Patents

Literature

46 results about "Perfluorooctane sulfonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

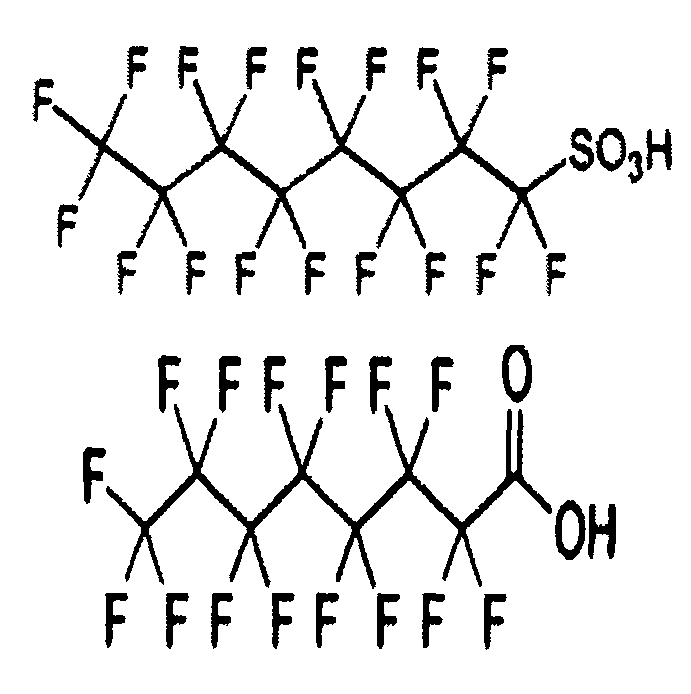

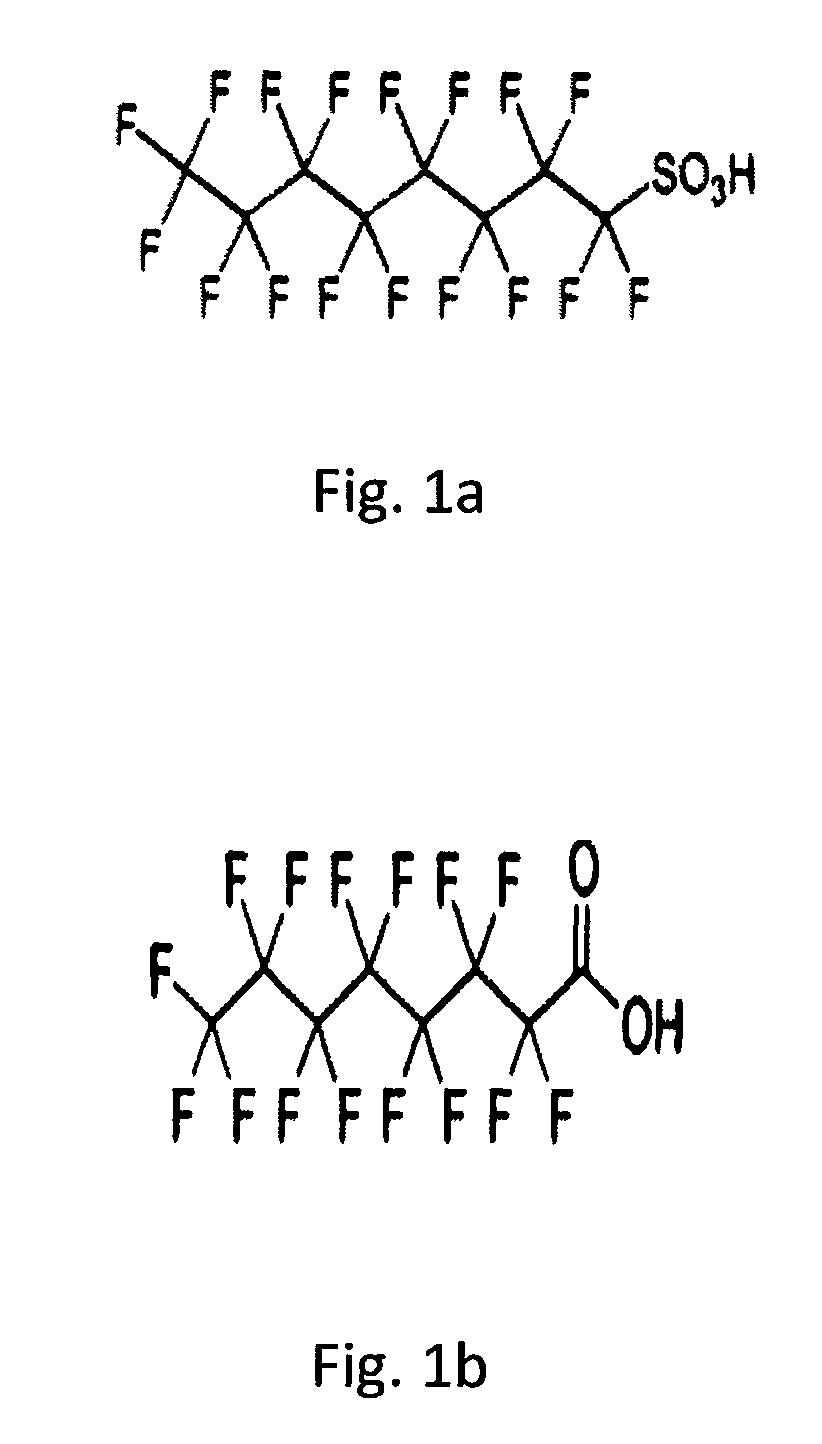

Perfluorooctanesulfonic acid (conjugate base perfluorooctanesulfonate) (PFOS) is an anthropogenic fluorosurfactant and global pollutant. PFOS was the key ingredient in Scotchgard, a fabric protector made by 3M, and numerous stain repellents.

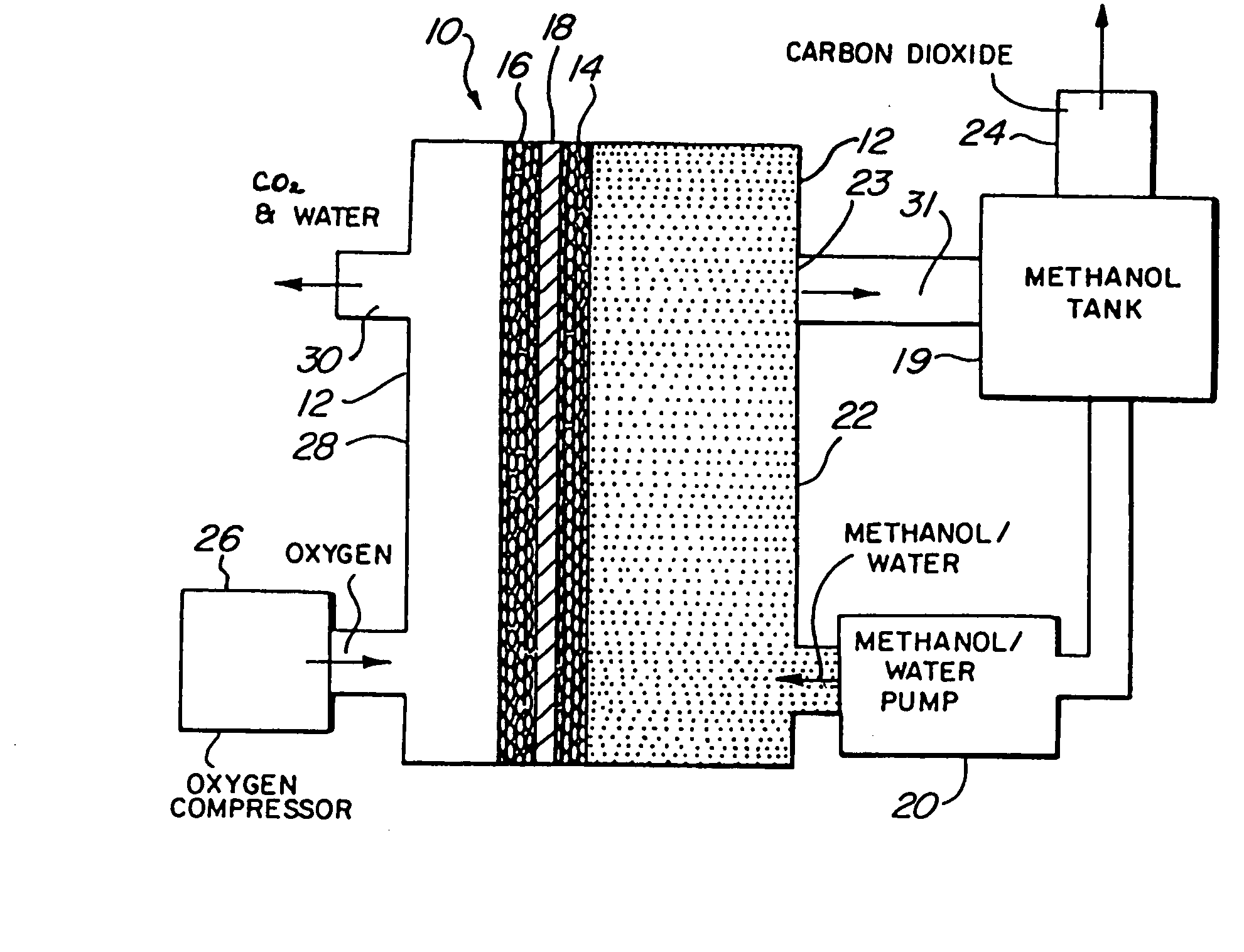

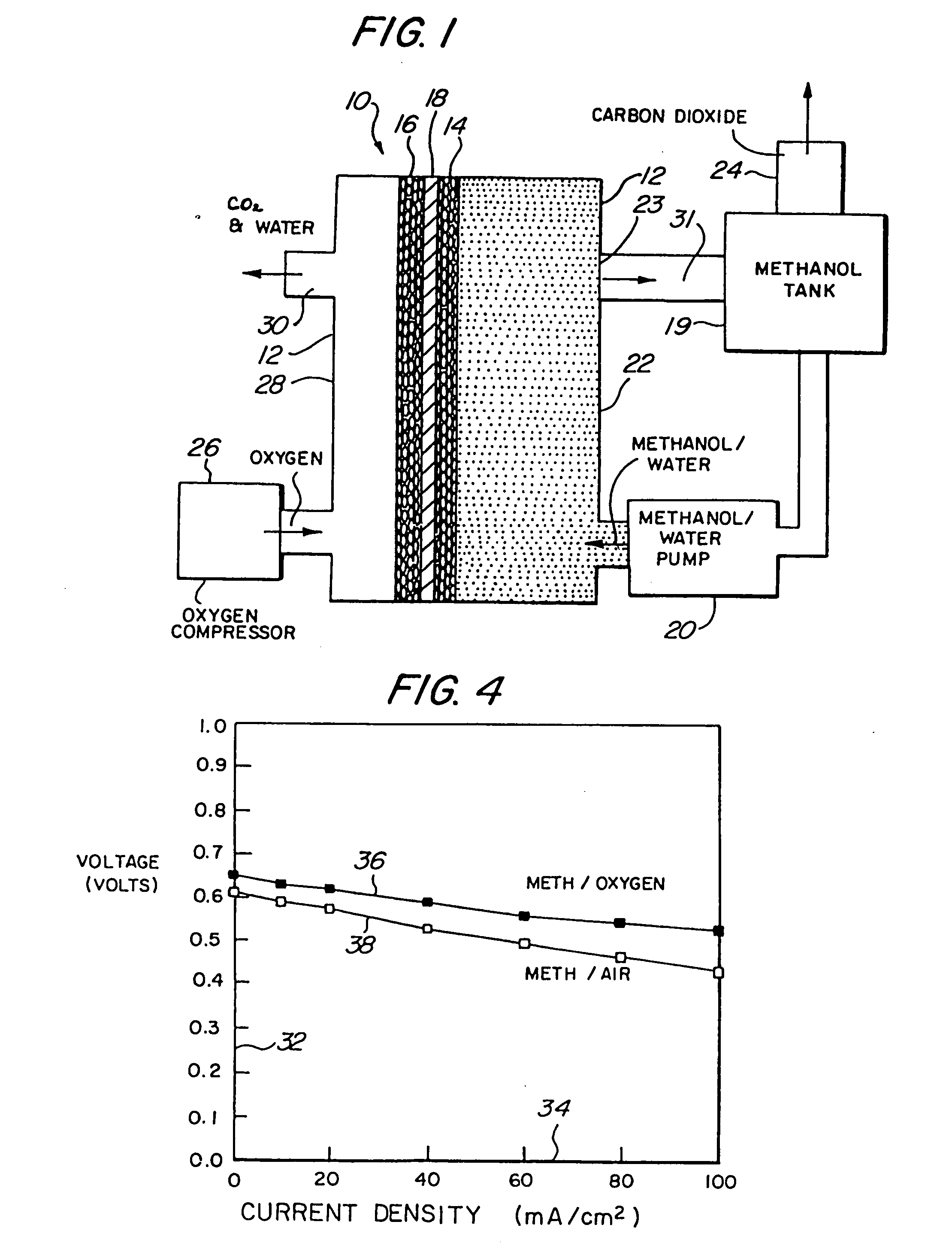

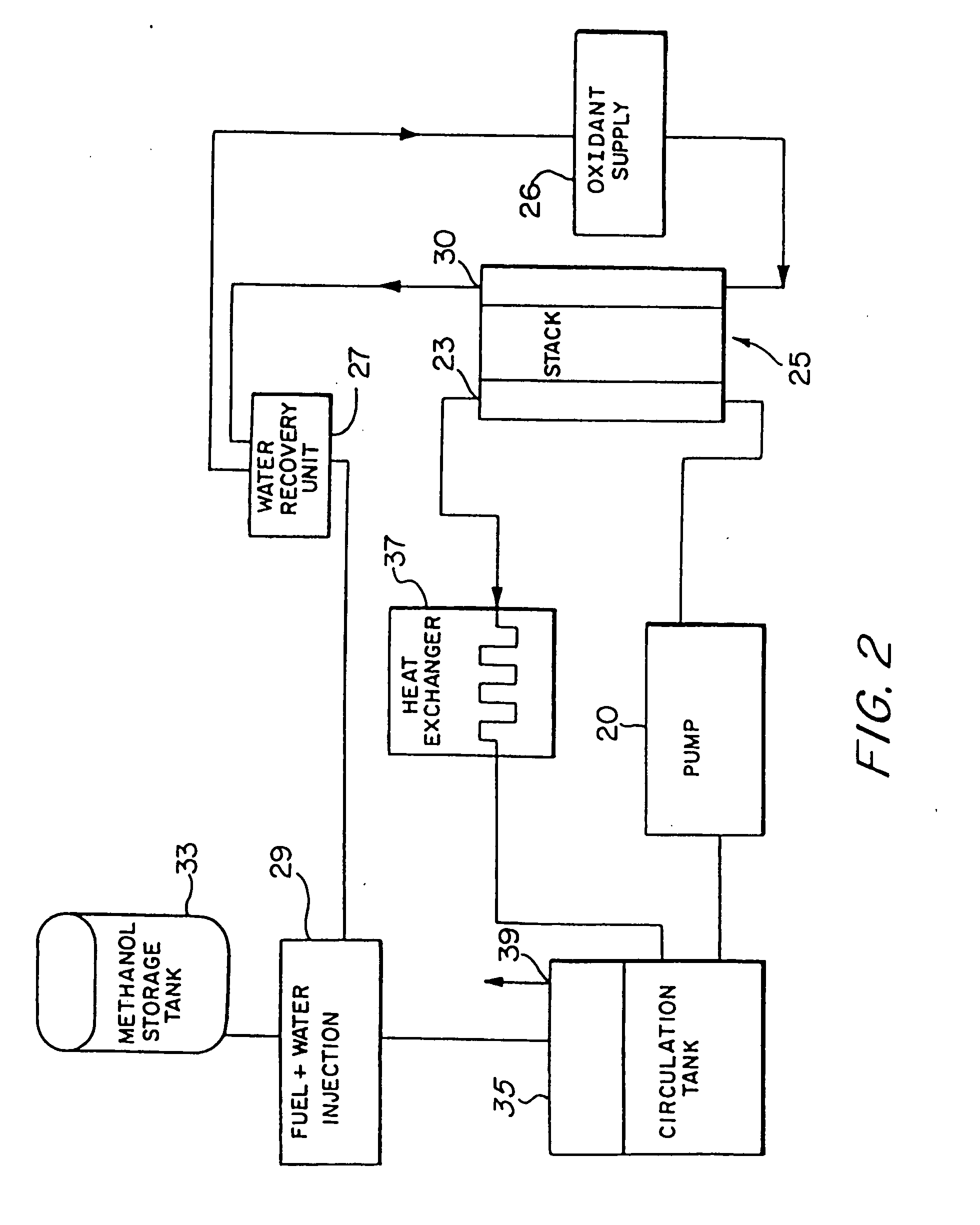

Organic fuel cell methods and apparatus

InactiveUS20060204810A1Poor fuel wetting propertyImprove wettabilitySolid electrolytesFuel cells groupingElectrical batteryOrganic fuel

A liquid organic, fuel cell is provided which employs a solid electrolyte membrane. An organic fuel, such as a methanol / water mixture, is circulated past an anode of a cell while oxygen or air is circulated past a cathode of the cell. The cell solid electrolyte membrane is preferably fabricated from Nafion™. Additionally, a method for improving the performance of carbon electrode structures for use in organic fuel cells is provided wherein a high surface-area carbon particle / Teflon™-binder structure is immersed within a Nafion™ / methanol bath to impregnate the electrode with Nafion™. A method for fabricating an anode for use in a organic fuel cell is described wherein metal alloys are deposited onto the electrode in an electro-deposition solution containing perfluorooctanesulfonic acid. A fuel additive containing perfluorooctanesulfonic acid for use with fuel cells employing a sulfuric acid electrolyte is also disclosed. New organic fuels, namely, trimethoxymethane, dimethoxymethane, and trioxane are also described for use with either conventional or improved fuel cells.

Owner:CALIFORNIA INST OF TECH +1

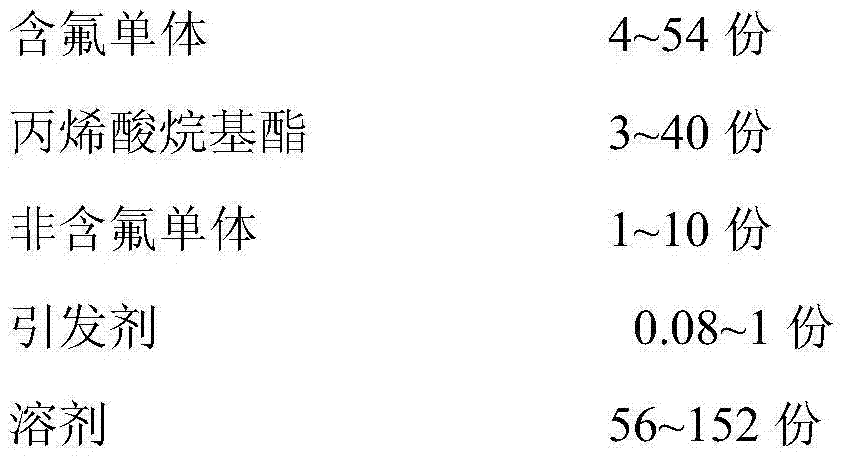

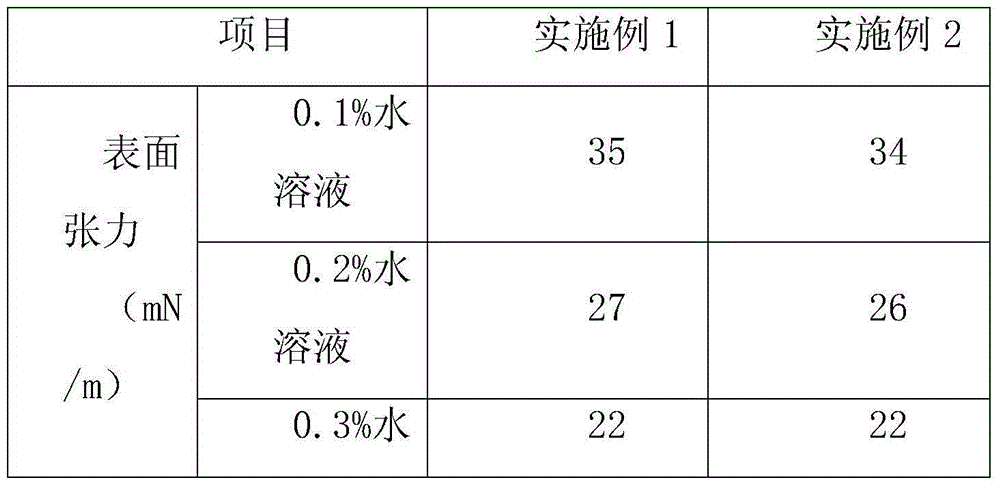

Novel environment-friendly oil and water repellent agent for leather

The invention discloses a novel environment-friendly oil and water repellent agent for leather. The agent consists of the following components by weight: 4-54 parts of fluorine monomers, 3-40 parts of alkyl acrylate, 1-10 parts of non-fluorinated monomers, 0.08-1 part of an initiator and 56-152 parts of a solvent. The novel environment-friendly oil and water repellent agent for leather provided by the invention does not contain perfluorooctanoic acid compound (PFOA) or perfluorooctane sulfonic acid compounds (PFOS), which cause negative impact on the environment, and has excellent waterproof and oil-proof performances.

