Environment-friendly negative ion far-infrared flame-retardant polyester staple fibers and preparation method thereof

A negative ion far-infrared, flame-retardant polyester technology, applied in the manufacture of fire-retardant and flame-retardant filament, melt spinning, stretch spinning, etc., can solve the problems of loss of functional materials, affecting the permanent function of , Good wearing value, and the effect of improving spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

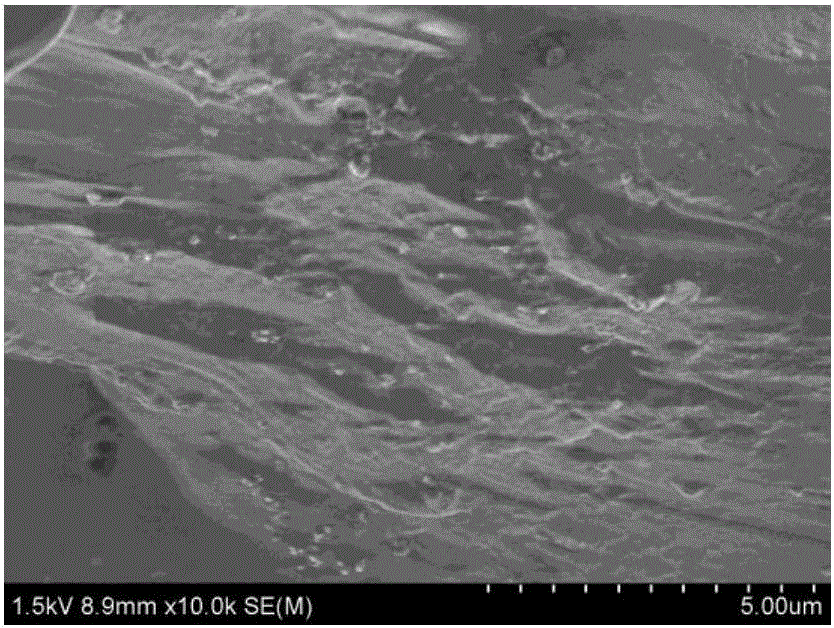

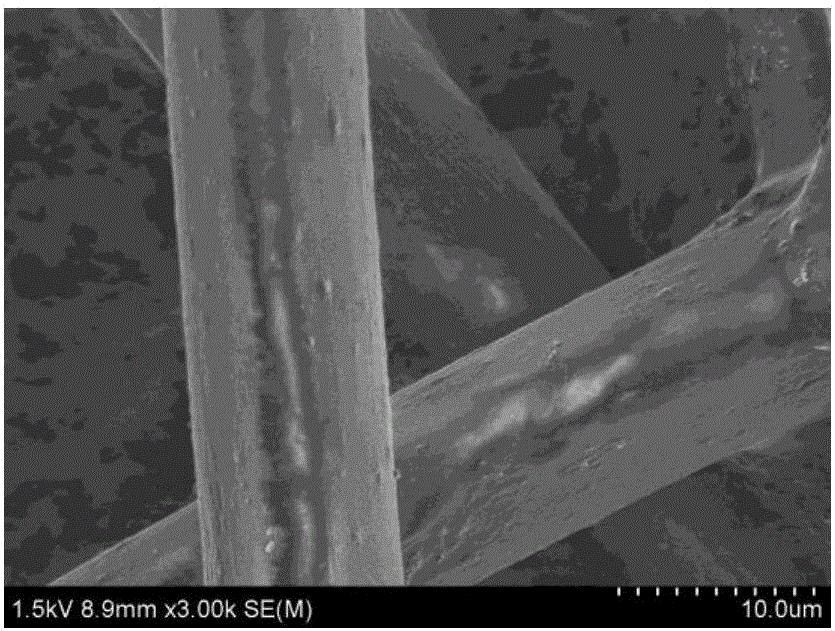

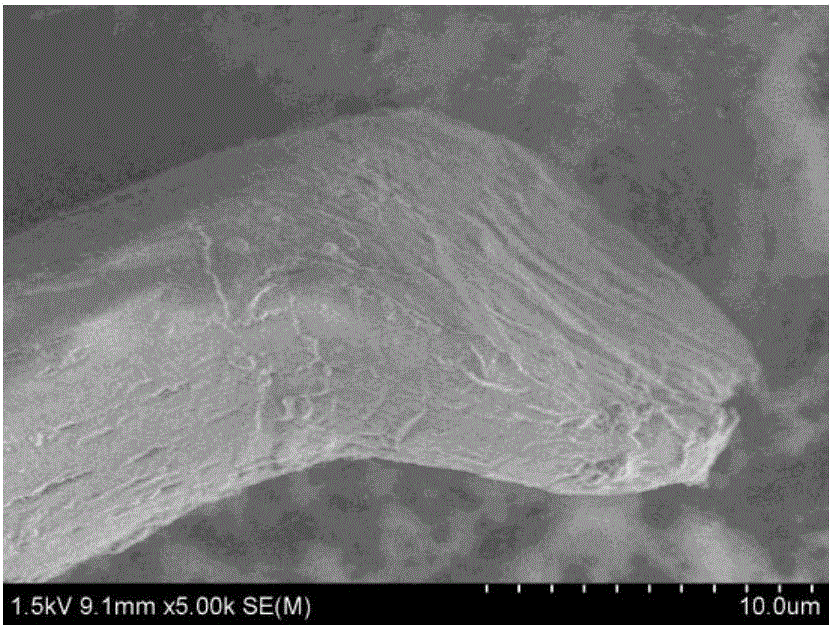

Image

Examples

Embodiment 1

[0024] The terephthalic acid and ethylene glycol after the alcoholysis of the polyester bottle flakes are beaten with a molar ratio of 1:0.9 and put into the esterification kettle. The esterification temperature is controlled at about 250°C. When the top temperature is lower than 100°C, it is the end point of esterification; after the end of esterification, add anion far-infrared powder solution with a mass percentage of 3% and N,N-bis(2-hydroxymethyl ) Aminoethylphosphonic acid dimethyl flame retardant treatment solution, heated to 260°C and introduced into the polycondensation kettle, the vacuum was less than 50Pa, when the polycondensation temperature reached 285°C, the stirring was stopped, cooled, pelletized and dried to obtain an environmentally friendly Type regenerative anion far infrared function flame retardant polyester chips. The slices are first dried at 75°C for 3 hours, then heated to 110°C for 2 hours, then heated to 130°C for 2 hours, and finally heated to 145...

Embodiment 2

