PFOS-free aqueous film-forming foam extinguishing agent and preparation method thereof

A foam fire extinguishing agent and aqueous film-forming technology, applied in fire prevention equipment, etc., can solve the problems of poor degradation performance of fluorocarbon surfactants and difficulty in decomposing organic pollutants, and achieve high environmental protection and pollution reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

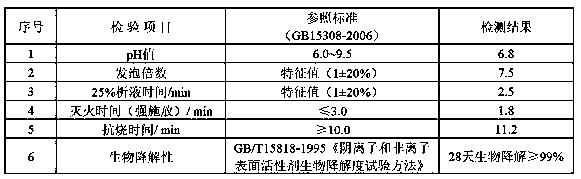

Embodiment 1

[0031] The composition of the fire extinguishing agent includes a combined hydrocarbon surfactant 15% (alkyl glycoside 10%+cocamidopropyl betaine 5%), PFOS-free fluorocarbon surfactant 2% (C 6 Fluorosurfactant 2%), foam stabilizer 5%, antifreeze agent 25%, solubilizer 4% and water 30%; first combine hydrocarbon surfactant 15% (alkyl glycoside 10% + cocamide Propyl betaine 5%) was fully dissolved in pure water to form component A; then 2% fluorocarbon surfactant without PFOS was added to component A and mixed to form component B; then, foam stabilizer 5%, 25% of antifreeze agent and 4% of solubilizer are mixed uniformly to form component C, and component C is slowly added to component B, and component C and component B are mixed uniformly and introduced into the stirring tank for sufficient stirring to form a reaction liquid , adjust the pH value of the reaction solution to 6.8-7.2, control the temperature to about 40° C., let stand to defoam, and prepare the PFOS-free aqueous ...

Embodiment 2

[0033] The composition of the fire extinguishing agent includes a combined hydrocarbon surfactant 23% (alkyl glycoside 17% + cocamidopropyl betaine 6%), PFOS-free fluorocarbon surfactant 4% (C 6 Fluorosurfactant 4%), foam stabilizer 7%, antifreeze agent 35%, solubilizer 3% and water 35%; first combine hydrocarbon surfactant 23% (alkyl glycoside 17% + cocamide Propyl betaine 6%) was fully dissolved in pure water to form component A; then 4% fluorocarbon surfactant without PFOS was added to component A and mixed to form component B; then, foam stabilizer 7%, 35% of antifreeze agent and 3% of solubilizer are uniformly mixed to form component C, and component C is slowly added to component B, and component C and component B are mixed and introduced into a stirring tank for sufficient stirring to form a reaction liquid, adjusting The pH value of the reaction solution is 6.8-7.0, the temperature is controlled at about 40° C., and the foam is defoamed by standing to prepare a PFOS-fr...

Embodiment 3

[0035] The composition of the fire extinguishing agent includes 30% by weight of combined hydrocarbon surfactant (15% alkyl glycoside + 15% cocamidopropyl betaine), 5% fluorocarbon surfactant without PFOS (C 6 Fluorosurfactant 4% and C 4fluorine-containing surfactant %), foam stabilizer 8%, antifreeze agent 50%, solubilizer 4.5% and water 40%; Base betaine 15%) was fully dissolved in pure water to form component A; then 5% of PFOS-free fluorocarbon surfactant was added to component A and mixed to form component B; then, foam stabilizer 8%, anti- Mix 50% of the freezing agent and 4.5% of the solubilizer to form component C, and slowly add component C to component B. After mixing component C and component B, import it into a stirring tank for sufficient stirring to form a reaction solution. Adjust The pH value of the reaction solution is 6.7-7.0, the temperature is controlled at about 40° C., and the foam is defoamed by standing to prepare a PFOS-free aqueous film-forming foam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com