Owner:JUHUA GROUP TECH CENT

Waterproof antibacterial fabric finishing agent and application thereof

InactiveCN111321594AUniform dense settingImprove long-lasting antibacterial performanceBiochemical fibre treatmentLiquid repellent fibresPolymer scienceAntibacterial agent

The invention relates to the waterproof processing and finishing technology, in particular to a waterproof antibacterial fabric finishing agent and an application thereof. The waterproof antibacterialfabric finishing agent is composed of the following components by weight parts of: 30 to 45 parts of acrylate copolymer, 5 to 10 parts of silica solution, 1 to 8 parts of long-acting antibacterial agent, 1 to 5 parts of dispersant, and 40 to 60 parts of water. In the invention, through adopting the compounded antibacterial agent components, the dispersion and stability of the long-acting antibacterial agent are improved, and at the same time, the long-acting antibacterial effect of the waterproof antibacterial fabric finishing agent is significantly improved. In addition, the waterproof antibacterial fabric finishing agent disclosed by the invention does not contain PFOS(perfluorooctane sulfonate) and PFOA(perfluorooctanoic acid), which is easily biodegraded, has no bioaccumulative properties, is less harmful to the human body, and is a relatively safe and environmentally friendly product.

Owner:京准化工技术(上海)有限公司

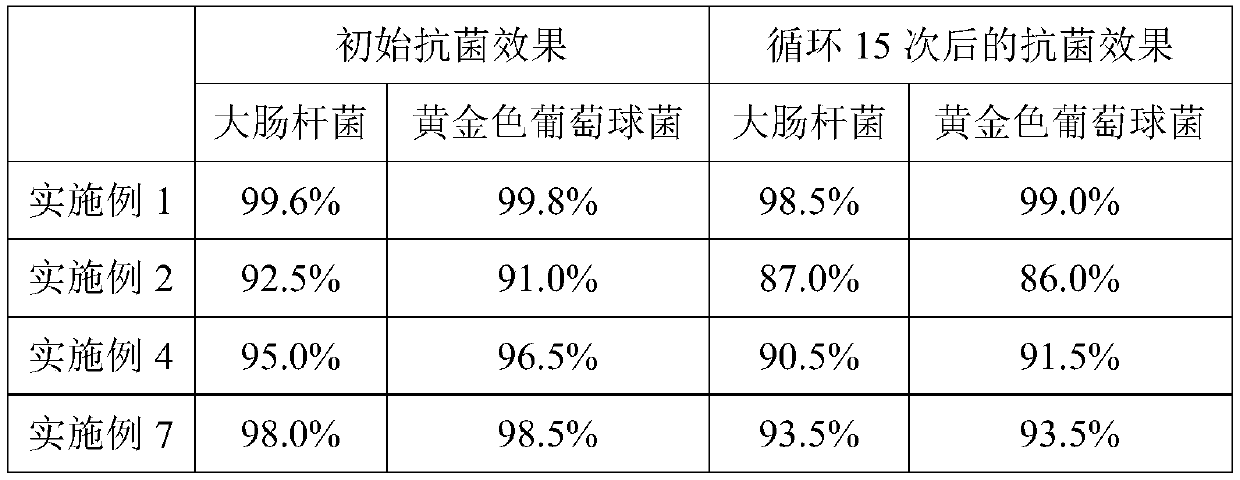

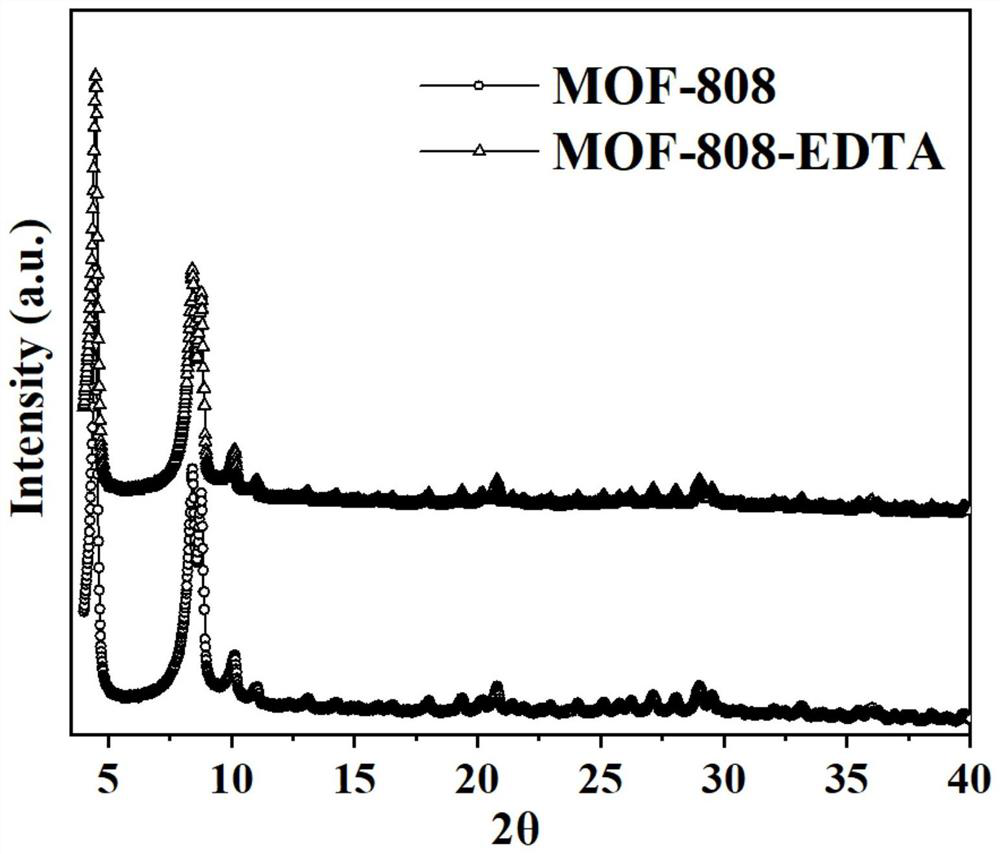

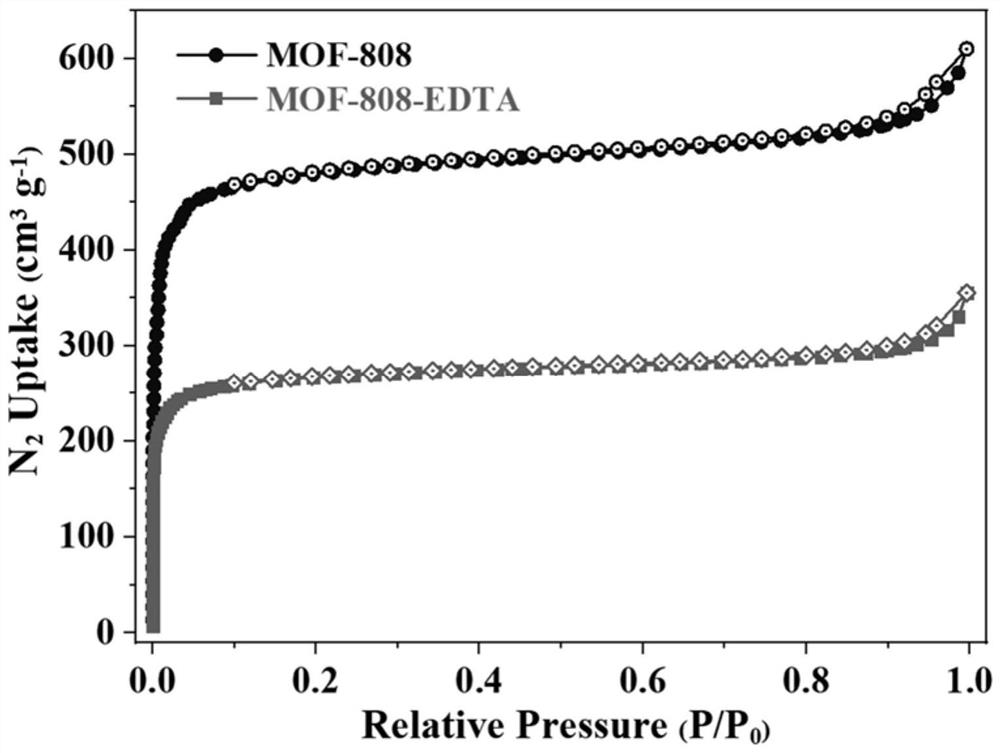

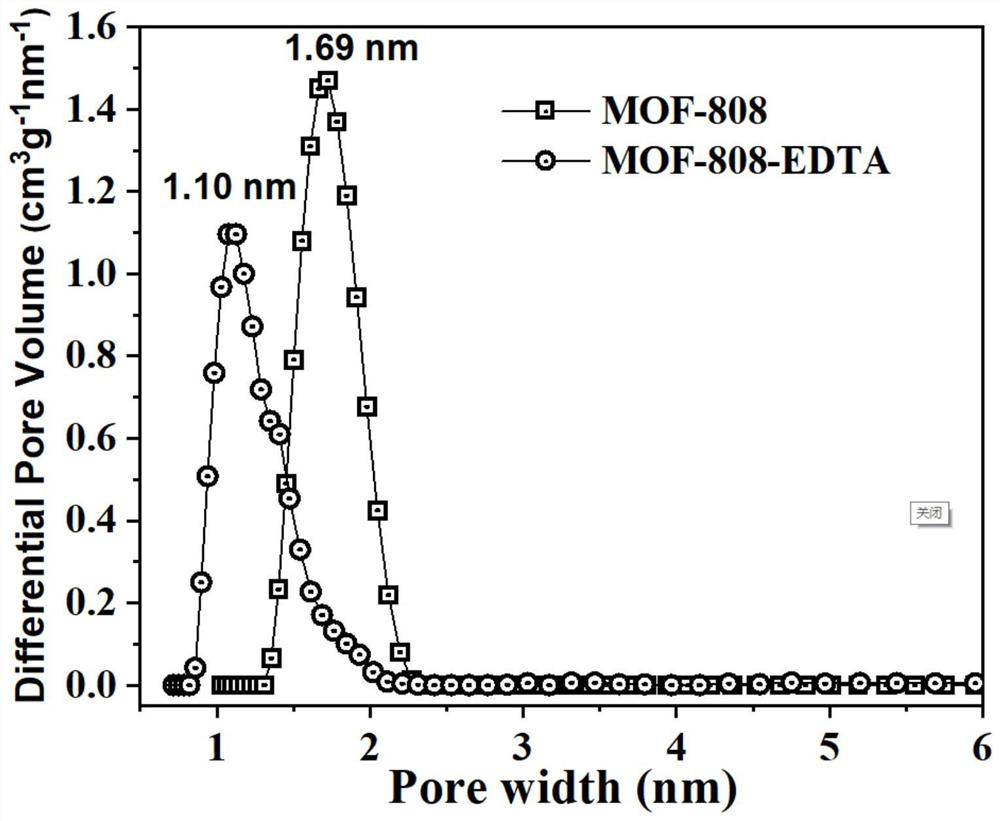

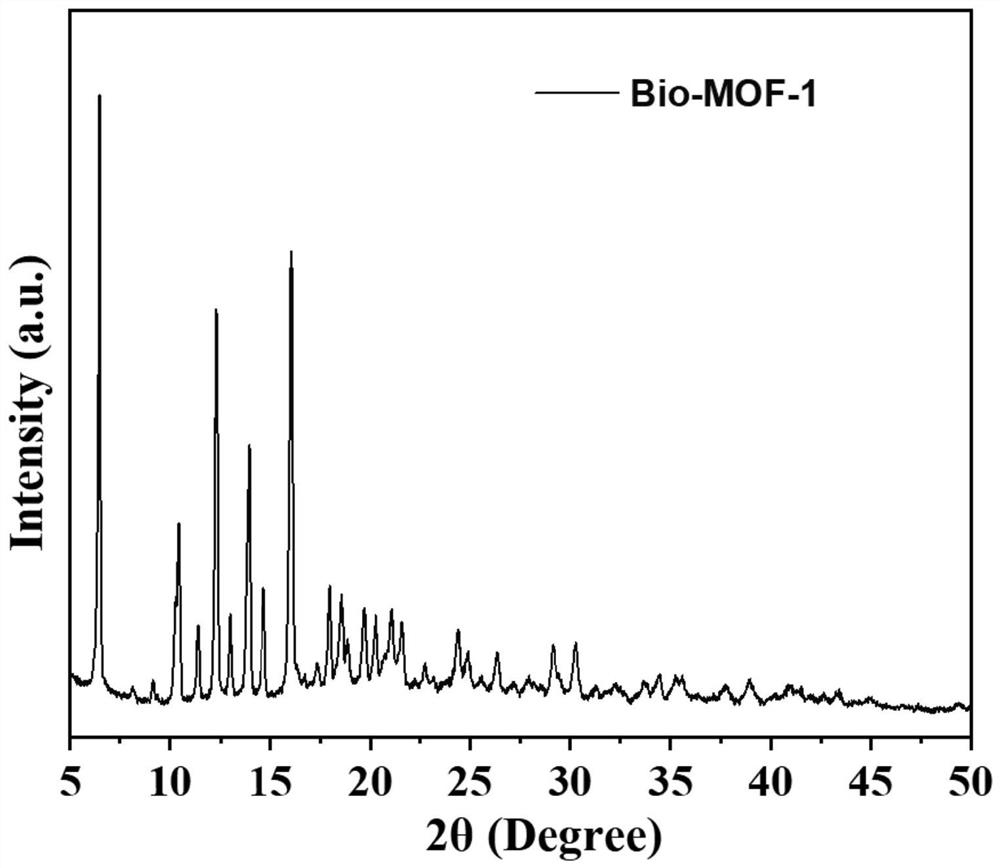

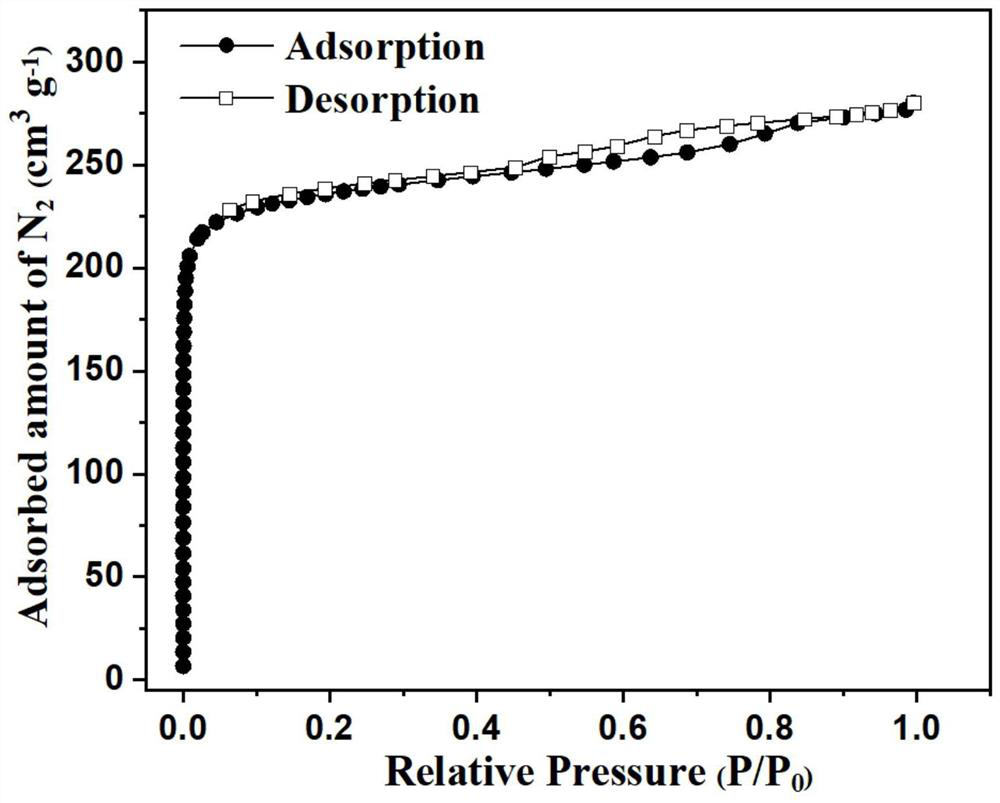

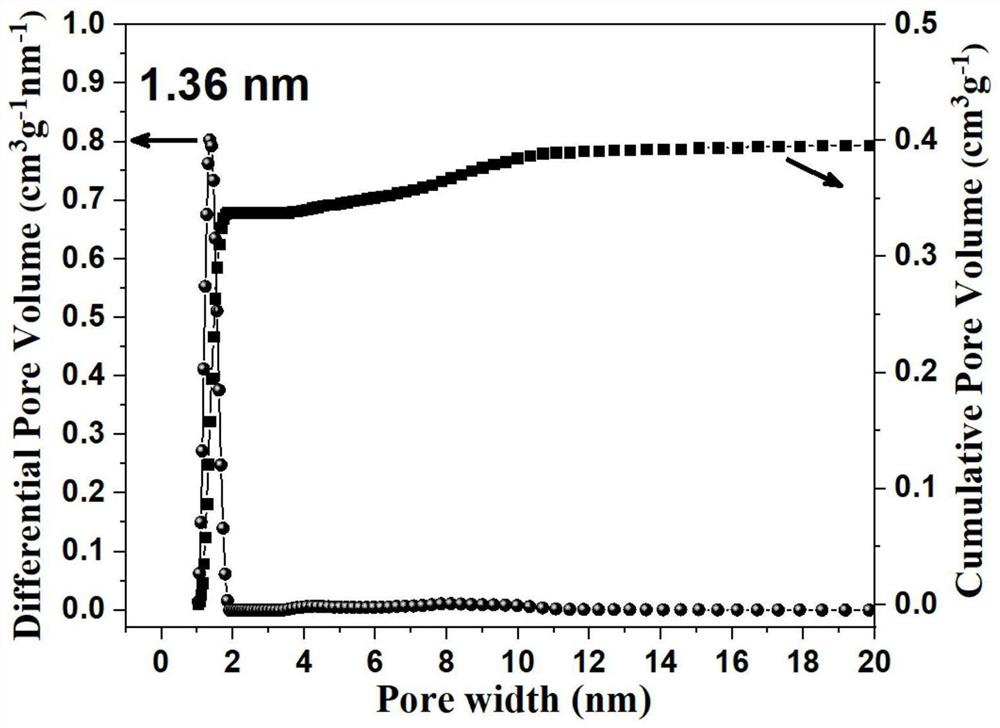

Porous material adsorbent as well as preparation method and application thereof

PendingCN113385144AEfficient removalEfficient selective adsorption capacityOther chemical processesWater contaminantsSorbentPerfluorocaprylic acid

The invention discloses a porous material adsorbent and a preparation method and application thereof. The preparation method comprises the steps of dissolving 1,3,5-benzenetricarboxylic acid and zirconium oxychloride octahydrate in a mixed solvent of formic acid and N,N-dimethylformamide (DMF), conducting heating to obtain white precipitate, and conducting washing to obtain a porous material; and dissolving the porous material into an ethylene diamine tetraacetic acid (EDTA) disodium solution, and conducting heating, filtering and washing to obtain the EDTA modified MOF-808 with the carboxyl functional group. The MOF-808-EDTA porous adsorbent disclosed by the invention can be used for efficiently removing perfluoroalkyl substances in water, wherein the perfluoroalkyl substances mainly comprise perfluorooctanoic acid (PFOA) and perfluorooctane sulfonic acid (PFOS). Meanwhile, heavy metal ion pollutants, mainly heavy metal ions such as Hg<2+>, As<2+>, Cd<2+> and Pb<2+>, in water can be efficiently removed, so that the water quality of drinking water meets the set standard and requirement of domestic drinking water.

