Fluoride-free environment-friendly foam extinguishing agent and preparation method thereof

A foam fire extinguishing agent and environmental protection technology, applied in fire protection equipment and other directions, can solve the problems of high combustion calorific value, cannot be biodegraded, fast burning speed, etc., and achieve the effect of improving fire extinguishing efficiency, good cooling effect, and improving high efficiency performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

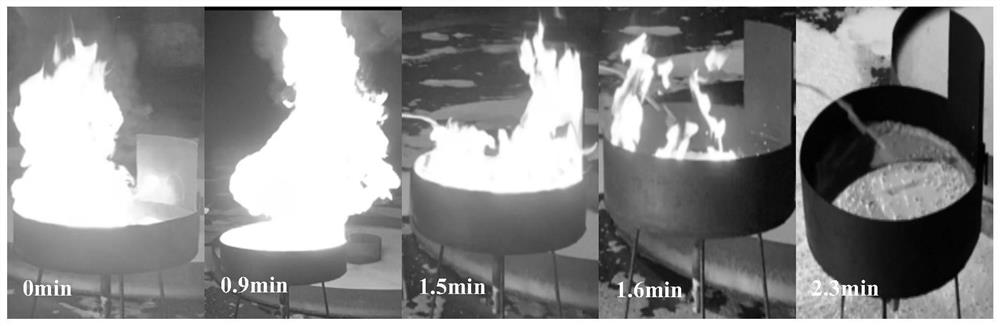

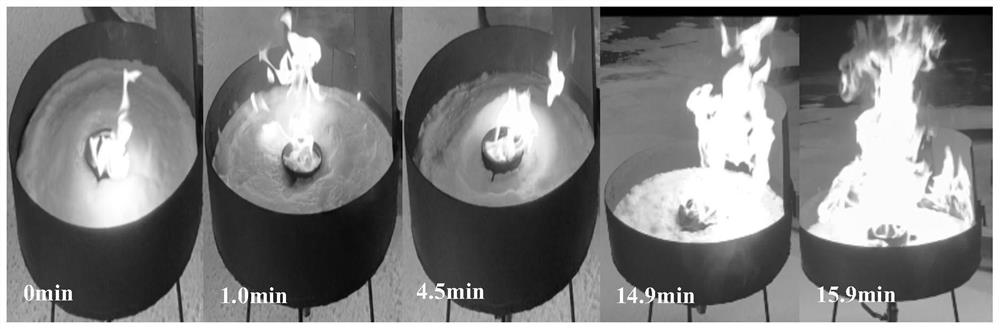

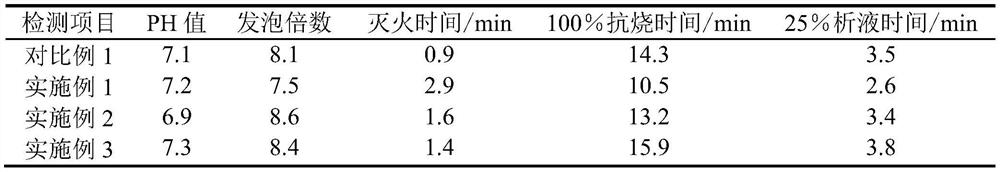

Image

Examples

Embodiment 1

[0021] Add 3g of sodium dodecyl sulfonate into 20g of water and fully stir, then add 5g of Sapindus saponin and 5g of cocamidopropyl betaine to form component A and stir evenly. Mix 3g of urea, 0.3g of xanthan gum and 0.2g of sodium carboxymethylcellulose to form component B. Add 15g of ethylene glycol and 5g of diethylene glycol monobutyl ether into the beaker in turn to form component C, and stir slowly. After C is evenly stirred, speed up the speed, slowly add B to C, and stir well. After the mixture of B and C is evenly stirred, slowly add A into C and stir quickly. Finally, deionized water was added until the total weight was 100 g.

Embodiment 2

[0023] Add 5 g of sodium dodecyl sulfonate into 20 g of water and stir well, then add 10 g of Sapindus saponin and 2 g of cocamidopropyl betaine to form component A and stir evenly. Mix 3g of urea, 0.3g of xanthan gum and 0.2g of sodium carboxymethylcellulose to form component B. Add 15g of ethylene glycol and 5g of diethylene glycol monobutyl ether into the beaker in turn to form component C, and stir slowly. After C is evenly stirred, speed up the speed, slowly add B to C, and stir well. After the mixture of B and C is evenly stirred, slowly add A into C and stir quickly. Finally, deionized water was added until the total weight was 100 g.

Embodiment 3

[0025] Add 5 g of sodium dodecyl sulfonate into 20 g of water and stir thoroughly, then add 15 g of Sapindus saponin and 5 g of cocamidopropyl betaine to form component A and stir evenly. Mix 3g of urea, 0.3g of xanthan gum and 0.2g of sodium carboxymethylcellulose to form component B. Add 15g of ethylene glycol and 5g of diethylene glycol monobutyl ether into the beaker in turn to form component C, and stir slowly. After C is evenly stirred, speed up the speed, slowly add B to C, and stir well. After the mixture of B and C is evenly stirred, slowly add A into C and stir quickly. Finally, deionized water was added until the total weight was 100 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com