Antibacterial post treatment method of latex gloves

A kind of latex gloves and latex technology, which can be applied in paints containing biocide, anti-fouling/underwater coatings, coatings, etc., can solve the problems of ineffective inhibition of various pathogens, high toxicity of antibacterial substances, and easy dissolution, etc., and achieve excellent Long-lasting antibacterial ability and comfortable wearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

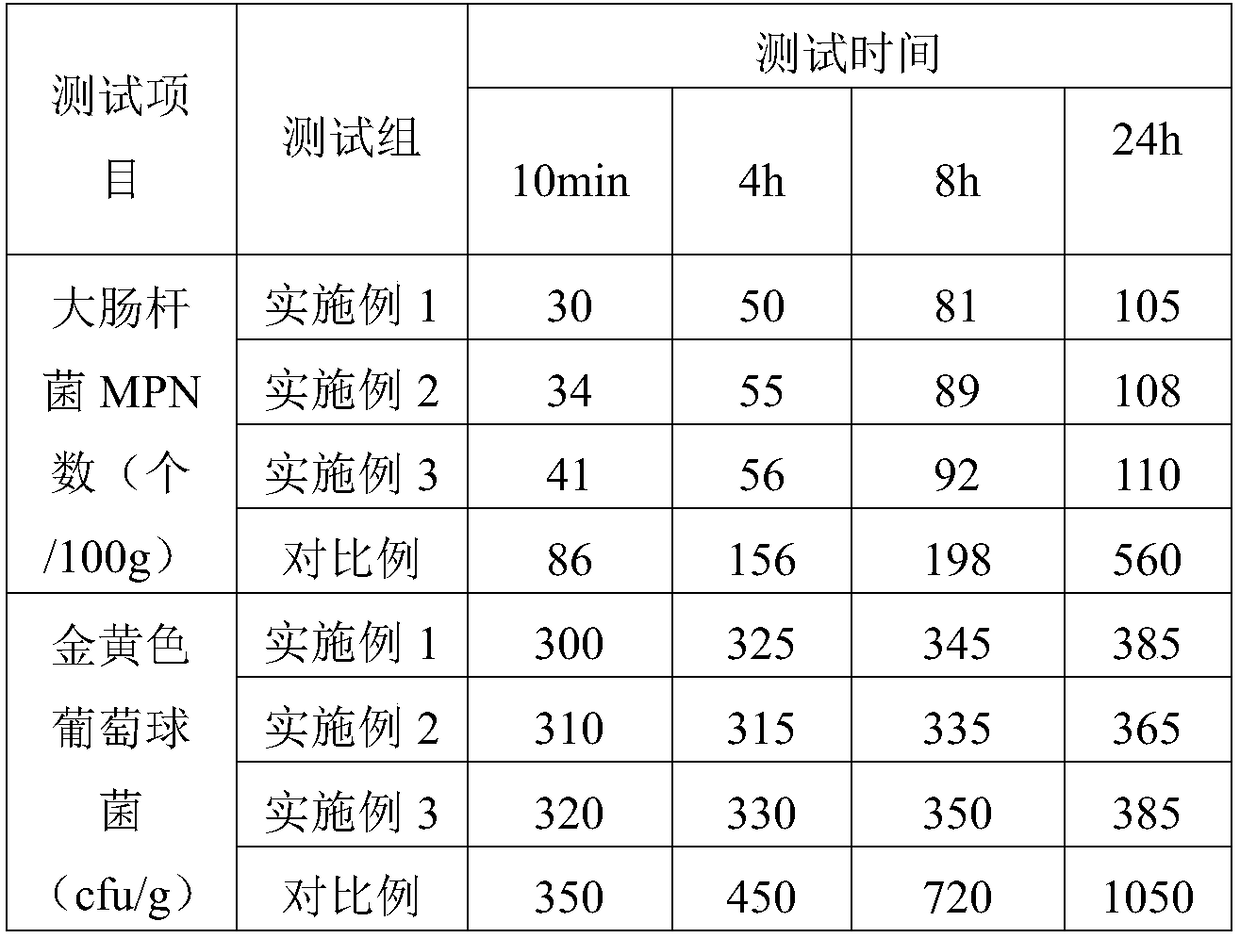

Examples

Embodiment 1

[0019] A kind of antibacterial aftertreatment method of latex gloves, comprises the steps:

[0020] (1) Low-temperature plasma treatment process: After the latex base material is added to the glove model, low-temperature plasma treatment process is performed: the glove model with the latex base material is placed in a low-temperature plasma treatment device, and the treatment gas is a gas with a volume ratio of 1:1. The mixture of inert gas and methane gas, the treatment power is 200W, and the specific treatment time is 6 minutes; after the treatment is completed, take it out at room temperature and place it at room temperature for 20 minutes, then continue to perform latex vulcanization, dipping, leaching, film drying, and demoulding processes to obtain semi-finished latex gloves; The treatment temperature of the low-temperature plasma treatment process is -20°C;

[0021] (2) antibacterial finishing agent treatment process: the latex glove semi-finished product is placed in c...

Embodiment 2

[0025] A kind of antibacterial aftertreatment method of latex gloves, comprises the steps:

[0026] (1) Low-temperature plasma treatment process: After the latex base material is added to the glove model, low-temperature plasma treatment process is performed: the glove model with the latex base material is placed in a low-temperature plasma treatment device, and the treatment gas is a gas with a volume ratio of 1:1. The mixture of inert gas and methane gas, the treatment power is 200W, and the specific treatment time is 8 minutes; after the treatment is completed, take it out at room temperature and place it at room temperature for 30 minutes, then continue to perform latex vulcanization, dipping, leaching, film drying, and demoulding processes to obtain semi-finished latex gloves; The treatment temperature of the low-temperature plasma treatment process is -10°C;

[0027] (2) antibacterial finishing agent treatment process: the latex glove semi-finished product is placed in c...

Embodiment 3

[0031] A kind of antibacterial aftertreatment method of latex gloves, comprises the steps:

[0032] (1) Low-temperature plasma treatment process: After the latex base material is added to the glove model, low-temperature plasma treatment process is performed: the glove model with the latex base material is placed in a low-temperature plasma treatment device, and the treatment gas is a gas with a volume ratio of 1:1. The mixture of inert gas and methane gas, the treatment power is 200W, and the specific treatment time is 7 minutes; after the treatment is completed, take it out at room temperature and place it at room temperature for 25 minutes, then continue to perform latex vulcanization, dipping, leaching, film drying, and demoulding processes to obtain semi-finished latex gloves; The treatment temperature of the low temperature plasma treatment process is -15°C;

[0033] (2) antibacterial finishing agent treatment process: the latex glove semi-finished product is placed in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com