Owner:XI AN JIAOTONG UNIV

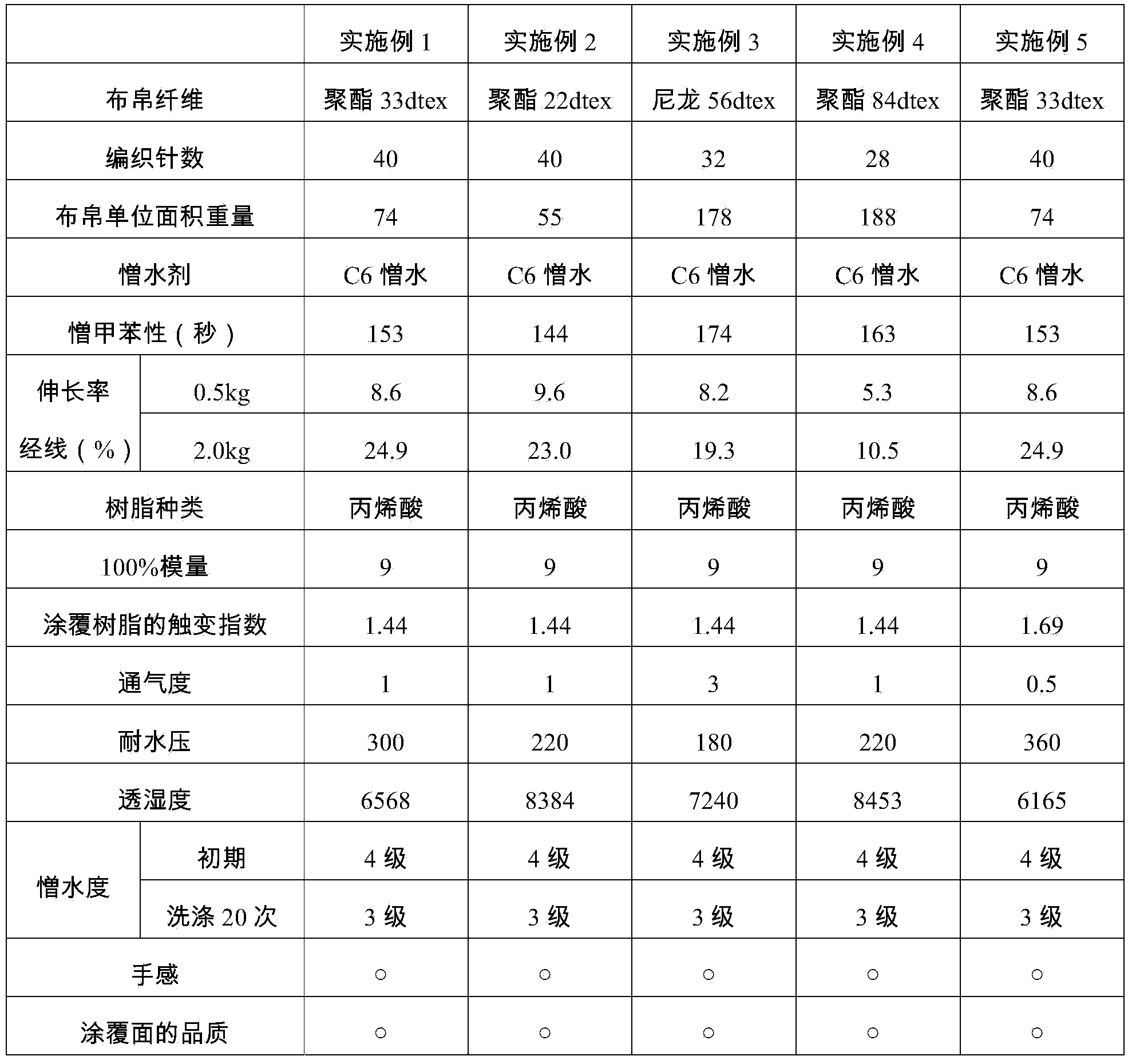

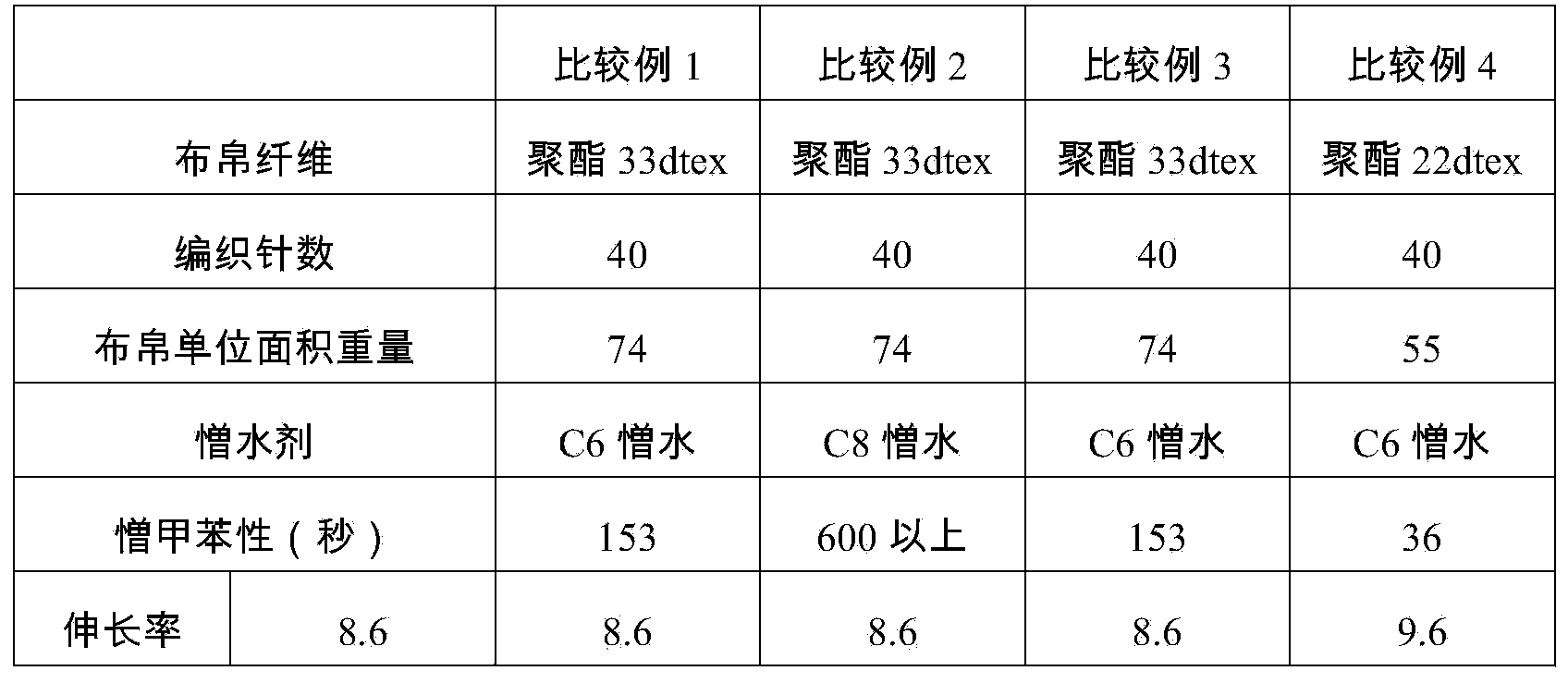

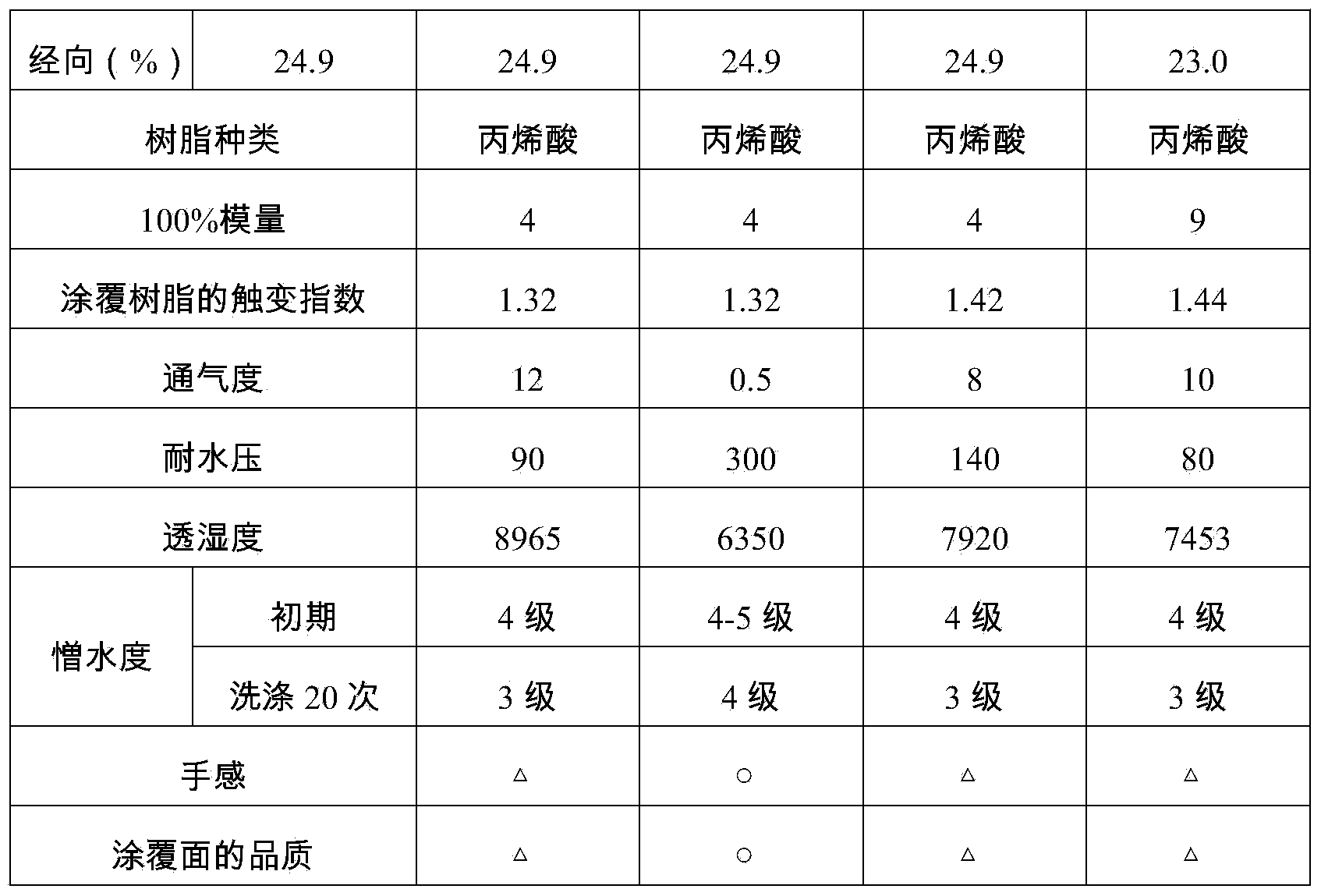

Stretchable coated fabric and process for producing same

InactiveCN104364437AImprove waterproof performanceImprove the windproof effectWeft knittingWarp knittingFiberPolymer science

A stretchable coated fabric to which water repellency has been imparted using a fluorochemical water repellent (C6 fluorochemical water repellent) comprising a copolymer containing a C6 or lower perfluoroalkyl group. As a result of this configuration, no C8 fluorochemical water repellent containing perfluorooctanoic acid, perfluorooctanesulfonic acid, or the like is used and, hence, the coated fabric exerts no influence on the environment. The fluorochemical water repellent has a toluene repellency of 100 seconds or higher, the synthetic-resin solution to be applied to at least one surface of a stretchable cloth has a thixotropic index measured at 23ºC of 1.4-2.0, and the synthetic resin has a 100% modulus of 5 kgf / cm2 or higher. Consequently, the stretchable coated fabric is free from, for example, synthetic-resin leakage to the back, and a coating resin film is formed with excellent film formation properties.

Owner:SEIREN CO LTD

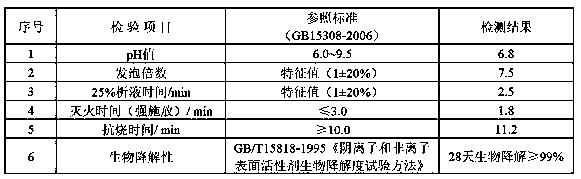

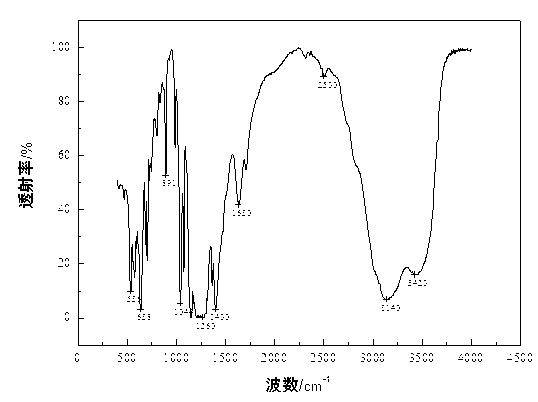

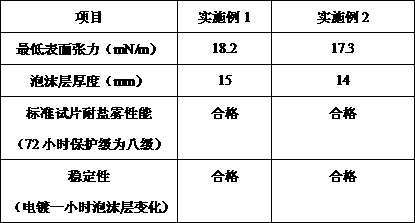

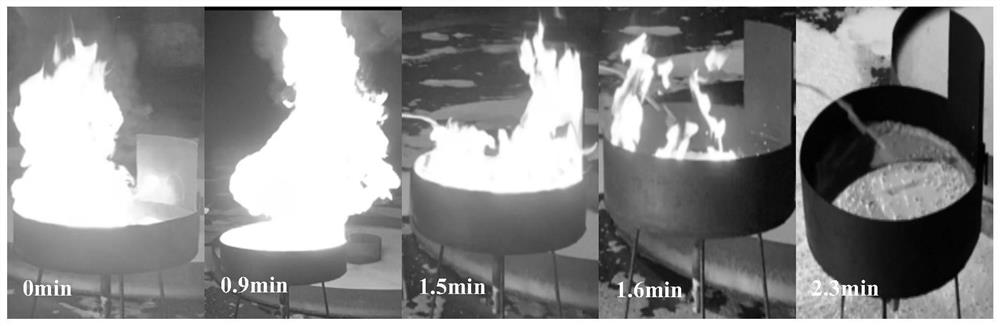

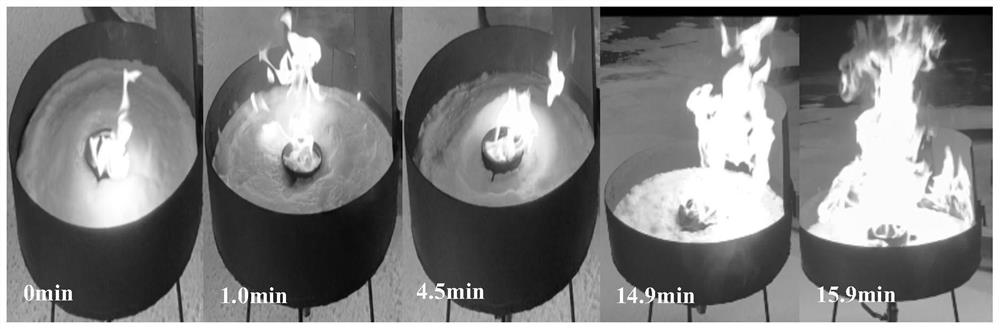

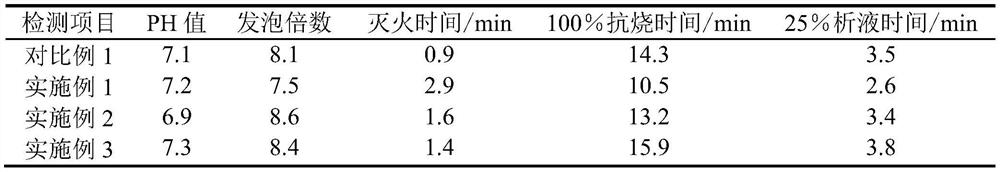

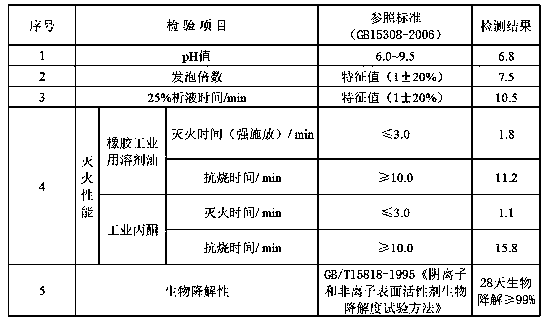

PFOS-free aqueous film-forming foam extinguishing agent and preparation method thereof

InactiveCN111054012AReduce pollutionPromote environmental protectionFire extinguisherActive agentSurface-active agents

The invention provides a PFOS-free aqueous film-forming foam extinguishing agent and a preparation method thereof. The PFOS-free aqueous film-forming foam extinguishing agent comprises the following components in percentage by weight: 12-30% of a combined hydrocarbon surfactant, 2-5% of a PFOS-free fluorocarbon surfactant, 5-8% of a foam stabilizer, 20-50% of an antifreeze agent, 3-5% of a solubilizer and 20-40% of water. The aqueous film-forming foam extinguishing agent disclosed by the invention does not contain perfluorooctane sulfonate which is difficult to degrade, so that the aqueous film-forming foam extinguishing agent has higher environmental friendliness, and the pollution to the environment is remarkably reduced; and by optimizing the components and the ratio, the excellent stability of the fire extinguishing agent is ensured at the same time.

