Preparation method of carbon nanosilver/titanium dioxide composite material

A technology of titanium dioxide and composite materials, applied in botany equipment and methods, chemicals for biological control, animal repellants, etc., can solve the problems of carcinogenicity, accelerated aging of furniture and electrical appliances, and limited application, and achieve antibacterial Strong durability, unlimited use environment, accelerated aging of furniture and electrical appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of carbon nano silver / titanium dioxide composite material, it comprises the following steps:

[0025] (1) Take nanoparticle carbon and add it to absolute ethanol, and obtain nanoparticle carbon suspension A by ultrasonication; the weight ratio of nanoparticle carbon to absolute ethanol is 1~2:7~16, the ultrasonic frequency is 100~150Hz, and the time is 1~2h;

[0026] (2) Add tetrabutyl titanate to the mixed solution of ethanol and acetic acid, stir for 1-1.5 hours to obtain mixed solution B; wherein, the volume ratio of ethanol and acetic acid is 95-99:1-5, tetrabutyl titanate The volume ratio of the mixed solution with ethanol and acetic acid is 3~5:45~47;

[0027] (3) The carbon suspension A is mixed with the mixed solution B, and the mixed solution C of ethanol and water is added under stirring conditions to form a gel; wherein, the volume ratio of the carbon suspension A to the mixed solution B is 3 to 5:45 ~47, ...

Embodiment 1

[0037] A kind of preparation method of carbon nano-silver / titanium dioxide composite material, it comprises the following steps:

[0038] (1) Add nanoparticle carbon into absolute ethanol, and obtain nanoparticle carbon suspension A by ultrasonication; the weight ratio of nanoparticle carbon to absolute ethanol is 2:7, the ultrasonic frequency is 150Hz, and the time is 2h;

[0039] (2) Add tetrabutyl titanate to the mixed solution of ethanol and acetic acid, stir for 1 hour to obtain mixed solution B; wherein, the volume ratio of ethanol and acetic acid is 95:5, and the mixed solution of tetrabutyl titanate, ethanol and acetic acid The volume ratio is 3:45;

[0040] (3) The carbon suspension A is mixed with the mixed solution B, and the mixed solution C of ethanol and water is added under stirring conditions to form a gel; wherein, the volume ratio of the carbon suspension A to the mixed solution B is 3:46, and mixed The volume ratio of ethanol and water in liquid C is 17:2, ...

