Antibacterial PE (Poly Ethylene) punched film, preparation process thereof and hygienic product therefrom

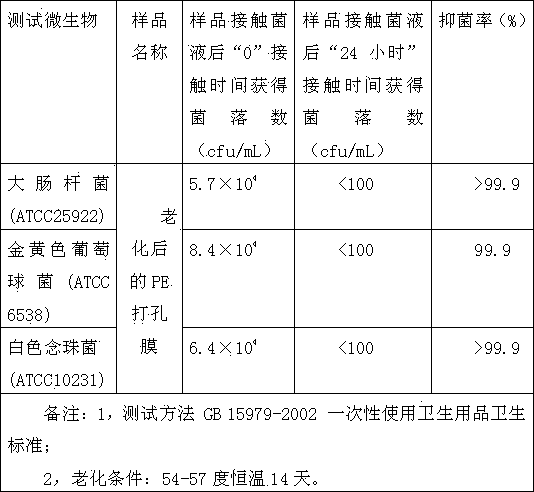

A technology of hygiene products and perforated membranes, applied in the field of hygiene products, can solve problems such as easy breeding of bacteria, danger to human health, poor dryness, etc., and achieve the effect of eliminating adverse effects and excellent and long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Antibacterial PE perforated film, used as a penetrating layer on the surface of sanitary products, prepared from the following ingredients by weight: 2% antibacterial masterbatch, 0.1% antioxidant, 4% whitening masterbatch, 4%PE Perforated film penetrant, 89.9% polyethylene plastic;

[0025] In the present embodiment, the antibacterial masterbatch comprises the following components by weight: 10% zirconium phosphate silver-loaded antibacterial powder, 90% polyethylene plastic;

[0026] Wherein, the whitening masterbatch is a polyethylene masterbatch containing 48% titanium dioxide by weight.

[0027] It should be noted that in this embodiment, the weight percentage of various components in the antibacterial PE perforated film is calculated based on the weight of the PE perforated film, and the weight percentage of each component in the antibacterial masterbatch is based on the weight of the antibacterial masterbatch calculated as the base. The method for calculating t...

Embodiment 2

[0029] Antibacterial PE perforated film, by weight percentage, includes 5% antibacterial masterbatch, 0.2% antioxidant, 4.8% whitening masterbatch, 5% PE perforated film penetrant, and 85% polyethylene plastic.

[0030] In this embodiment, the antibacterial masterbatch includes 20% silver-loaded zirconium phosphate antibacterial powder and 80% polyethylene plastic.

[0031] Wherein, the whitening masterbatch is a polyethylene masterbatch containing 52% titanium dioxide by weight.

Embodiment 3

[0033] Antibacterial PE perforated film, by weight percentage, includes 2.5% antibacterial masterbatch, 0.3% antioxidant, 2.7% whitening masterbatch, 4.5% PE perforated film penetrant, and 90% polyethylene plastic.

[0034] Among them, the antibacterial masterbatch includes 15% zirconium phosphate silver-loaded antibacterial powder and 85% polyethylene plastic.

[0035] In this embodiment, the whitening masterbatch is polyethylene masterbatch containing 50% titanium dioxide by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com