Owner:江苏锁龙消防科技股份有限公司

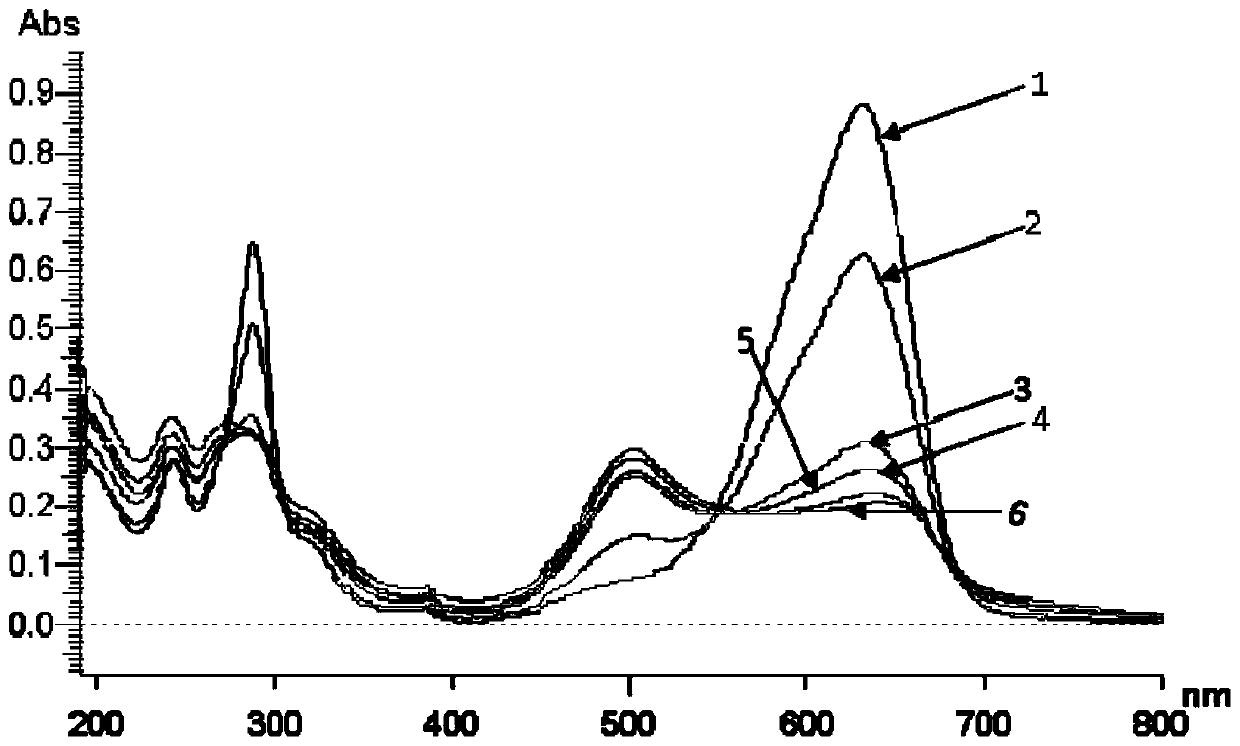

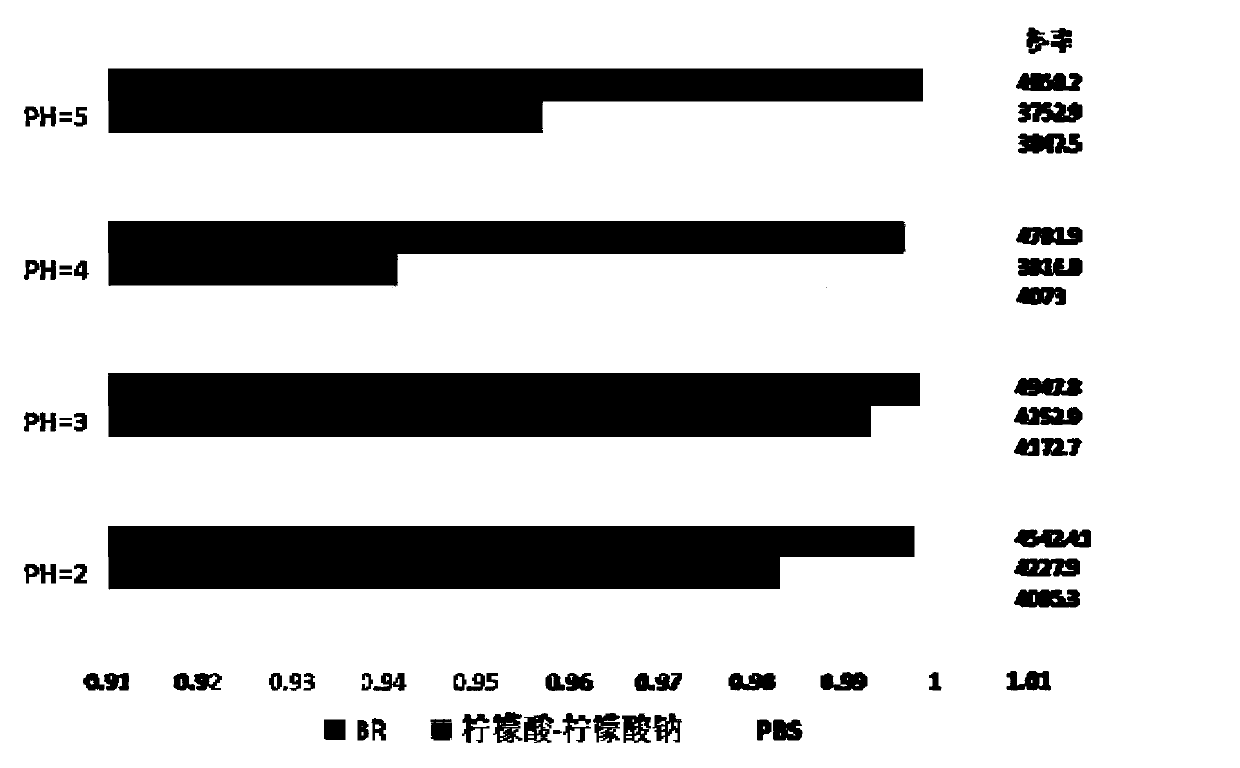

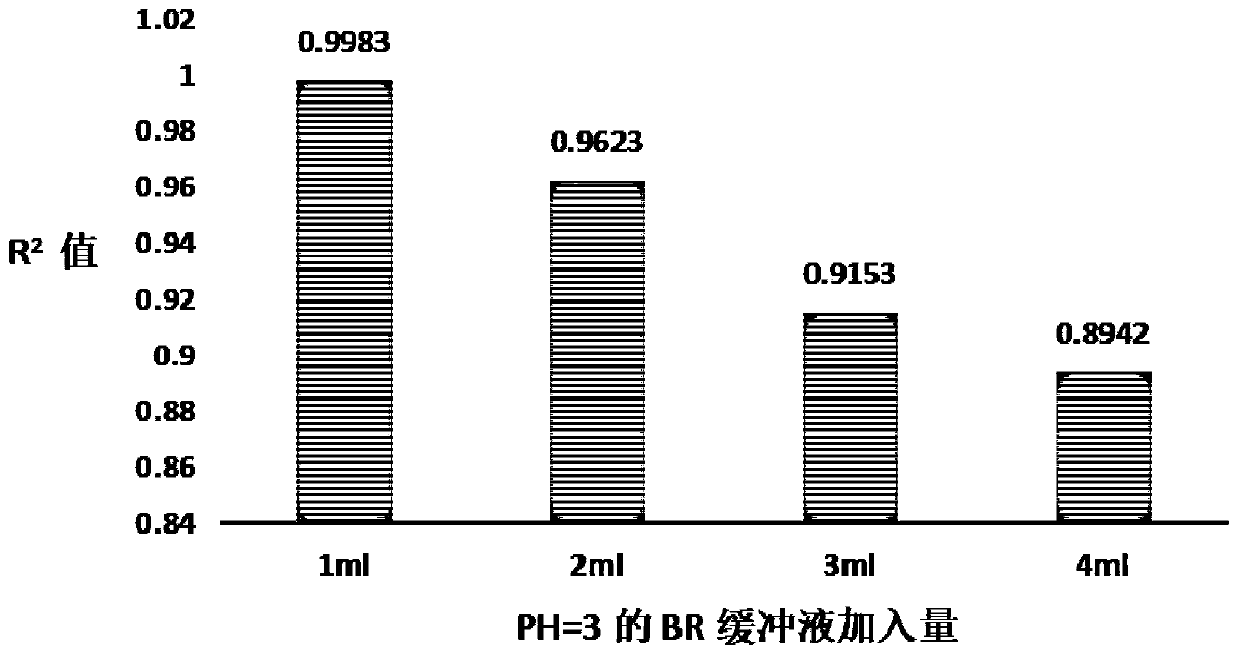

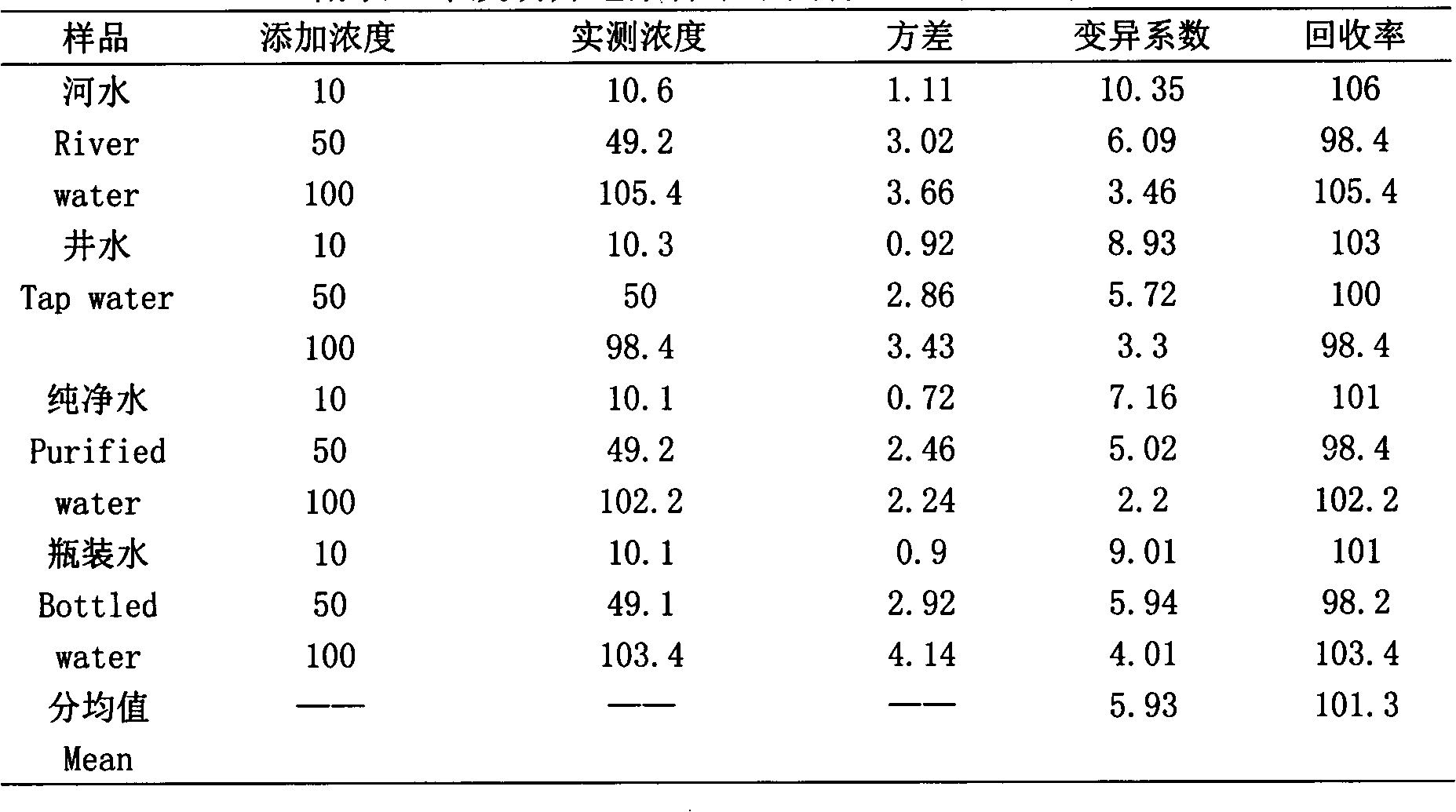

Method for measuring perfluorooctane sulfonate by using dual-wavelength ratio ultraviolet spectroscopy, and application thereof

ActiveCN110749562APotential for applicationSimple and fast operationColor/spectral properties measurementsUltravioletUltraviolet absorption

The invention relates to a method for measuring perfluorooctane sulfonate by using dual-wavelength ratio ultraviolet spectroscopy, and belongs to the field of physical and chemical inspection research. Perfluorooctane sulfonate molecules do not have ultraviolet absorption functional groups and do not have ultraviolet absorption properties. In the method provided by the invention, the ultraviolet absorption generates electrostatic interaction with toluidine blue under acidic conditions to form an ionic associate, the ionic associate shows two characteristic peaks at 632 nm and 502 nm and performs rational absorption, the concentration of a perfluorooctane sulfonate solution has a good linear relationship with an ultraviolet dual-wavelength absorption ratio value under selected conditions, and the dual-wavelength ratio ultraviolet spectroscopy for measuring the perfluorooctane sulfonate is established accordingly. The method provided by the invention is suitable for measuring the perfluorooctane sulfonate in environmental water samples, and has the advantages of simple and convenient operation, high sensitivity, strong anti-interference ability and the like.

Owner:GUANGDONG PHARMA UNIV

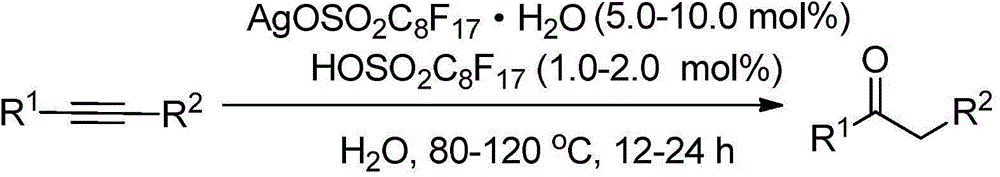

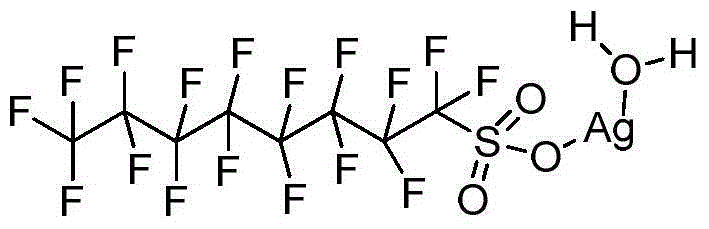

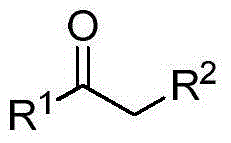

Method for synthesizing ketone through catalyzing and hydrolyzing alkyne with silver perfluorooctanesulfonate

ActiveCN104529725AEasy to separateGood choiceCarboxylic acid nitrile preparationOrganic compound preparationKetoneAlkyne

The invention provides a method for synthesizing a corresponding ketone through catalyzing and hydrolyzing an alkyne with silver perfluorooctanesulfonate. According to the method, water serves as a solvent, an alkyne serves as a raw material, silver perfluorooctanesulfonate serves as a main catalyst, and perfluorooctanesulfonic acid serves as an auxiliary catalyst, and reaction is carried out to synthesize a corresponding ketone. The method provided by the invention is an environment-friendly method for synthesizing a ketone by hydrolyzing an alkyne. The method has the advantages that the selectivity and yield of the target product are more than 90%, n-hexane or diethyl ether is added at the end of reaction to divide reactants into two phases, the catalysts can be reused directly in the water phase, the product of reaction is extracted and separated simply to obtain a corresponding ketone, and the whole reaction and separation processes are simple and environment-friendly.

Owner:HUNAN UNIV

Waterproof aerated concrete block and preparation method thereof

InactiveCN104556935AImprove waterproof performanceImprove water resistanceCeramicwareSODIUM METAPHOSPHATEAluminium chloride

The invention discloses a waterproof aerated concrete block and a preparation method thereof. The waterproof aerated concrete block is prepared from the following raw materials in parts by weight: 46-64 parts of desert sand, 28-36 parts of ash calcium powder, 15-20 parts of tuff, 22-28 parts of red mud, 14-21 parts of desulfurization ash, 10-15 parts of ardealite, 12-16 parts of bauxite, 4-7 parts of aluminum chloride crystal, 3-6 parts of sodium hexametaphosphate, 5-10 parts of alum, 2-3 parts of waste molasses, 3-5 parts of water glass, 1.5-2.5 parts of candelilla wax powder, 1-2 parts of methyl-ethyloxy silicone oil, 0.5-1 part of potassium perfluorooctane sulfonate and 0.7-1.3 parts of modified aluminum powder. The aerated concrete block disclosed by the invention has good waterproof property and excellent water resistance and hydration resistance and can be used for effectively solving the influence of bad conditions such as dampness and raininess on the performance of the aerated concrete block so as to prolong the service life of the aerated concrete block. The aerated concrete block also has good heat insulation property, relatively high compressive strength and broad application prospect.

Owner:安徽中龙建材科技有限公司

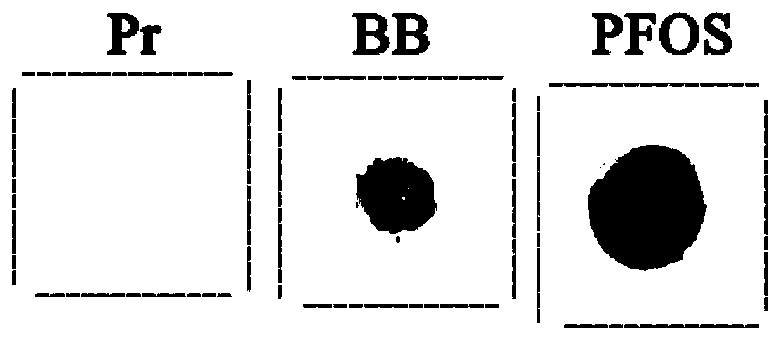

Chromium fog inhibitor and preparation method thereof

InactiveCN103130691AHarm reductionShort carbon chainCellsSulfonic acid amide preparationChlorosulfuric acidAcyl group

The invention discloses a chromium fog inhibitor, namely N-perfluorosulfonyl-(N-perfluorohexylsulfonyl) amine sulfonate, and further discloses a preparation method of the chromium fog inhibitor. According to the preparation method, N-perfluorosulfonyl-(N-perfluorohexylsulfonyl) amine reacts with chlorosulfonic acid and alkaline aqueous liquor to prepare N-perfluorosulfonyl-(N-perfluorohexylsulfonyl) amine sulfonate. Surface tension of the chromium fog inhibitor reaches the standard of the chromium fog inhibitor, and the fog inhibiting effect of the chromium fog inhibitor provided by the invention is equivalent to that of chromium fog inhibitors available in market, so that the chromium fog inhibitor provided by the invention can be used for replacing perfluorooctane sulfonate and salt (PFOS) of perfluorooctane sulfonate, as well as perfluorooctane sulfonate fluoride (PFOSF).

Owner:WUHAN UNIV

Degrading halogenated organic compounds

InactiveUS9814919B2Reduce compoundingLiquid degasificationConstructionsSimple Organic CompoundsCompound (substance)

A method of degrading halogenated organic compounds, use of the method for decontaminating PFOS (perfluorooctanesulfonic acid) and PFOA (perfluorooctanoic acid) contaminated medium, and a composition such as that which is suitable to be applied in said method.

Owner:ARCADIS NEDERLAND

Fluoride-free environment-friendly foam extinguishing agent and preparation method thereof

PendingCN113926131AReduce surface tensionSpread quicklyFire extinguisherNaturally occurring surfactantsActive agent

The invention discloses a fluoride-free environment-friendly foam extinguishing agent and a preparation method thereof, and belongs to the technical field of fire extinguishing agents. The fluoride-free environment-friendly foam extinguishing agent is characterized in that the extinguishing agent comprises, by weight, 5-15% of a natural surfactant, 7-10% of a hydrocarbon surfactant, 0.5-0.7% of a foam stabilizer, 3-8% of a cosolvent, 10-15% of an antifreeze agent, and the balance of water. Under the interaction of the components, the extinguishing agent has excellent fire extinguishing performance, and meanwhile, the extinguishing agent does not contain perfluorooctane sulfonic acid and perfluorooctanoic acid which are difficult to degrade, so that the extinguishing agent does not pollute the environment.

Owner:CHANGZHOU UNIV

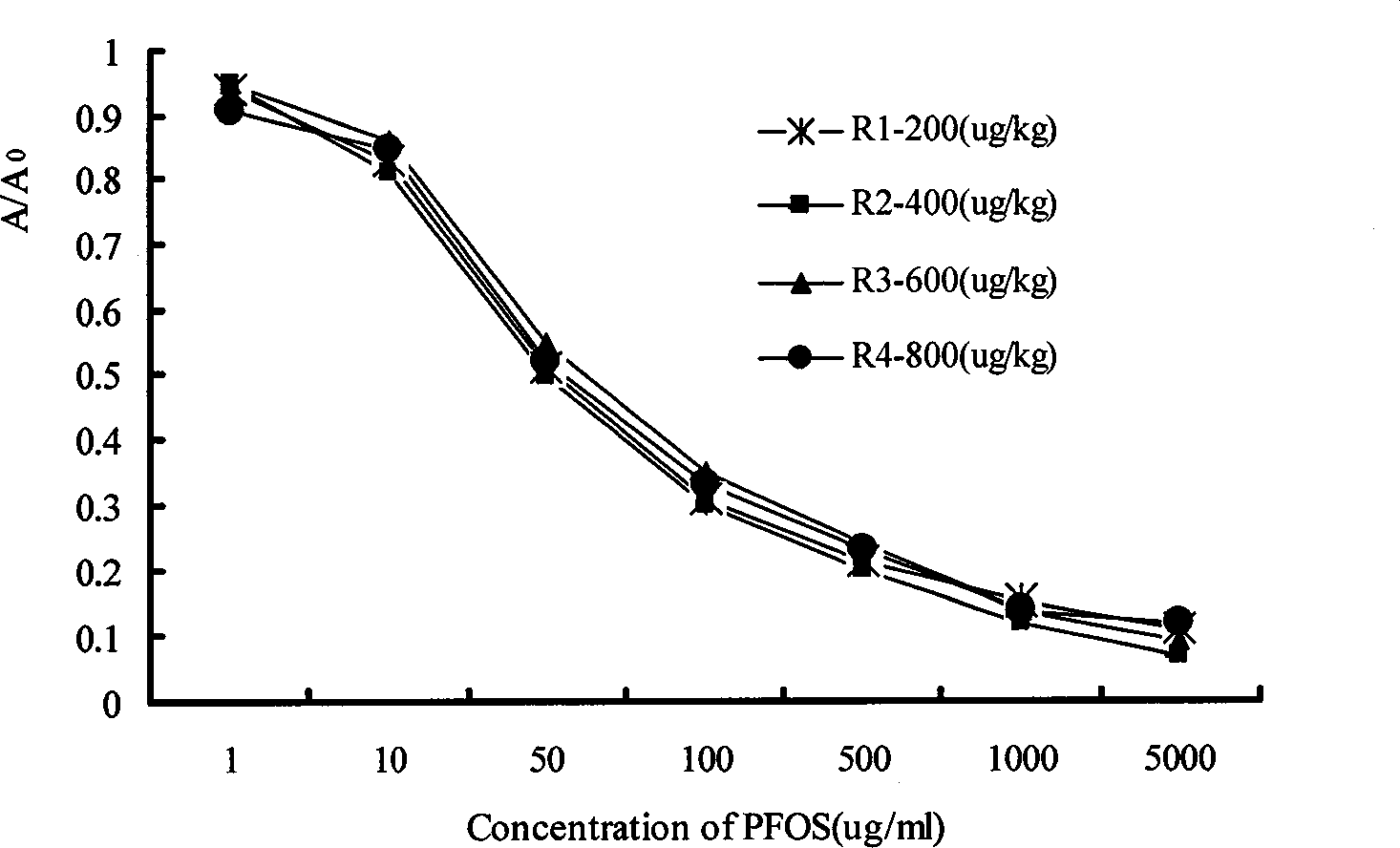

Enzyme-linked immunosorbent assay (ELISA) detection method for perfluorooctane sulfonate residual in environment

The invention relates to an enzyme-linked immunosorbent assay (ELISA) detection method, which can be applied to enzyme-linked immunosorbent assay (ELISA) detection of perfluorooctane sulfonated (PFOs) residual in the environment. The method comprises following steps: step one, synthesizing and identifying PFOs artificial antigen; step two, preparing and purifying PFOs antibody; step three, establishing PFOs indirectly competing ELISA quantitative detection method; step four, substituting PFOs with 9 PFCs with similar structures as that of PFOs, and then respectively measuring the cross-reactivity of the 9 PFCs with an antibody. The technology provides a method of rapidly detecting PFOs residual in the environment, better improves the detection sensitivity, guarantees the precision of the detection results, satisfy the requirements on PFOs residual detection at present, and is convenient for carrying out PFOs residual detection in the environment.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

