Stretchable coated fabric and process for producing same

A manufacturing method, stretchable technology, applied in the direction of coating, textile and papermaking, liquid repellent fiber, etc., can solve the problem of high environmental load, and achieve the effect of excellent moisture permeability, water resistance and wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

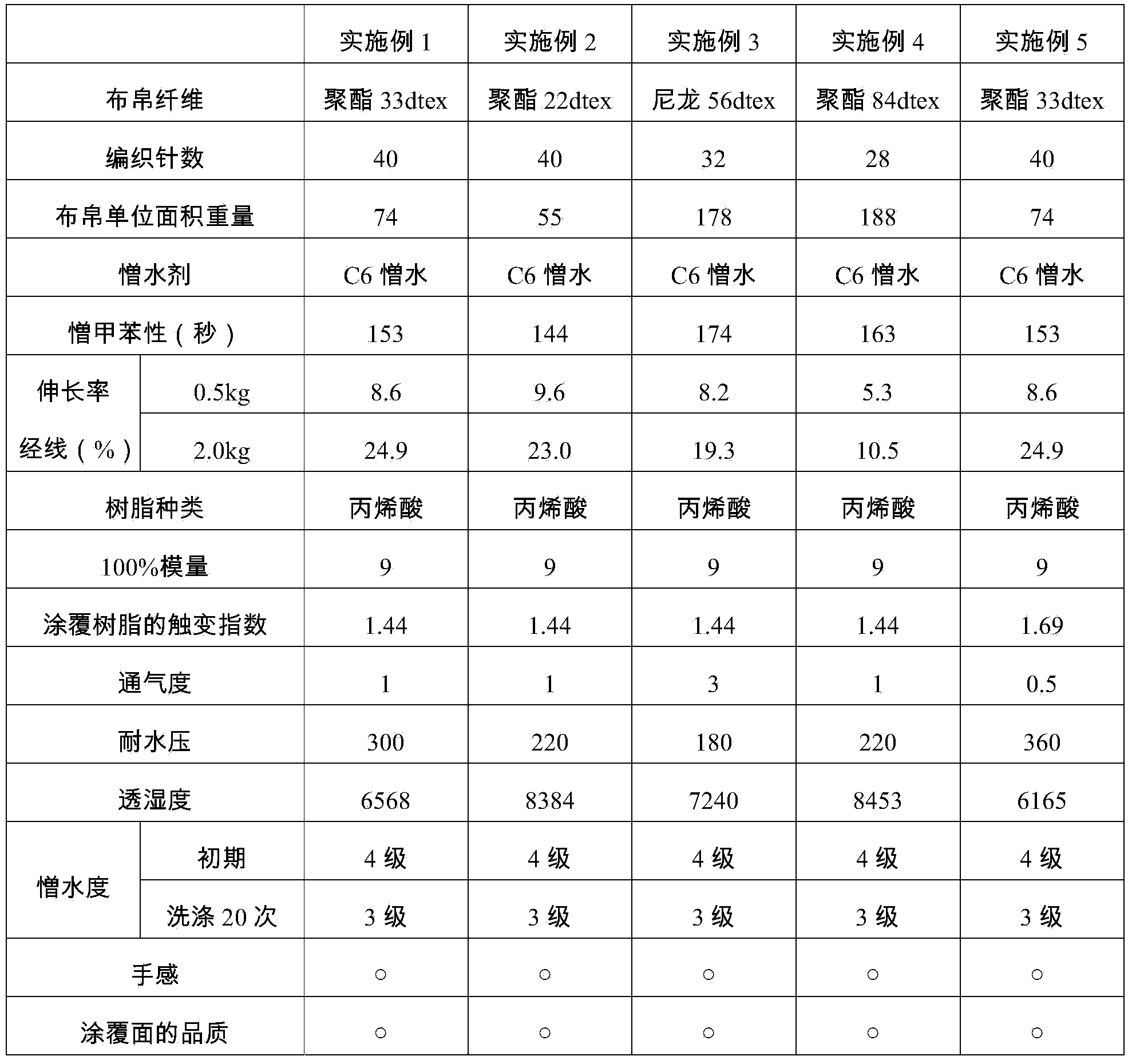

Embodiment 1

[0095] Use 33dtex / 36 filament polyester yarn and use a 40-needle weft knitting machine to weave a smooth textured braid. Then, scrub and dye in the usual way. The weight per unit area of the knitted fabric after dyeing is 74g / m 2 . In addition, the elongation in the warp direction of the knitted fabric was 8.6% under a load of 0.5 kgf, and 24.9% under a load of 2.0 kgf.

[0096] Next, the knitted fabric prepared above was dipped in the aqueous solution using two types of C6 fluorine-based water repellent shown in Recipe 1, squeezed with a mandrel (extrusion rate: 55% by weight), and dried at 120°C. 60 seconds, and then heated at 160° C. for 60 seconds to perform water-repellent processing. When the toluene repellency of the water-repellent processed fabric was evaluated after the water-repellent processing, it was 153 seconds.

[0097]

[0098] 1) NUVA 2114LIQ

[0099] 3.0% by weight

[0100] (C6 fluorine-based water repellent, manufactured by Clariant Japan Co., Ltd...

Embodiment 2

[0129] Use 22dtex / 24 filament polyester yarn and use a 40-needle weft knitting machine to weave a smooth texture. Then, scrub and dye in the usual way. The weight per unit area of the knitted fabric after dyeing is 55g / m 2 . In addition, the elongation in the warp direction of the knitted fabric was 9.6% under a load of 0.5 kgf, and 23.0% under a load of 2.0 kgf.

[0130] Next, the knitted fabric prepared above was dipped in the aqueous solution using two types of C6 fluorine-based water-repellents in the above-mentioned recipe 1, squeezed with a mandrel (extrusion ratio: 53% by weight), and dried at 120° C. for 60 seconds. Minutes, and then heated at 160°C for 60 seconds for hydrophobic processing. When the toluene repellency of the water-repellent processed fabric was evaluated after the water-repellent processing, it was 144 seconds.

[0131] Next, using a knife coater, the synthetic resin solution shown in the above formulation 2 was coated by the float knife coating...

Embodiment 3

[0134] Use nylon 6 filaments of 56dtex / 48 filaments to weave 32-needle warp knitted fabrics. Then, scrub and dye in the usual way. The weight per unit area of the knitted fabric after dyeing is 178g / m 2 . In addition, the elongation in the warp direction of the knitted fabric was 8.2% under a load of 0.5 kgf, and 19.3% under a load of 2.0 kgf.

[0135] Next, the braided fabric prepared above was dipped in the aqueous solution of two kinds of C6 fluorine-based water-repellent agents with different usability in the above formula 1, extruded with a mandrel (extrusion rate: 56% by weight), and dried at 120°C. 60 seconds, and then heated at 160° C. for 60 seconds to perform water-repellent processing. When the toluene repellency of the water-repellent processed fabric was evaluated after the water-repellent processing, it was 174 seconds.

[0136] Next, using a knife coater, the synthetic resin solution shown in the above formulation 2 was coated by the float knife coating me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com