Organic fuel cell methods and apparatus

a fuel cell and organometallic technology, applied in the direction of cell components, non-aqueous electrolyte cells, electrochemical generators, etc., can solve the problems of high cost, significant constraints on the construction materials of the fuel cell, and sulfuric acid electrolyte in the current-art direct methanol fuel cell, etc., to improve the wetting properties, reduce interfacial tension, and poor fuel wetting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

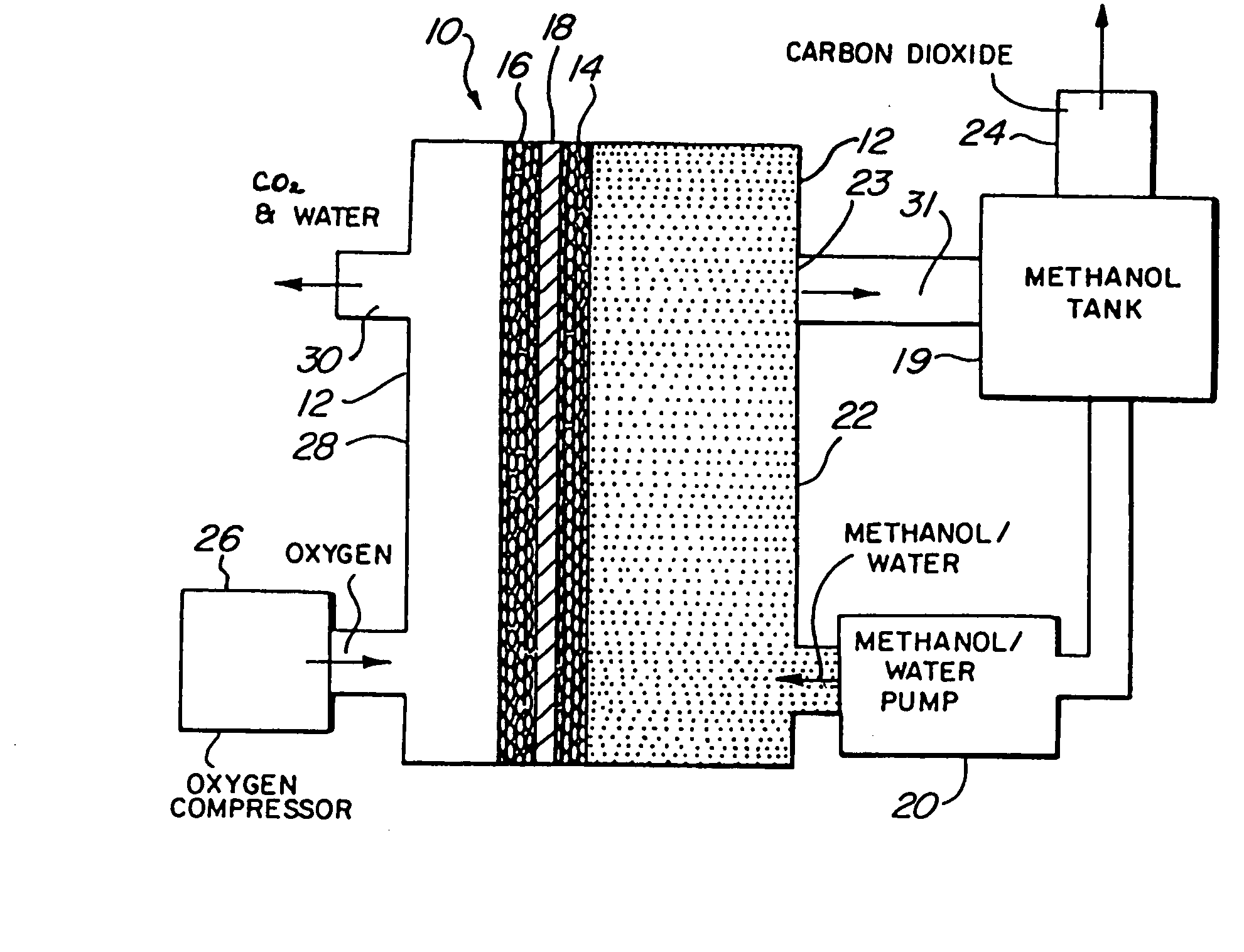

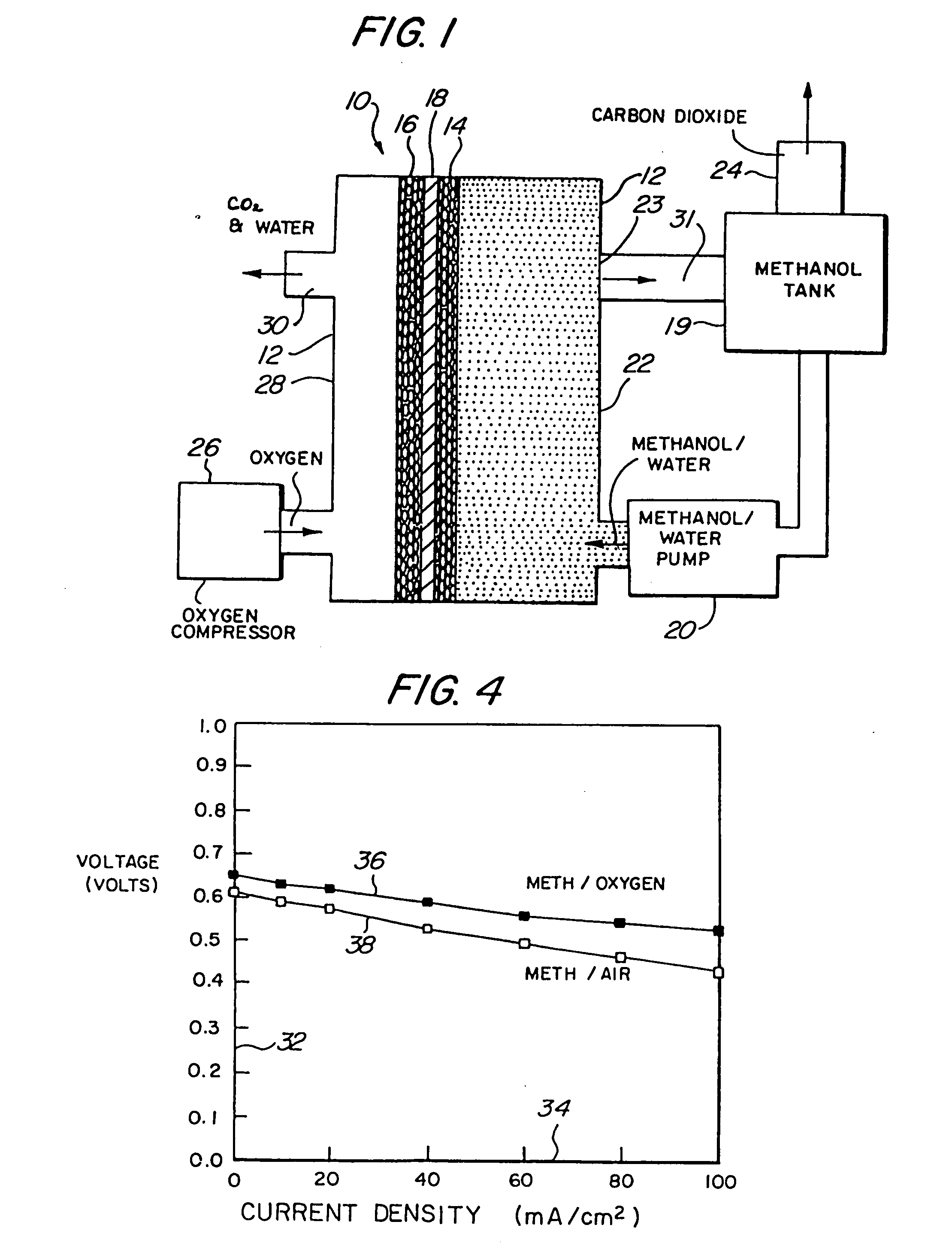