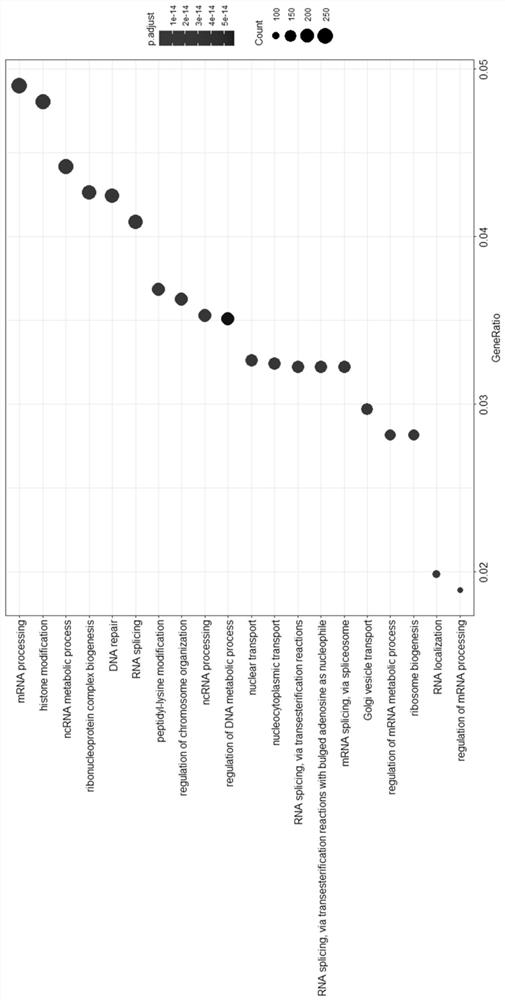

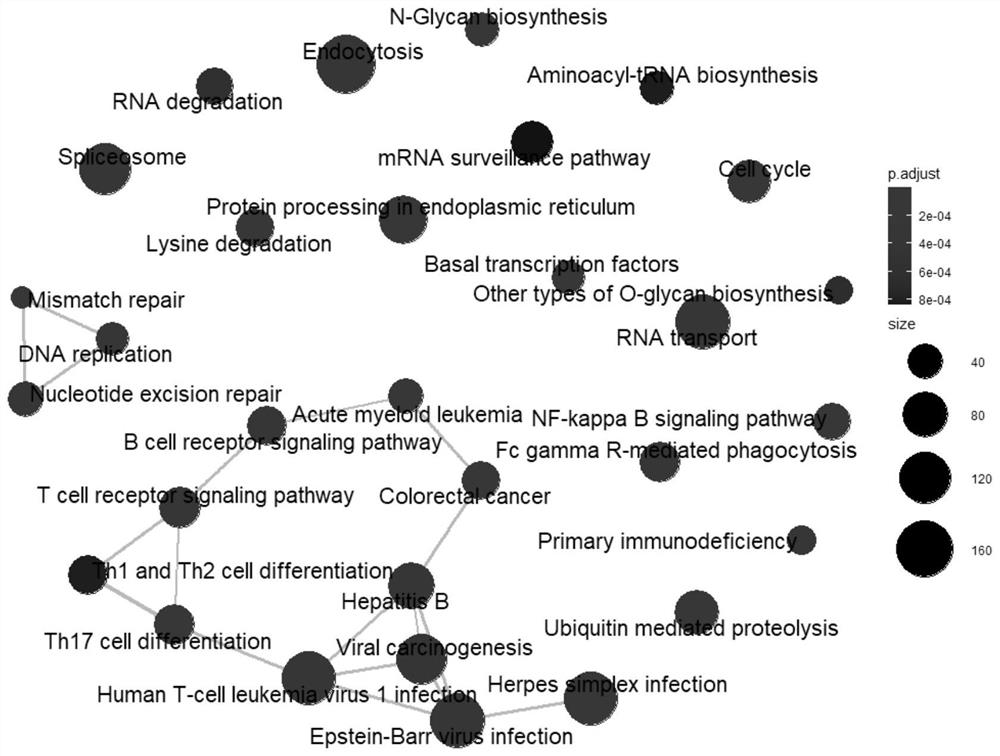

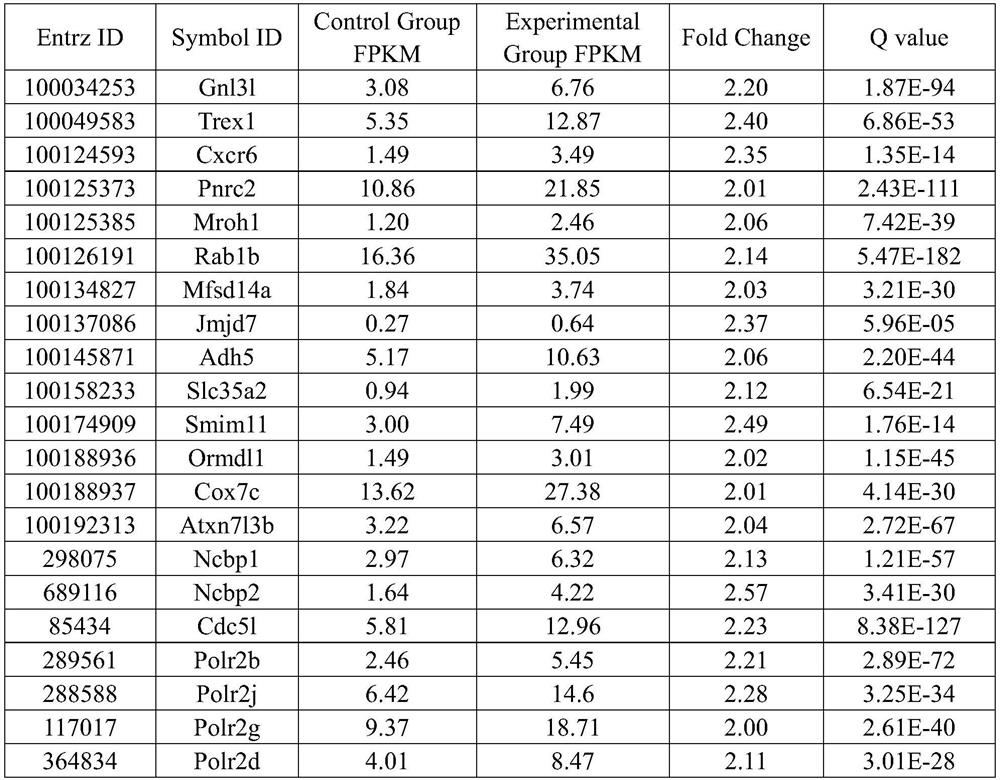

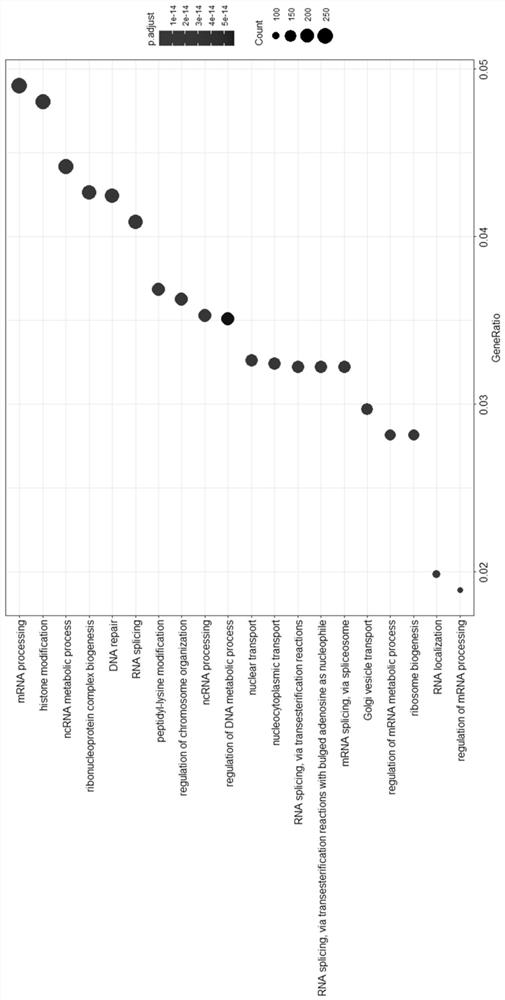

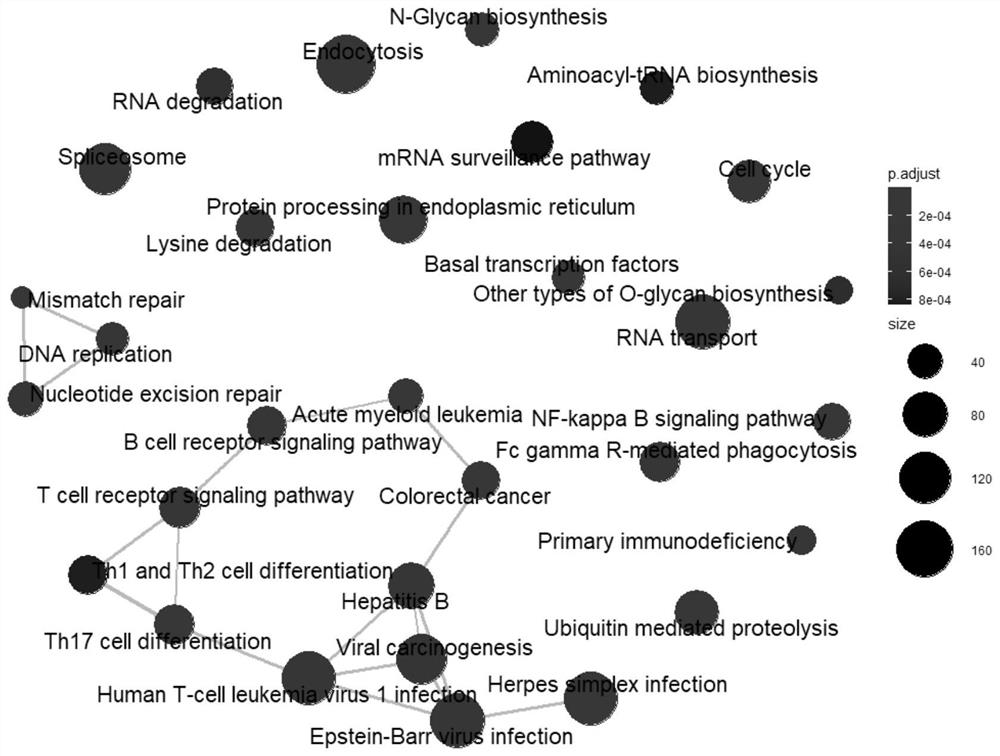

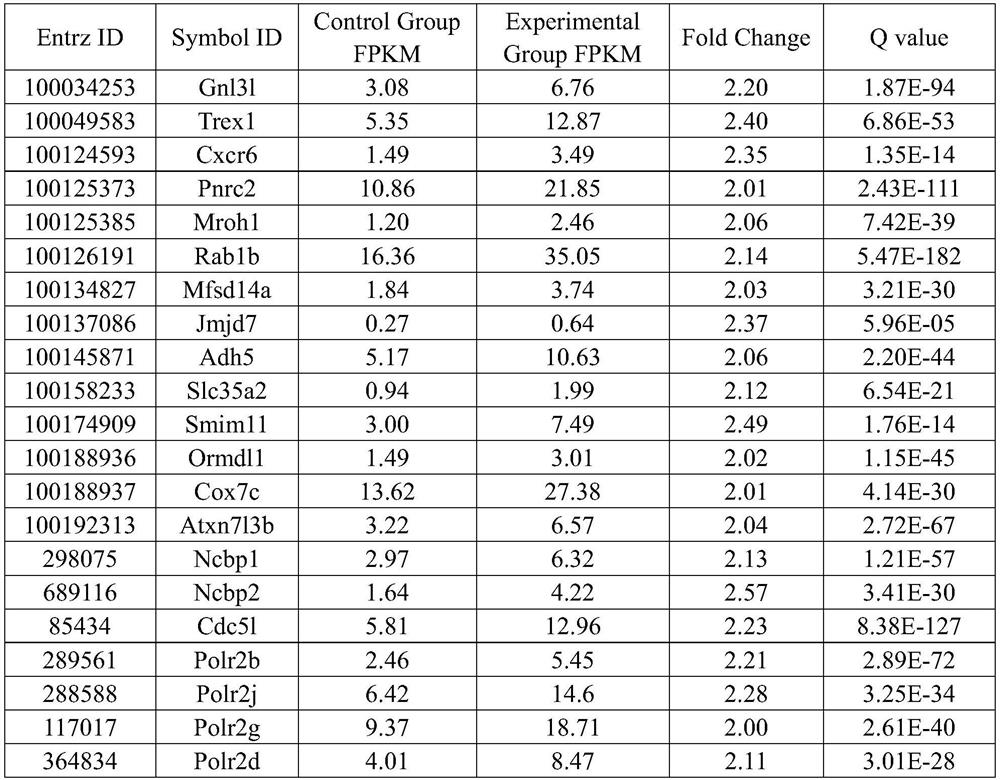

Method for screening perfluorooctane sulfonate toxicity hub gene and key signal channel by applying transcriptomics

The invention discloses a method for screening a PFOS toxicity hub gene and a key signal channel by applying transcriptomics. According to the method, firstly, a blank control group and a PFOS exposure group of experimental animals are set and processed to obtain a biological sample, RNA of the obtained biological sample is extracted, transcriptomics data of the biological sample are obtained through a high-throughput sequencer, the the obtained sequencing data is subjected to bioinformatics analysis comprising differential gene GO enrichment analysis, KEGG pathway enrichment analysis, protein interaction network analysis and GSEA analysis, and finally the PFOS toxic hub gene and key signal pathway results are obtained through screening. By applying the method provided by the invention, help can be provided for identifying the serious influence of the PFOS on animals or human beings and / or the toxicity mechanism of the PFOS on the animals or human beings and developing related drugs aiming at the toxicity of the PFOS.

Owner:INST OF QUALITY STANDARD & TESTING TECH FOR AGRO PROD OF CAAS

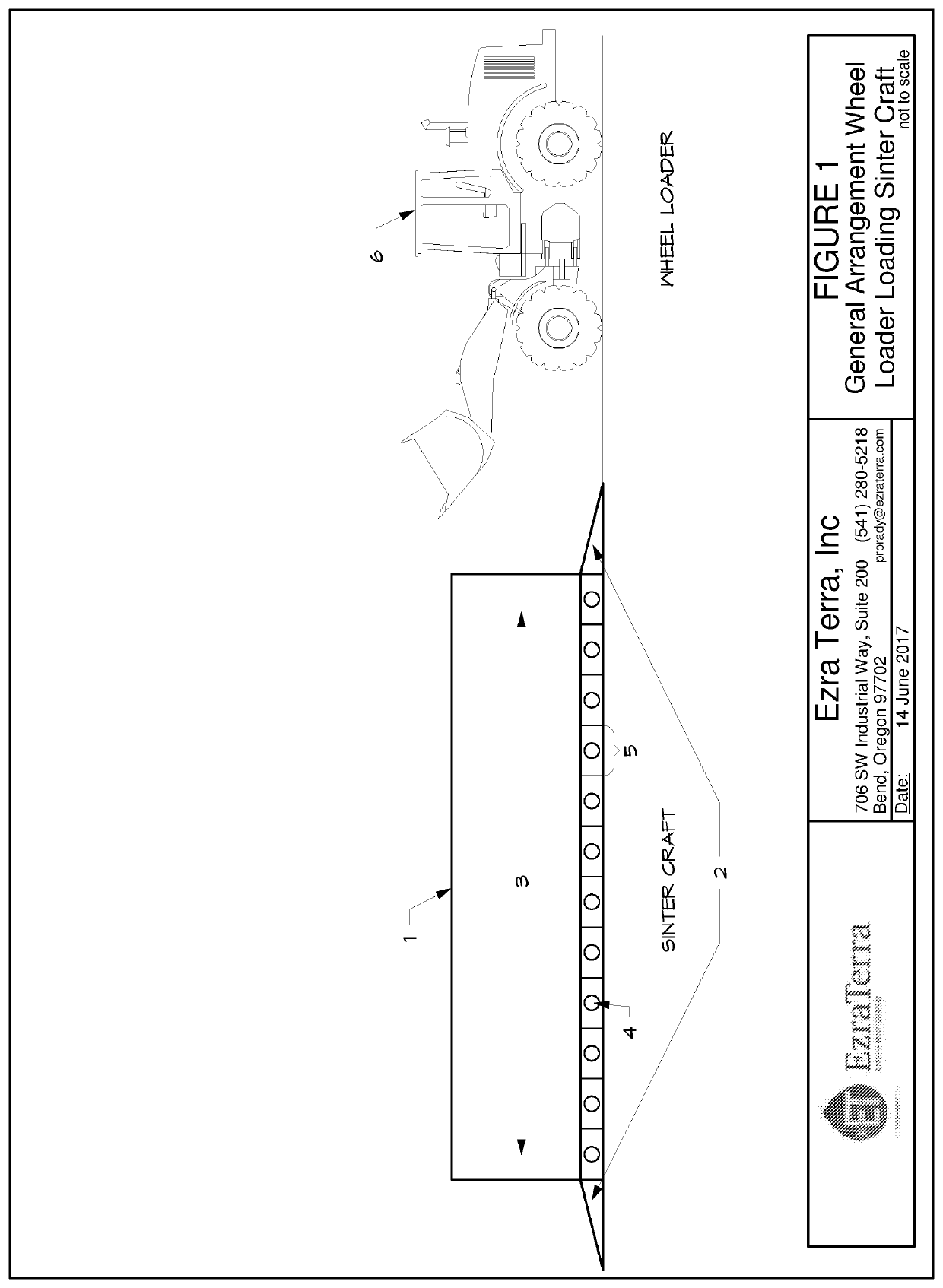

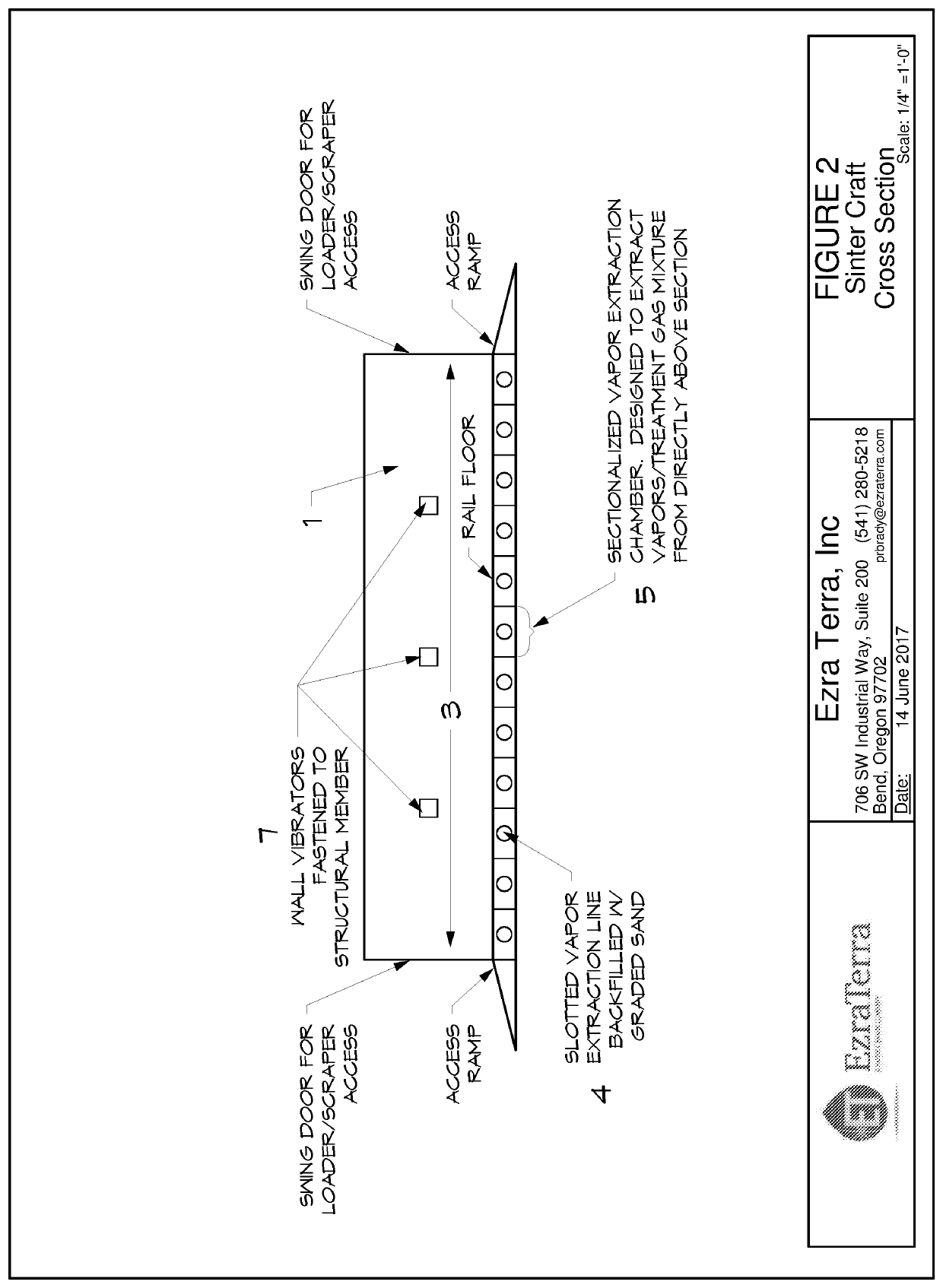

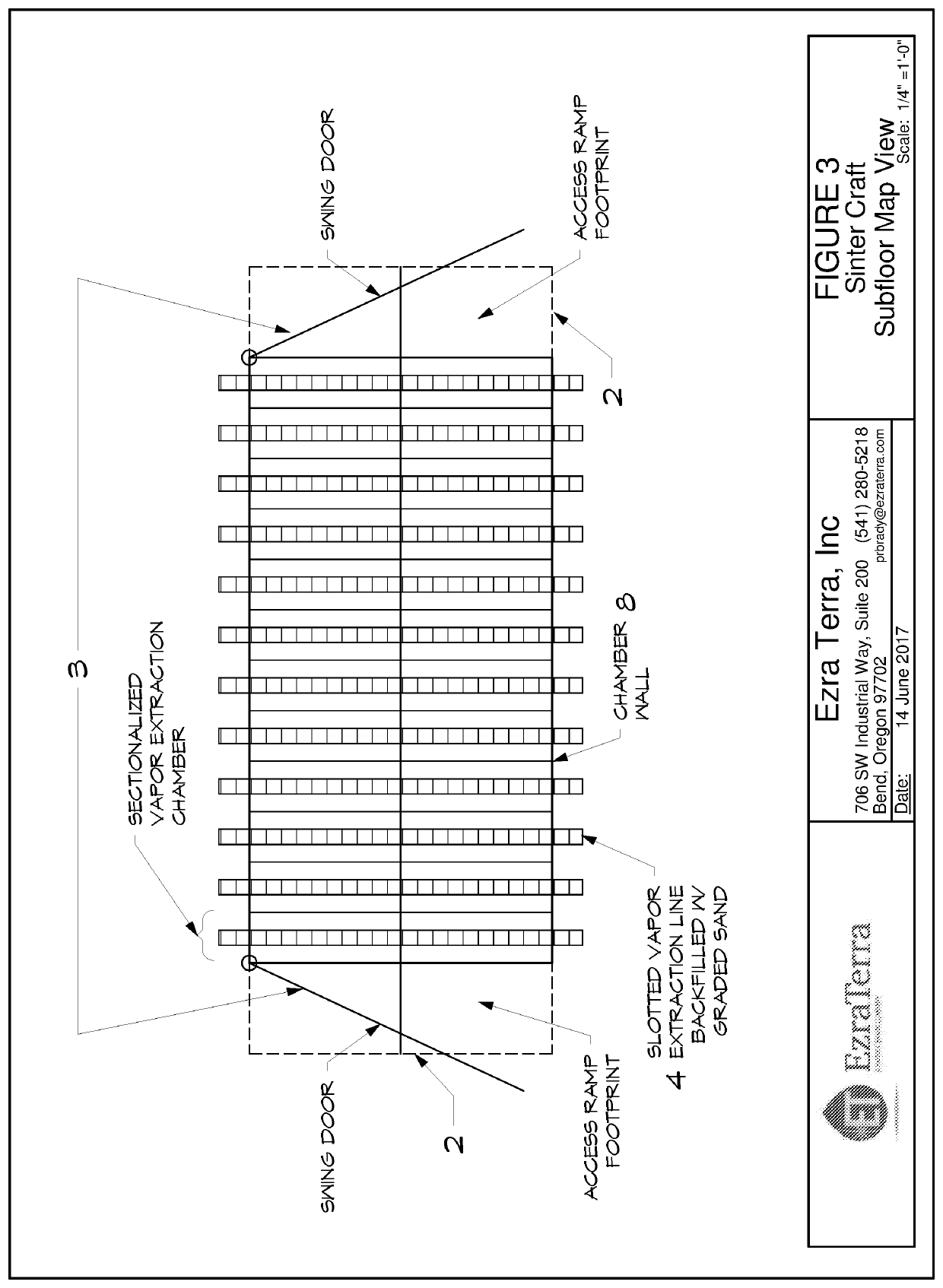

Sintered Wave Porous Media Treatment, Apparatus and Process for Removal of Organic Compounds and Nondestructive Removal and Condensation of Per and Polyfluoroalkyl Substances and related fluorinated compounds

