Waterproof finishing agent and preparation method and application method thereof

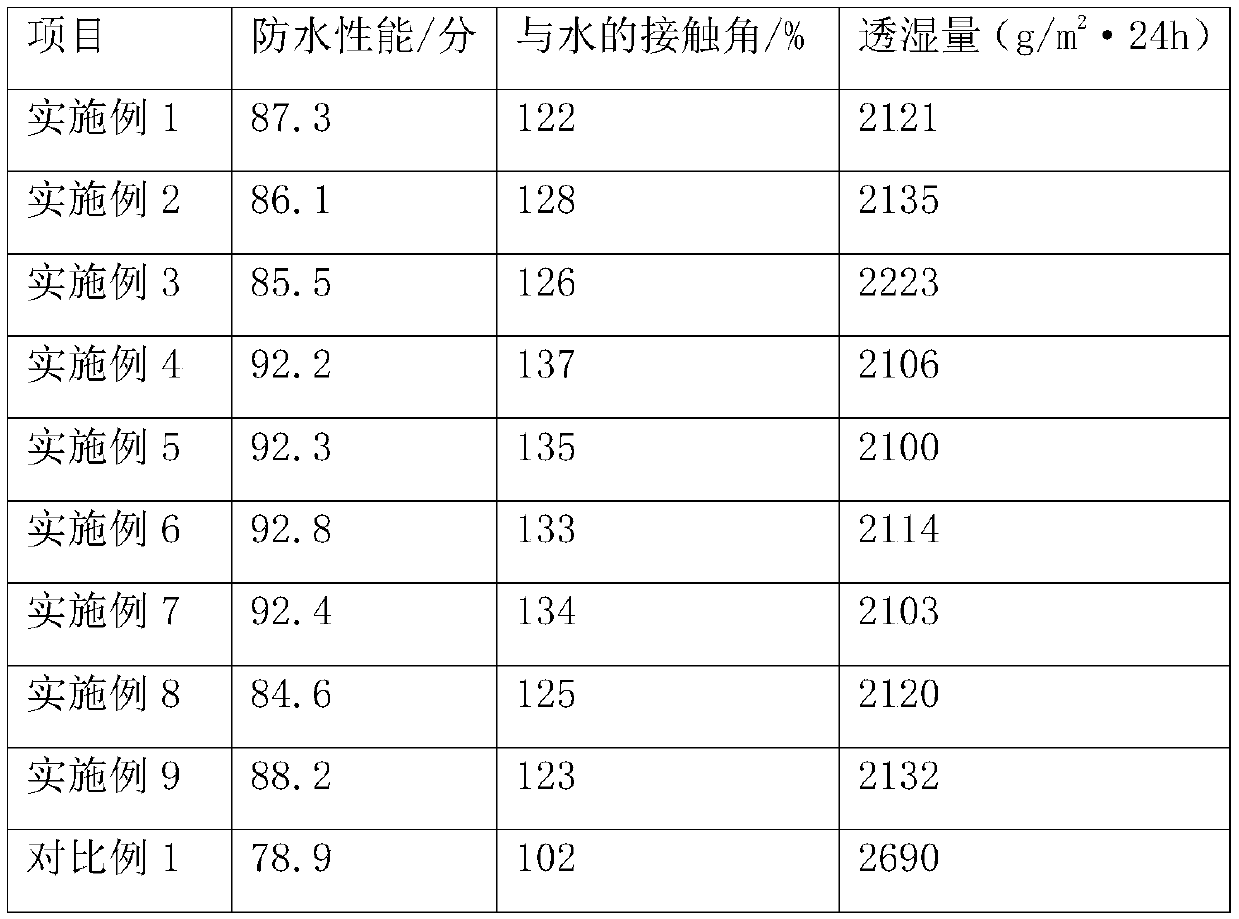

A technology of waterproof finishing and antibacterial agent, which is applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc. It can solve the problems of poor softness and elasticity of fabrics and easy creases on the surface, and achieve good film-forming properties and strong water resistance. Vapor barrier performance, waterproof performance, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

