Novel functional graphene composite fiber, and preparation method and application thereof

A graphene composite and functional technology, applied in the direction of fiber chemical characteristics, rayon manufacturing, conjugated synthetic polymer rayon, etc., can solve the problems of few researches on graphene composite fibers, and achieve excellent antibacterial and antistatic , good antibacterial, soft touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present embodiment provides a method for preparing a novel functionalized graphene composite fiber, which comprises the following steps:

[0039] (1) Fluid shear assisted supercritical CO 2 Preparation of graphene nanosheets by exfoliation:

[0040] Add the graphite raw material into the supercritical device, and seal the device;

[0041] Turn on the heating device, adjust the temperature of the device to 40 °C, and transfer the liquid CO through the hydraulic pump. 2 Pass into the supercritical device, control the pressure in the device to 10MPa, turn on the stirring motor, and set the rotational speed to 2000r / min;

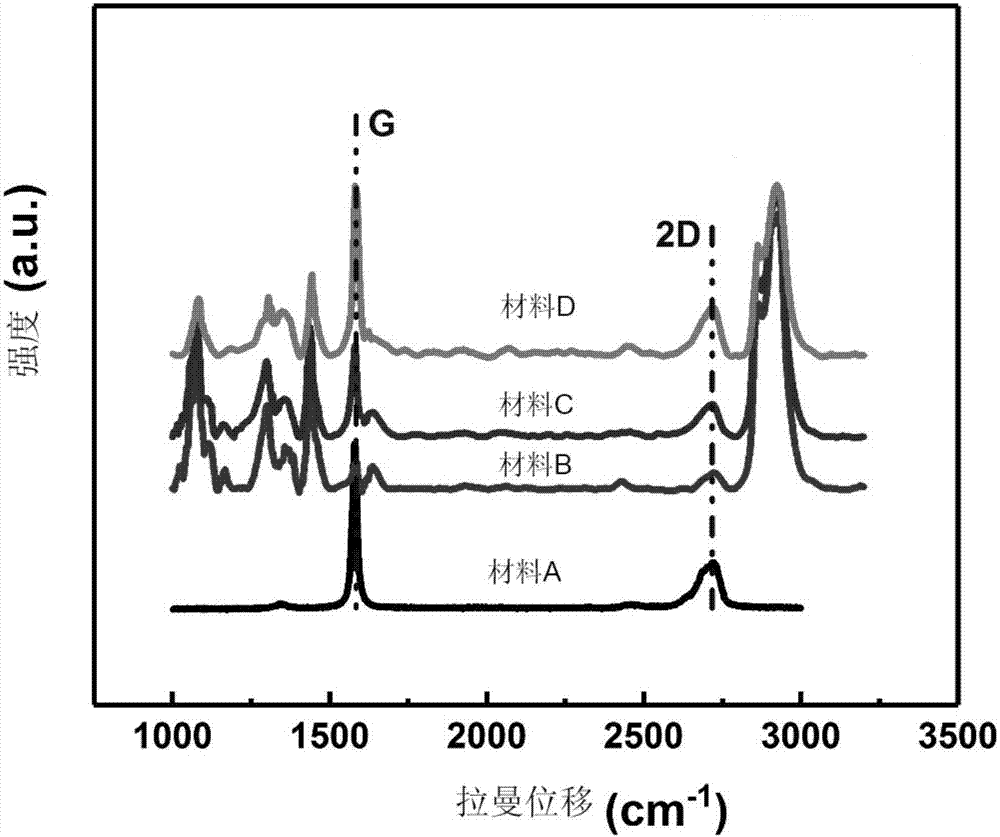

[0042] After 1 h of reaction, the stirring motor was turned off, the gas was exhausted, and the sample was taken out, and the obtained sample was the graphene nanosheet (referred to as material A).

[0043] (2), the graphene nano-sheet and the fiber raw material are blended to prepare the graphene composite master batch:

[0044] The graphene nano...

Embodiment 2

[0049] The present embodiment provides a method for preparing a novel functionalized graphene composite fiber, which comprises the following steps:

[0050] (1) Fluid shear assisted supercritical CO 2 Preparation of graphene nanosheets by exfoliation:

[0051] Add the graphite raw material into the supercritical device, and seal the device;

[0052] Turn on the heating device, adjust the temperature of the device to 40 °C, and transfer the liquid CO through the hydraulic pump. 2 Pass into the supercritical device, control the pressure in the device to 10MPa, turn on the stirring motor, and set the rotational speed to 2000r / min;

[0053] After 1 h of reaction, the stirring motor was turned off, the gas was exhausted, and the sample was taken out, which was the graphene nanosheet.

[0054] (2), the graphene nano-sheet and the fiber raw material are blended to prepare the graphene composite master batch:

[0055] The graphene nanosheets are added to the molten polyamide mater...

Embodiment 3

[0060] The present embodiment provides a method for preparing a novel functionalized graphene composite fiber, which comprises the following steps:

[0061] (1) Fluid shear assisted supercritical CO 2 Preparation of graphene nanosheets by exfoliation:

[0062] Add the graphite raw material into the supercritical device, and seal the device;

[0063] Turn on the heating device, adjust the temperature of the device at 40 °C, and transfer the liquid CO through the hydraulic pump. 2 Pass into the device, control the pressure in the device to 10MPa, turn on the stirring motor, and set the speed to 2000r / min;

[0064] After 1 h of reaction, the stirring motor was turned off, the gas was exhausted, and the sample was taken out, which was the graphene nanosheet.

[0065] (2), the graphene nano-sheet and the fiber raw material are blended to prepare the graphene composite master batch:

[0066] The graphene nanosheets are added to the melted polyethylene terephthalate material, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com