ActiveUS20200108429A1Facilitate effectiveImprove securityContaminated soil reclamationParticulatesPorous medium

Sintered Wave Porous Media Treatment and Apparatus and Process is disclosed, which uses an automated static enclosed arrangement to efficiently remove water, organic contaminants (petroleum, solvents, pcbs, pesticides) and per- and polyfluoroalkyl substances (PFAS) and fluorinated related compounds from large volumes of porous media such as a mixture of soil, gravel, rocks, sediments or other porous media. The Sintered Wave technology is a multipurpose treatment device that uses a Sinter Craft as a treatment vessel that allows earth moving machines to easily enter and exit during loading / unloading. The soil is then conditioned to accommodate treatment by sintering (densifying) by vibrating the soil bed, which removes soil vapor and fluids. The soil bed is then shaped by placing hexagonal holes or slots containing 120 degree angles from top to the bottom of the soil bed. The sintered and shaped soil bed is treated in a sequential manner (small sections at a time) with a narrow band of high velocity hot or cold air, which is conveyed from the top of the bed to the bottom (or the bottom to the top) through the shapes placed in the soil bed; hot or cold air moves through the soil bed in open channels rather than pulled through the porous media itself. Vapor extraction lines situated below (or above) the soil bed extracts vapors from narrow sections in a sequential manner in concert with the narrow band of high velocity hot or cold air. In order to remove high concentration hydrocarbons, small sections of the bed are treated by passing an inert (less than 10% oxygen) narrow band of high velocity hot air (inert wave), followed by a period of no active treatment (soak zone), then followed by an ambient (21% oxygen) narrow band of high velocity hot air (ambient wave). The space between the inert wave and ambient wave takes advantage of the poor thermal conductivity of soils by allowing the soil to remain at temperature without the addition of additional energy (soak zone). The heat sources are flameless electric heaters that produce a maximum temperature of 1,200 F that do not produce oxides of Nitrogen or Oxides of Sulfur. The dense static condition of the soil bed prevents the formation of particulate matter (PM) in emissions. The vapor conveyance and off-gas treatment system are sized to the small active treatment zone rather than the entire soil bed, which saves costs. The Sintered Wave technology uses a self-diagnostic regenerative wave system in high hydrocarbon concentration situations to automatically retreat areas of concern when carbon monoxide, acetone and methylethylketone are detected at certain proportions. The system relies on enhanced capillary flow as the modality of water and contaminant transport. The system also allows for a means to rapidly cool soils to prevent the formation of thermal degradation by products such as acetone and methylethylketone (simple alcohols) in high organic soils. In order to nondestructively remove PFAS and related fluorinated compounds such as Perfluorooctane Sulfonate and Perfluoroctanic Acid (PFOS / PFOA) the same sequence is performed as above except the initial wave consists of a narrow band of high velocity hot ambient air (21% oxygen) followed by a soak zone with the final wave consisting of a narrow band of high velocity ambient unheated air. The final ambient unheated air wave is a polishing step to remove residual contaminants, which reduces the temperature of the soil in an effort to capitalize on the low temperature Cristobalite quartz inversion sudden volumetric change. Cristobalite is present in most clay soils. Cristobalite inversion occurs in a narrow temperature range from 365 F to 419 F where a sudden volume reduction of 0.8% as the temperature increases from ambient conditions. PFOS / PFOA boiling ranges are just below the Cristobalite inversion temperature. The volumetric change is reversable upon cooling where there is a sudden volumetric increase squeezing out vapors from the soil matrix. The system relies on enhanced capillary flow as the modality of water and contaminant transport. Capillary flow has the capacity to cause high vacuum pressures within the pore throats when the porous media is saturated or near saturated conditions. The surfactant nature of PFAS lowers the surface tension of water, which in accordance with the Law of Laplace equalizes the pressure in a variety of pore throat diameters with the soil bed. This invention uses a special cooling and treatment gas conditioning system to nondestructively remove PFAS from the vapor stream. This vapor handling system can be used in conjunction with commercially available vapor treatment systems that allow simultaneous treatment of hydrocarbon and PFAS contaminated soils. Contaminated vapors exit the Sinter Craft where they are cooled with a direct spray of water into the vapor stream. PFAS will selectively condense in the cooling water. The water mist laden air moves through a tank equipped with baffles to knock out the majority of the mist. A demister screen tower removes any residual water mists. The cooling water is recirculated within the system. The warming of the water prevents any significant water condensation from the vapor stream because the vapor stream is always above ambient temperatures. A vapor phase activated carbon vessel is used to remove any residual contaminants from the vapor stream prior to discharge to the atmosphere. The cooling water can be analyzed to determine PFAS concentration from a give batch of soil. The cooling water is then treated through aqueous granular activated carbon.

Owner:EZRATERRA LLC

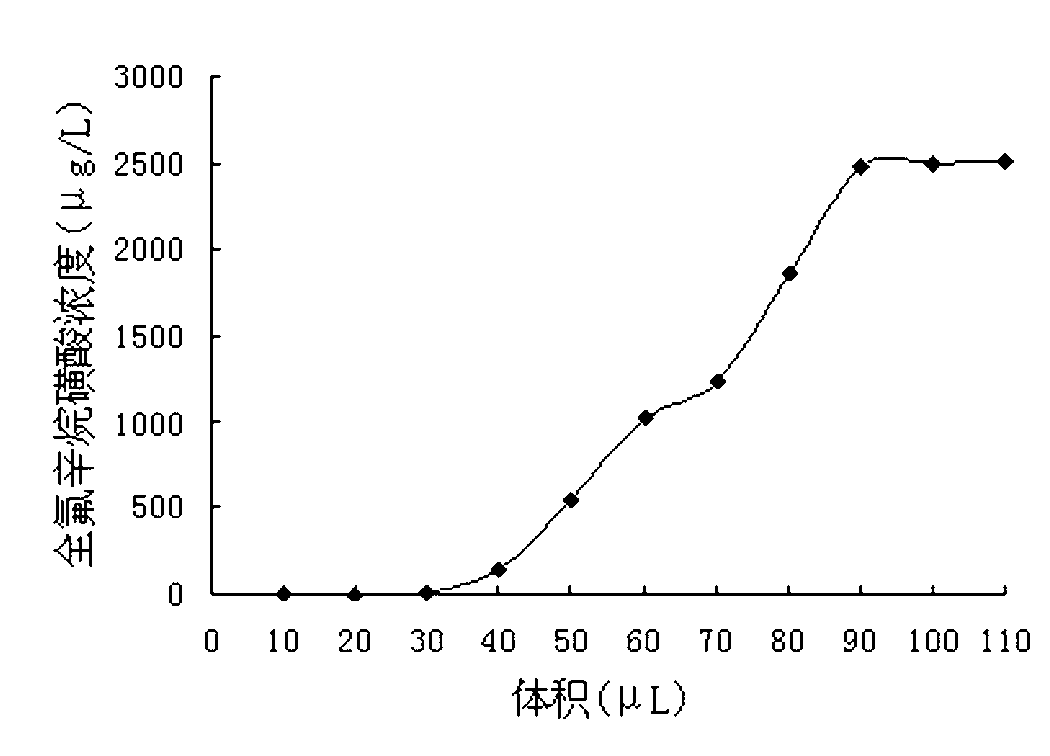

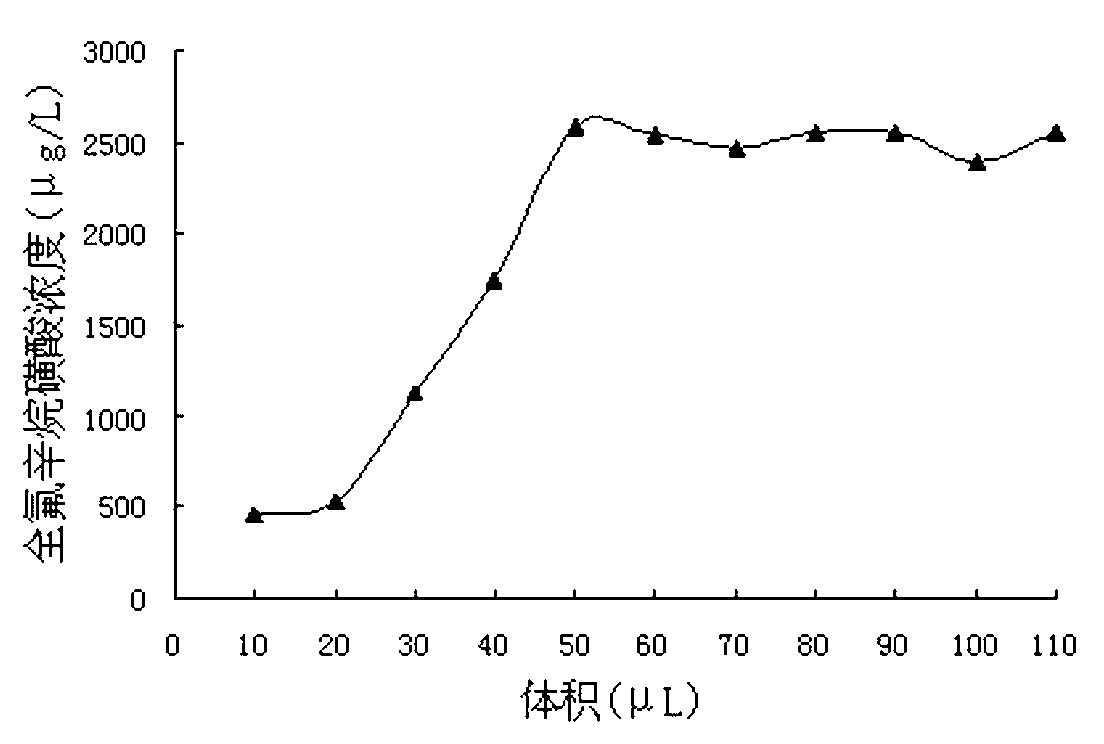

Solid-phase extraction analysis method of perfluorooctane sulfonic acid compounds in wastewater

ActiveCN104977371AImprove representationReproducible and stableComponent separationLiquid chromatography mass spectroscopySolid phase extraction

The present invention discloses a solid-phase extraction analysis method of perfluorooctane sulfonic acid compounds in wastewater. The solid-phase extraction analysis method comprises: rinsing a solid-phase extraction column sequentially with 0.1% ammonium acetate-containing methanol, pure methanol and ultrapure water, and discarding the solutions after completing the rinsing; using a vacuum solid-phase extraction device to suck a wastewater sample, passing through the solid-phase extraction column, sequentially adding 2 mL of a solution containing acetone, acetonitrile and formic acid according to a ratio of 50:50:1, 3 mL of pure methanol and 3 mL of 0.1% ammonium acetate-containing methanol to carry out elution, and collecting and merging the eluent; blowing the eluent with nitrogen to approach a drying state, adding 1 mL of a solution containing methanol and water according to a ratio of 1:1, and uniformly mixing; and carrying out analysis testing through LC / MS / MS to obtain the result. According to the present invention, the sampling amount of the method is large, such that the samples have the good representativeness and can characterize the performance of the wastewater to the maximum extent; the operation process is simple and efficient, and the reproducibility of the laboratory data is stable; and the standard addition method recovery rate achieves 70%, the detection limit is low and is 0.01 [mu]g / L, the ecological requirements of the environment are met, and the tested compound variety is diverse.

Owner:深圳天祥质量技术服务有限公司

Chromium fog inhibitor and preparation method thereof

InactiveCN104611733ALower surface energyHarm reductionOrganic compound preparationSulfonic acids salts preparationTriethoxysilaneReaction temperature

The invention discloses a chromium fog inhibitor-tetraethylammonium perflurohexane sulfonate free of PFOS (perfluorooctane sulfonate). The invention further discloses a preparation method for the chromium fog inhibitor, that is to say, perflurohexane sulphonyl fluoride, triethylamine and methyl triethoxysilane react in an inert solvent to obtain tetraethylammonium perflurohexane sulfonate, wherein a proper reaction temperature is 0-40 DEG C, a molar ratio of perflurohexane sulphonyl fluoride, triethylamine and methyl triethoxysilane is 1:(1-1.8):(0.6-1.5), and the proper inert solvent is chlorobenzene, benzene or isopropyl ether. The provided method is simple and convenient in process, and the chromium fog inhibitor is high in yield and good in surface activity.

Owner:湖北恒新化工有限公司

PFOS-free aqueous film-forming foam extinguishing agent and preparation method thereof

InactiveCN112206459AReduce pollutionPromote environmental protectionFire extinguisherActive agentSurface-active agents

The invention provides a PFOS-free aqueous film-forming foam extinguishing agent and a preparation method thereof. The PFOS-free aqueous film-forming foam extinguishing agent comprises the following components in percentage by weight: 12-30% of a combined hydrocarbon surfactant, 2-5% of a fluorocarbon surfactant without PFOS, 5-8% of a foam stabilizer, 20-50% of an antifreeze agent, 3-5% of a solubilizer and 20-40% of water. The aqueous film-forming foam extinguishing agent disclosed by the invention does not contain perfluorooctane sulfonate which is difficult to degrade, so that the aqueousfilm-forming foam extinguishing agent has higher environmental friendliness, and the pollution to the environment is remarkably reduced; and by optimizing the components and the ratio, the excellent stability of the fire extinguishing agent is ensured at the same time.

Owner:应急管理部消防产品合格评定中心 +1

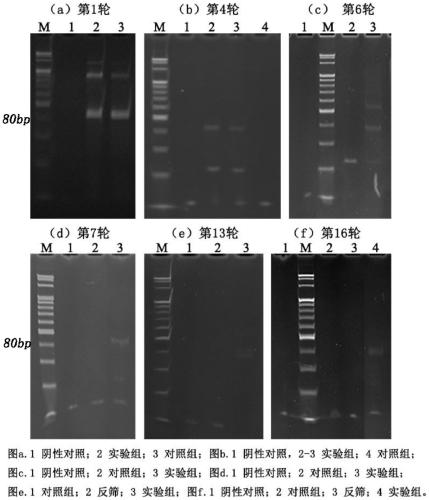

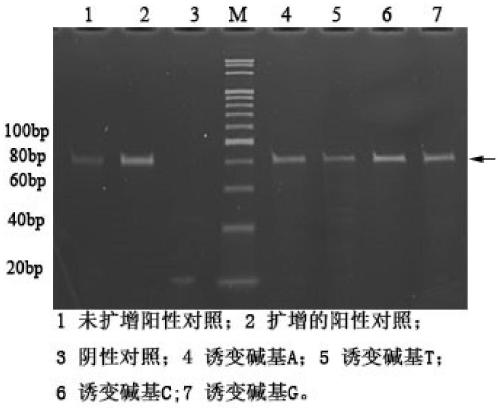

Preparation and application of aptamer resisting potassium perfluorooctane sulfonate

The invention discloses an aptamer for resisting potassium perfluorooctane sulfonate. The aptamer comprises at least one of PS1, PS36, PS39 and PS96, wherein the PS1 comprises a sequence as shown in SEQ ID NO.01, the PS36 comprises a sequence as shown in SEQ ID NO.02, the PS39 comprises a sequence as shown in SEQ ID NO.03, and the PS96 comprises a sequence as shown in SEQ ID NO.04. The aptamer canbe specifically combined with a persistent organic pollutant, potassium perfluorooctane sulfonate, and can be applied to a biosensor for detecting the potassium perfluorooctane sulfonate.

Owner:HUAQIAO UNIVERSITY

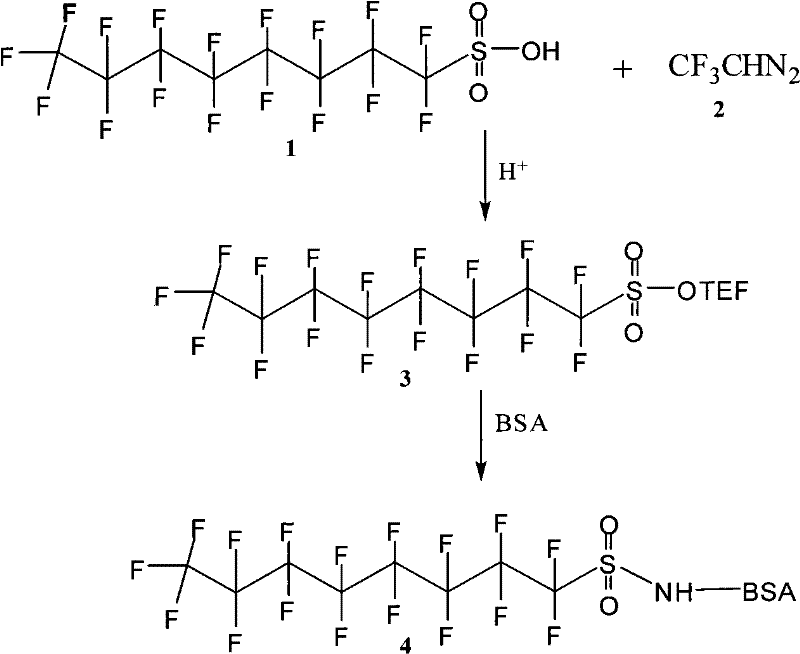

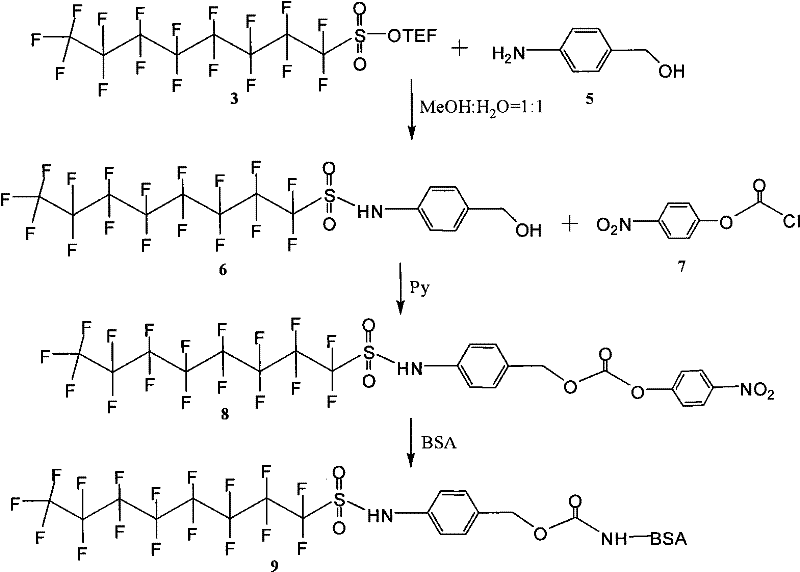

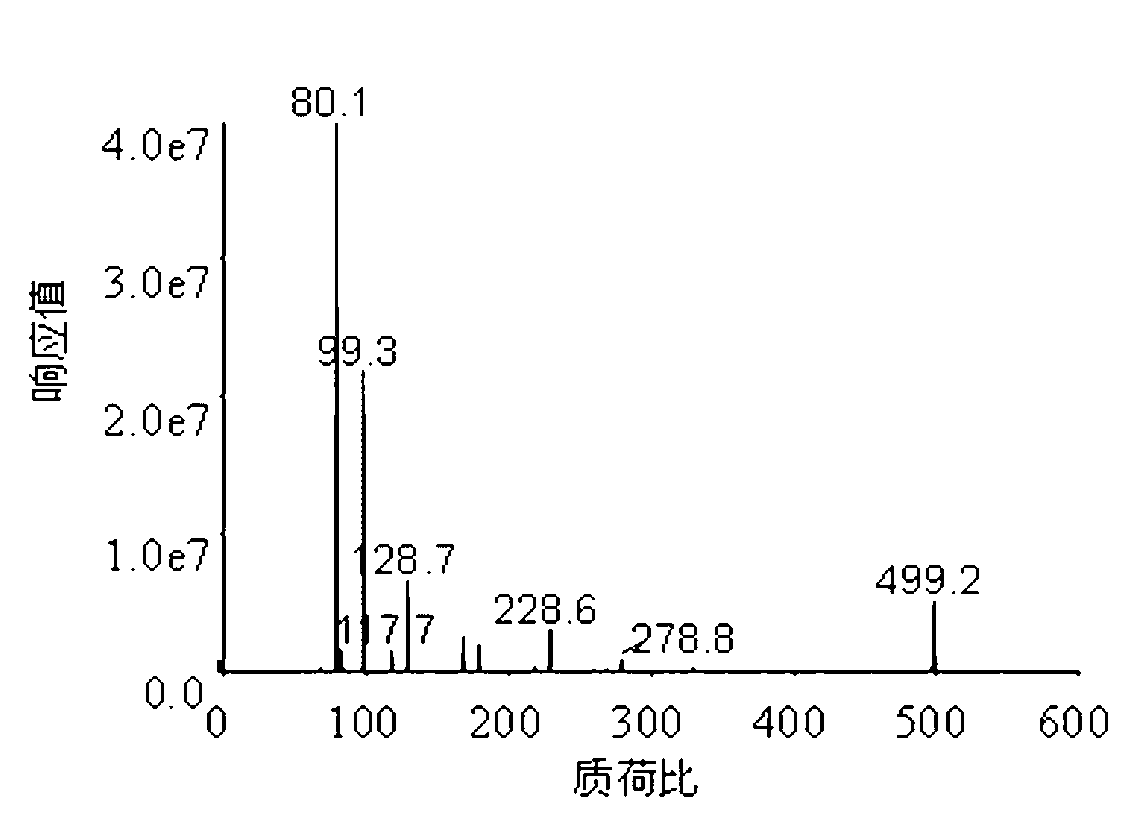

Preparation method of perfluorooctane sulfonate artificial complete antigen

InactiveCN102276711AEasy to operateLow costOvalbuminSerum albuminAcyl carrier proteinImmunologic Technique

The invention relates to a preparation method of artificial complete antigen of perfluorooctane sulfonates (PFOS), which belongs to the technical field of organic chemistry and immunology. Using the carboxylic acid group of perfluorooctane sulfonic acid, the perfluorooctane sulfonic acid is linked to the carrier protein directly or through a linking arm of appropriate length to prepare the complete antigen of perfluorooctane sulfonic acid. The carrier protein can be bovine serum albumin (BSA), ovalbumin (OVA), limpet hemocyanin (KLH) or human serum albumin (HSA). MALDI-TOF-MS mass spectrometry to determine the amount of PFOS on the carrier protein. The method is simple to operate, does not require special equipment and has low cost, and provides a basis for screening out its specific antibody and establishing an immunoassay method in the future.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Ionic skeleton structure porous adsorption material and preparation method and application thereof

PendingCN113351167AEfficient selective adsorption capacityHigh selectivityOther chemical processesWater contaminantsPotable waterSorbent

The invention discloses an ionic skeleton structure porous adsorption material and a preparation method and application thereof, and two porous material adsorbents with different ionic skeletons, namely a porous adsorption material with an anionic skeleton structure and a porous adsorption material with a cationic skeleton structure, are prepared. The porous adsorption materials with the two ionic skeleton structures can efficiently adsorb and remove perfluoroalkyl substances and heavy metal ion pollutants in water, the mainly removed perfluoroalkyl substances are perfluorooctanoic acid (PFOA) and perfluorooctane sulfonic acid (PFOS), and the mainly removed heavy metal ions are Hg < 2 + >, As < 2 + >, Cd < 2 + > and Pb < 2 + >. Drinking water is treated by using the porous adsorbent material with the ionic skeleton structure, so that the water quality of the drinking water meets the set standards and requirements of domestic drinking water.