[0026] The terephthalic acid and ethylene glycol after the alcoholysis of polyester bottle flakes are beaten in a molar ratio of 1:0.8 and put into the esterification kettle. The esterification temperature is controlled at about 245°C. When the top temperature is lower than 100°C, it is the end point of esterification; after the end of esterification, add anion far-infrared powder solution with a mass percentage of 5% and a flame retardant N,N-bis(2- Hydroxymethyl) aminoethyl phosphonic acid dimethyl flame retardant treatment liquid, after heating up to 260 ° C, import it into the polycondensation kettle, the vacuum is less than 50 Pa, stop stirring when the polycondensation temperature reaches 285 ° C, after cooling, pelletizing and drying, An environment-friendly regenerated anion far-infrared functional flame-retardant polyester chip was prepared. The slices are first dried at 70°C for 4 hours, then heated to 100°C for 1 hour, then heated to 120°C for 2 hours, and finally h...

Embodiment 3

[0028]Put the terephthalic acid and ethylene glycol after the alcoholysis of polyester bottle flakes into pulp at a molar ratio of 1:0.7 and put them into the esterification kettle. The esterification temperature is controlled at 258°C. When the column top temperature is lower than 100°C, it is the end point of the esterification; after the esterification is completed, add an anion far-infrared powder solution with a mass percentage of 1% and a flame retardant N,N-bis(2 -Hydroxymethyl) aminoethyl phosphonic acid dimethyl ester treatment solution, heated up to 260°C and introduced into the polycondensation kettle, the vacuum was less than 50Pa, when the polycondensation temperature reached 285°C, the stirring was stopped, cooled, pelletized and dried to obtain Environmentally friendly regenerated anion far-infrared function flame-retardant polyester chips. The slices are first dried at 80°C for 3 hours, then heated to 120°C for 2 hours, then heated to 140°C for 1 hour, and fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com