Two-dimensional graphene imprinted composite material, preparation method and application thereof

A composite material, graphene technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as trace amounts of perfluorinated compounds that have not been seen, accurate detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A kind of two-dimensional graphene imprinting composite material provided by the invention, its preparation method comprises the following steps:

[0032] Disperse the graphene material in 1-10mL of acetonitrile, add perfluorooctanesulfonic acid as a template, shake at room temperature for no less than 30 minutes, add different fluorine-substituted styrenes and 4-aminostyrenes as monomers, Ethylene glycol dimethacrylate is used as a cross-linking agent, and imprinted holes are prepared through the interaction of fluorine-fluorine and amino-sulfonic acid. Then add hydrogen peroxide and acetylacetone system to mediate the polymerization reaction initiated by free radicals, synthesize at 50-80 degrees for more than 10 hours, and obtain white polymer. After the template was washed away with an organic solvent, a two-dimensional graphene-imprinted composite material was obtained.

Embodiment 1

[0034] Disperse 2 mg of graphene material in 6 mL of acetonitrile, add 1 mmol perfluorooctanesulfonic acid as a template, shake at room temperature for 60 min, add 2 mmol 2,3,4,5,6-pentafluorostyrene and 2 mmol 4- Aminostyrene was used as a monomer, 20mmol ethylene glycol dimethacrylate was used as a crosslinking agent, and imprinted holes were prepared by the interaction of fluorine-fluorine and amino-sulfonic acid. Subsequently, 400 μL of hydrogen peroxide and 5 μL of acetylacetone were added to mediate the polymerization reaction initiated by free radicals, and the synthesis was carried out at 60°C for 16 hours to obtain a white polymer. After the template was washed away with an organic solvent, a two-dimensional graphene-imprinted composite material was obtained.