Owner:XI AN JIAOTONG UNIV

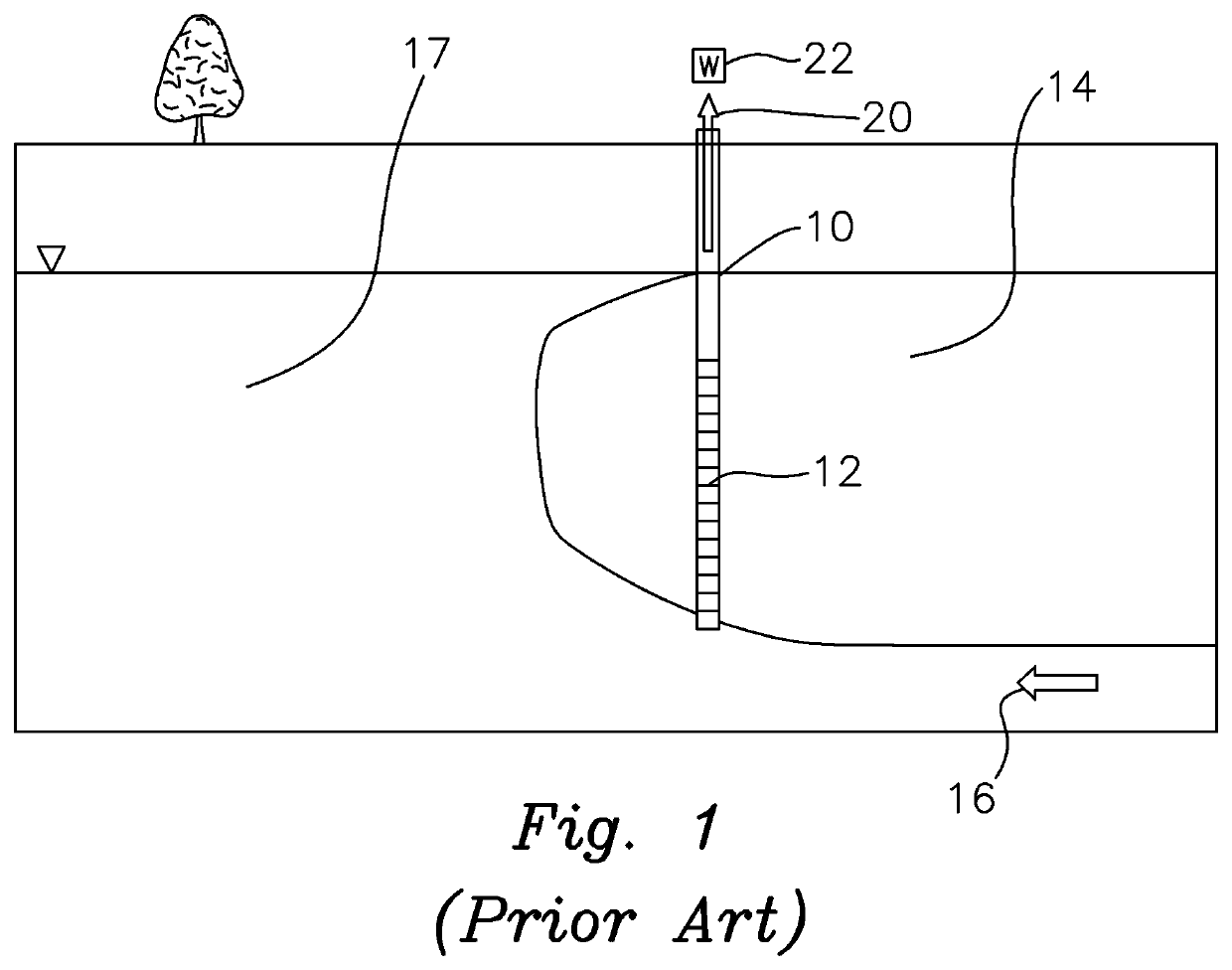

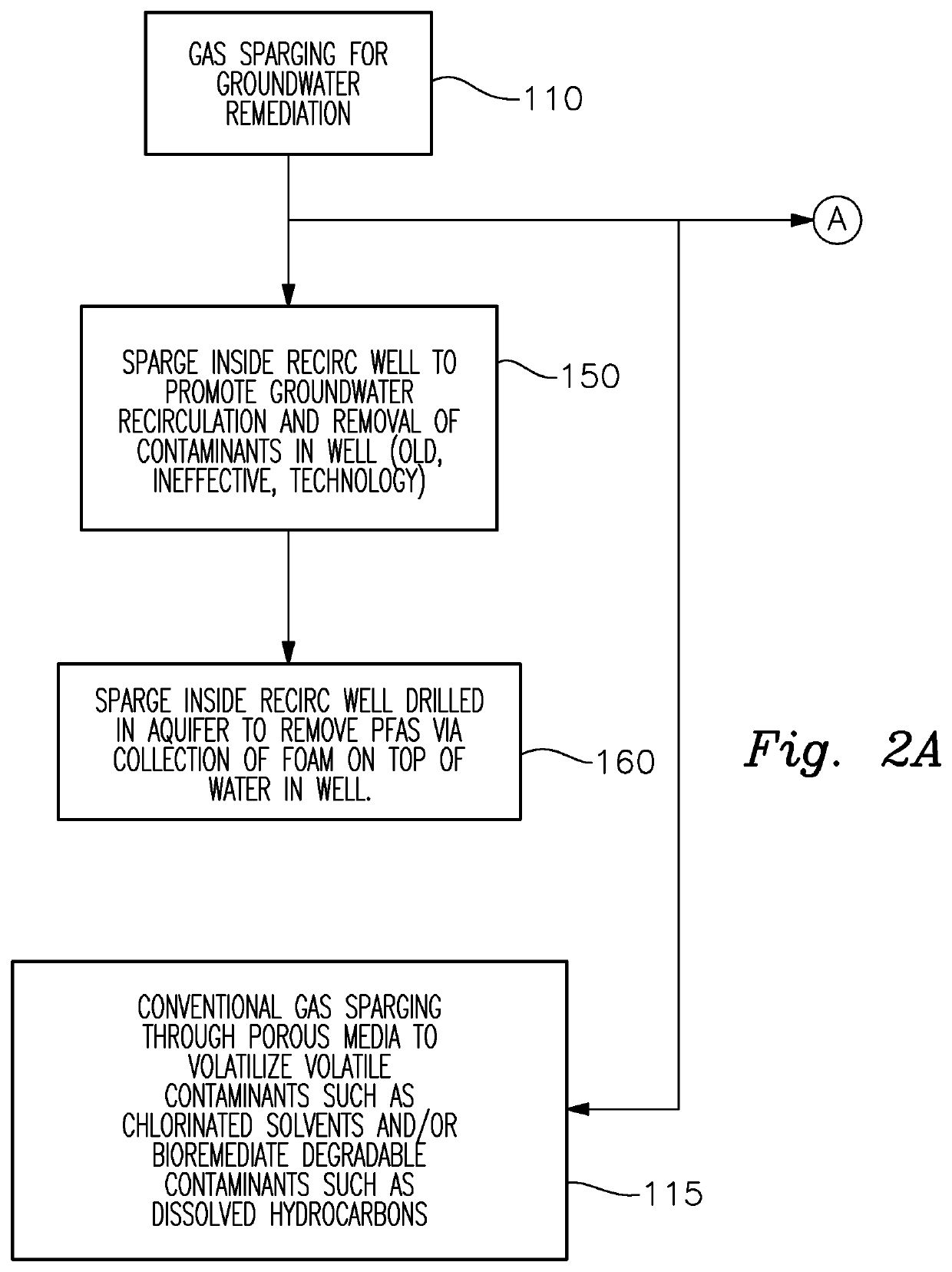

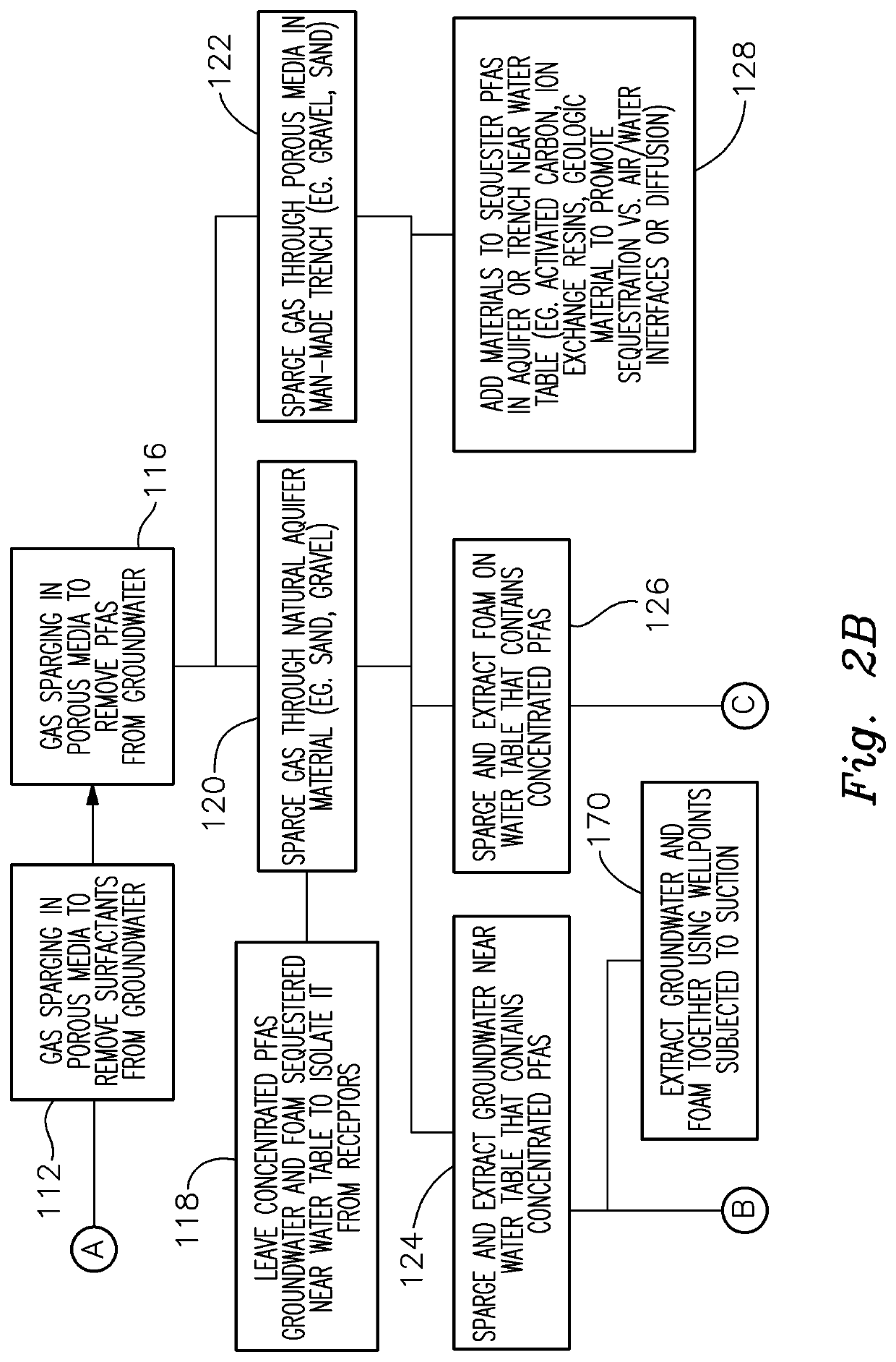

Method and Apparatus for Removal of Per- and Polyfluoroalkyl Substances (PFAS) from Groundwater

PendingUS20210214241A1Increase concentrationHigh concentrationFatty/oily/floating substances removal devicesSpecific water treatment objectivesPorous mediumEngineering

A decontamination method for subsurface aquifers having per- and polyfluoroalkyl substances (PFAS) contaminants by injecting gas through a screened well or open tube through a porous media to form buoyant material where the PFAS contaminants accumulate on and / or in the buoyant material and rise to the water table or top of the aquifer with PFAS that desorbs from the buoyant material and concentrates in the shallow groundwater, and extracting or sequestering the groundwater near the water table or top of the confined aquifer and / or collecting the buoyant material for treatment. The method may include treatment of aquifer material consisting of gravel, sand, silt, clay, or fractured geologic media, or combination, and extraction through phytoremediation, groundwater extraction wells, wellpoint systems, or groundwater extraction trenches and include a seal and / or check valve near the water table in the trench to selectively permit water and buoyant material to flow upward.

Owner:GSI ENVIRONMENTAL

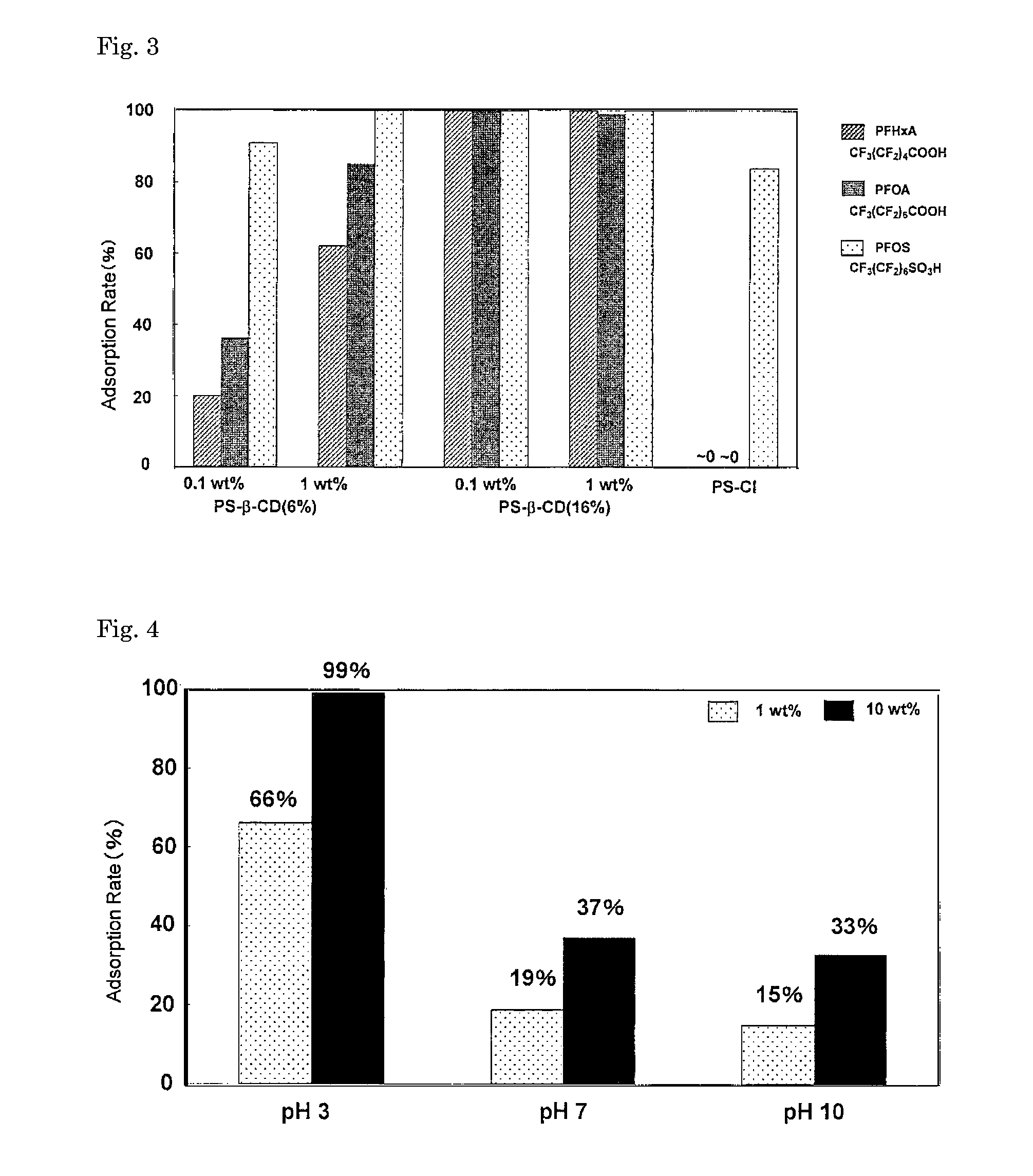

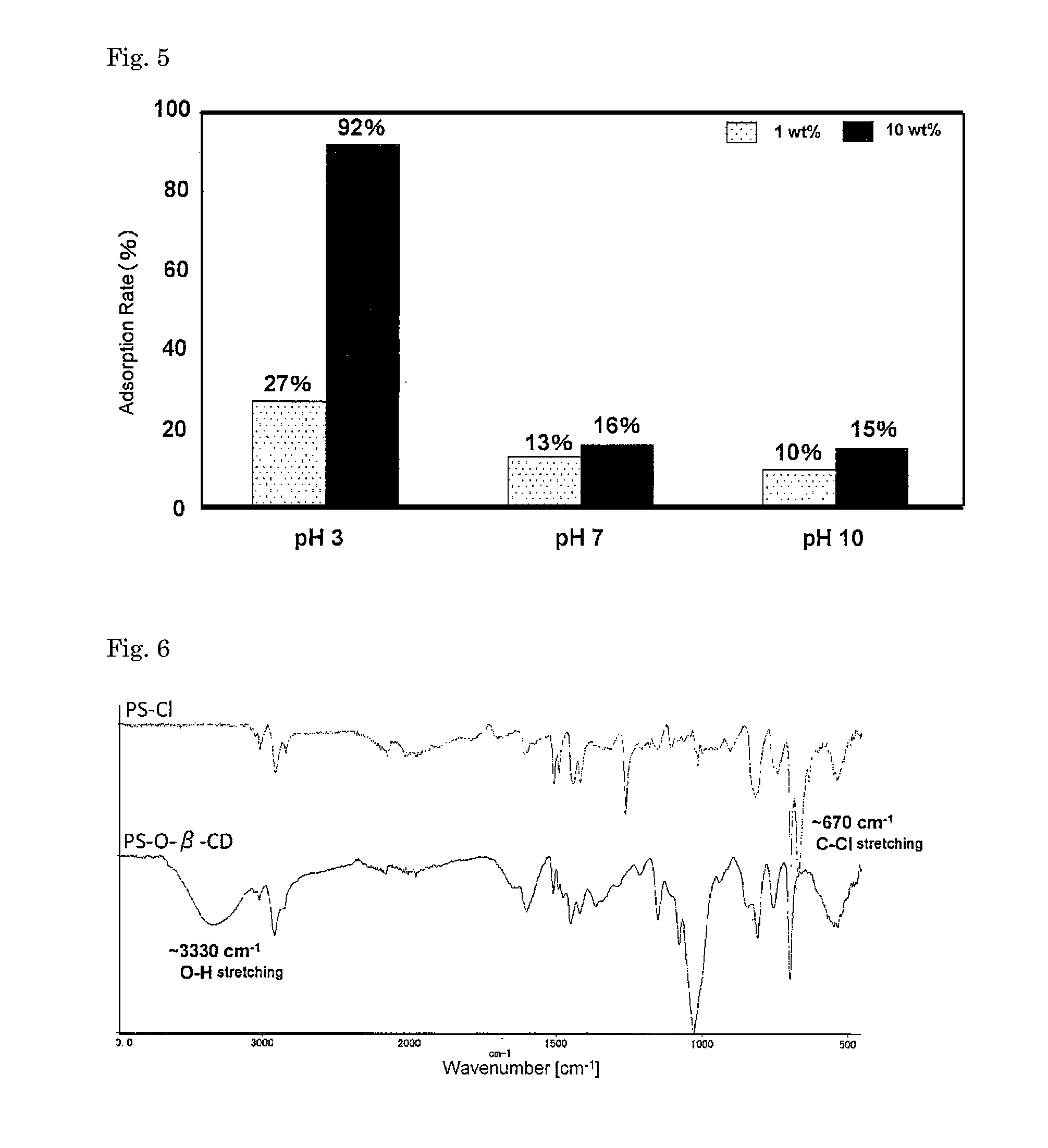

Adsorbent for organic fluoro-compound comprising cyclodextrin-supported polymer

ActiveUS9308519B2Improve adsorption capacityIon-exchange process apparatusOther chemical processesSorbentWater insoluble

The present invention is to provide a material that is capable of selectively adsorbing organic fluoro-compounds such as perfluorooctane sulfonic acid, allows the adsorbed organic fluoro-compounds to be recovered, and is reusable as an adsorbent, specifically to provide a polymer in which cyclodextrin is supported on the surface of a water-insoluble polymer, and an adsorbent containing the same, and a method of use of the same as a selective adsorbent of, in particular, an organic fluoro-compound.

