A kind of antibacterial powder and its preparation method and use

An antibacterial powder and system technology, applied in the field of antibacterial agents, can solve the problems of poor dispersion of antibacterial components, low product purity, and small specific surface area, and achieve good antibacterial and antifungal effects, good application prospects, and uniform particle size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] At room temperature, 0.01mol of silver nitrate, 0.10mol of zinc nitrate, and 0.10mol of copper nitrate were dissolved in 10mL of deionized water, and then 0.25mol of tartaric acid was added for complexation reaction. The reaction time was 30 minutes, and then some deionized Ionized water controls the pH of the solution to be acidic, which is 4, and a clear metal complex acidic solution is obtained.

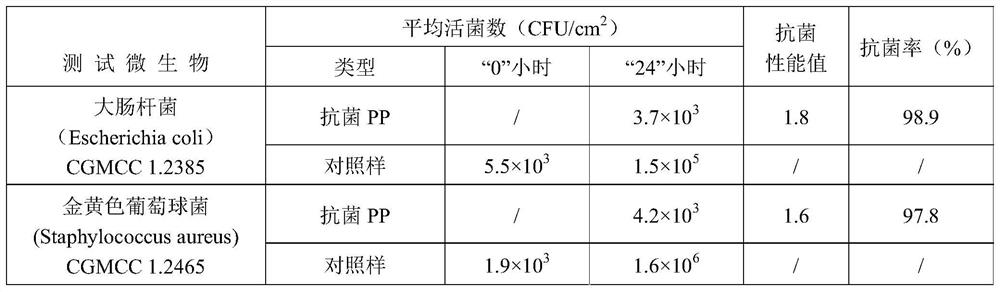

[0033] Take 0.5 mol of tetraethyl orthosilicate solution (125mL), dissolve it in 270mL of isopropanol solution, and slowly add the metal complex acidic solution in the first step into tetraethyl orthosilicate isopropyl under the condition of ice bath Alcohol solution, stir vigorously to disperse, then slowly raise the temperature to 50°C for 60 minutes, evaporate the solution to dryness, put the obtained solid in a muffle furnace for calcination at 500°C, and obtain an antibacterial powder of silicon-based material doped with silver, copper, and zinc. In the antibacterial p...

Embodiment 2

[0038] At room temperature, 0.02mol of silver nitrate, 0.10mol of zinc nitrate, and 0.10mol of copper nitrate were dissolved in 12mL of deionized water, and then 0.28mol of tartaric acid was added for complexation reaction. The reaction time was 60 minutes, and then some deionized Ionized water controls the pH of the solution to be acidic, which is 4.5, and a clear metal complex acidic solution is obtained.

[0039] Take 0.6mol of tetraethyl orthosilicate solution (150mL), dissolve it in 320mL of isopropanol solution, and slowly add the metal complex acidic solution in the first step into tetraethyl orthosilicate isopropyl under ice bath condition Alcohol solution, stir vigorously to disperse, then slowly raise the temperature to 45°C for 30 minutes, evaporate the solution to dryness, put the obtained solid in a muffle furnace for calcination at 450°C, and obtain an antibacterial powder of silicon-based material doped with silver, copper, and zinc. In the antibacterial powder,...

Embodiment 3

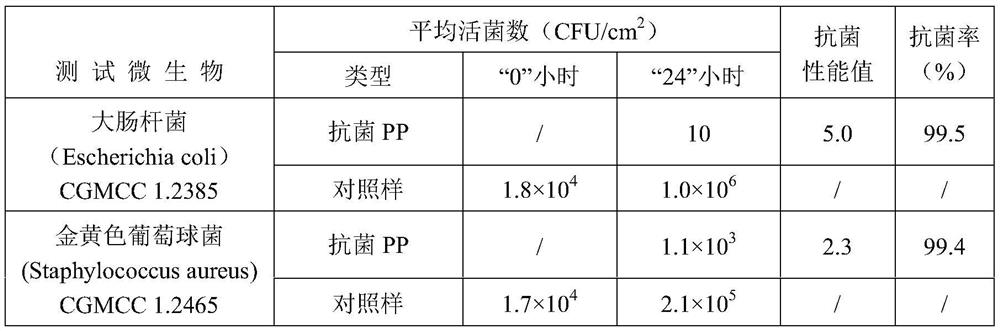

[0044] At room temperature, weigh 0.01mol silver nitrate, 0.15mol zinc nitrate, 0.15mol copper nitrate dissolved in 20mL deionized water, then add 0.8mol citric acid for complexation reaction, the reaction time is 60 minutes, then add some Deionized water is used to control the pH of the solution to be acidic, which is 4.5, and a clear metal complex acidic solution is obtained.

[0045] Take 1.2 mol of tetraethyl orthosilicate solution (300mL), dissolve it in 600mL of isopropanol solution, and slowly add the metal complex acidic solution in the first step into tetraethyl orthosilicate isopropyl under ice bath condition Alcohol solution, stir vigorously to disperse, then slowly raise the temperature to 40°C for 30 minutes, evaporate the solution to dryness, put the obtained solid in a muffle furnace for calcination at 400°C, and obtain an antibacterial powder of silicon-based material doped with silver, copper, and zinc.

[0046] The basic particle size of the powder particles is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com