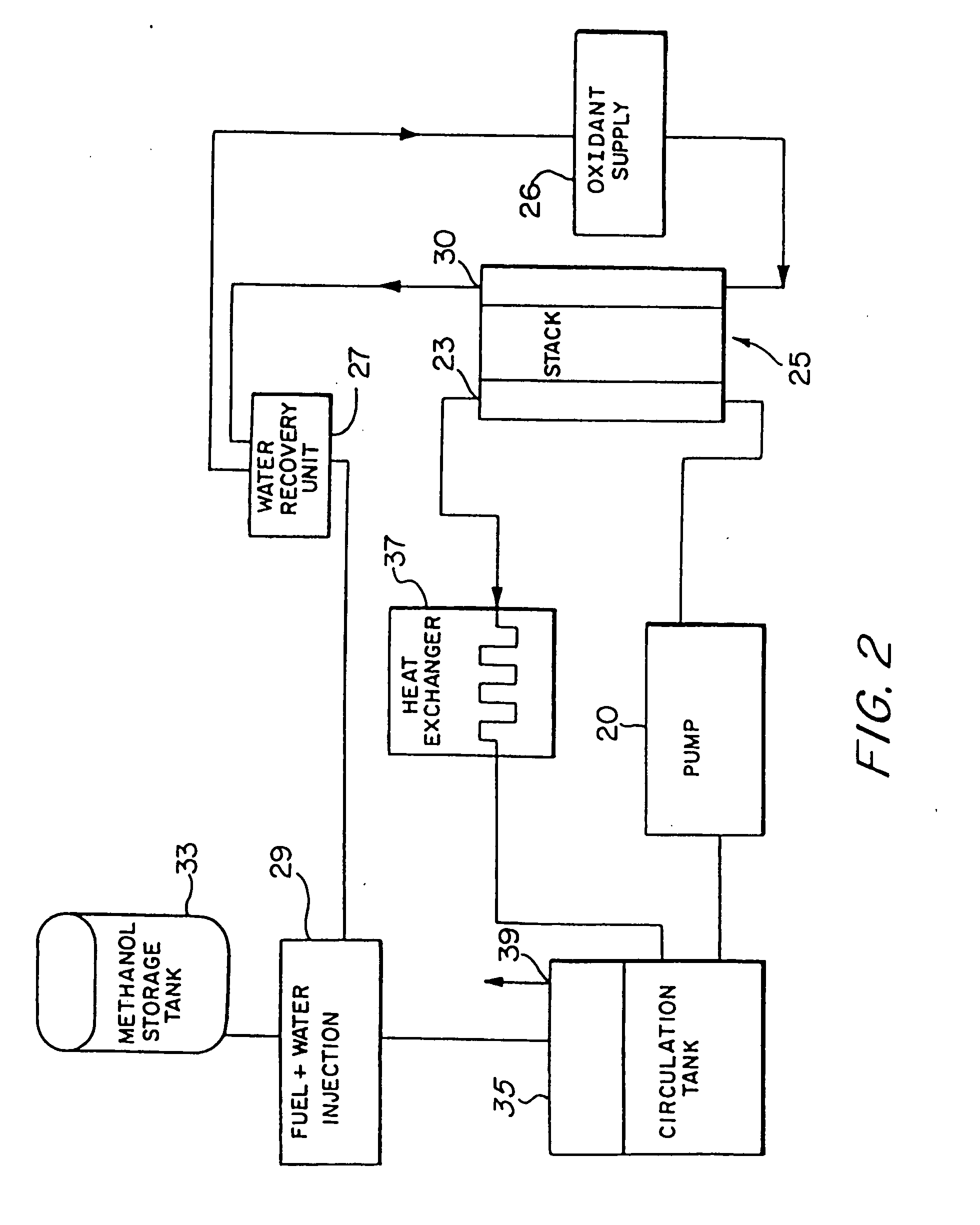

[0054] Referring to the figures, the preferred embodiments of the invention will now be described. Initially, an improved liquid feed organic fuel Cell using a solid polymeric electrolyte membrane and a ionomeric anode additive is described, primarily with reference to FIGS. 1-6. Then, a method for fabricating the anode having the ionomeric additive is described with reference to FIGS. 7-8. A method for achieving improved wetting by fabricating an electrode within a bath containing perfluorooctanesulfonic acid is described with reference to FIGS. 9-11. A fuel cell employing perfluorooctanesulfonic acid as a fuel additive is described with reference to FIG. 12. Fuel cells employing dimethoxymethane, trimethoxymethane and trioxane as fuels are described with referen&to FIGS. 13-21.

Fuel Cell Employing Solid Proton Conducting Elecrolyte Membrane.

[0055]FIG. 1 illustrates a liquid feed organic fuel cell 10 having a housing 12, an anode 14, a cathode 16 and a solid polymer proton-conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Hydrophilicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com