Owner:DAIKIN IND LTD +1

PFOS and PFOA-free insoluble aqueous film-forming foam extinguishing agent and preparation method thereof

InactiveCN111054010AReduce pollutionPromote environmental protectionFire extinguisherActive agentSoluble Film

The invention provides a PFOS and PFOA-free insoluble aqueous film-forming foam extinguishing agent and a preparation method thereof. The agent comprises the following components in percentage by weight: 0.5-1% of biological polysaccharide, 2-5% of a fluorocarbon surfactant without PFOS and PFOA, 12-30% of a combined hydrocarbon surfactant, 20-50% of an anti-freezing agent, 3-5% of a solubilizer and 20-40% of water. The water-soluble film-forming foam extinguishing agent does not contain perfluorooctane sulfonic acid and perfluorooctanoic acid which are difficult to degrade, so that the water-soluble film-forming foam extinguishing agent has higher environmental friendliness, and the pollution to the environment is remarkably reduced; and by optimizing the components and the ratio, the excellent stability of the fire extinguishing agent is ensured at the same time.

Owner:江苏锁龙消防科技股份有限公司

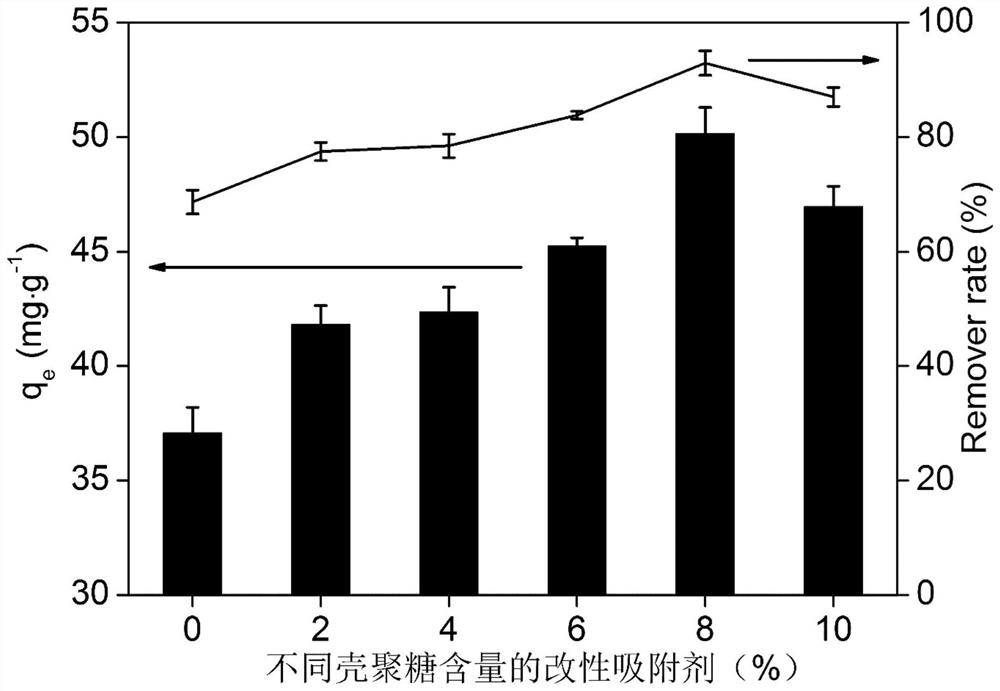

Modified hydrated iron oxide adsorbent, preparation method and application thereof

InactiveCN112973642ABiocompatibleGood removal effectOther chemical processesWater contaminantsHydration reactionSorbent

The invention provides a preparation method of a modified hydrated iron oxide adsorbent. The method comprises the following steps: dissolving 0.2-1g of chitosan in 100 mL of acetic acid aqueous solution with a mass concentration of 4%, then respectively adding 10 g of ferric chloride hexahydrate, and stirring for one hour by using a magnetic stirrer until the mixture is completely dissolved; adding 0.1 mol / L NaOH into the mixture to adjust the pH value to 7; aging at room temperature for 24 hours, centrifugally collecting precipitate particles, and washing with ultrapure water multiple times to remove residual ions; and finally, freeze-drying the precipitate particles, grinding in an agate mortar, sieving with a 200-mesh sieve, collecting the obtained precipitate particles, and storing in a brown glass bottle. According to the invention, ferric oxide hydrate is modified by chitosan, so that the adsorption capacity of the ferric oxide hydrate is improved, and the removal of pollutants, namely perfluorooctane sulfonic acid (PFOS), is facilitated.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Perfluoro-capillary extraction monolithic column and preparation method and application thereof

InactiveCN102183603BAvoid interferenceThe preparation method is simple, quick and reliableComponent separationIn situ polymerizationCarboxylic salt

The invention discloses a perfluoro-capillary extraction monolithic column and a preparation method and application thereof. The perfluoro-capillary extraction monolithic column is a monolithic column in which silica gel matrix is polymerized in situ in a quartz capillary tube with diameter of 75 to 530 microns and perfluoro functional groups are bonded on the surface of the silica gel matrix. The perfluoro functional groups comprise perfluoro-octyl (C6F13), perfluoro-decyl (C8F17), N-perfluorooctanoic sulfonyl and derivatives thereof. The monolithic column can be used for enriching a series of trace perfluoro-chemicals, such as perfluorooctane sulfonate (PFOS), perfluorooctane carboxylate (PFOA), perfluorodecanoate (PFDA), perfluorohexyl sulfonate (PFHXS) and the like. The preparation method of the monolithic column is simple, fast and reliable, the average adsorption quantity can reach over 6.0*10<-2>mug, and the average enrichment times is 30 times; the average recovery rate is over 90 percent, the sensitivity of analysis and detection is greatly improved, and interference of impurities is avoided; and the monolithic column is convenient and fast to carry, a trace perfluoro-chemical sample can be directly enriched at a remote acquisition point, the transport cost is reduced, and the analysis time is shortened.

Owner:HUNAN NORMAL UNIVERSITY

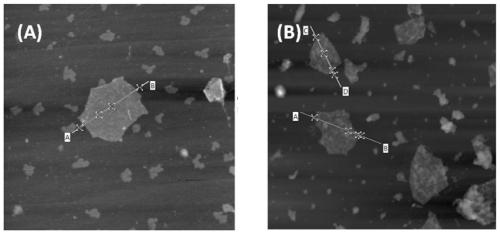

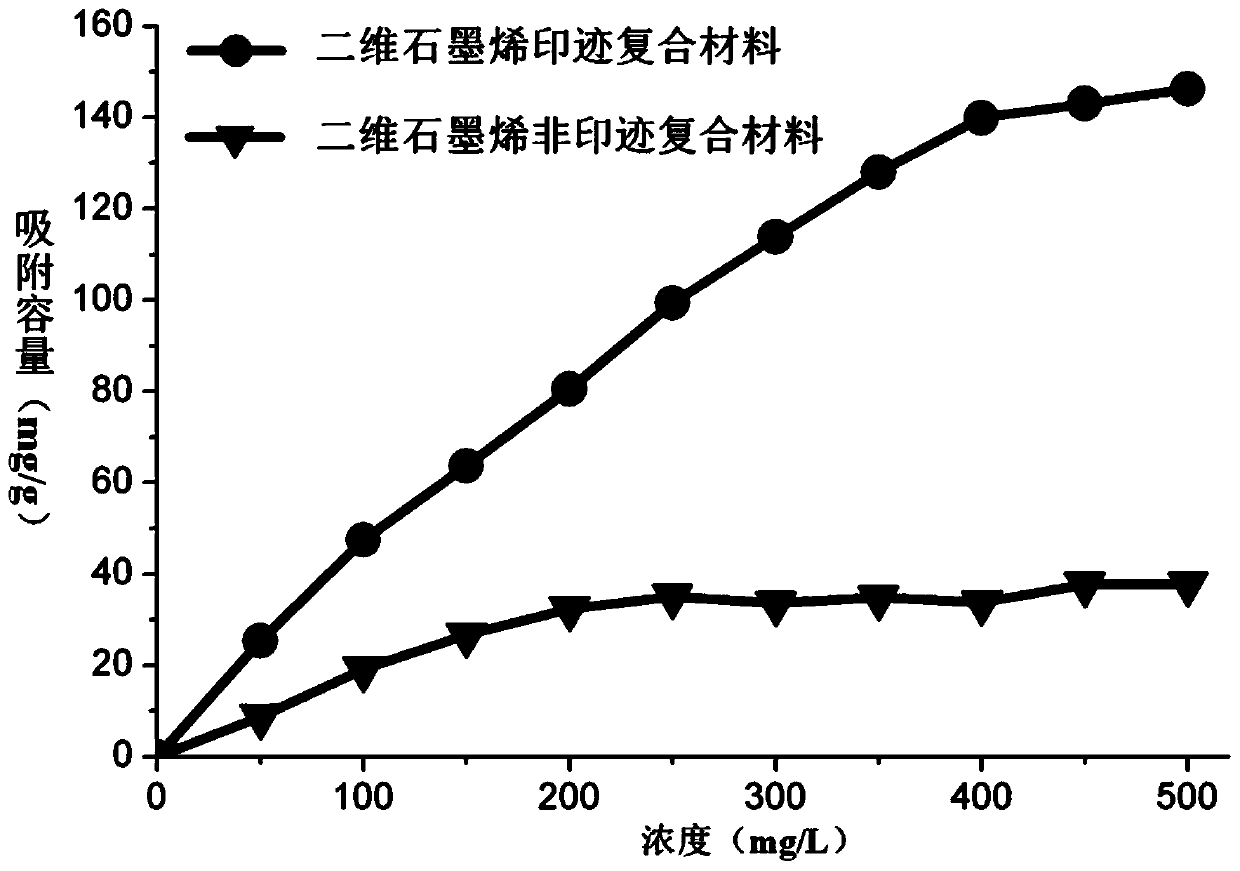

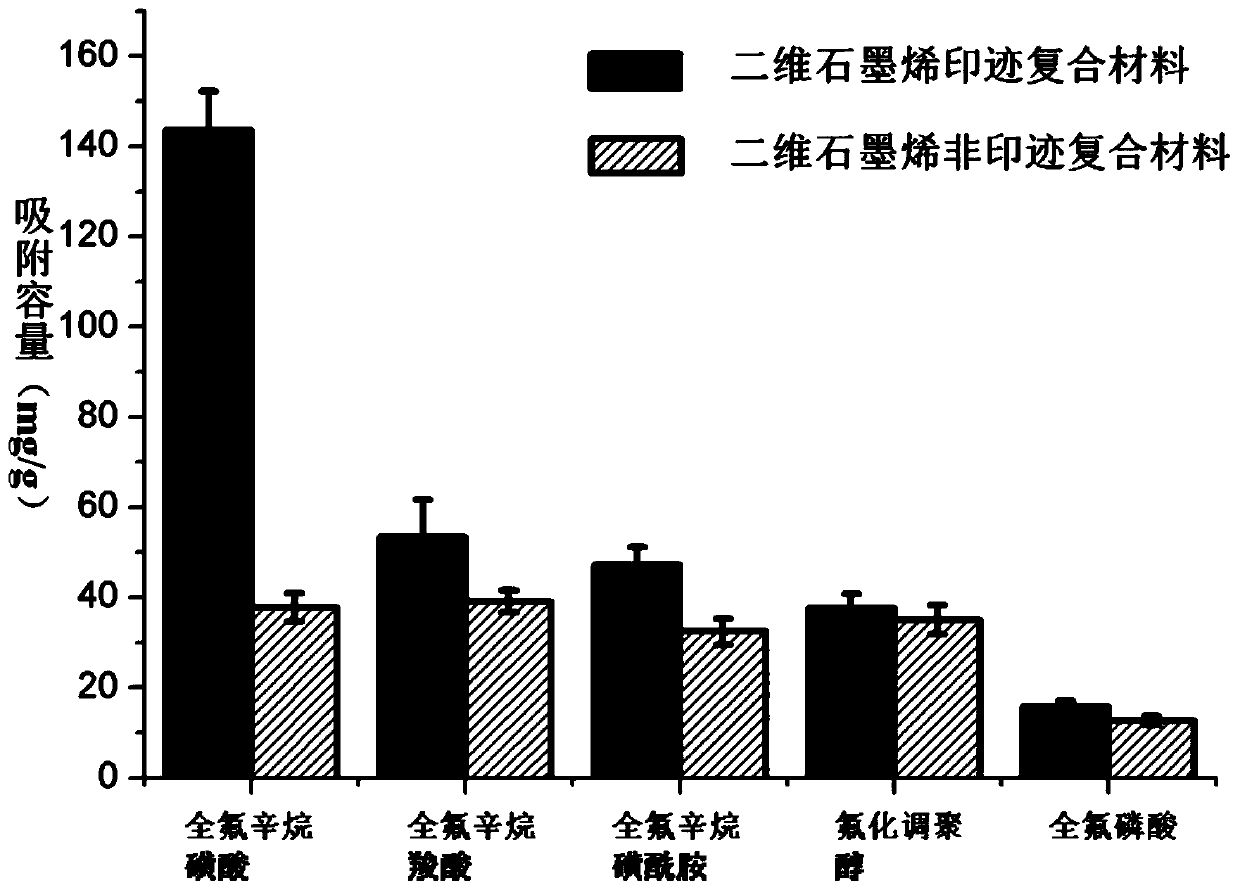

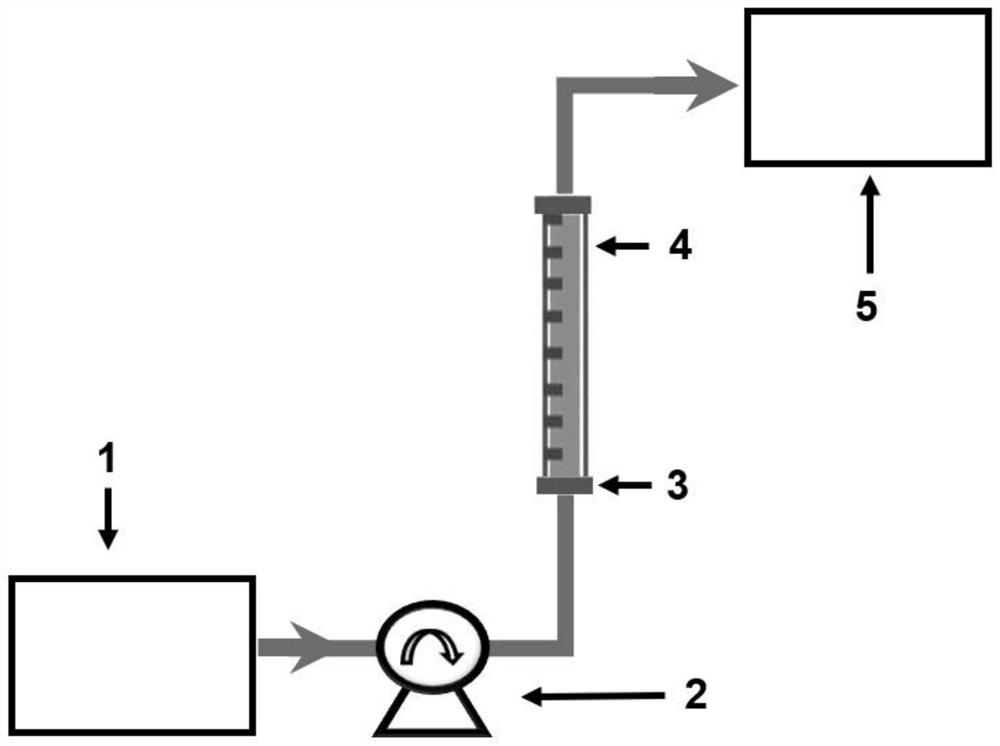

Two-dimensional graphene imprinted composite material, preparation method and application thereof

ActiveCN108586653BEfficient CatalysisDirect preparationOther chemical processesPolymer scienceGraphite

The invention discloses a two-dimensional graphene imprinted composite material, and a preparation method and an application thereof, and belongs to the field of new materials. The inventors of the invention find that a graphene-hydrogen peroxide-acetylacetone system has a free radical regeneration process in order to mediate a free radical-initiated organic polymerization reaction, a molecularlyimprinted film is directly synthesized on the surface of graphene with perfluorooctane sulfonic acid as a template by using the above characteristic, and the two-dimensional graphene imprinted composite material is prepared without secondary modification of the film, so the composite material can selectively identify target molecules, maintain the good catalytic performance of graphene and ensurethe application and promotion in multiple fields. In addition, the graphene has a great specific surface area, has a high adsorption capacity for perfluorinated compounds, significantly increases thenumber of imprinting sites per unit area, and enhances the selective identification ability of the imprinted composite material.

Owner:HUBEI INSPECTION & QUARANTINE TECH CENT

K monatomic doped biomass charcoal adsorption material as well as preparation method and application thereof

ActiveCN114768759AEasy to anchorWide variety of sourcesOther chemical processesWater contaminantsEnvironmental engineeringCarbon adsorption

The invention relates to a K monatomic doped biomass charcoal adsorption material as well as a preparation method and application thereof. Clt; ct; 1 [mu] g / L) perfluorooctanoic acid (PFOS) and perfluorooctane sulfonic acid (PFOS) are efficiently adsorbed and removed. Dry coconut shells and KOH are used as precursors, and the K monatomic doped coconut shell carbon adsorption material is prepared through a curing-induced calcination method. The local charge density of the substrate can be changed through doping of K monatomic, and an effective electron migration channel is constructed; the adsorption capacity and the adsorption stability of the BC-K1 on PFOA and PFOS can be remarkably enhanced through the synergistic effect of non-equivalent double sites formed by K single atoms and adjacent C. According to the invention, environmental concentrations PFOA and PFOS in deionized water, tap water and lake water are adsorbed in a dynamic adsorption system, the adsorption rate reaches 96% or above, and the concentration of target pollutants in effluent can be maintained to be 70 ng / L or below.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Environment-friendly foam extinguishing agent and preparation method thereof

InactiveCN114712766AImprove stabilityReduce pollutionFire extinguisherActive agentEnvironmental engineering

The invention relates to the technical field of foam extinguishing agents, in particular to an environment-friendly foam extinguishing agent and a preparation method thereof.The fire extinguishing agent can be automatically degraded within a certain period, does not contain perfluorooctane sulfonic acid and perfluorooctanoic acid which are difficult to degrade, has higher environment friendliness and remarkably reduces pollution to the environment; the cleaning agent comprises the following components in percentage by weight: 0.5-1% of biological polysaccharide, 5-15% of an environment-friendly fluorocarbon surfactant, 12-30% of a combined hydrocarbon surfactant, 5-20% of an antifreeze agent, 3-5% of a solubilizer and 20-40% of water.

Owner:江苏优尼科工业消防有限公司

A method for screening pivotal genes and key signaling pathways of perfluorooctane sulfonate toxicity using transcriptomics

The invention discloses a method for screening PFOS toxicity key genes and key signaling pathways by using transcriptomics. The method provided by the present invention first sets the blank control group and the PFOS exposure group of experimental animals and processes them to obtain biological samples, extracts the RNA of the obtained biological samples, and obtains the transcriptomic data of the biological samples through a high-throughput sequencer, and will obtain Bioinformatics analysis was performed on the sequencing data, including differential gene GO enrichment analysis, KEGG pathway enrichment analysis, protein interaction network analysis and GSEA analysis, and finally screened to obtain the results of PFOS toxicity hub genes and key signaling pathways. Applying the method provided by the present invention can help to identify the serious impact of PFOS on animals or humans and / or the toxicity mechanism of PFOS to animals or humans and to develop related drugs against PFOS toxicity.

Owner:INST OF QUALITY STANDARD & TESTING TECH FOR AGRO PROD OF CAAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com