Polyurethane system antibacterial powder paint, preparation method of polyurethane system antibacterial powder paint and coating

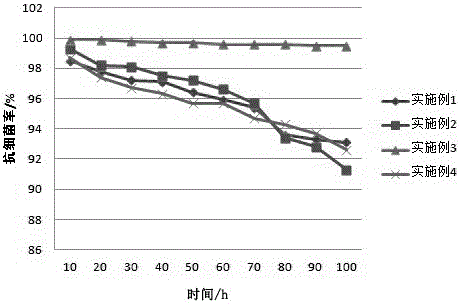

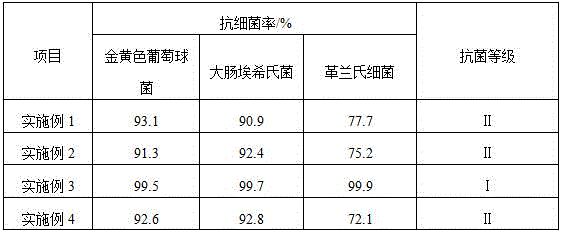

An antibacterial powder and powder coating technology, applied in the preparation of polyurethane system antibacterial powder coatings, polyurethane system antibacterial powder coatings, thermosetting antibacterial coatings, can solve the problems of unstable antibacterial effect, etc., and achieve the effect of strong antibacterial durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

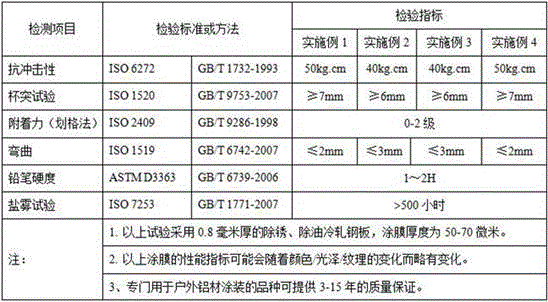

Examples

preparation example Construction

[0055] Correspondingly, the present invention also provides a kind of preparation method of polyurethane system antibacterial powder powder, comprises the following steps:

[0056] (1) Weigh 45-55 parts of hydroxyl polyester resin, 6-12 parts of isocyanate curing agent, 0.1-2.5 parts of antibacterial agent, 20-28 parts of titanium dioxide, 10-15 parts of precipitated barium sulfate, 0.5-1.5 parts 1 part of leveling agent, 0.2-0.5 part of benzoin, 0.5-1 part of brightening agent;

[0057] (2) Add the weighed raw materials into the mixer for pre-mixing;

[0058](3) The pre-mixed material is sent to the melt mixing extruder to melt and extrude the melt mixed material;

[0059] (4) The molten mixture material is pressed into thin slices through a tablet cooler, and cooled and broken into thin and small sheet materials by a crusher;

[0060] (5) Transport the flake materials to an air classifying mill for fine crushing, and collect most of the crushed semi-finished products throu...

Embodiment 1

[0070] 1. Formula:

[0071] Including the following raw materials in parts by weight:

[0072] 48 parts of polyester resin;

[0073] 9 parts of isocyanate;

[0074] 0.2 parts of nano silver ion antibacterial agent;

[0075] 26 parts of titanium dioxide;

[0076] 13 parts of precipitated barium sulfate;

[0077] Leveling agent 1 part;

[0078] Benzoin 0.4 parts;

[0079] Brightening agent 0.7 part.

[0080] 2. Preparation method:

[0081] (1) Weigh 48 parts of hydroxyl polyester resin, 9 parts of isocyanate curing agent, 0.2 parts of nano silver ion antibacterial agent, 26 parts of titanium dioxide, 13 parts of precipitated barium sulfate, 1 part of leveling agent, 0.4 part of benzoin according to the formula, 0.7 parts brightening agent;

[0082] (2) Add the weighed raw materials into the mixer for pre-mixing;

[0083] (3) The pre-mixed material is sent to the melt mixing extruder to melt and extrude the melt mixed material;

[0084] (4) The molten mixture material ...

Embodiment 2

[0090] 1. Formula:

[0091] Including the following raw materials in parts by weight:

[0092] 50 parts of polyester resin;

[0093] 10 parts of isocyanate;

[0094] 0.3 parts of nano zinc ion antibacterial agent;

[0095] 25 parts of titanium dioxide;

[0096] 12 parts of precipitated barium sulfate;

[0097] Leveling agent 1.2 parts;

[0098] Benzoin 0.3 parts;

[0099] Brightening agent 0.8 part.

[0100] 2. Preparation method:

[0101] (1) According to the formula, 50 parts of hydroxyl polyester resin, 10 parts of isocyanate curing agent, 0.3 parts of nano zinc ion antibacterial agent, 25 parts of titanium dioxide, 12 parts of precipitated barium sulfate, 0.8 parts of leveling agent, 0.3 parts of benzoin, 0.8 parts brightening agent;

[0102] (2) Add the weighed raw materials into the mixer for pre-mixing;

[0103] (3) The pre-mixed material is sent to the melt mixing extruder to melt and extrude the melt mixed material;

[0104] (4) The molten mixture material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com