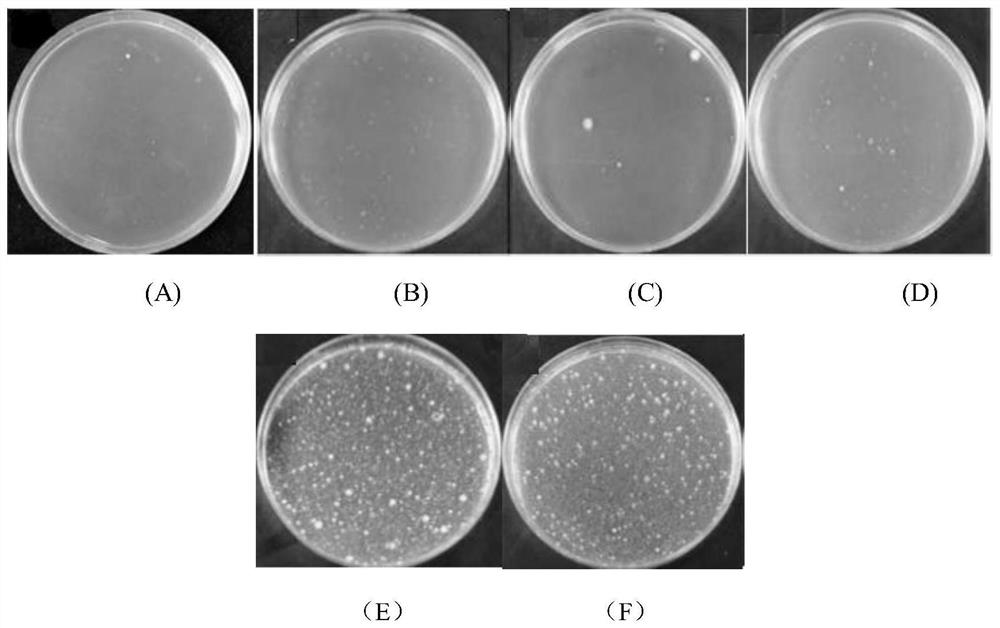

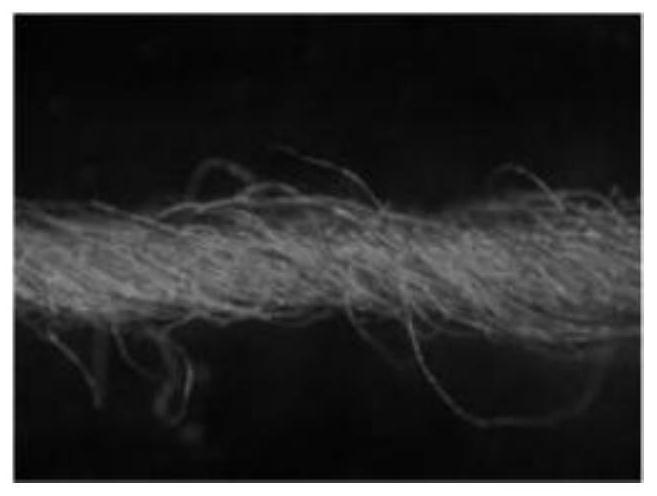

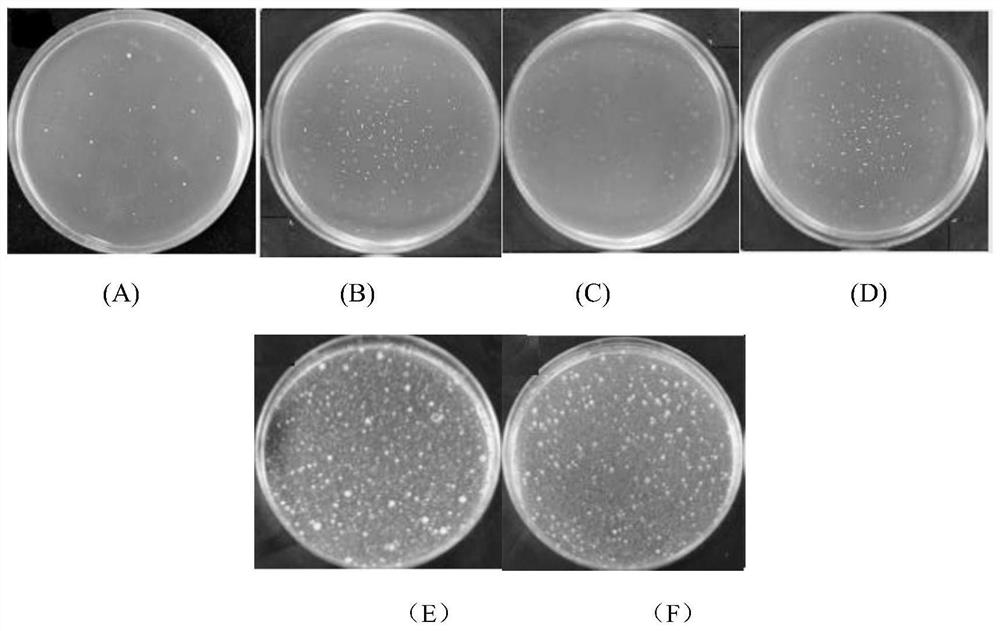

Embodiment 1

[0058] Take the production of 29.5tex antibacterial and durable vortex spinning core-spun yarn on the MVS861 vortex spinning machine equipped with a filament feeding device as an example. The outsourcing viscose staple fiber is evenly mixed with the electrospun nanofiber, and the mass ratio of the outsourcing fiber to the core filament is 4:1. The specific production plan is as follows: the viscose staple fiber is made into a viscose cotton roll according to the opening and cleaning process; the polymer solution containing the antibacterial agent is configured, and the nanofiber containing the antibacterial agent is sprayed and deposited by electrospinning method On the viscose cotton net combed by the carding machine, the viscose raw sliver is obtained by clustering through the bell mouth; the prepared viscose raw sli The cooked sliver is fed into the air-jet vortex spinning machine, and the nylon filament is fed through the yarn guide device from the gap between the front ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com