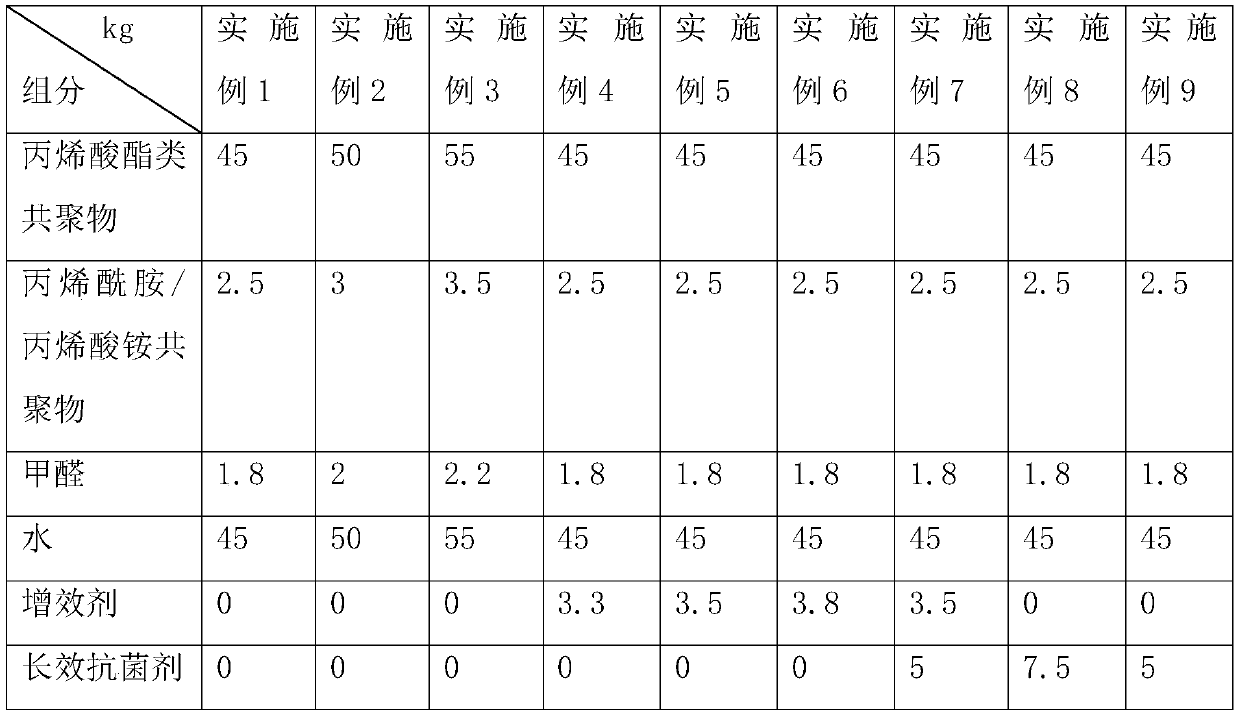

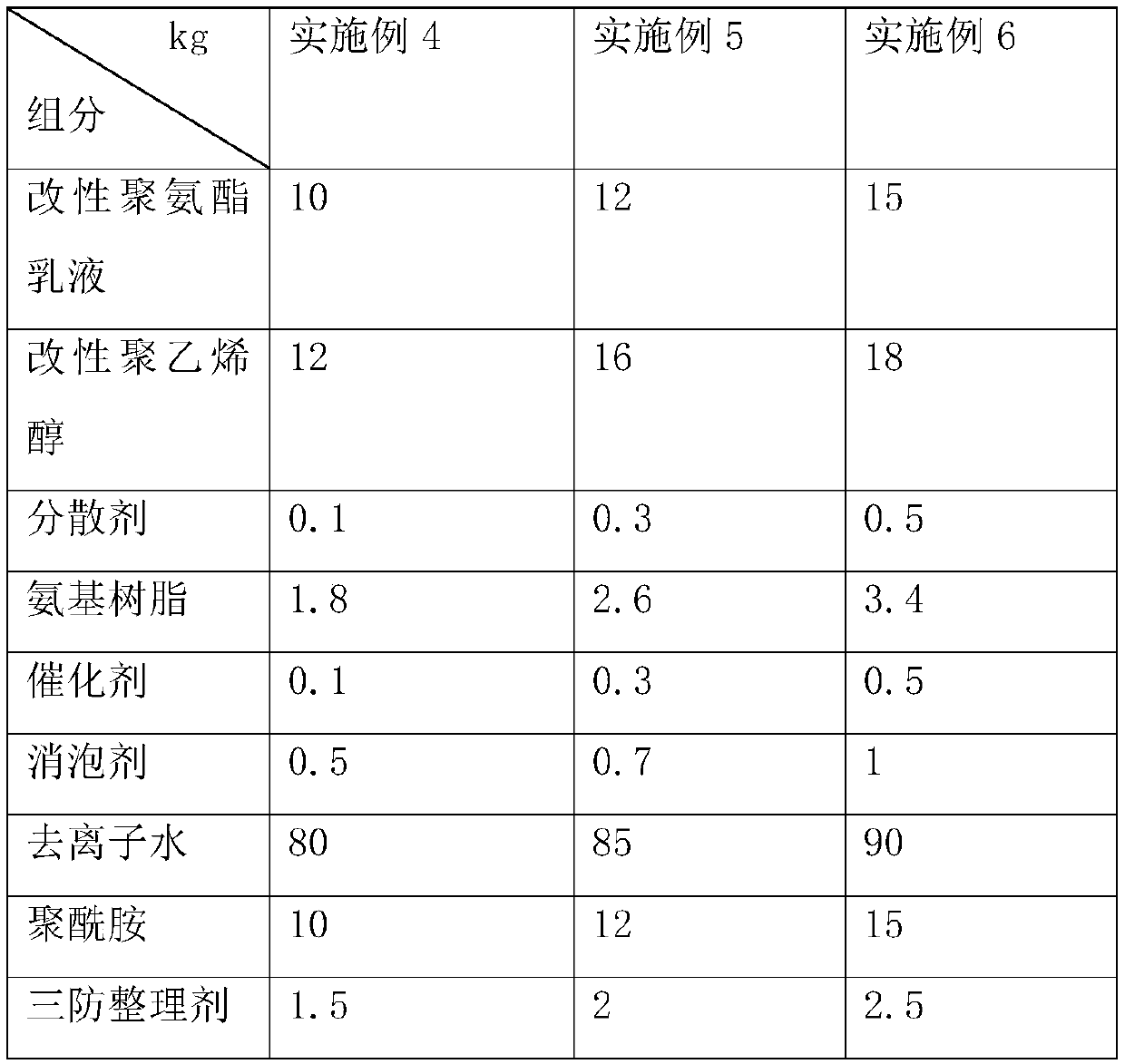

Method used

Image

Examples

preparation example 1-3

[0042] In the preparation example 1-3, the organic montmorillonite is selected from the organic montmorillonite whose article number is 689 sold by Weifang Shengshi Montmorillonite Technology Co., Ltd., and the graphite is selected from the graphite whose article number is 612 sold by Shijiazhuang Lishang Mineral Products Co., Ltd., poly Ether polyols are selected from the polyether polyols sold by Jiangsu Haian Petrochemical Factory as P123.

preparation example 1

[0043] Preparation Example 1: (1) Mix 1kg of organic montmorillonite, 1.5kg of graphite and 4kg of polyether polyol, heat in a water bath at 85°C, stir for 2.5h, cool to room temperature, add 5kg of deionized water, stir, suction filtration, vacuum drying, grinding, and passing through a 200-mesh sieve to obtain intercalated polyether polyol;

