Waterproof antibacterial fabric finishing agent and application thereof

A technology for antibacterial fabrics and finishing agents, applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problems of unable to maintain waterproof performance for a long time, unable to have antibacterial effect, and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

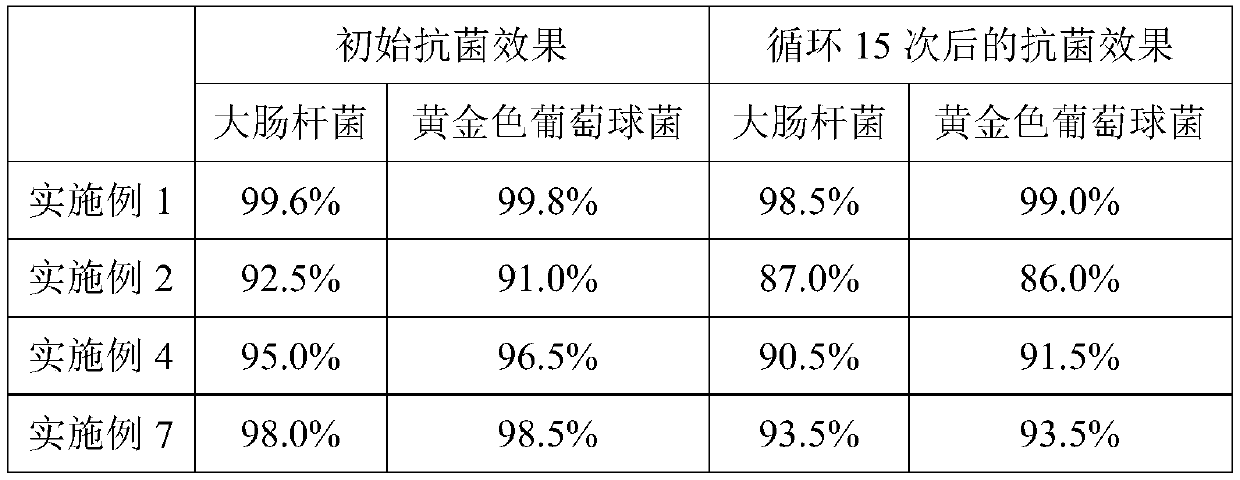

Examples

preparation example Construction

[0027] In some embodiments, the preparation method of the acrylate copolymer comprises the steps of:

[0028] Take by weighing preparation monomer long carbon chain acrylate, hydroxyethyl acrylate and methyl acrylate, and prepare the pre-emulsifier of 5wt% of monomer weight (such as can be equal weight sodium lauryl sulfate and lauryl alcohol) polyoxyethylene ether), added to deionized water, and stirred at 40 degrees Celsius for 15 minutes to obtain a pre-emulsion; then adding sodium bicarbonate buffer solution to the pre-emulsion to adjust the acidity and alkalinity of the system to neutral, and adding the prepared Initiator (such as ammonium persulfate, etc.) with 0.5% monomer weight is heated up to 80 degrees Celsius, and kept for 1 hour, then cooled to room temperature, demulsified, filtered, the filtrate is discarded, and the product is dried at 80 degrees Celsius to obtain Acrylate copolymer.

[0029] The silica sol in the present invention is a dispersion of nano-scal...

Embodiment 1

[0052] Embodiment 1: Provide a kind of waterproof and antibacterial fabric finishing agent, it is made up of following components by weight: 40 parts of acrylate copolymers, 9 parts of silica sol, 4 parts of long-acting antibacterial agents, 4 parts of dispersants , 55 parts of water.

[0053] The silica sol is HS-1430 purchased from Guangdong Huierte Nano Technology Co., Ltd.

[0054] The long-acting antibacterial agent is composed of long-chain alkylamine compounds, [(phenylmethoxy)methoxy]methanol and 1,2-benzisothiazolin-3-one, and its weight ratio is 2: 1.8:1; the long-chain alkylamine compound is N,N-di(3-aminopropyl)dodecylamine.

[0055] The dispersant is a mixture of palm oil amidomethyl MEA and potassium stearate in a weight ratio of 1:1.2.

[0056] The preparation method of described acrylate copolymer comprises the steps:

[0057] Take by weighing preparation monomer long carbon chain acrylate, hydroxyethyl acrylate and methyl acrylate, and prepare the pre-emuls...

Embodiment 2

[0058] Embodiment 2: provide a kind of waterproof and antibacterial fabric finishing agent, it is made up of following components by weight: 40 parts of acrylate copolymers, 9 parts of silica sol, 4 parts of long-acting antibacterial agents, 4 parts of dispersants , 55 parts of water.

[0059] The silica sol is HS-1430 purchased from Guangdong Huierte Nano Technology Co., Ltd.

[0060] The long-acting antibacterial agent is N,N-di(3-aminopropyl)dodecylamine.

[0061] The dispersant is a mixture of palm oil amidomethyl MEA and potassium stearate in a weight ratio of 1:1.2.

[0062] The preparation method of described acrylate copolymer comprises the steps:

[0063] Take by weighing preparation monomer long carbon chain acrylate, hydroxyethyl acrylate and methyl acrylate, and prepare the pre-emulsifier of 5wt% of monomer weight (such as can be equal weight sodium lauryl sulfate and lauryl alcohol) polyoxyethylene ether), added to deionized water, and stirred at 40 degrees Cel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com