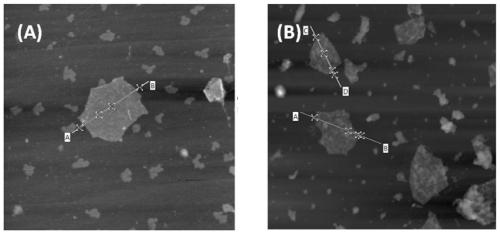

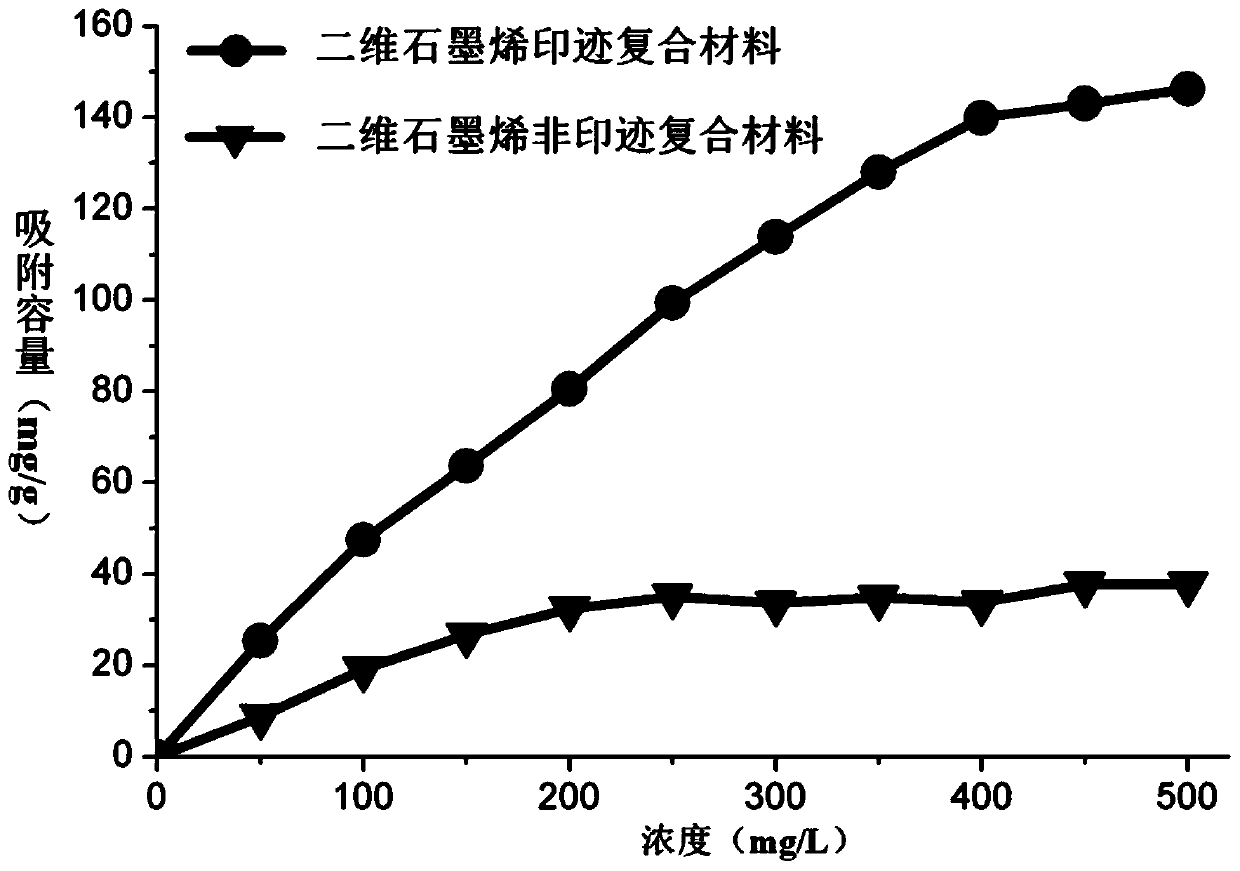

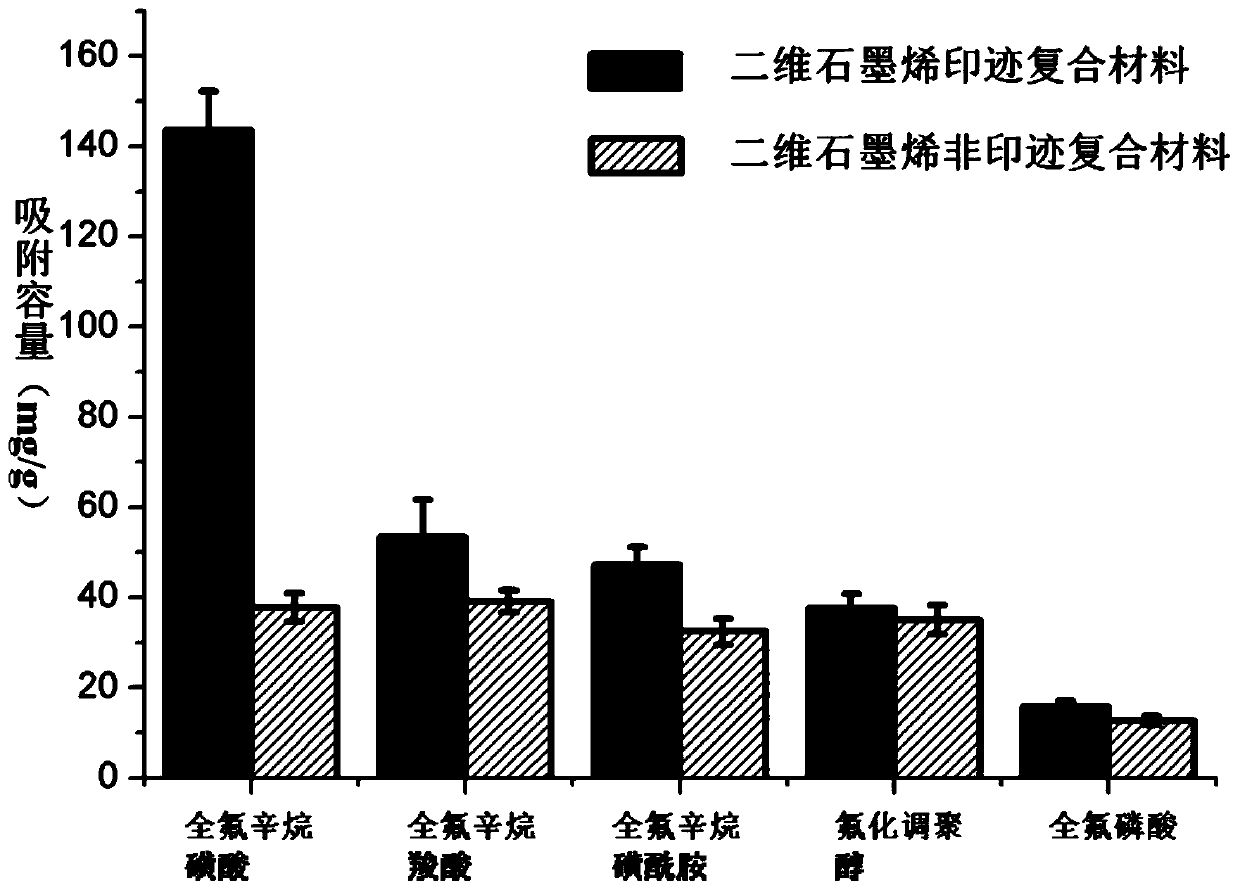

[0035] In the present invention, the performance test of the material prepared in Example 1 is carried out, and the accompanying drawings illustrate it in detail. figure 1 In the graphene, the thickness of sim...

Embodiment 2

[0039] Disperse 1 mg of graphene material in 1 mL of acetonitrile, add 1 mmol of perfluorooctanesulfonic acid as a template, shake at room temperature for 30 min, add 1 mmol of 4-aminostyrene as monomer, 5 mmol of ethylene glycol dimethacrylate As a cross-linking agent, imprinted holes are prepared by means of fluorine-fluorine and amino-sulfonic acid interactions. Subsequently, 100 μL of hydrogen peroxide and 0.5 μL of acetylacetone were added to mediate the polymerization reaction initiated by free radicals, and the synthesis was carried out at 50°C for 10 hours to obtain a white polymer. After the template is washed away with an organic solvent, a two-dimensional graphene imprinted composite material is obtained;

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com