[0044] (2) Stir 3.5kg of polyether polyol, 0.05kg of the intercalation polyether polyol obtained in step (1), and 1.2kg of N,N-dimethylcyclohexylamine at 75°C, react for 5 hours, and add 0.15 kg triethanolamine, stirred for 30 min, added 5 kg of deionized water to disperse to obtain an emulsion, added 5.5 kg of polymethyl polyphenyl polyisocyanate, and continued to stir for 4 h to obtain a modified polyurethane emulsion.

preparation example 2

[0045] Preparation Example 2: (1) Mix 2kg of organic montmorillonite, 2kg of graphite and 7kg of polyether polyol, heat in a water bath at 88°C, stir for 2.8h, cool to room temperature, add 10kg of deionized water, stir, pump Filtration, vacuum drying, grinding, and passing through a 200-mesh sieve to obtain intercalated polyether polyols;

[0046] (2) Stir 4kg of polyether polyol, 0.08kg of the intercalation polyether polyol obtained in step (1), and 1.8kg of N,N-dimethylcyclohexylamine at 75°C, react for 6h, and add 0.2kg Triethanolamine was stirred for 40 min, and 6 kg of deionized water was added to disperse to obtain an emulsion, and 7 kg of polymethyl polyphenyl polyisocyanate was added, and stirring was continued for 4.5 h to obtain a modified polyurethane emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com