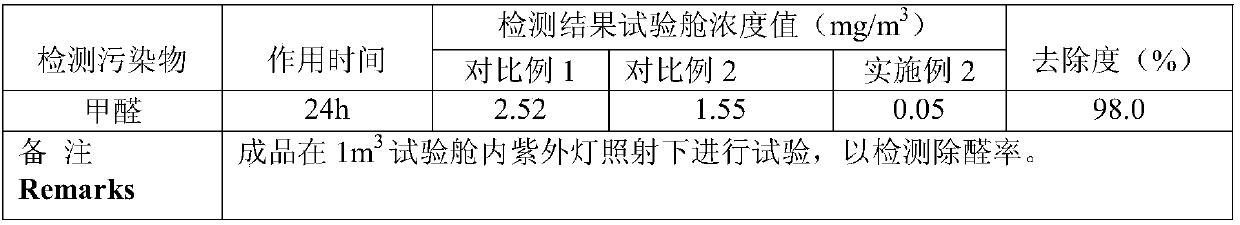

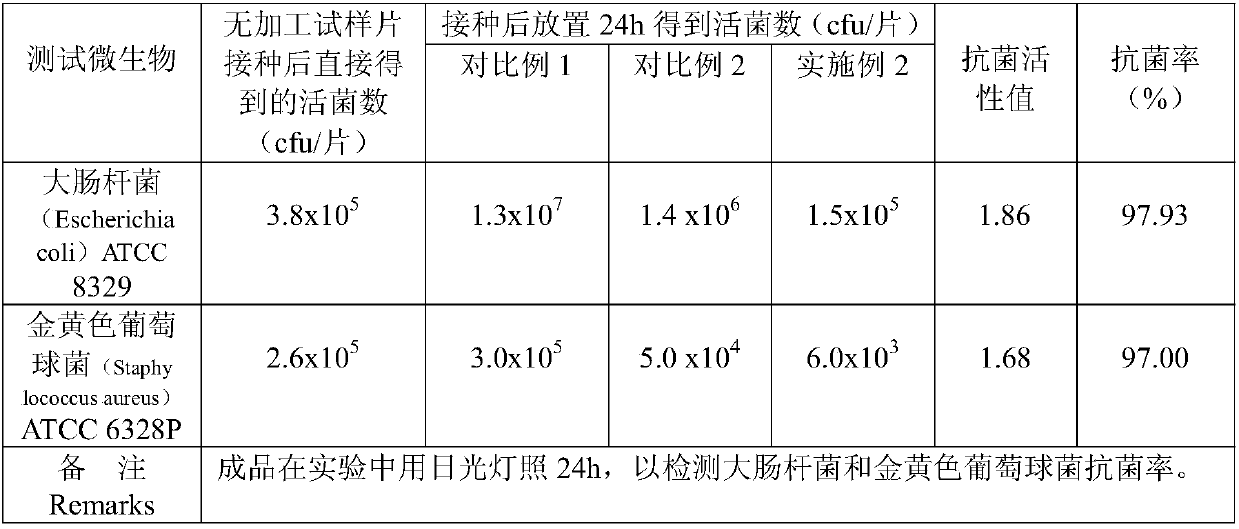

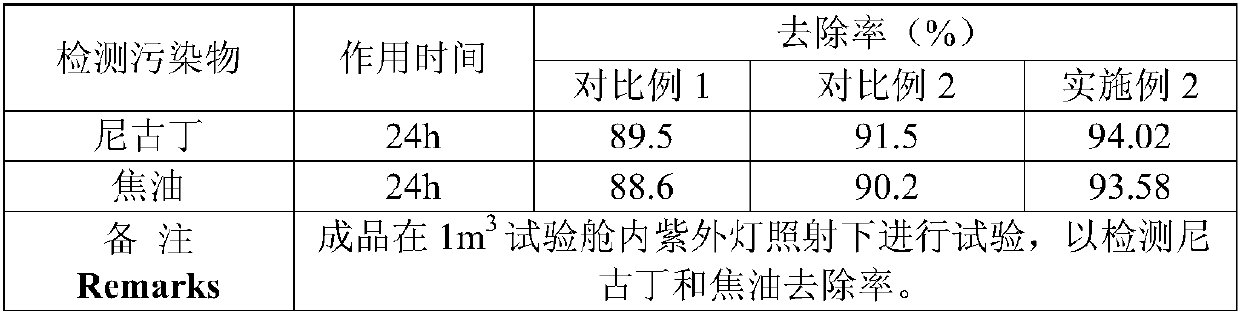

Embodiment 2

[0046] A kind of preparation method of carbon nano-silver / titanium dioxide composite material, it comprises the following steps:

[0047] (1) Take nanoparticle carbon and add it to absolute ethanol, and obtain nanoparticle carbon suspension A by ultrasonication; the weight ratio of nanoparticle carbon to absolute ethanol is 1:10, the ultrasonic frequency is 100Hz, and the time is 1.5h;

[0048] (2) Add tetrabutyl titanate to the mixed solution of ethanol and acetic acid, stir for 1.5h to obtain mixed solution B; wherein, the volume ratio of ethanol and acetic acid is 99:1, and the mixture of tetrabutyl titanate, ethanol and acetic acid The volume ratio of the liquid is 4:46;

[0049] (3) The carbon suspension A is mixed with the mixed solution B, and the mixed solution C of ethanol and water is added under stirring conditions to form a gel; wherein, the volume ratio of the carbon suspension A to the mixed solution B is 5:45, and mixed The volume ratio of ethanol and water in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com